Ink storage device for ink-jet printer

An inkjet printing machine and ink storage technology, which is applied in the field of ink storage devices for inkjet printing machines, can solve problems such as waste, easy occurrence of air bubbles, unstable pressure in the ink supply system, etc., and achieve convenient operation of adding ink and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

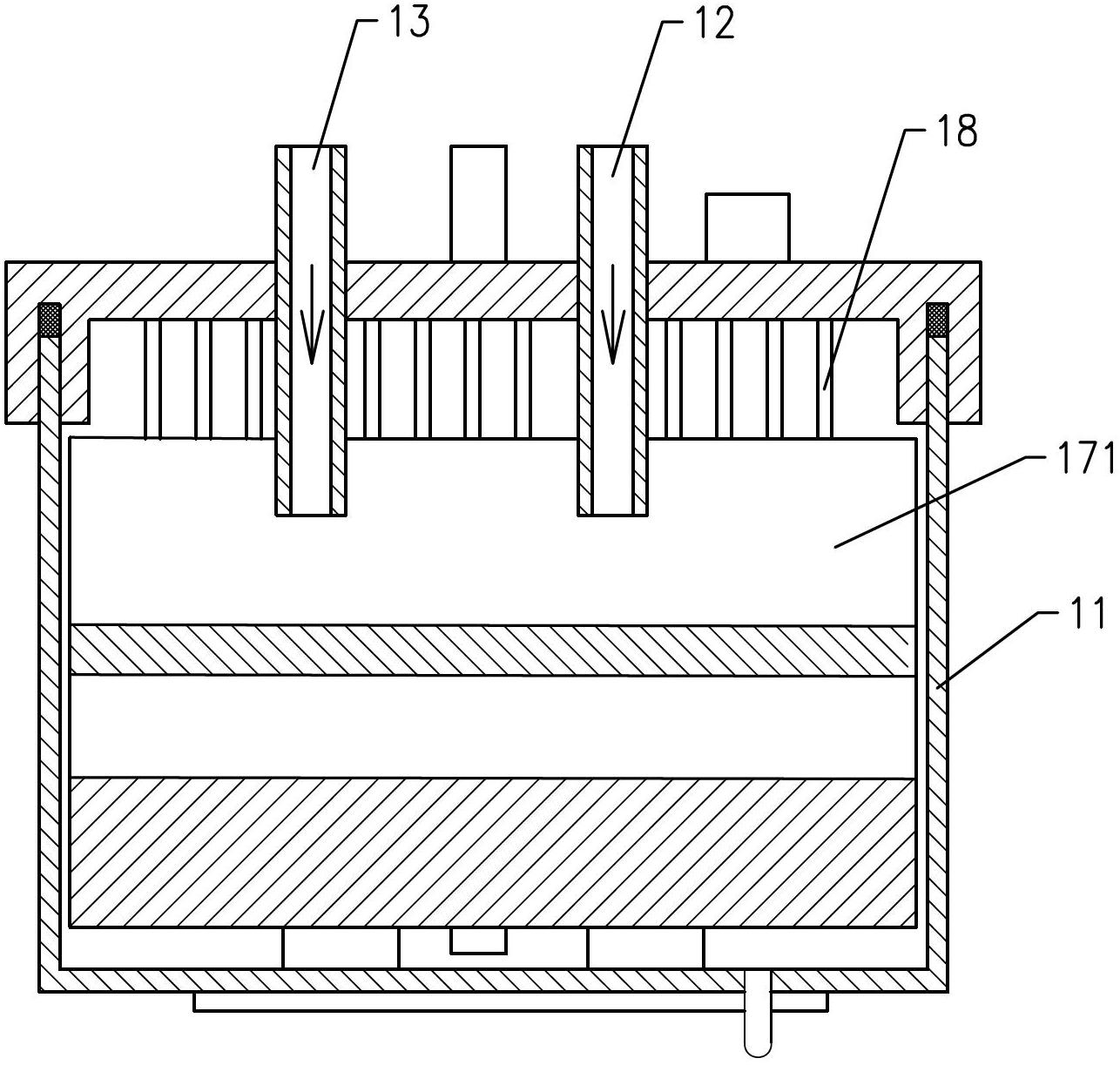

[0029] In order to realize the continuous ink supply of the circulating ink supply system of the inkjet printer and keep its negative pressure stable within a certain range, it is required that the ink entering the circulating ink supply system must not have any air bubbles. This embodiment provides a spraying machine that can eliminate air bubbles An ink storage device for an ink printing machine solves the problem of wasting ink cartridges and saves printing costs.

