Patents

Literature

30results about How to "Minimize current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

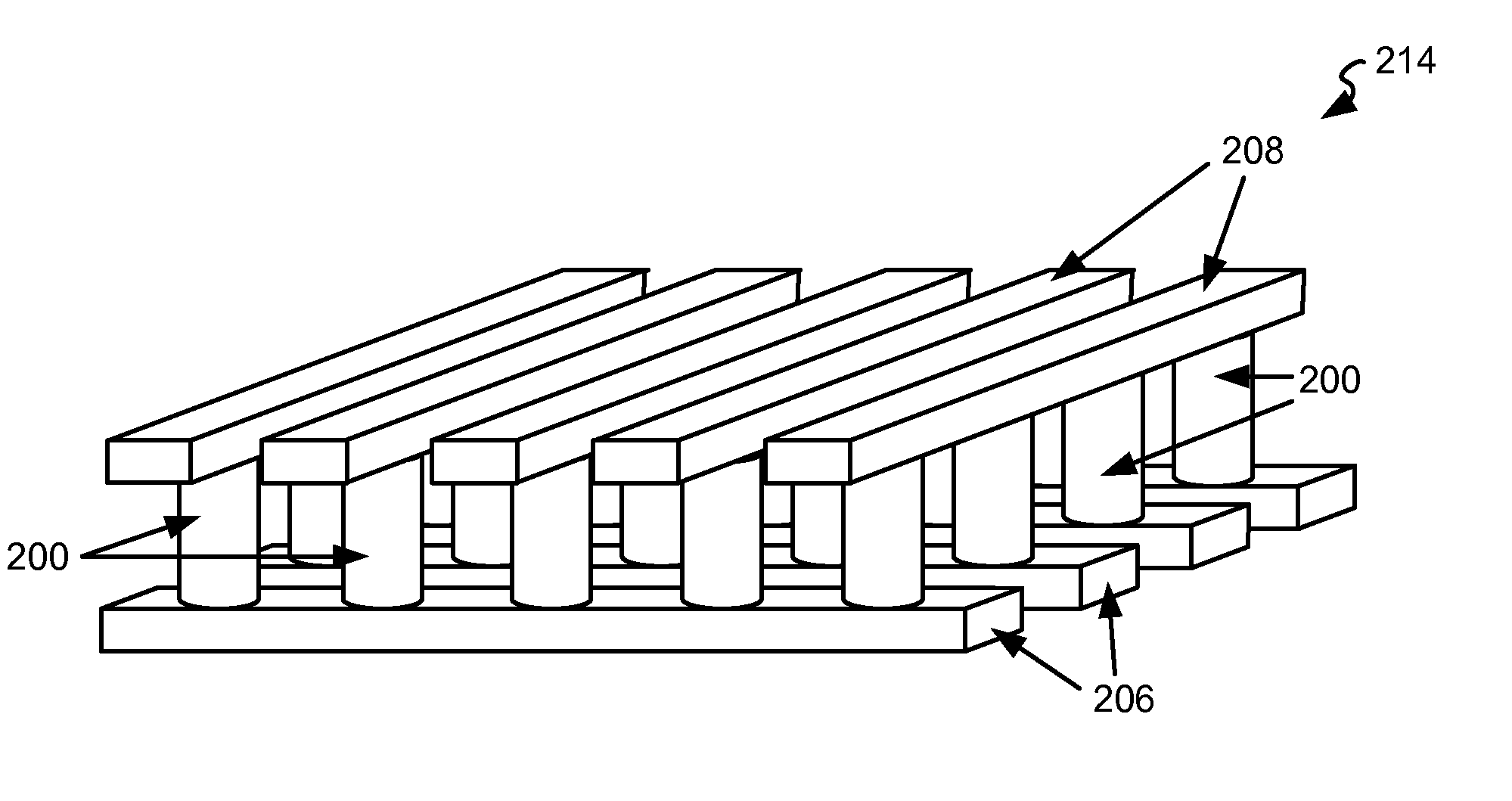

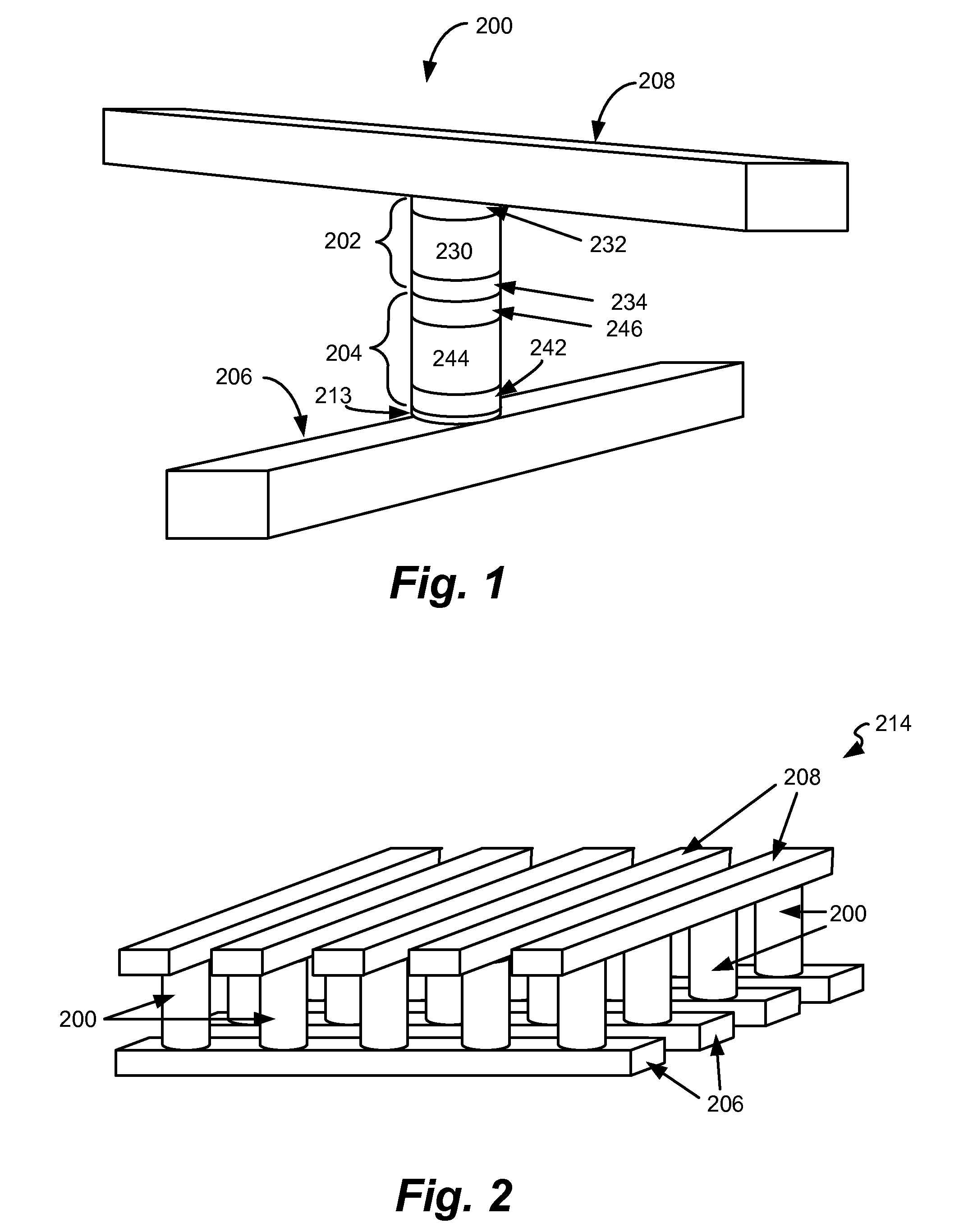

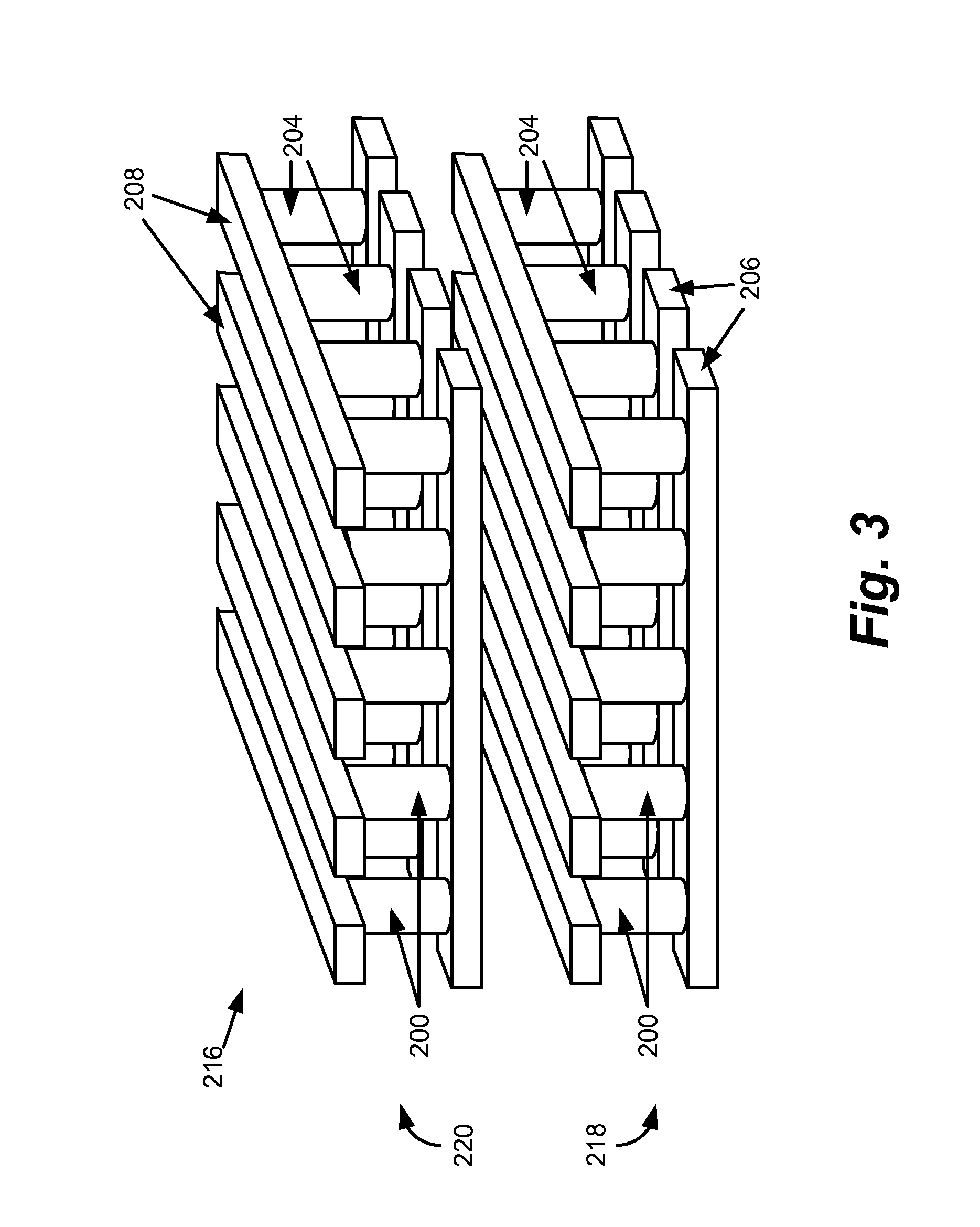

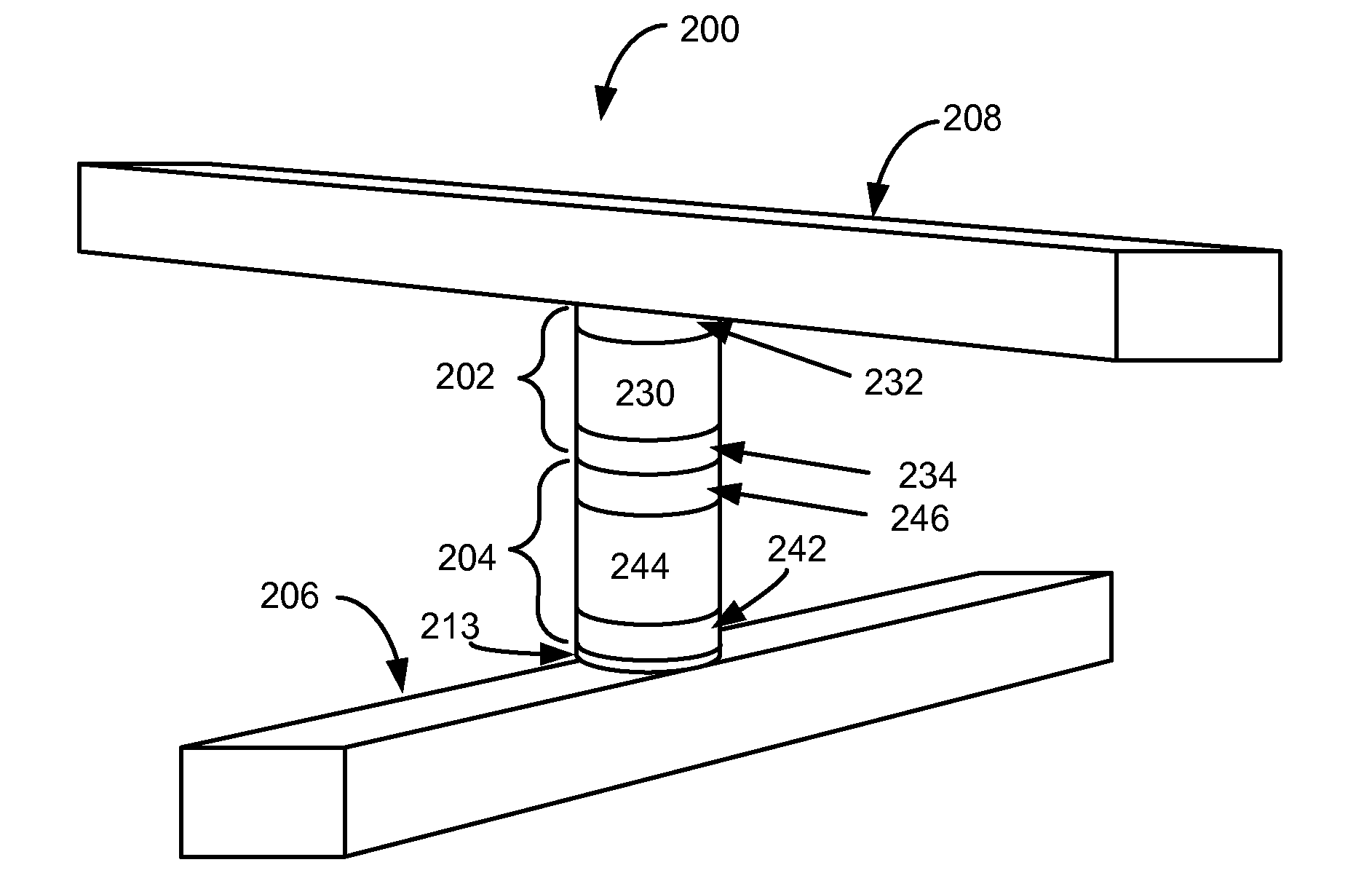

