Monolithic integration method of hyperspectral image sensor

A hyperspectral image and image sensor technology, applied in the field of monolithic integration of hyperspectral image sensors, can solve the problems of poor step structure height uniformity, device failure, etc., achieve easy etching, reduce device failure rate, and improve product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

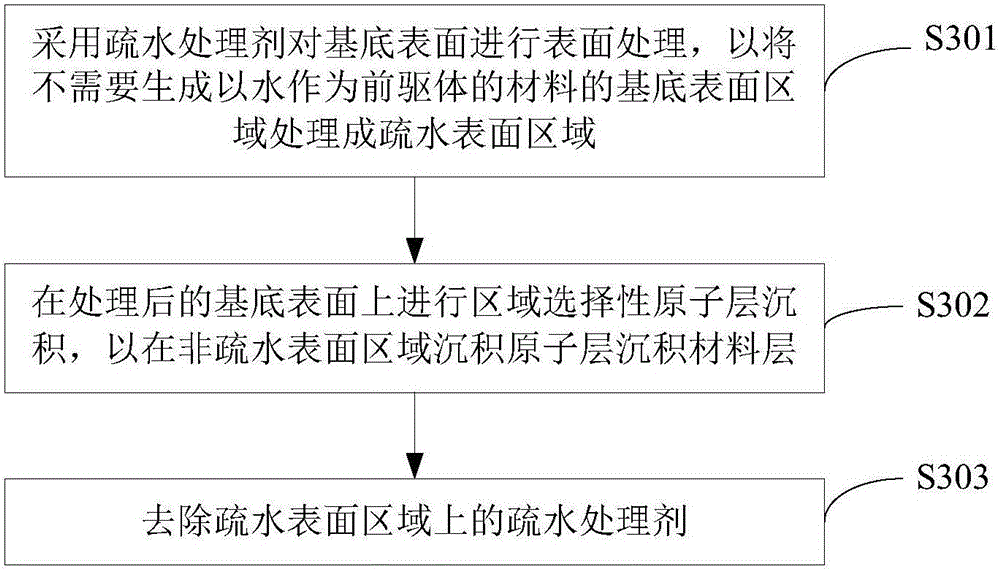

[0091] Figure 9 It is a schematic flowchart of a monolithic integration method of a hyperspectral image sensor provided by an embodiment of the present invention. Such as Figure 9 Shown, this preparation method comprises the following steps:

[0092] S901, pretreating the surface of the photosensitive region of the CMOS image sensor wafer to make it planar;

[0093] The schematic diagram of the cross-sectional structure corresponding to the process is shown in Figure 10A shown. This step is specifically as follows: the entire CMOS image sensor 101 wafer (including the surface of the photosensitive area 102 ) may be planarized by using a chemical mechanical polishing (CMP) process to make the surface of the photosensitive area flat.

[0094] S902, forming a bottom reflective layer on the surface of the photosensitive region of the preprocessed CMOS image sensor wafer:

[0095] Figure 10B It is a schematic cross-sectional view of the structure corresponding to this pro...

Embodiment approach

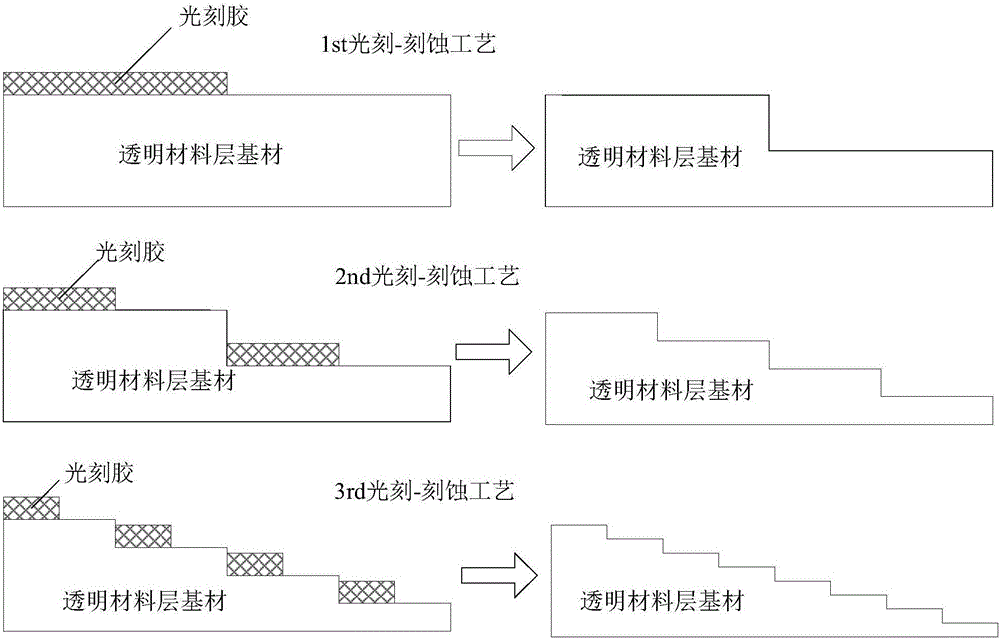

[0179] Through the first and second specific implementation manners of step S903 , the purpose of forming N step structures on the bottom reflective layer can be achieved through a relatively small number of area-selective atomic layer deposition processes. It should be noted that, in the embodiment of the present invention, step S903 is not limited to the above two specific implementation manners. For example, the present invention can also use each region-selective atomic layer deposition process to form a stepped structure, but this implementation method will The use of a large number of regional selective atomic layer deposition processes and the production of corresponding photoresist plates result in relatively high costs, increased errors, and very low efficiency.

[0180] It should be noted that the first specific implementation manner and the second specific implementation manner of the above-mentioned step S903 are examples of specific implementation manners for prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com