Preparation method of graphene oxide/waterborne polyurethane nanometer composite material

A nano-composite material and water-based polyurethane technology, which is applied in the field of graphene oxide and water-based polyurethane nano, can solve the problems of poor compatibility and poor dispersion of graphene oxide, and achieve low cost, high performance and improved thermal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

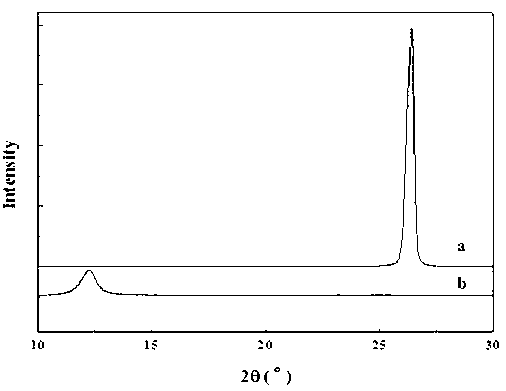

[0031] Example 1: Preparation of Graphene Oxide

[0032] 1. Preparation of graphite oxide: Use the improved Hummer method to take 2g of natural flake graphite and put it into a 250mL three-neck flask, add 2g of sodium nitrate, slowly pour 96mL of concentrated sulfuric acid, and then slowly add 14g of potassium permanganate, Ice bath, stir for 90 minutes, then transfer to a water bath at 35°C, heat and stir for 2 hours, then slowly add 80mL of deionized water, due to the presence of concentrated sulfuric acid, the heat release is severe, so put the flask in water to cool for 5 minutes Finally, add 200mL of deionized water, then slowly add hydrogen peroxide to the flask to eliminate excess potassium permanganate until no bubbles are generated; finally add a large amount of deionized water to dilute, settle, stand overnight, and continue to wash for more Repeat until the pH value of the solution is neutral, and then go through the centrifugal washing of a low-speed centrifuge (...

example 2

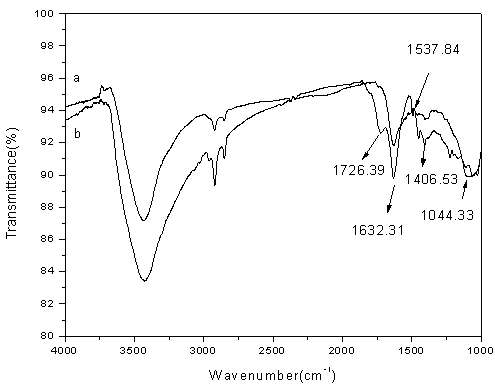

[0034] Example 2: Preparation of graphene oxide modified by silane coupling agent (KH550)

[0035] Slowly add 20mL of dehydrated alcohol containing 0.3g KH550 into the graphene oxide suspension prepared by Example 1, and keep stirring during the addition process; 2 React in an oil bath at 90°C for 24 hours under protection. The obtained pasty product was first washed 3 times with absolute ethanol to remove excess KH550, then washed 3 times with deionized water, and finally vacuum-dried at 60°C.

example 3

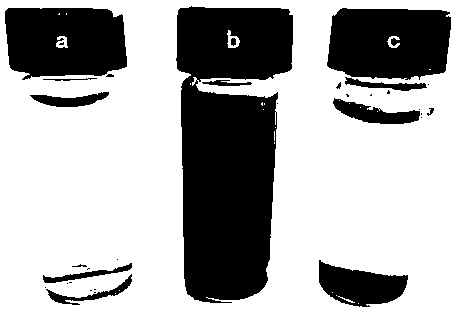

[0036] Example 3: Preparation of functionalized graphene oxide / waterborne polyurethane

[0037] 1. Use 250mL of acetone and ultrasonic to prepare 0.5g of functionalized graphene oxide in Example 2 to make a uniform dispersion of 2mg / mL, and then put it together with 34g of polypropylene glycol (N220) into an agitator, reflux condenser and Stir in the three-necked flask of the dropping funnel, stir evenly at 80°C, add 1.8g of DMPA, after it is completely dissolved, then add 12g of IPDI and 0.25g of dibutyltin dilaurate and maintain the reaction at 80°C; the viscosity of the mixture increases, so Use the method of dropping acetone to reduce the viscosity so that the stirring can proceed smoothly. After continuing to react under the above conditions for 2 hours, add 1gTMP to carry out the cross-linking reaction; Make the stirring go smoothly, then add 1.5gTEA to neutralize, continue stirring for 20min, then quickly add 100mL water and 0.8gEDA to emulsify for 1h under the condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com