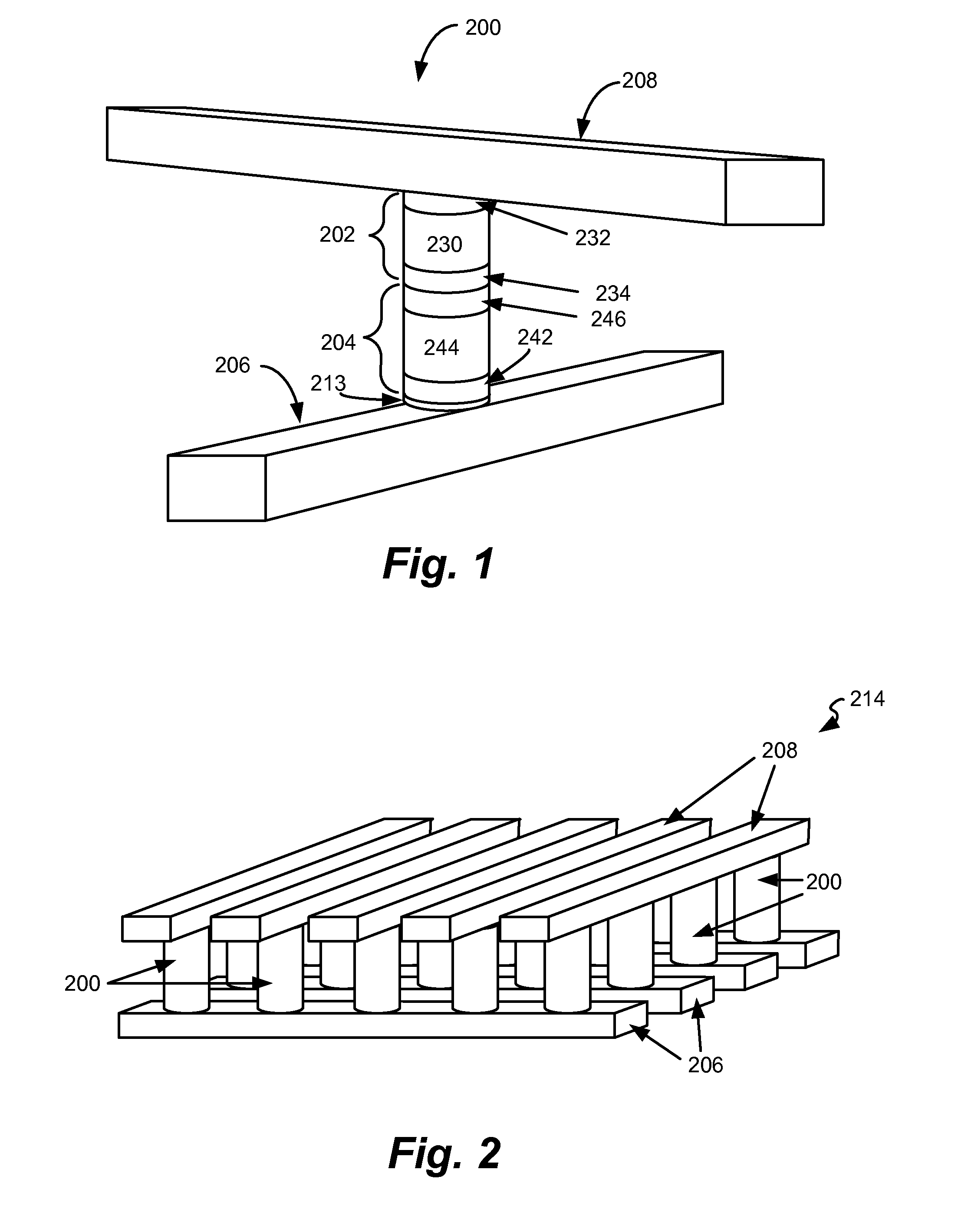

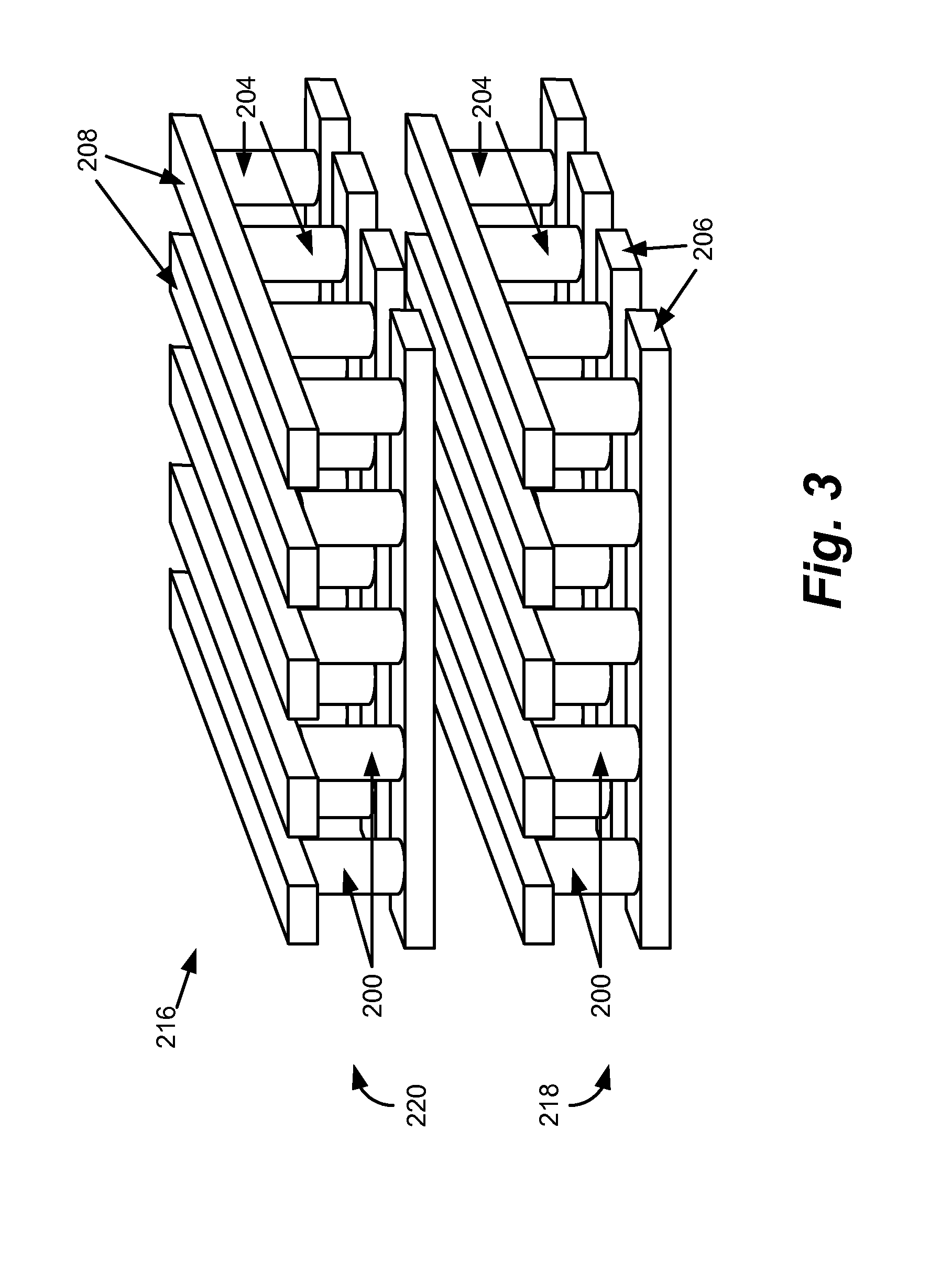

Programming reversible resistance switching elements

ActiveUS20120147657A1Save powerShorten the timeRead-only memoriesDigital storageElectrical resistance and conductanceTime efficient

