Diamond film preparing device and method

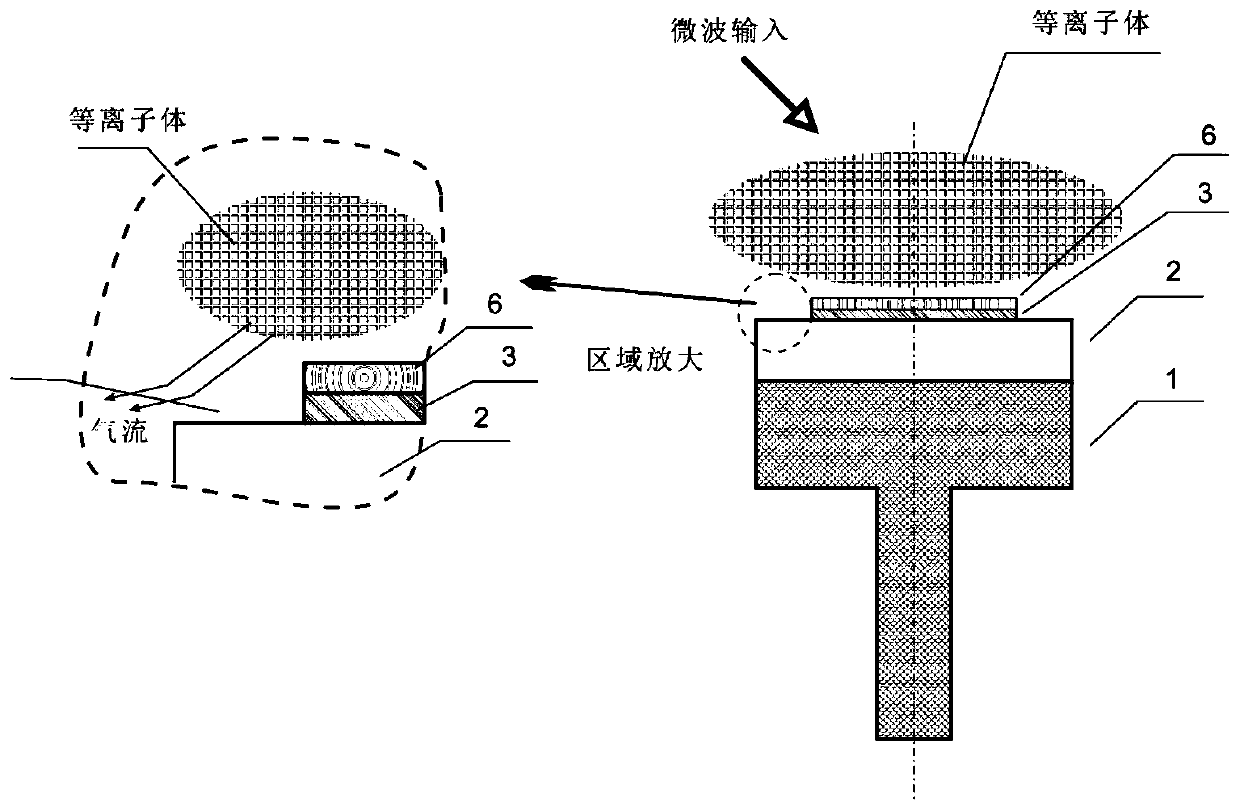

A diamond film and film-forming technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of poor uniformity of diamond film thickness, difficult diamond film polishing process, diamond waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

