Whole-process autotrophic nitrogen removal method and device

A technology of whole-process autotrophic denitrification and ammonia nitrogen, applied in the field of new start-up of whole-process autotrophic denitrification and whole-process autotrophic denitrification device, which can solve the problem of incomplete contact of anammox granular sludge, reduce system denitrification efficiency, and decrease anammox mud activity and other problems, to achieve the effect of saving investment and energy consumption, improving denitrification efficiency, and increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

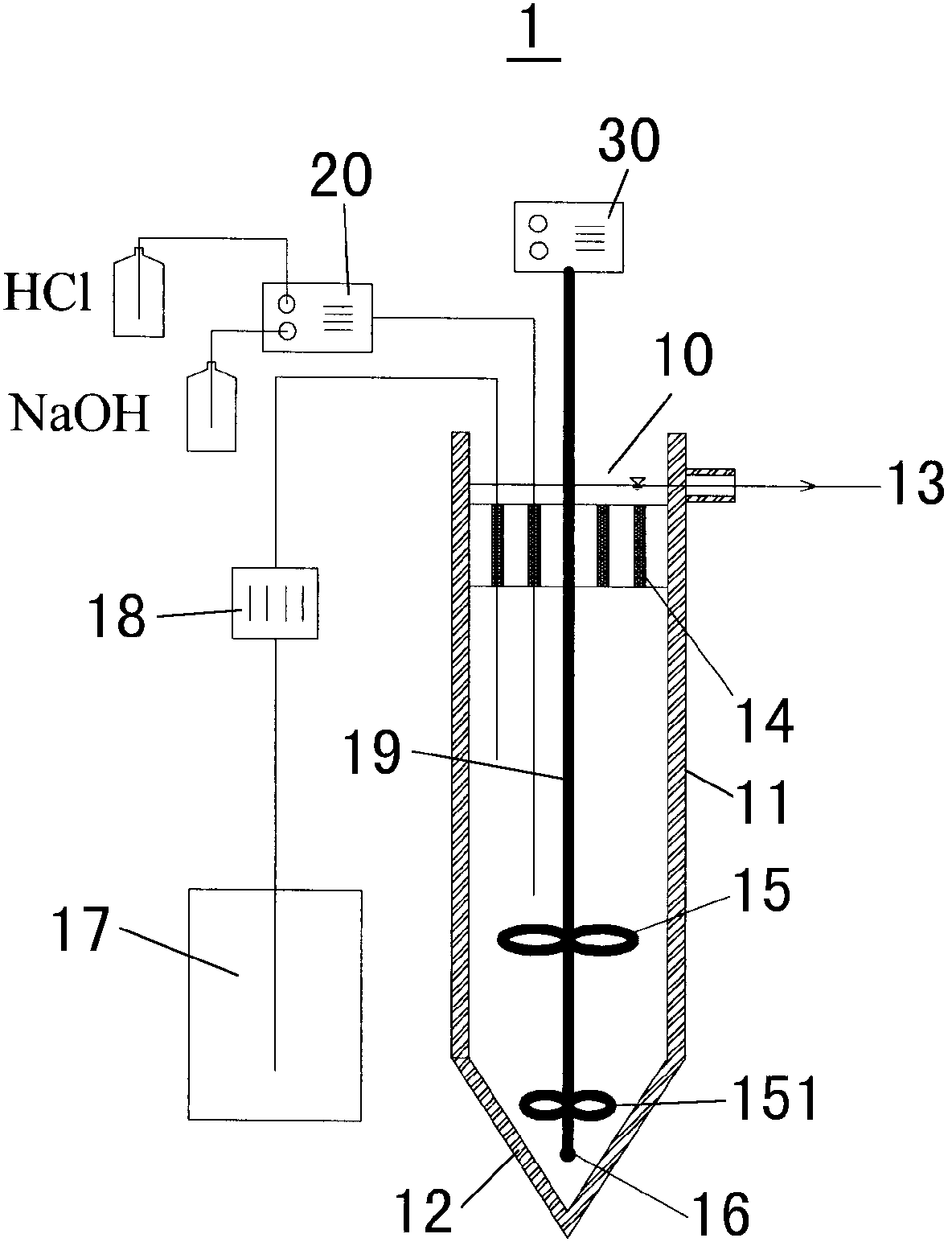

[0049] 1) The effective volume of the reactor is 5L, and 8g / L of anammox sludge is inoculated into the reactor;

[0050] 2) Configure artificial nitrogen-containing wastewater, the composition of wastewater: NH 4 -N100mg / L, NO 2 -N100mg / L, KHCO 3 1.5-2.0g / L, NaCl10g / L, KH 2 PO 4 54mg / L, FeSO 4 ·7H 2 O9mg / L, EDTA5mg / L, trace elements 1mL / L (CuSO 4 ·5H 2 O0.25mg / L, ZnSO 4 ·7H 2 O0.43mg / L, CoCl 2 ·6H 2 O0.24mg / L, MnCl 2 ·4H 2 O0.99mg / L, NaMoO 4 ·2H 2 O0.22mg / L, NiCl 2 ·6H 2 O0.19mg / L, NaSeO 4 0.11mg / L, H 3 BO 3 0.014mg / L), adjust the pH to 7-8 by 1mol / L HCl;

[0051] 3) Use nitrogen to aerate the inlet bucket to make the DO concentration in the inlet bucket about 0mg / L; the experimental wastewater enters the reactor under the action of the peristaltic pump, the hydraulic residence time (HRT) is about 5h, and the stirring rate of the stirring paddle About 30 rpm, at this time the water inlet load is about 0.96kg-N / m 3 / day; The stirring speed of the stirring paddle is controlled at abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com