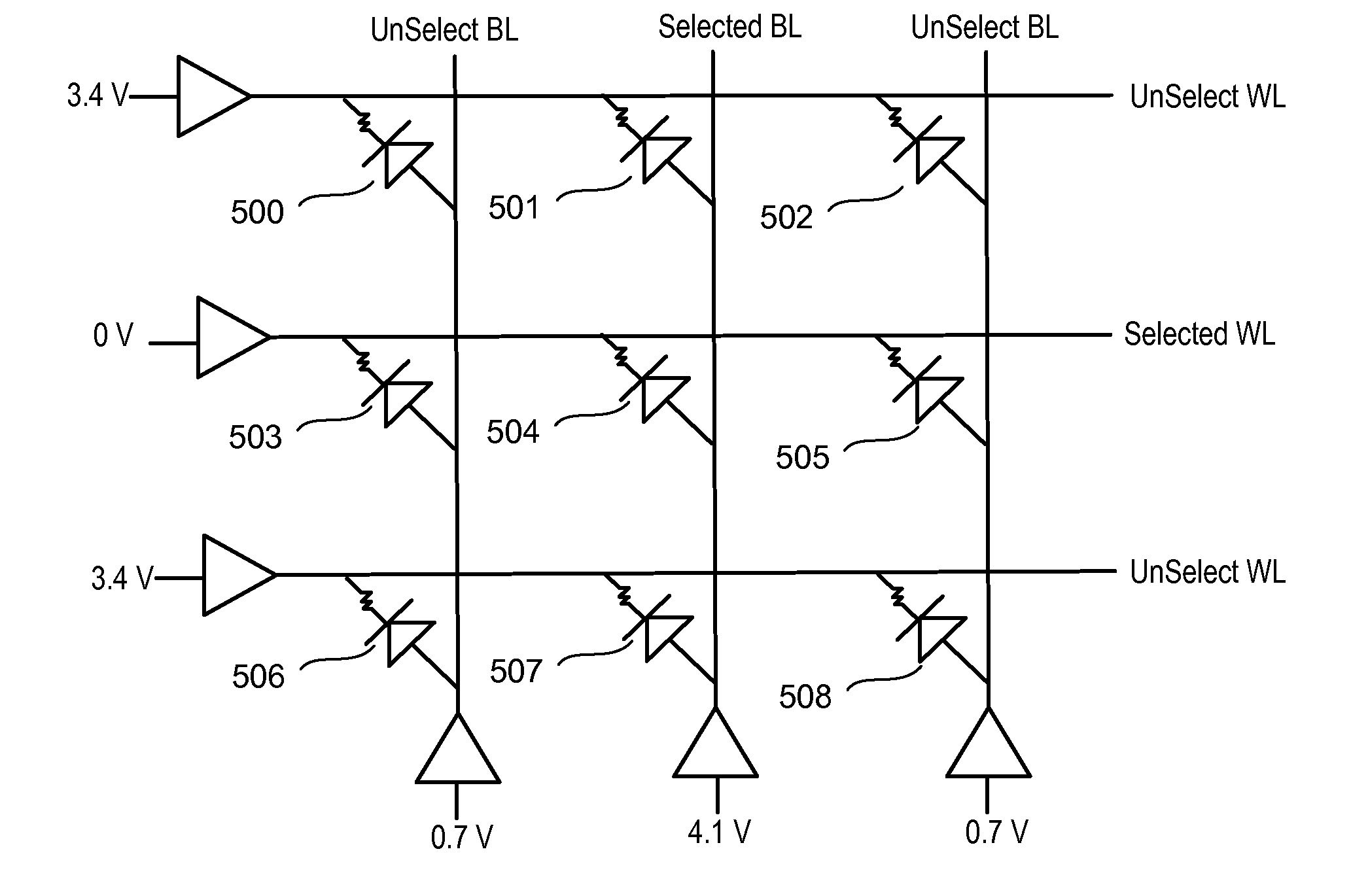

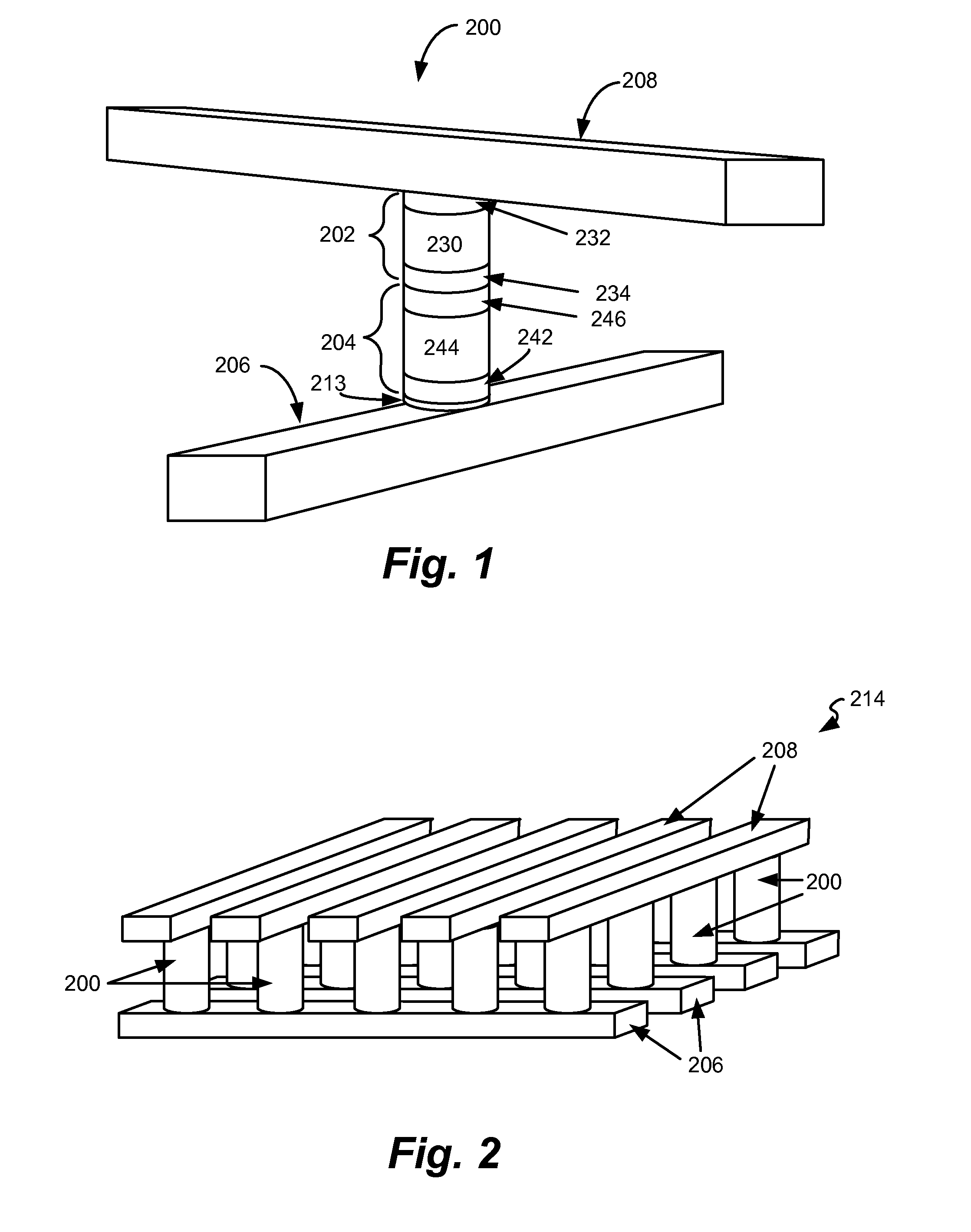

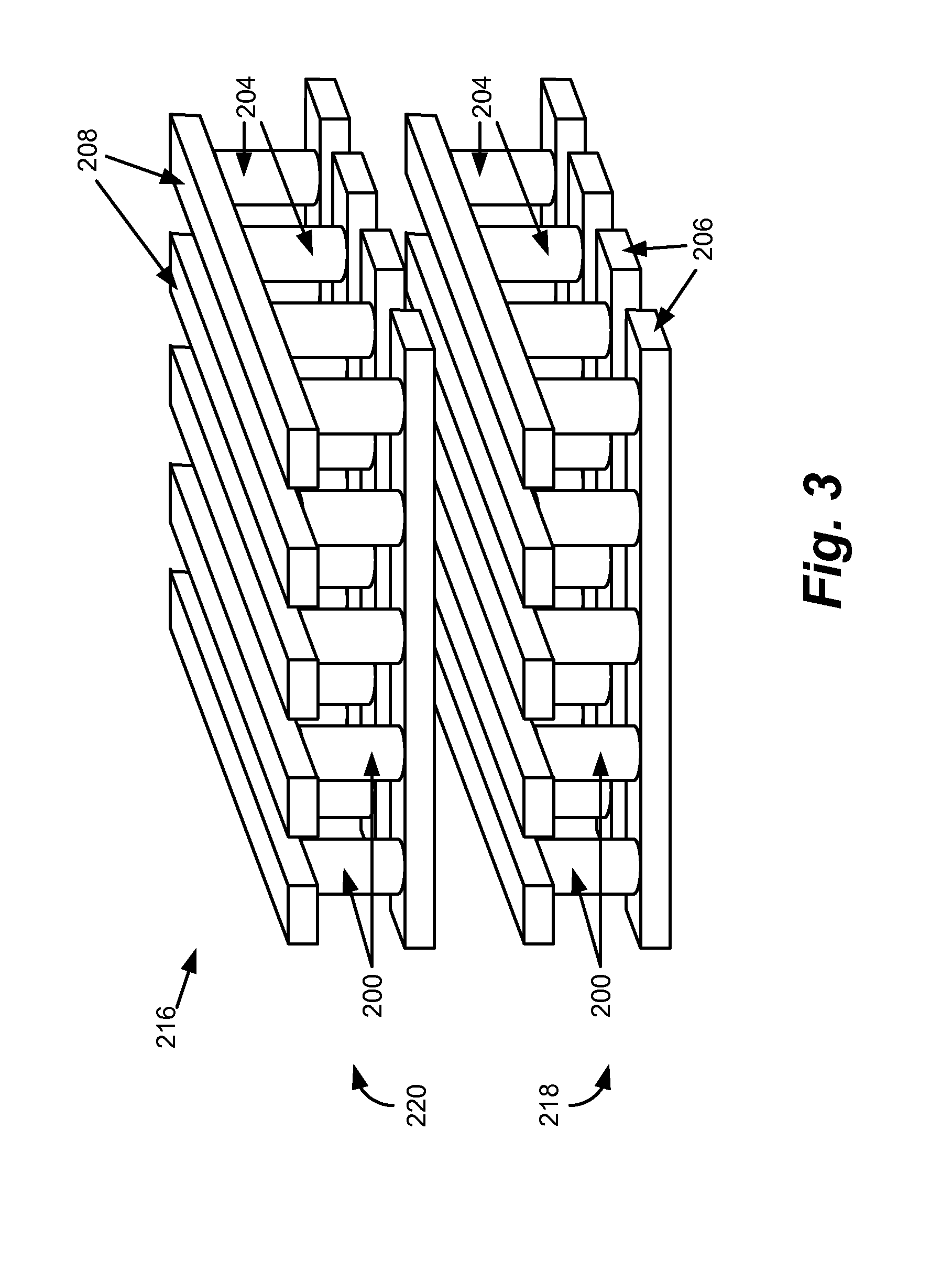

A storage system and method for operating the storage system that uses reversible resistance-switching elements is described. Techniques are disclosed herein for varying programming conditions to account for different resistances that memory cells have. These techniques can program memory cells in fewer attempts, which can save time and / or power. Techniques are disclosed herein for achieving a high programming bandwidth while reducing the worst case current and / or power consumption.

