Graphene composite conductive slurry as well as preparation method and application thereof

A graphene composite, conductive paste technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of agglomeration, graphene dispersion hindering application, etc., and achieve the effect of low cost, excellent electrochemical performance, and improved electrode capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Another aspect of the embodiments of the present invention provides a method for preparing a graphene composite conductive paste, which includes:

[0041] (1) mix expanded graphite, dispersant and solvent uniformly, and carry out shear peeling, make the first slurry;

[0042] (2) adding the non-flaky conductive agent to the first slurry, and then at least partially intercalating the non-flaky conductive agent by grinding to embed the non-flaky conductive agent between the graphene sheets to obtain the second slurry, Obtain graphene composite conductive paste.

[0043] As one of the preferred schemes, step (1) specifically includes: uniformly mixing expanded graphite, dispersant and solvent, and performing shear dispersion treatment in a high-speed mixer at a speed of 500 to 1000 r / min for 5 to 60 minutes, and then placing the graphite on sand The first slurry is obtained by performing shearing and peeling treatment in the mill at a rotational speed of 1000-3000 r / min f...

Embodiment 1

[0064] A kind of preparation method of graphene composite conductive paste in the present embodiment comprises the following steps:

[0065] 1) Mix 80g of worm graphite (100 mesh) expanded by 400 times, 10g of polyvinylpyrrolidone and 1850g of N-methylpyrrolidone, use a high-speed mixer to stir and disperse at a speed of 500r / min for 30 minutes, and then use a sand mill to grind, The rotating speed is 2800r / min, and the grinding time is 60 minutes;

[0066] 2) Take 60g of multi-walled carbon nanotubes and add them to the above slurry for further grinding, the rotation speed is 800r / min, and the grinding time is 30 minutes;

[0067] 3) Adjust the viscosity of the slurry obtained above with polyvinylidene fluoride, and adjust the viscosity to 5000 mPa·s.

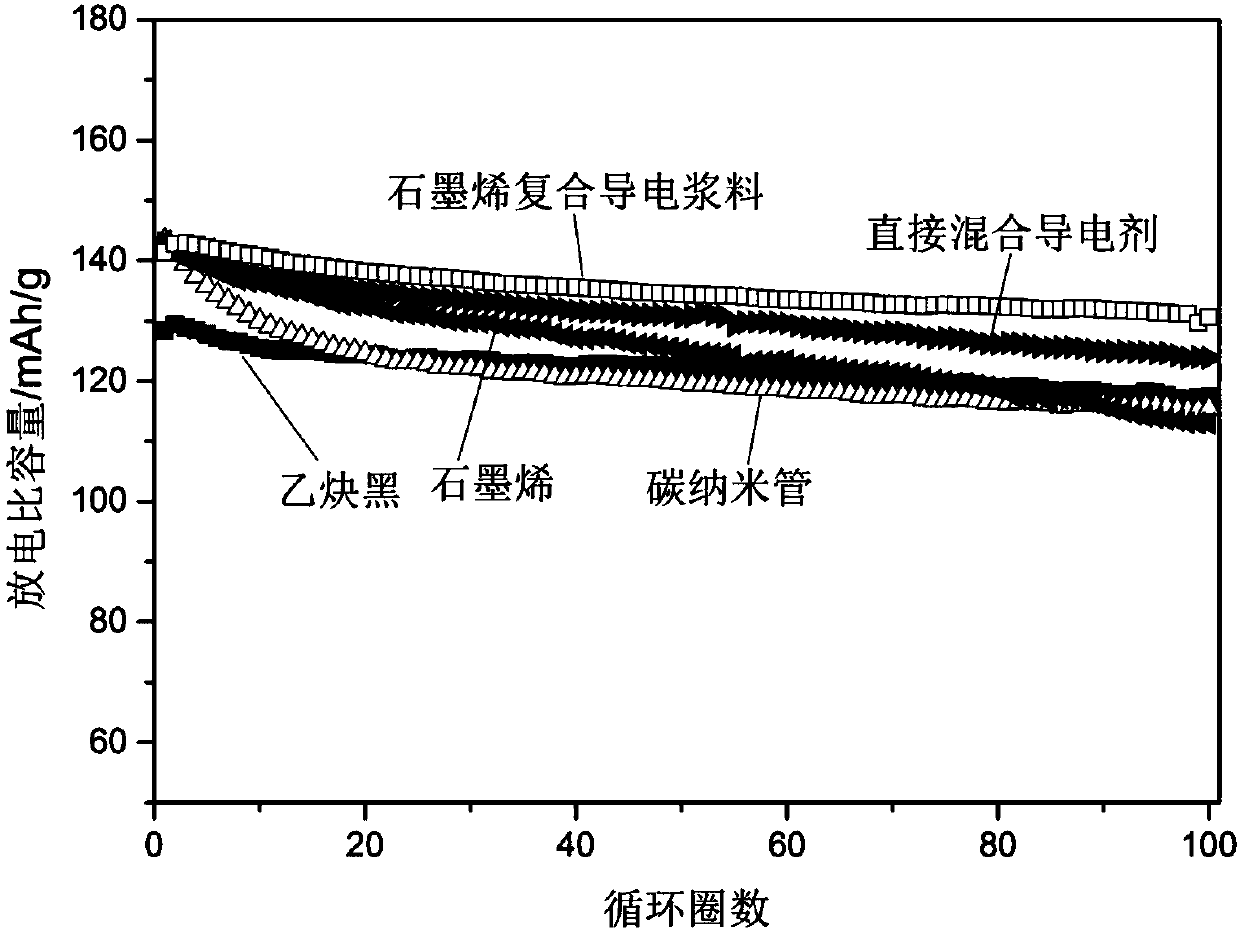

[0068] 4) The graphene composite slurry is used in the ternary positive electrode material of lithium ion battery, according to the mass fraction of ternary active material, polyvinylidene fluoride, graphene composite conduct...

Embodiment 2

[0079] A kind of preparation method of graphene composite conductive paste in the present embodiment comprises the following steps:

[0080] 1) Mix 20g of worm graphite (800 mesh) expanded by 100 times with 1860g of N-methylpyrrolidone, use a high-speed mixer to stir and disperse at a speed of 1000r / min for 30 minutes, then use a sand mill to grind at a speed of 3000r / min, Grinding time is 5 minutes;

[0081] 2) Take 120g of acetylene black and add it to the above slurry for further grinding, the rotating speed is 3000r / min, and the grinding time is 30 minutes;

[0082] 3) Adjust the viscosity of the slurry obtained above with polyvinyl alcohol, and adjust the viscosity to 4000 mPa·s.

[0083] 4) The graphene composite conductive paste is used in the lithium iron phosphate positive electrode material of lithium ion battery. After testing, it is found that the graphene composite conductive paste prepared in this embodiment can reduce the dosage while reducing the dosage compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com