Method and device for removing fine particles in high-humidity gas fume

A technology for fine particulate matter and flue gas, applied in the field of removing fine particulate matter in flue gas, can solve the problems of unseen application and high energy consumption, and achieve the effect of simple process and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

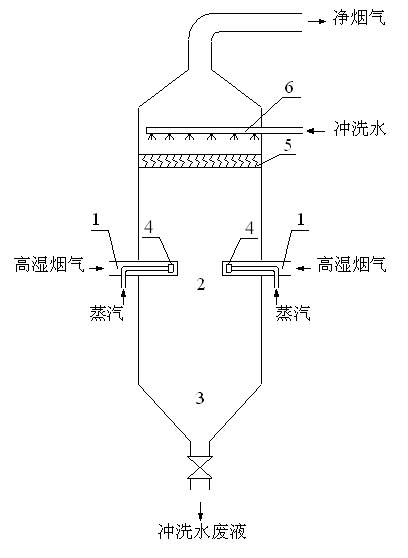

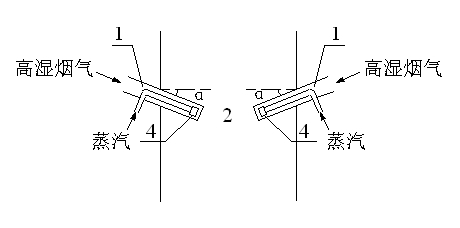

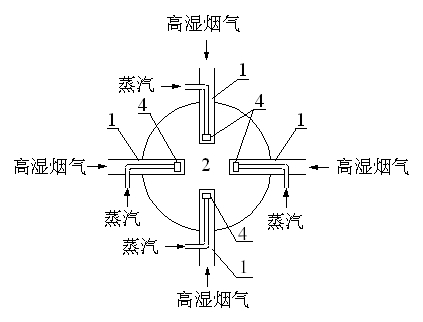

Embodiment 1

[0031] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 150Nm 3 / h, using limestone / gypsum wet desulfurization process, after desulfurization, the flue gas temperature drops from 110°C to 51°C, and the relative humidity is 97%. The desulfurization and purification of wet flue gas is divided into two streams by a pair of flue gas ducts and enters the main body of the impinging flow phase change chamber. A wire mesh demister is installed at the flue gas outlet of the phase change chamber. 3 When the flue gas is injected with 0.06kg of normal pressure saturated steam, the supersaturation S that can be achieved is about 1.22. After real-time online measurement by the electric low-pressure impactor, after adding steam, the concentration of fine particles at the outlet of the wire mesh demister is changed from 4.20′10 7 piece / cm 3 down to 1.37′10 7 piece / cm 3 , the number concentration removal rate increased by 67.4%.

Embodiment 2

[0033] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 150Nm 3 / h, the flue gas desulfurization technology is the spray drying method, after desulfurization, the flue gas temperature drops from 157°C to 59°C, and the relative humidity is 63%. After the desulfurization and purification of wet flue gas is removed by the cyclone dust collector to remove coarse particles, it is divided into two streams and enters the main body of the impingement flow phase change chamber. A wire mesh demister is installed at the flue gas outlet of the phase change chamber. 3 When 0.12kg of steam is injected into the flue gas, the supersaturation degree that can be achieved is about 1.15. After real-time online measurement by the electric low-pressure impactor, after adding steam, the concentration of fine particles at the outlet of the wire mesh demister is changed from 5.62′10 7 piece / cm 3 down to 3.08′10 7 piece / cm 3 , the number concentration remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com