Device and method for removing ultrafine particles in flue gas of coal boiler

A technology for coal-fired boilers and ultra-fine particles, which is applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of large resistance, complicated actual operation, and many equipment, and achieves increased collision probability, increased agglomeration efficiency, The effect of less steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

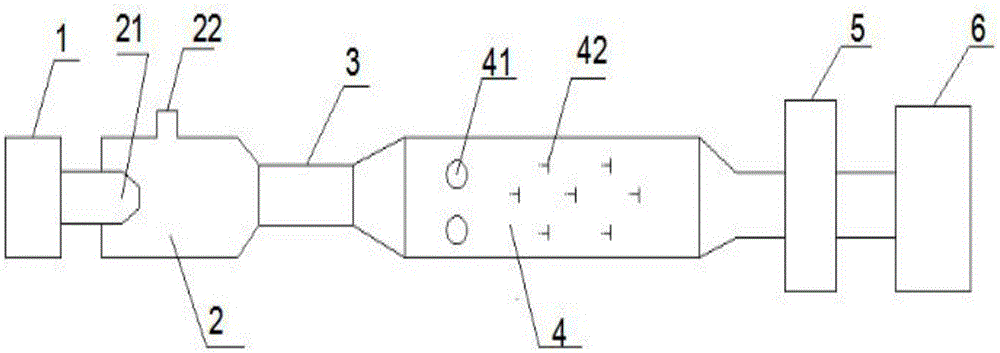

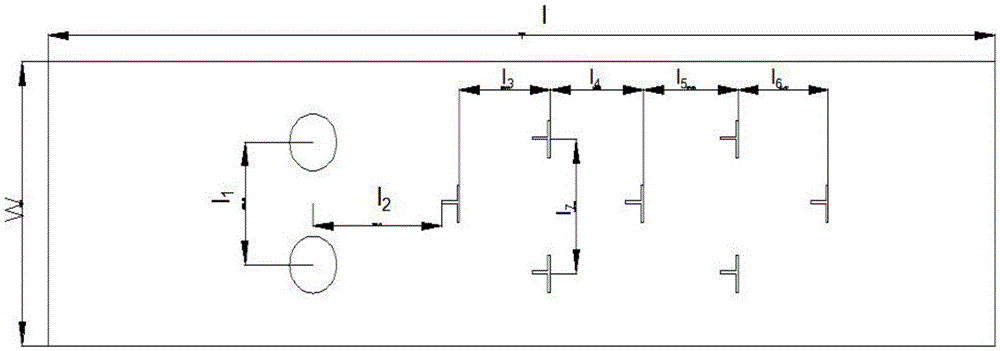

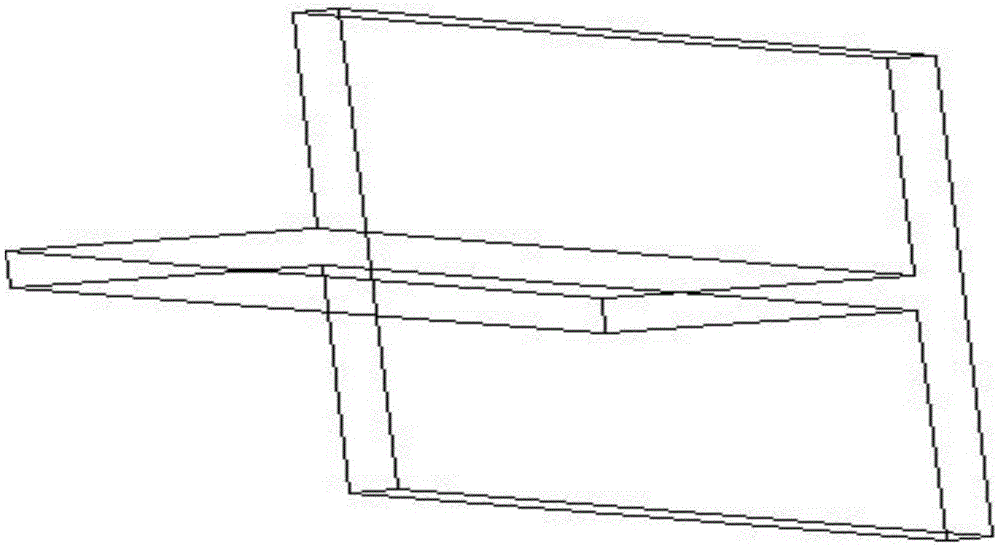

Embodiment 1

[0045] In this embodiment, the device for removing ultrafine particles in the flue gas of a coal-fired boiler is located after the flue desulfurization equipment 1 at the tail of the coal-fired boiler, and before the electrostatic precipitator 6 of the boiler, and after the desulfurization equipment 1 along the flow direction of the flue gas according to the process flow The smoke steam ejector 2, the steam phase change agglomeration chamber 3, the turbulent flow agglomeration chamber 4 and the mist eliminator 5 are arranged in sequence, and the outlet of the mist eliminator 5 is connected with the electrostatic precipitator 6; the flue gas steam ejector 2 One end connected to the desulfurization equipment 1 is provided with a flue gas inlet 21, and a water vapor inlet 22 is provided on the upper part of the flue gas steam ejector 2; the turbulent agglomeration chamber 4 is provided with a turbulent flow column 41 and a turbulent vortex 42 , the turbulent flow cylinder 41 is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com