Owner:SANDISK TECH LLC

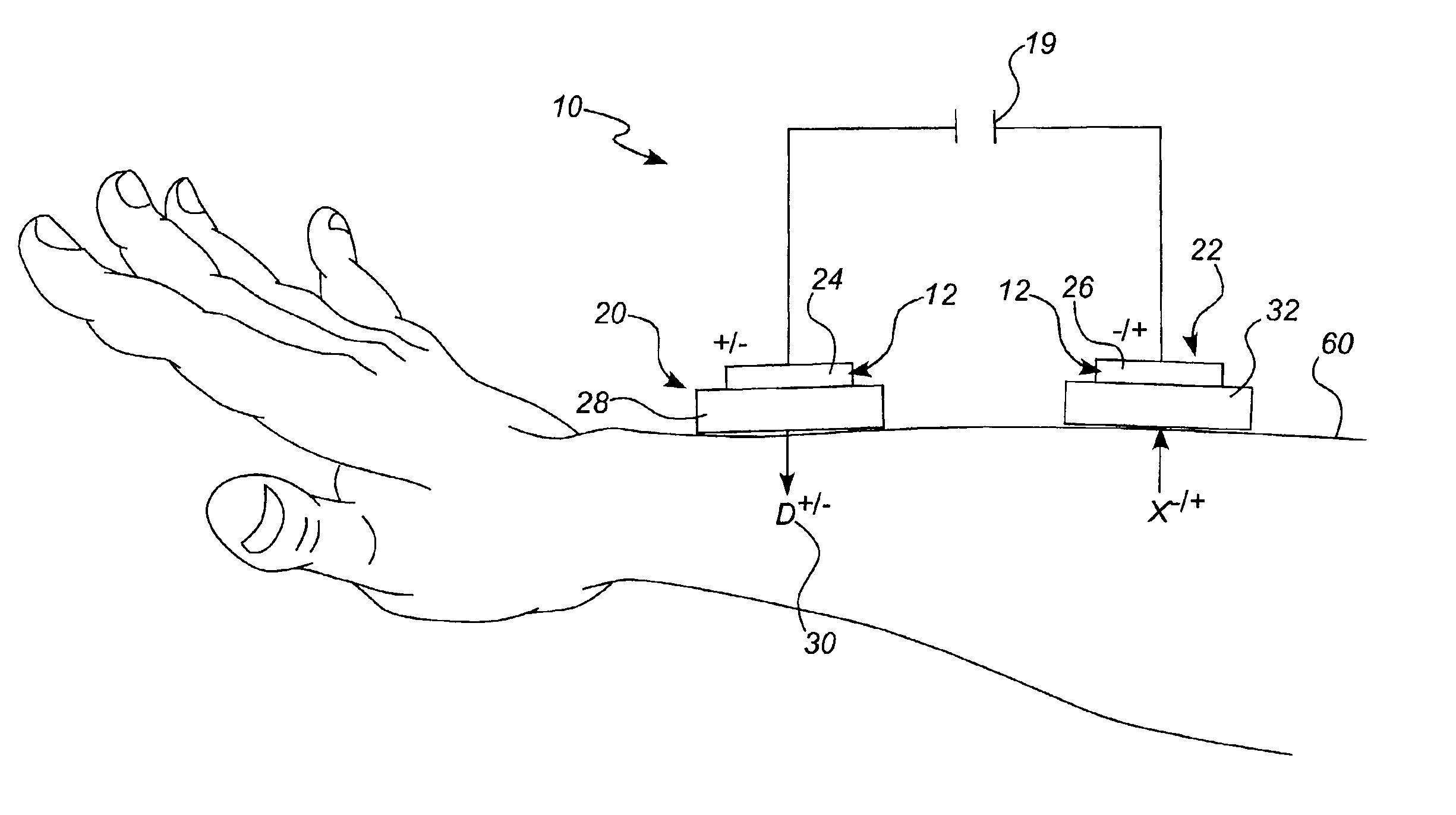

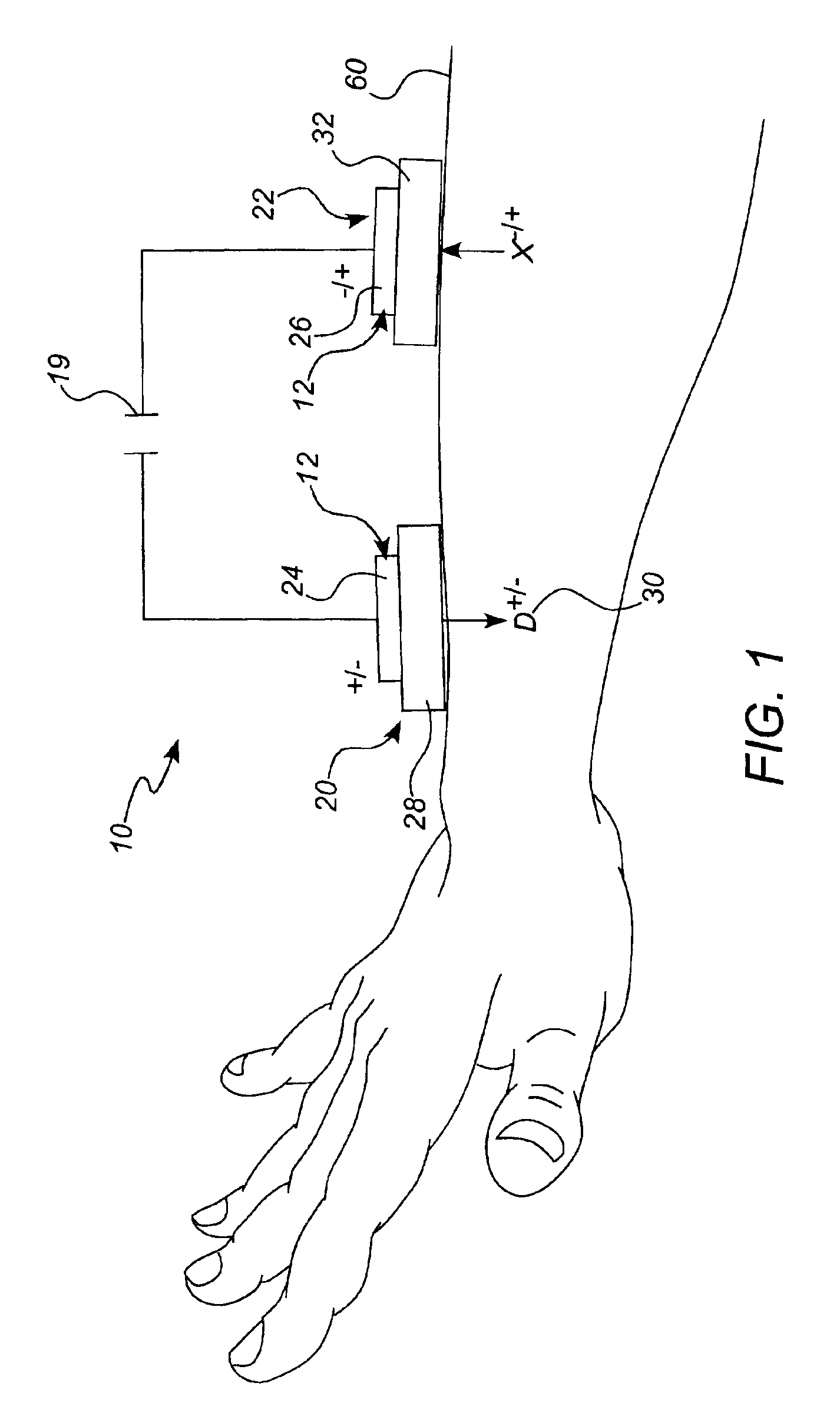

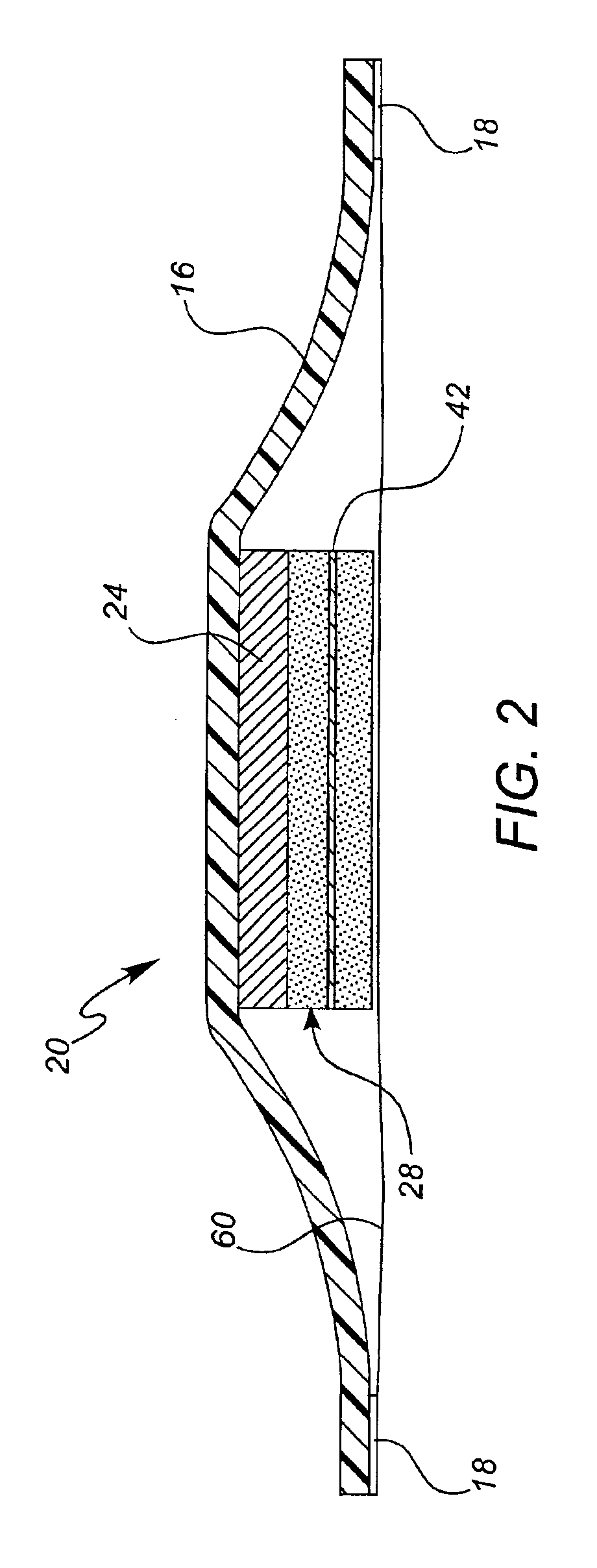

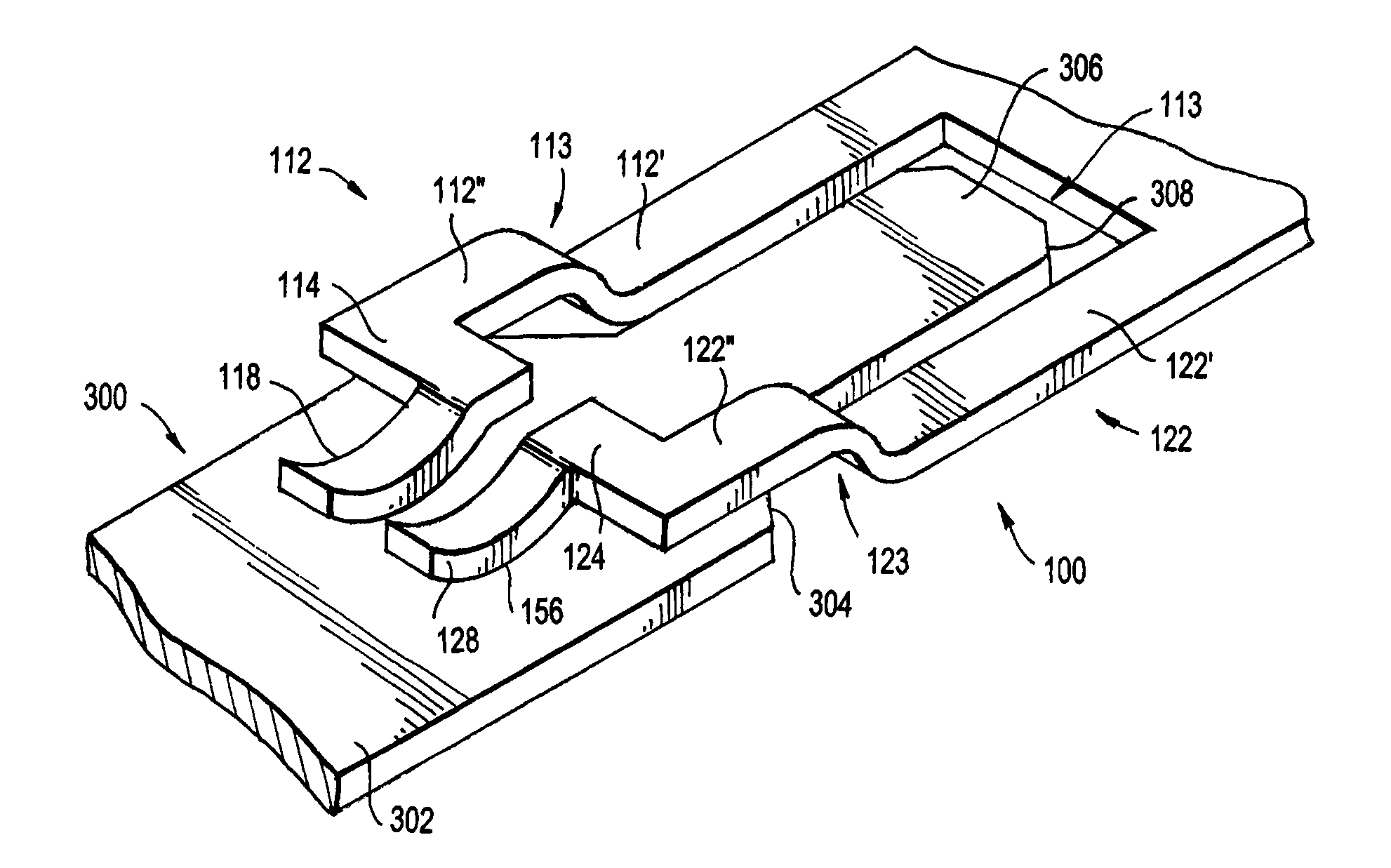

Iontophoretic drug delivery device and reservoir and method of making same

InactiveUS6862473B2Minimize currentReduce availabilityElectrotherapyPharmaceutical delivery mechanismDrugDrug delivery

