Lithium metal negative electrode with double-layer interface film, preparation thereof and application

A lithium metal negative electrode and interfacial film technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low mechanical strength, reduced coulombic efficiency and cycle life of lithium metal batteries, and low conductivity of lithium fluoride ions , to achieve the effects of inhibiting continuous reaction and consumption, accelerating interfacial lithium ion transport, and improving the uniformity of lithium deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

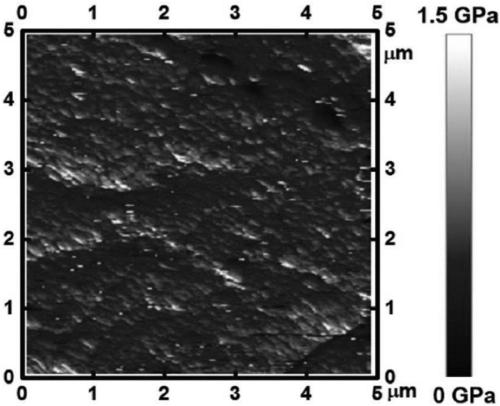

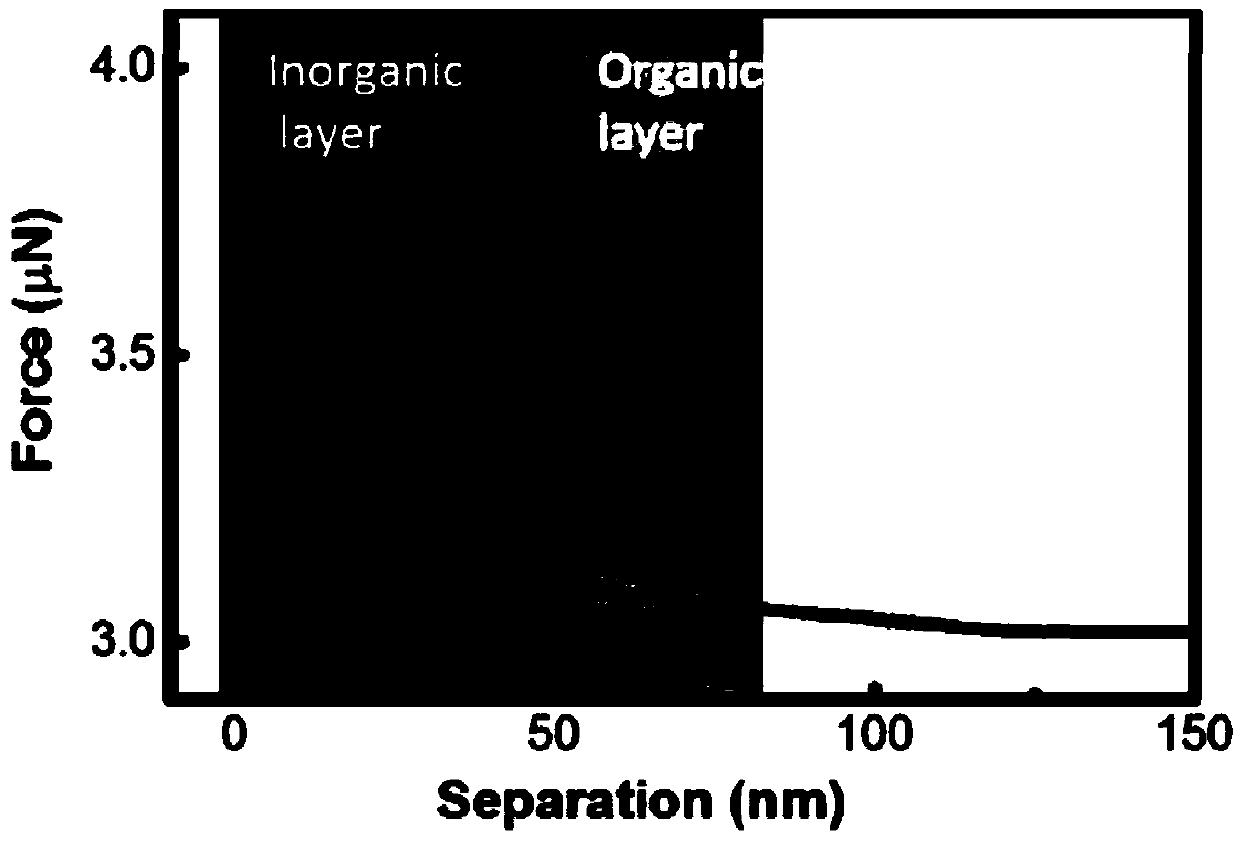

[0038] Weigh 0.15g of carbon fluoride nanoparticles and dissolve them in 3g of DOL solvent, stir for 10h to obtain carbon fluoride precursor solution A; dissolve 0.3g of lithium bisfluorosulfonyl imide (LiFSI) in 3g of DOL-DME ratio is 1:1) solution, stirred for 10h to obtain the polymer solution precursor solution B. Evenly drop-coat 50 μL of fluorocarbon precursor solution A on a lithium sheet with a diameter of 1.6 mm, and dry at room temperature; then evenly drop-coat 50 μL of polymer solution precursor solution B on the above-mentioned lithium sheet, and react in situ on the lithium surface A hybrid bilayer interfacial film was prepared. The inner lithium fluoride thickness of the double-layer interface film is 10 μm, and the outer polymer thickness is 80 μm.