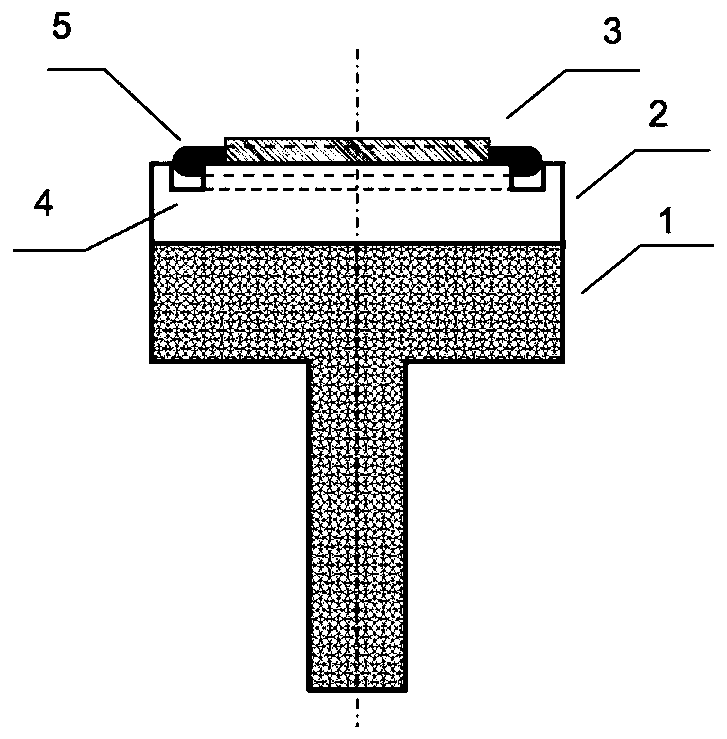

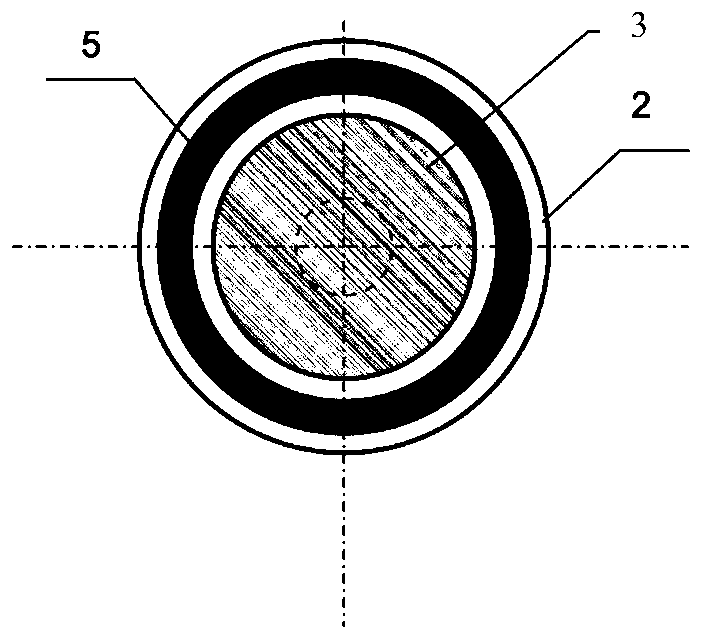

[0048] The substrate material is a circular metal molybdenum plate with a diameter of 60mm and a thickness of 4.0mm. The outer diameter of the annular pit on the surface is 57mm, the width is 3.0mm, and the depth is 1.0mm. The filler metal is Fe wire with a diameter of 3.0mm. Put the molybdenum plate and Fe wire together in an acetone solution for 10 minutes of ultrasonication, take out the dustproof and dry it to get a clean substrate material.

[0049] The diamond film was deposited on a P-type (100) single crystal silicon wafer with a diameter of 50 mm and a thickness of 0.2 mm as the film-forming base material. Grind the silicon chip with diamond powder with a particle size of 100nm for 15 minutes on a grinding disc, then ultrasonicate it in an acetone solution containing a small amount of 100nm diamond powder for 5 minutes, rinse it in acetone for 5 minutes, and dry it with absorbent cotton to obtain a surface degreasing treatment. film-forming substrate material.

[005...

Embodiment 2

[0062] The substrate material is a circular metal molybdenum plate with a diameter of 30mm and a thickness of 4.0mm. The outer diameter of the annular pit on the surface is 28mm, the width is 2.0mm, and the depth is 1.0mm. The filler metal is Ni wire with a diameter of 2.0mm. Put the molybdenum plate and Ni wire together in the acetone solution for 10 minutes of ultrasonication, take out the dustproof and dry it to get a clean substrate material.

[0063] The diamond film was deposited on a P-type (100) single crystal silicon wafer with a diameter of 25 mm and a thickness of 0.2 mm as the film-forming base material. Grind the silicon chip with diamond powder with a particle size of 100nm for 15 minutes on a grinding disc, then ultrasonicate it in an acetone solution containing a small amount of 100nm diamond powder for 5 minutes, rinse it in acetone for 5 minutes, and dry it with absorbent cotton to obtain a surface degreasing treatment. film-forming substrate material.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com