A reservoir electrode assembly of the present invention for an iontophoretic drug delivery device includes an electrode and a hydrophilic reservoir situated in electrically conductive relation to the electrode. The hydrophilic reservoir is formed from a bibulous hydrophilic cross-linked polymeric material having a first surface and a second surface that is adhesively adherent to the electrode. The first surface of the polymeric material is releasably adhesively adherent when applied to an area of a patient's skin. The polymeric material has a cohesive strength forms an adhesive bond with a bond strength between the second surface of the polymeric material to the electrode that is greater than the cohesive strength of the polymeric material. Additionally, an adhesive bond strength of the first surface of the polymeric material to the applied area of the patient is less than the cohesive strength of the polymeric material so that upon removal of the reservoir assembly of the invention from the applied area of the patient, substantially no polymeric material remains on the applied area and the hydrophilic reservoir remains substantially intact and adhesively adherent to the electrode.

Owner:LINCOLN FAIR LAWN ASSOC

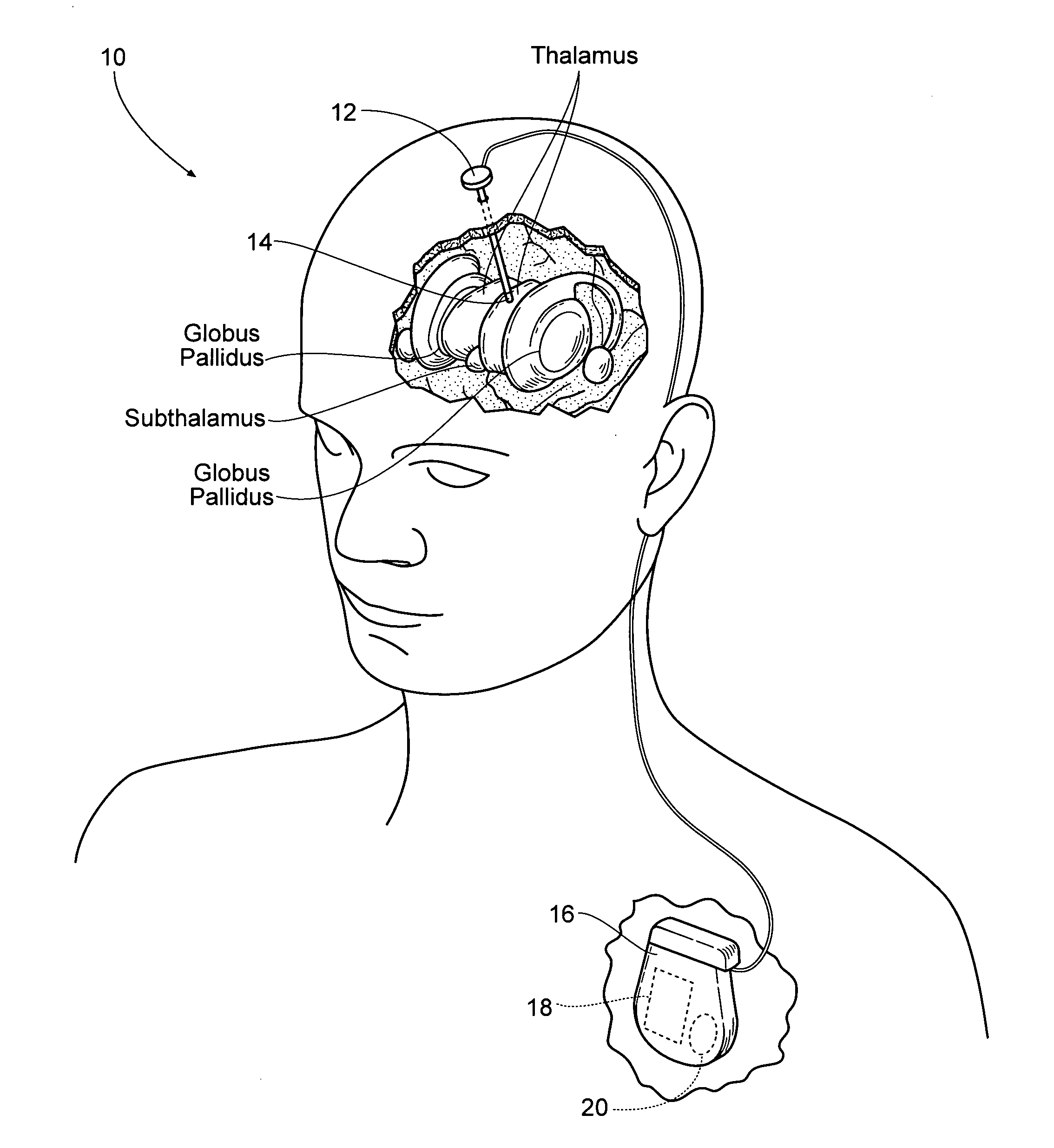

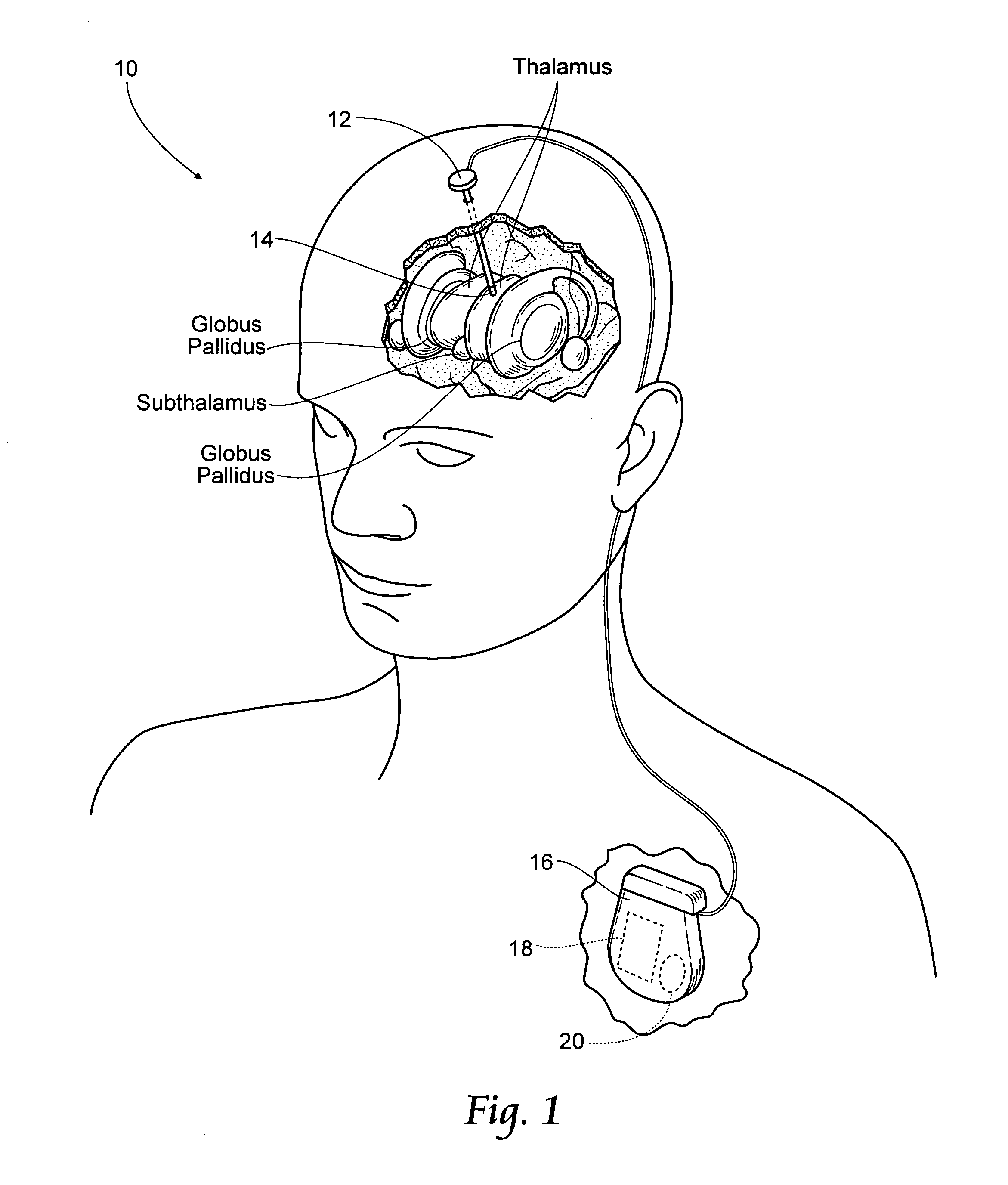

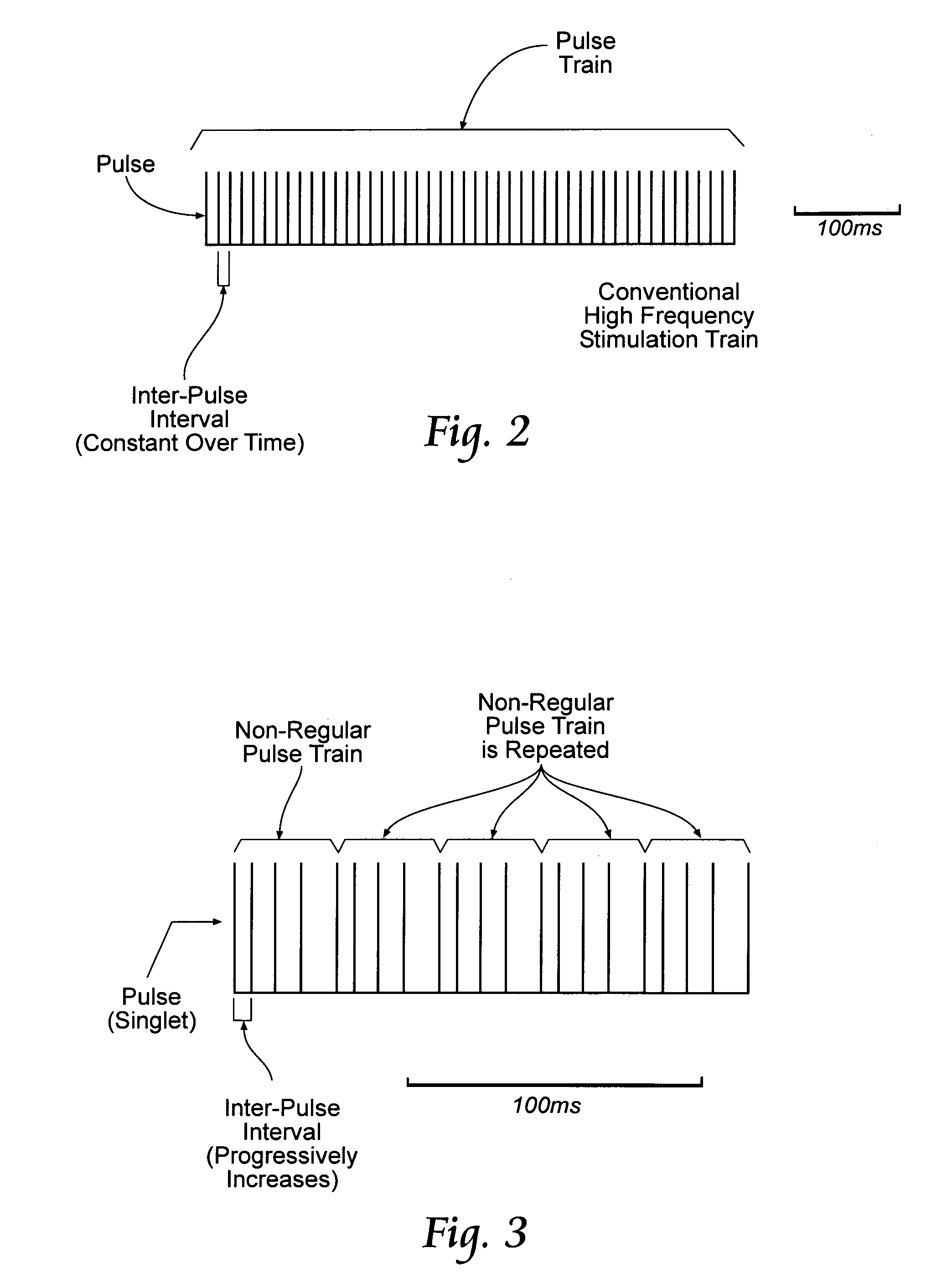

Non-regular electrical stimulation patterns for treating neurological disorders

ActiveUS20100152807A1Improves stimulation efficiencyMinimize currentHead electrodesExternal electrodesHigh rateElectricity

Systems and methods for stimulation of neurological tissue generate stimulation trains with temporal patterns of stimulation, in which the interval between electrical pulses (the inter-pulse intervals) changes or varies over time. Compared to conventional continuous, high rate pulse trains having regular (i.e., constant) inter-pulse intervals, the non-regular (i.e., not constant) pulse patterns or trains that embody features of the invention provide a lower average frequency.