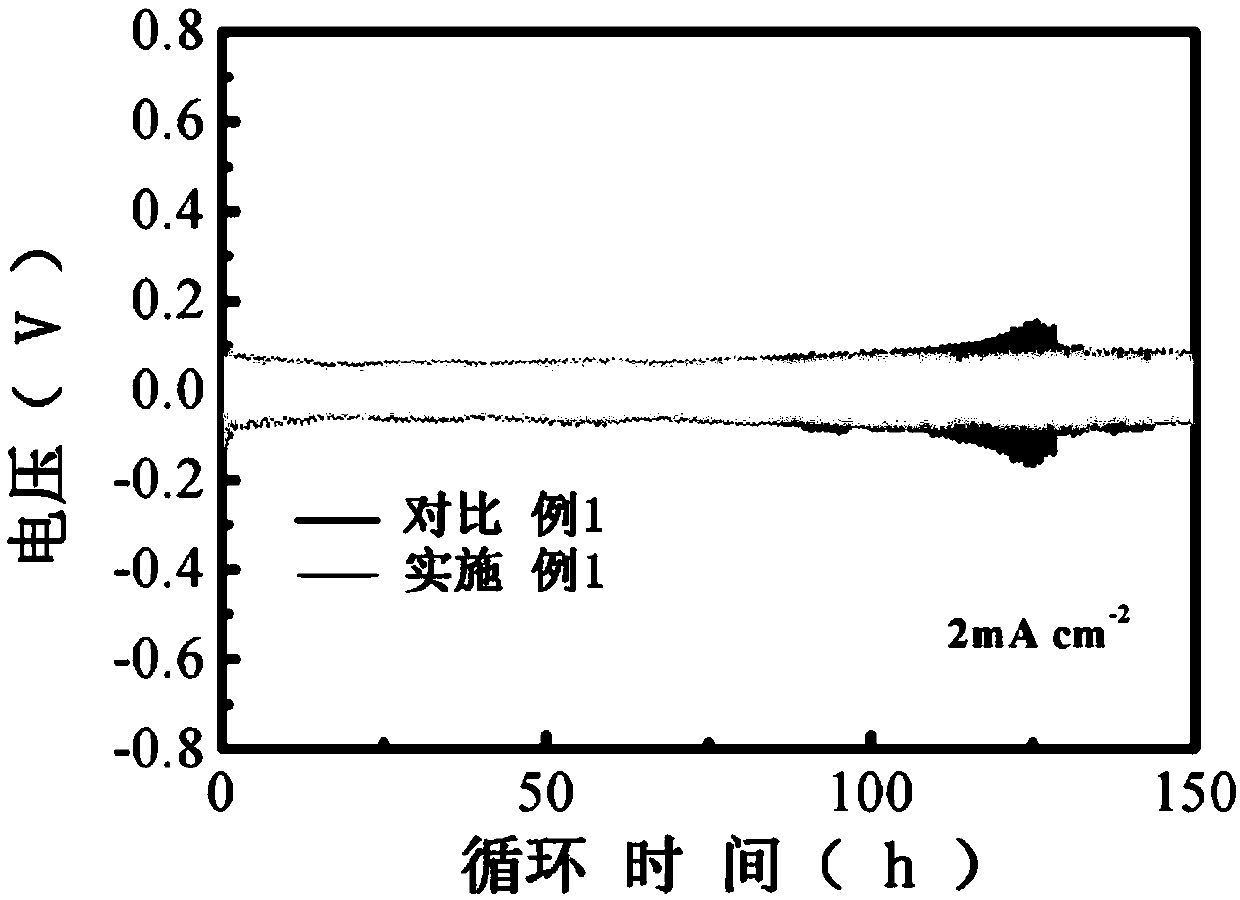

[0039] The pretreated lithium sheet was assembled into a lithium|lithium symmetric battery according to the method of Comparative Example 1. 2mA / cm 2At a current density of 1mAh / cm 2 The deposited and dissolved...

Embodiment 2

[0041] Weigh 0.3g of carbon fluoride nanoparticles and dissolve them in 3g of DOL solvent, stir for 10h to obtain carbon fluoride precursor solution A; dissolve 0.3g of lithium bisfluorosulfonyl imide (LiFSI) in 3g of DOL-DME ratio is 1:1) solution, stirred for 10h to obtain the polymer solution precursor solution B. Evenly drop-coat 50 μL of fluorocarbon precursor solution A on a lithium sheet with a diameter of 1.6 mm, and dry at room temperature; then evenly drop-coat 50 μL of polymer solution precursor solution B on the above-mentioned lithium sheet, and react in situ on the lithium surface An inorganic / polymer hybrid bilayer interfacial film was prepared. The thickness of the lithium fluoride inner layer of the double-layer interface film is 20 μm, and the polymer thickness of the outer layer is 80 μm.

[0042] The pretreated lithium sheet was assembled into a lithium|lithium symmetric battery according to the method of Comparative Example 1. 1mA / cm 2 At a current dens...

Embodiment 3

[0044] Weigh 0.15g of carbon fluoride nanoparticles and dissolve them in 3g of DOL solvent, stir for 10h to obtain carbon fluoride precursor solution A; dissolve 0.3g of lithium bisfluorosulfonyl imide (LiFSI) in 3g of DOL-DME ratio is 1:1) solution, stirred for 10h to obtain the polymer solution precursor solution B. Evenly drop-coat 50 μL of fluorocarbon precursor solution A on a lithium sheet with a diameter of 1.6 mm, and dry at room temperature; then evenly drop-coat 50 μL of polymer solution precursor solution B on the above-mentioned lithium sheet, and react in situ on the lithium surface An inorganic / polymer hybrid bilayer interfacial film was prepared.

[0045] The pretreated lithium sheet was assembled into a lithium|lithium symmetric battery according to the method of Comparative Example 1. 1mA / cm 2 At a current density of 1mAh / cm 2 The deposited and dissolved capacity is charged and discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com