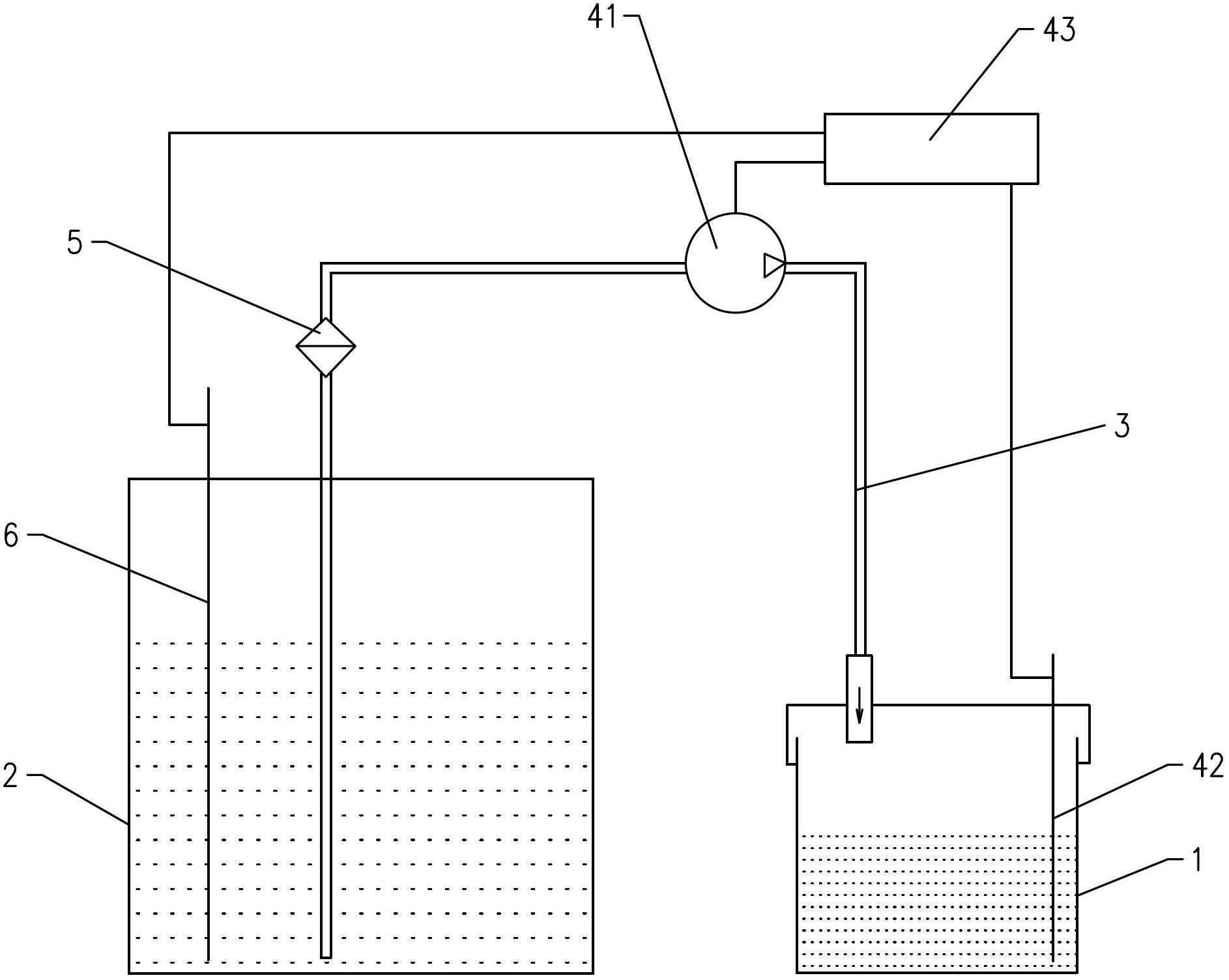

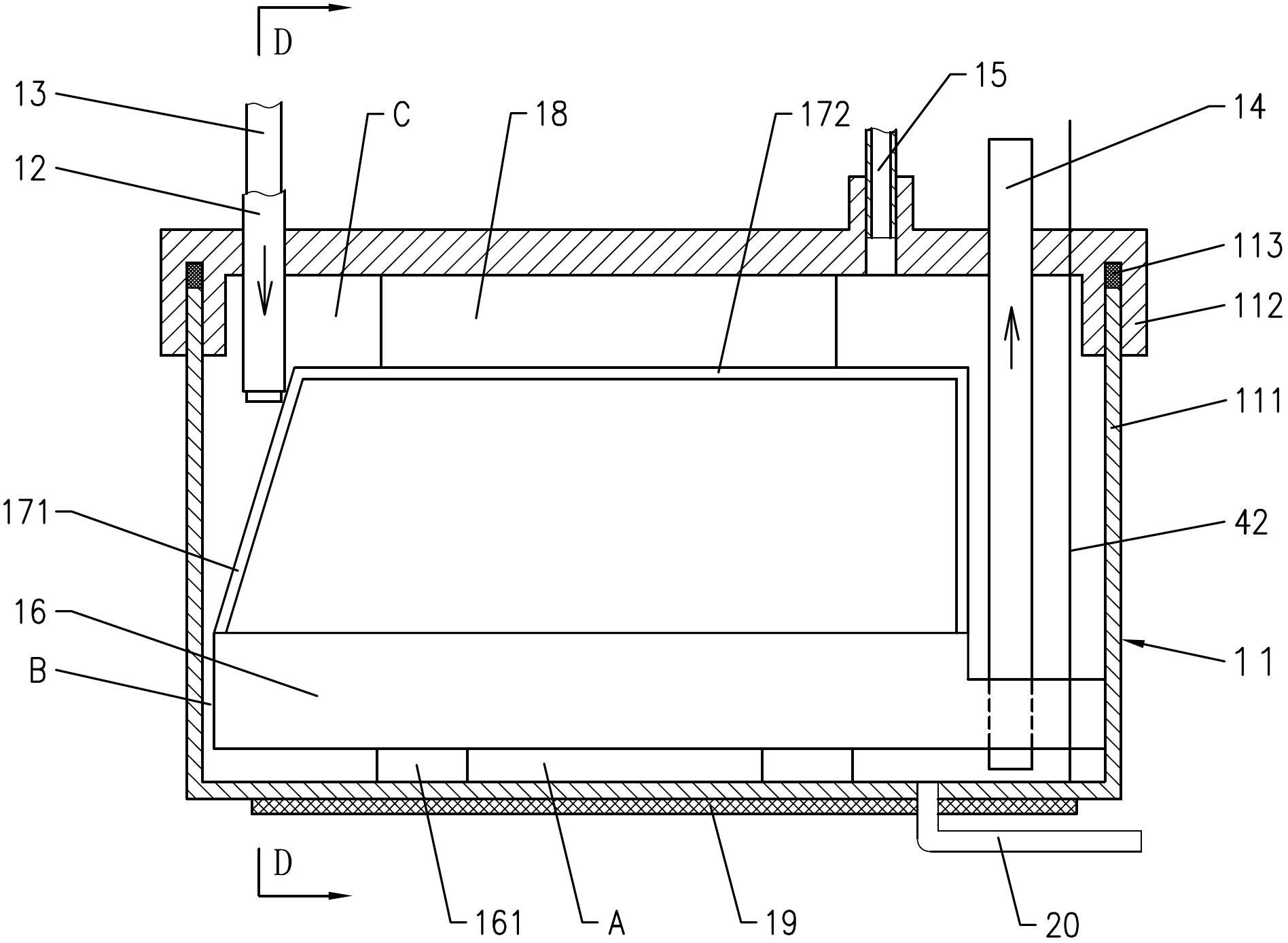

[0030] Such as figure 1 As shown, the ink storage device for inkjet printing machine of the present invention includes an ink cartridge 1 and an ink barrel 2 for adding ink to the ink cartridge 1, and an ink filling pipe 3 and an ink filling pipe 3 are arranged between the ink cartridge 1 and the ink barrel 2. Control System. The ink filling control system includes: a pump 41 installed on the ink filling pipe 3; a liquid level sensor 42 inserted into the shell of the ink cartridge 1; an electronic control unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com