Owner:DUKE UNIV

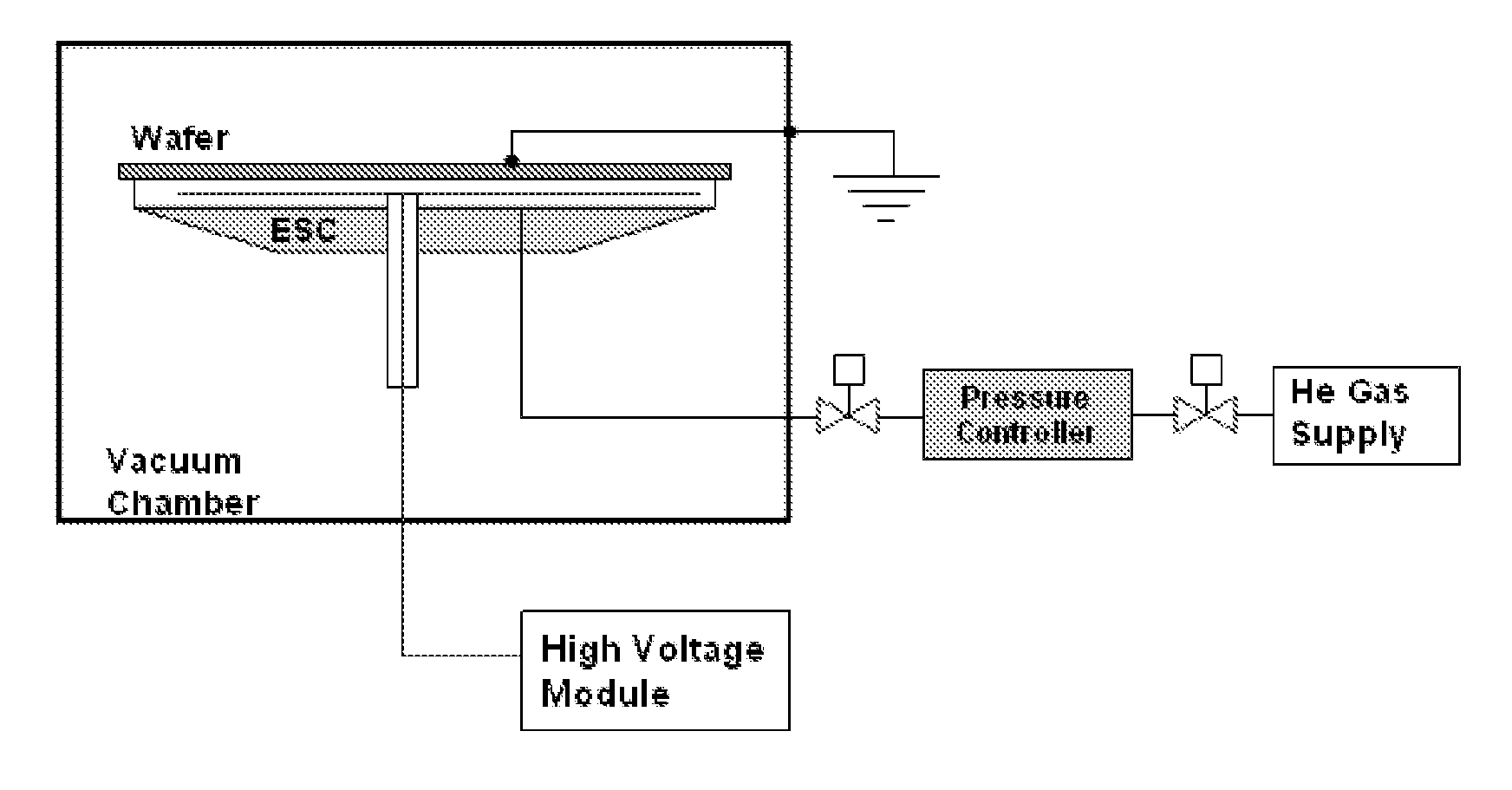

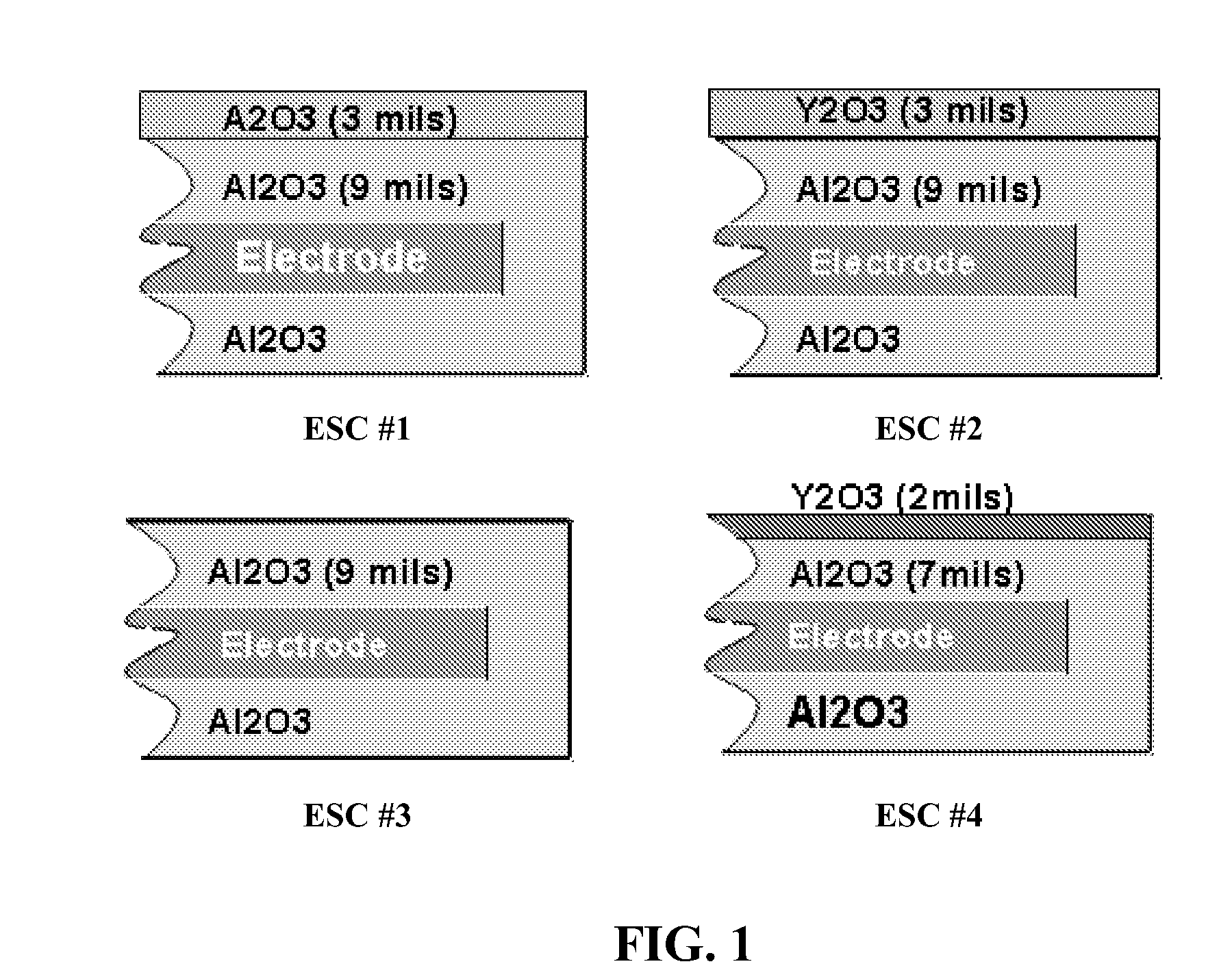

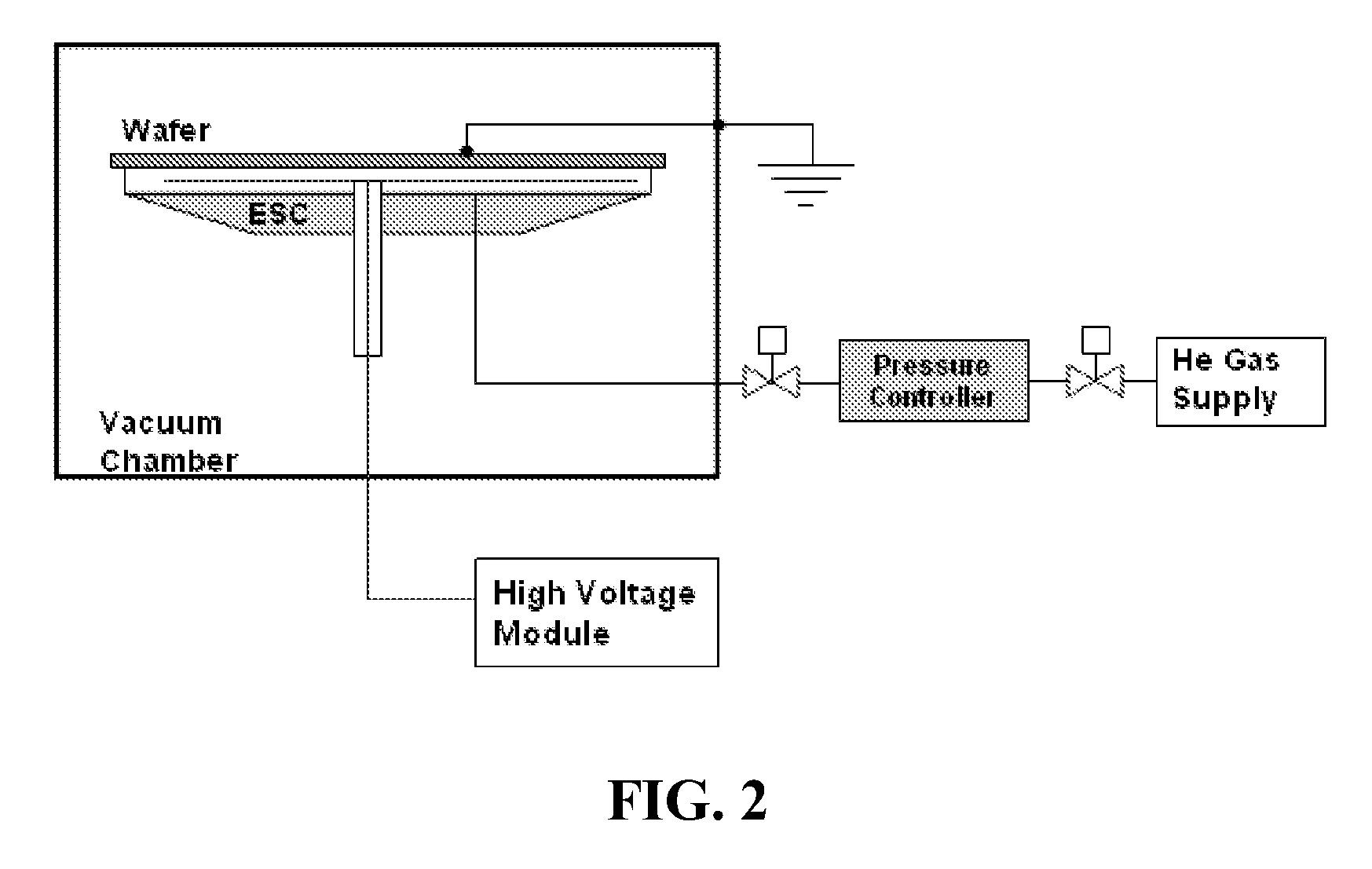

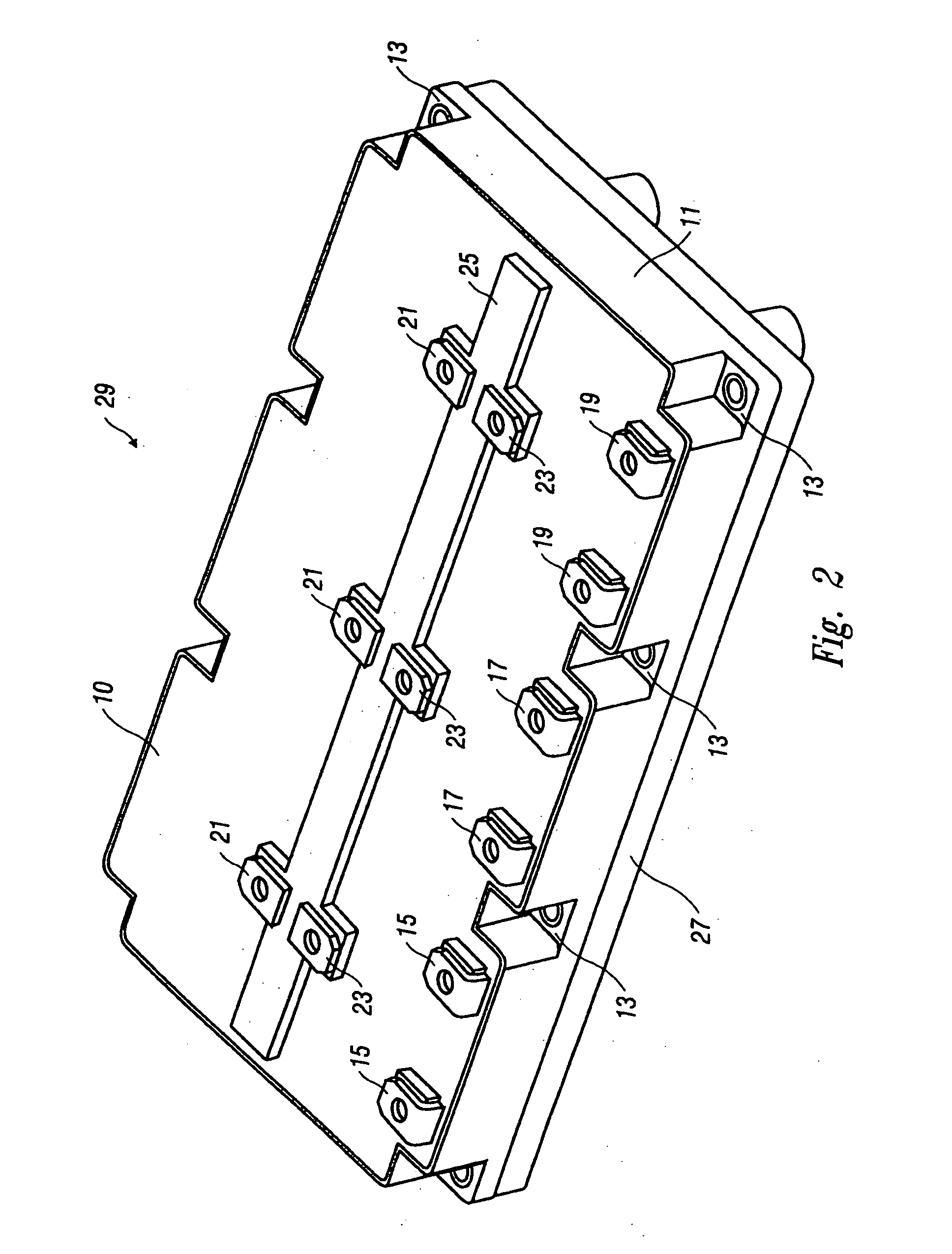

Substrate supports for semiconductor applications

ActiveUS20120141661A1Enhance attractive and chuck forceMinimize currentSemiconductor/solid-state device manufacturingCoatingsCorrosionOxide

This invention relates to substrate supports, e.g., coated electrostatic chucks, having a dielectric multilayer formed thereon; dielectric multilayers that provide erosive and corrosive barrier protection in harsh environments such as plasma treating vessels used in semiconductor device manufacture; process chambers, e.g., deposition chambers, for processing substrates; methods for protecting substrate supports; and methods for producing substrate supports and electronic devices. The dielectric multilayer comprises (a) an undercoat dielectric layer comprising a metal oxide or metal nitride formed on a surface; and (b) a topcoat dielectric layer comprising a metal oxide formed on the undercoat dielectric layer. The topcoat dielectric layer has an aluminum oxide content of less than about 1 weight percent. The topcoat dielectric layer has a corrosion resistance and / or plasma erosion resistance greater than the corrosion resistance and / or plasma erosion resistance of the undercoat dielectric layer. The undercoat dielectric layer can have a resistivity greater than the resistivity of the topcoat dielectric layer. The topcoat dielectric layer can have a dielectric constant greater than the dielectric constant of the undercoat dielectric layer. The undercoat dielectric layer can have a porosity greater than the porosity of the topcoat dielectric layer. The invention is useful, for example, in the manufacture and protection of electrostatic chucks used in semiconductor device manufacture.

Owner:FM INDS

Programming reversible resistance switching elements

ActiveUS20100321977A1Shorten the timeSave powerRead-only memoriesDigital storageElectrical resistance and conductanceTime efficient

A storage system and method for operating the storage system that uses reversible resistance-switching elements is described. Techniques are disclosed herein for varying programming conditions to account for different resistances that memory cells have. These techniques can program memory cells in fewer attempts, which can save time and / or power. Techniques are disclosed herein for achieving a high programming bandwidth while reducing the worst case current and / or power consumption. In one embodiment, a page mapping scheme is provided that programs multiple memory cells in parallel in a way that reduces the worst case current and / or power consumption.

