Wet air purification method and air purification apparatus

An air purification and wet process technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of secondary pollution, inconvenient disposal of pollutants in dry household purifiers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

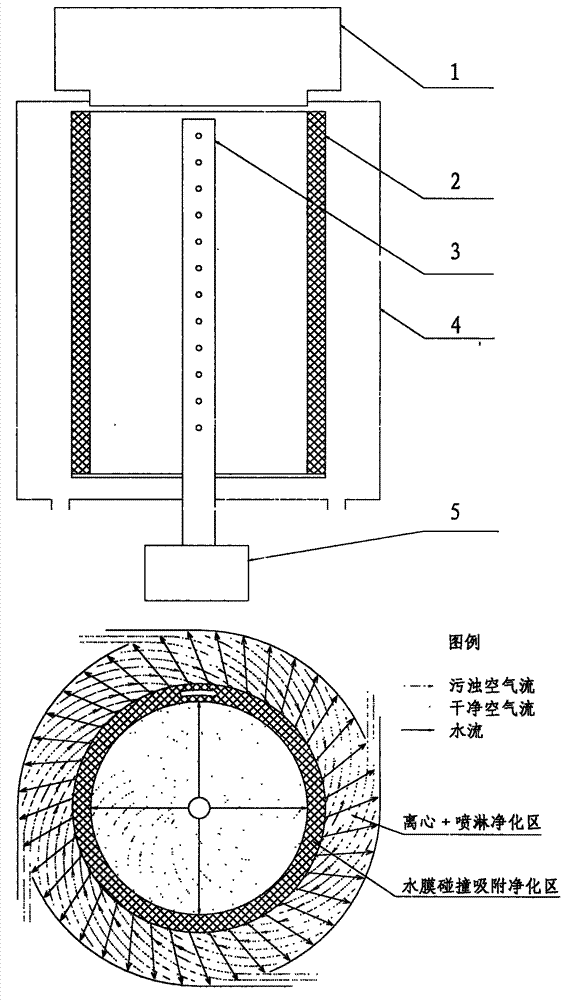

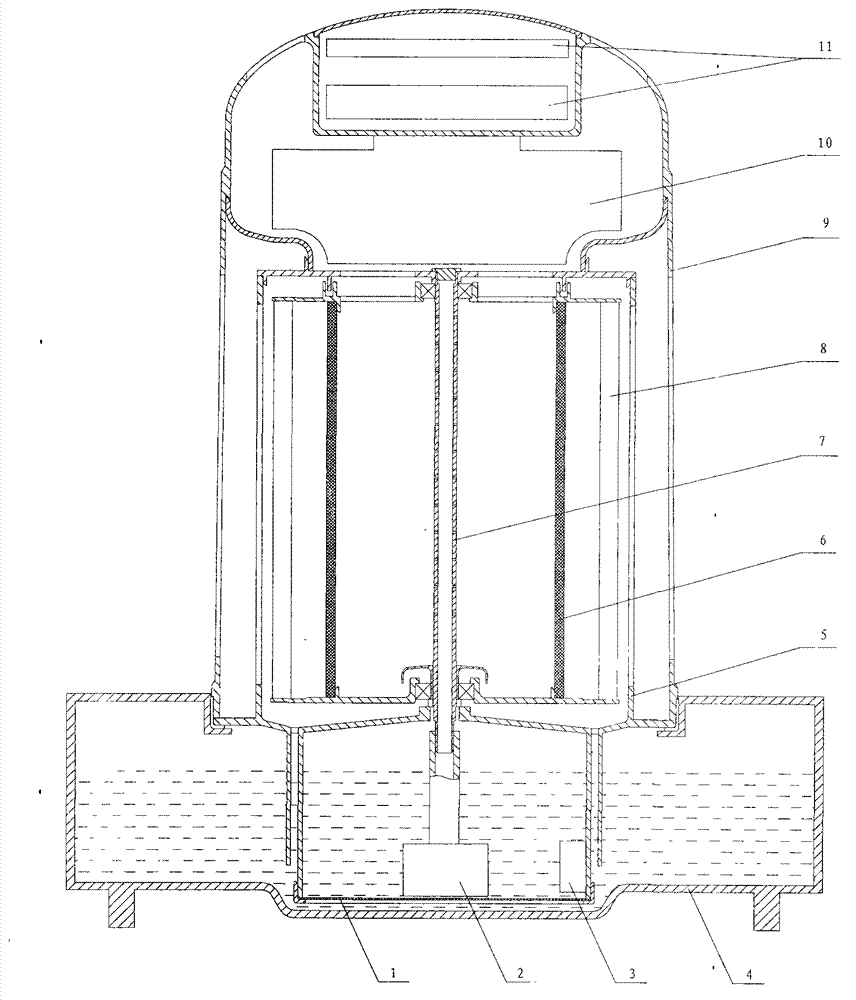

[0008] The technical principle of the wet air purification method of the present invention is described as follows:

[0009] As shown in Figure 1, the cylindrical filter screen 2 formed by stacking multi-layer wire mesh is placed in a cylindrical container 4, and a water spray pipe 3 is installed on the central axis of the filter screen, and the filter screen 2 is sprayed with water. The tube 3 rotates freely on the central axis, the bottom end surface of the filter screen 2 is a solid body, the upper end surface is open and connected with 1, and the container 4 wall is perforated in a tangential direction. Due to the suction of the fan 1, the air will enter from the side hole of the container 4 along the tangential direction, and generate a rotating air flow in the container 4, and the rotating air flow pushes the filter screen 2 to rotate (the rotation of the filter screen 2 can also be driven by independent power alone ), the rotating air flow moves toward the axis at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com