Graphene composite material and preparation method thereof

A graphene material sheet and composite material technology, applied in the field of graphene composite materials and their preparation, can solve the problems of reduced specific surface area, high surface active energy, easy agglomeration, etc., and achieves low resistivity, high specific surface area, high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

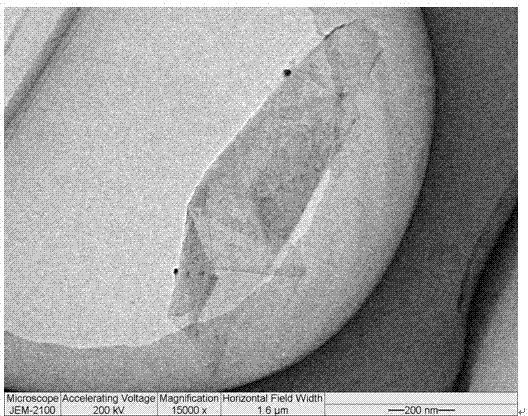

[0068] Embodiment 1 Preparation of expanded graphite flakes

[0069] Take a piece of flexible expanded flake graphite, wash and dry it, and use a roller press to gradually adjust the gap for repeated rolling. During the rolling process, auxiliary heating is performed at the same time to increase the flexibility of the graphite. Roll until the thickness of the graphite sheet reaches 0.05mm, and the expanded graphite flake is obtained.

Embodiment 2

[0070] Example 2 Preparation of expanded graphite flakes

[0071] Take a piece of flexible expanded flake graphite, wash and dry it, and use a roller press to gradually adjust the gap for repeated calendering. During the calendering process, auxiliary heating is performed at the same time to increase the flexibility of the graphite, and calender until the thickness of the graphite flake reaches 0.025mm, and the expanded graphite flake is obtained.

Embodiment 3

[0072] Example 3 Preparation of expanded graphite flakes

[0073] Take a piece of flexible expanded flake graphite, wash and dry it, and use a roller press to gradually adjust the gap to carry out repeated rolling. During the rolling process, auxiliary heating is carried out at the same time to increase the flexibility of the graphite. Roll until the thickness of the graphite sheet reaches 0.015mm, and the expanded graphite flake is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com