Spray bar balance active prediction adjustment system and method

A technology for adjusting the system and the spray bar, which is applied to the device for catching or killing insects, application, animal husbandry, etc. It can solve the problems of poor adaptability, adjustment lag, and poor balance effect, so as to improve the uniformity of deposition and reduce environmental pollution. , the effect of saving pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The invention relates to an active forecasting and adjusting system for spray rod balance, which includes a mechanical part and a control part.

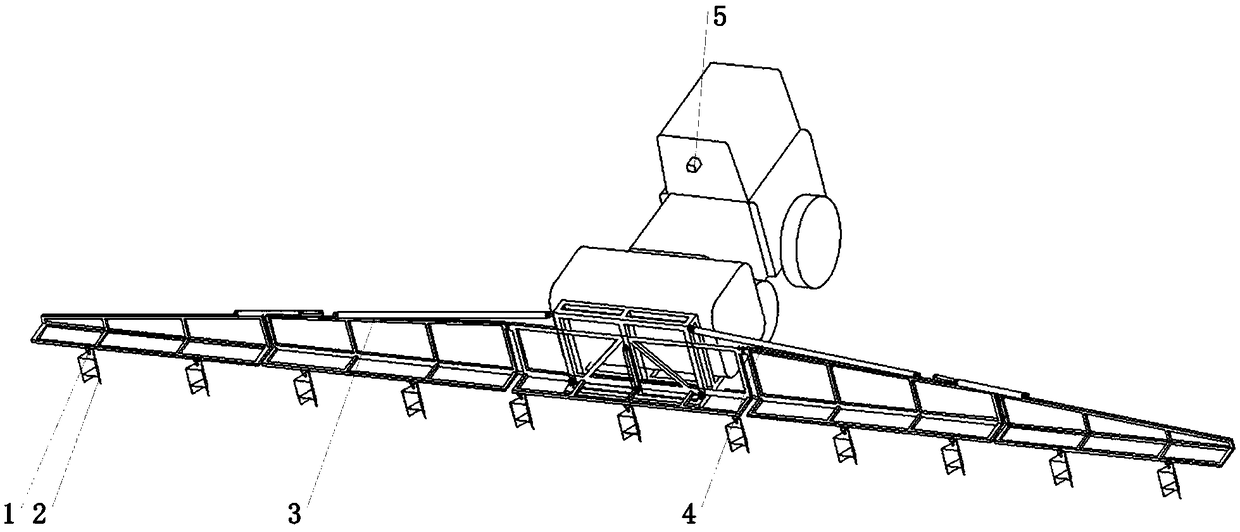

[0026] combined with figure 1 As shown, the mechanical part consists of the driving chassis, the main frame of the sprayer, the spray boom, the roller, the distributor 2, the spray boom lifting hydraulic cylinder, the left balance hydraulic cylinder 3, the right balance hydraulic cylinder 4, and the left horizontal folding hydraulic cylinder , and the right horizontal folding hydraulic cylinder. Wherein, a plurality of distributors 2 are arranged on the spray boom.

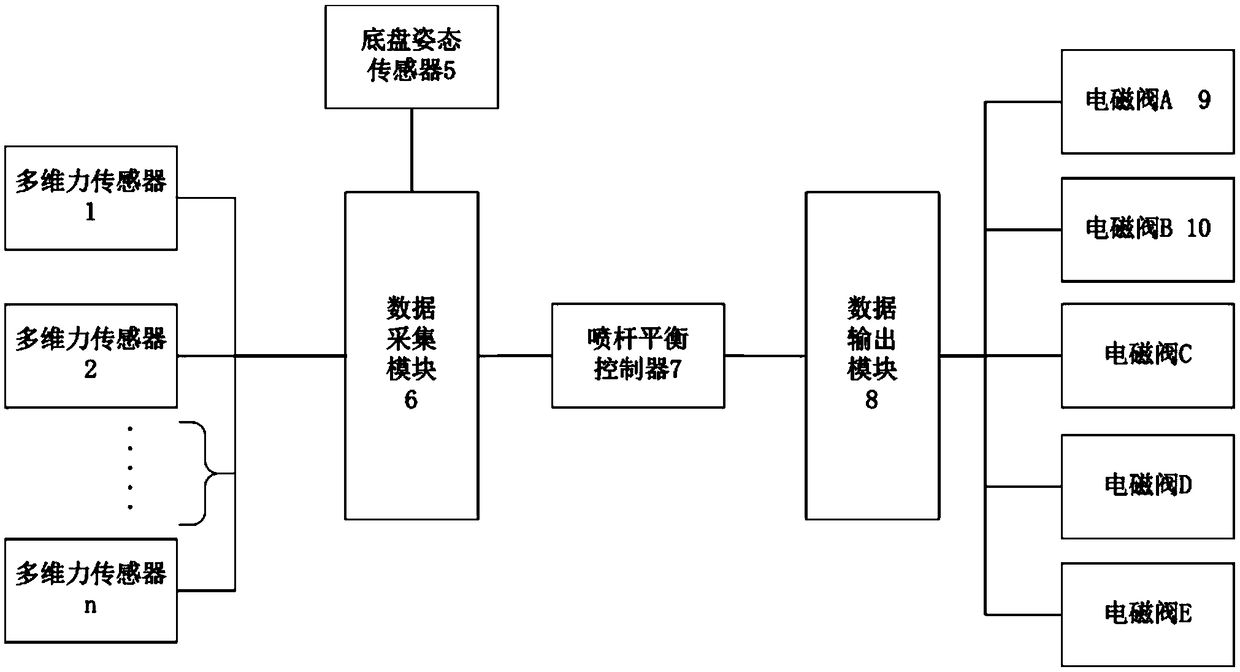

[0027] combined with figure 2 As shown, the control part consists of chassis attitude sensor 5, multi-dimensional force sensor 1, data acquisition module 6, boom balance controller 7, data ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com