Owner:SANDISK TECH LLC

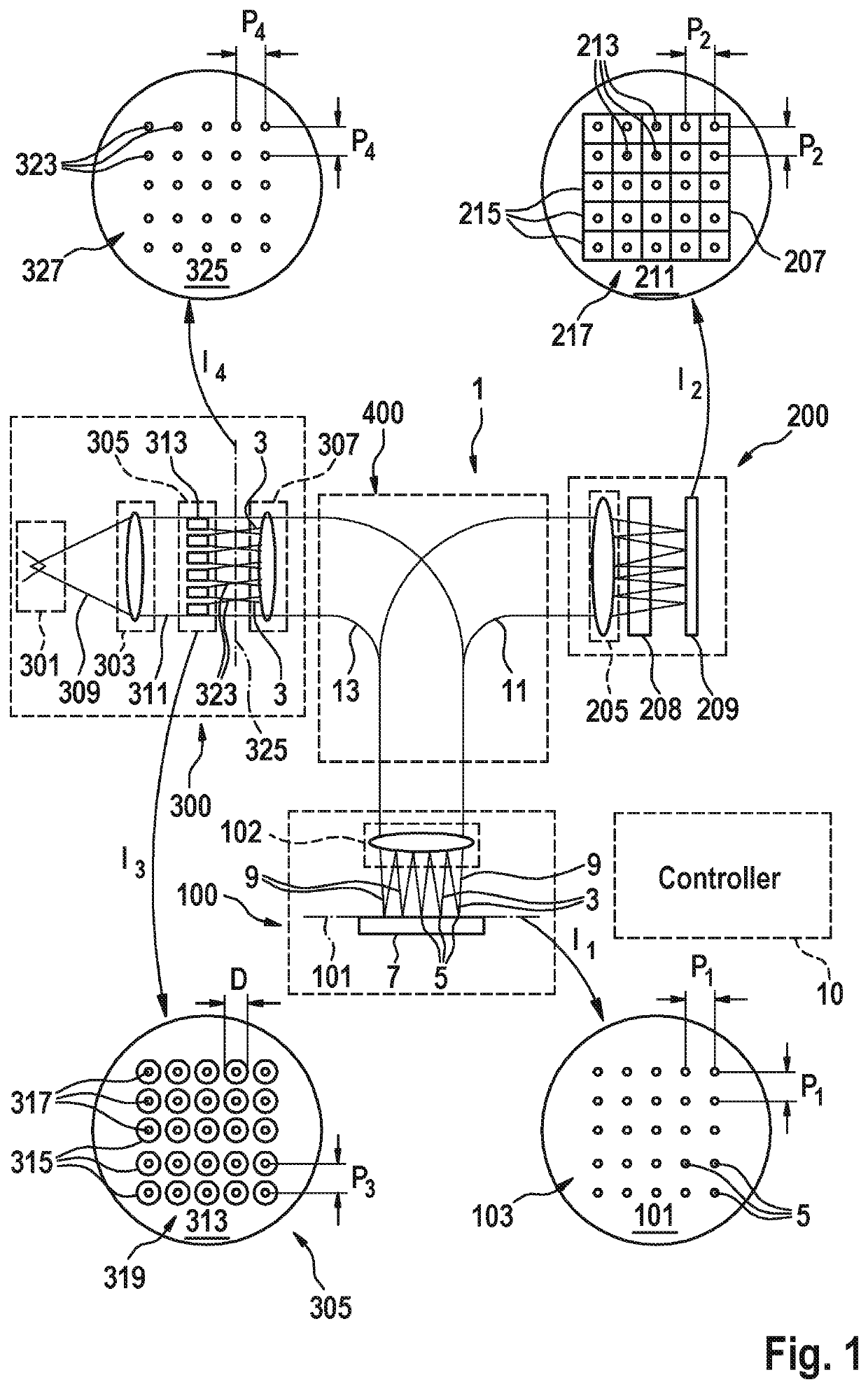

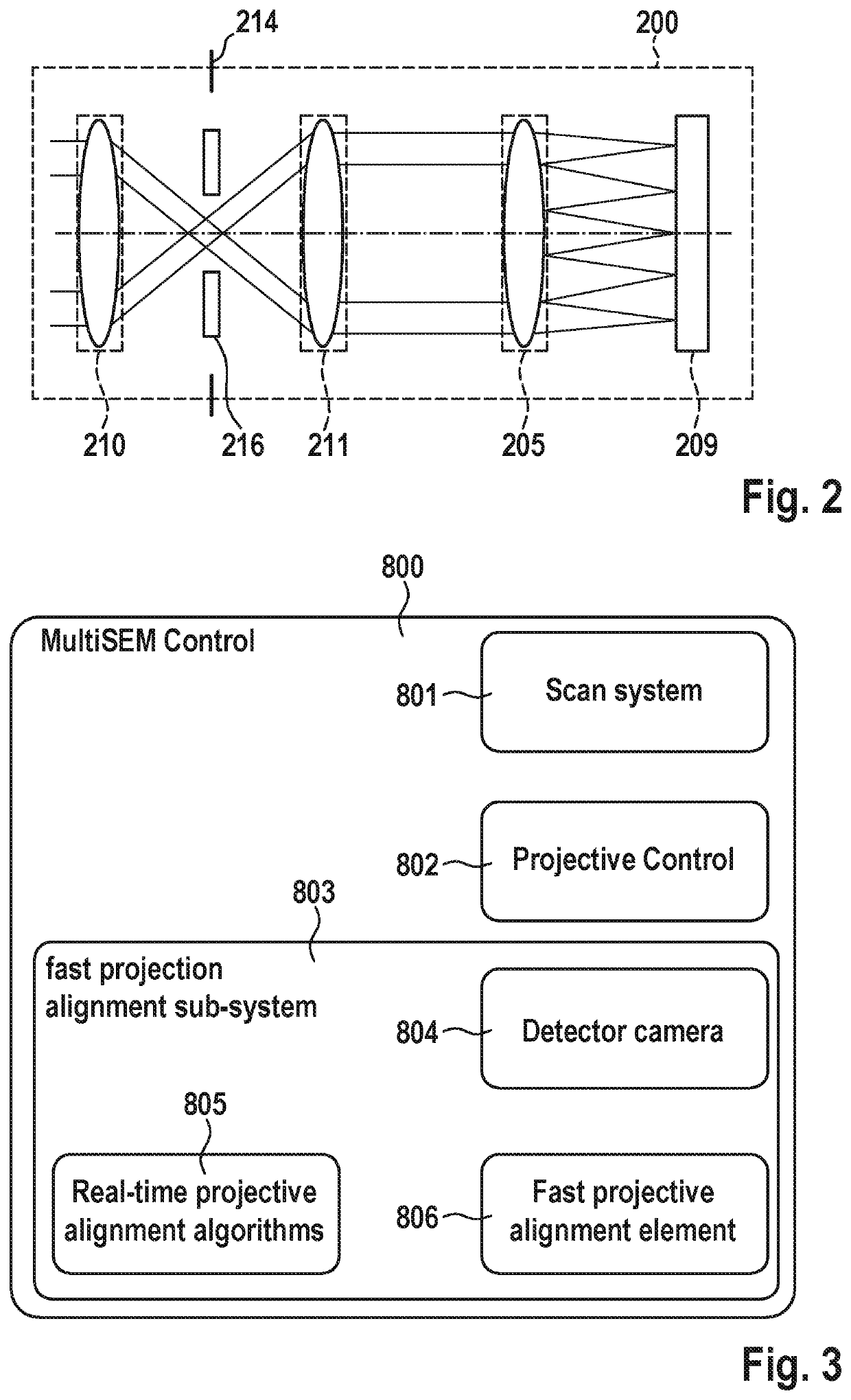

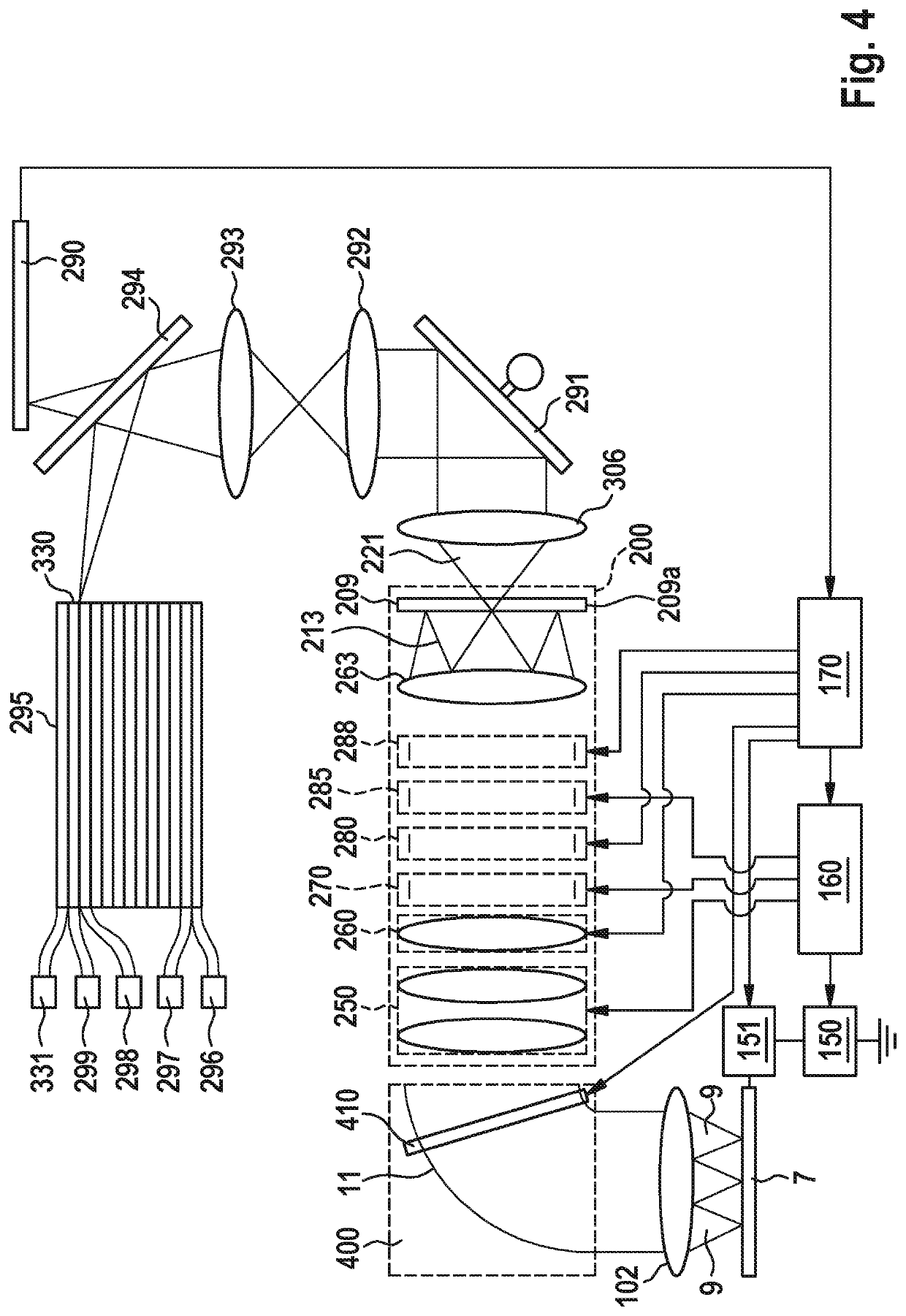

Charged particle beam system and method

ActiveUS20190355544A1Fast switchMinimize currentElectric discharge tubesParticle beamProjection system

A charged particle beam system includes a charged particle source, a multi beam generator, an objective lens, a projection system, and a detector system. The projection system includes a first subcomponent configured to provide low frequency adjustments, and the projection system comprises a second subcomponent configured to provide a high frequency adjustments.

Owner:CARL ZEISS MULTISEM GMBH

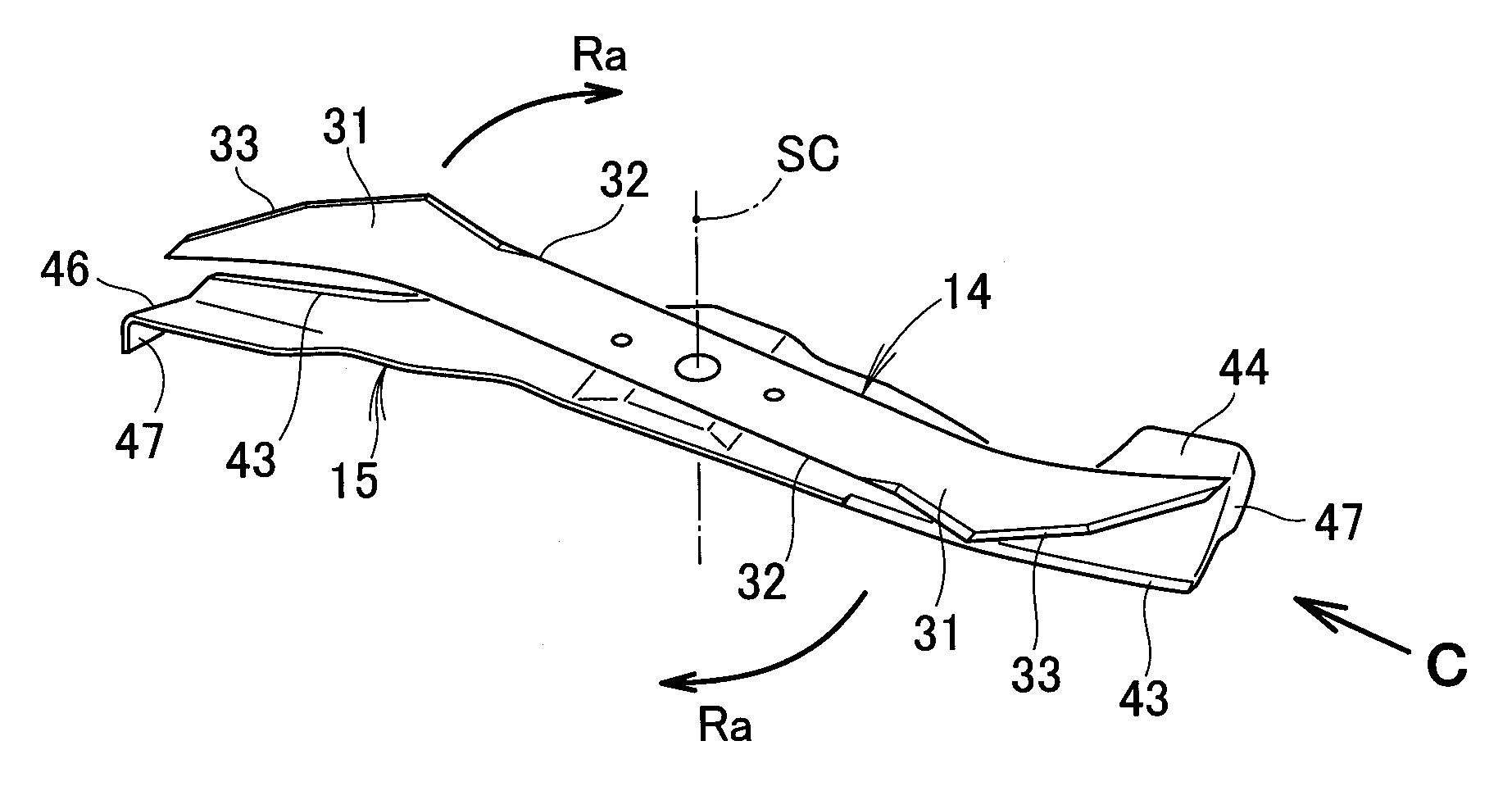

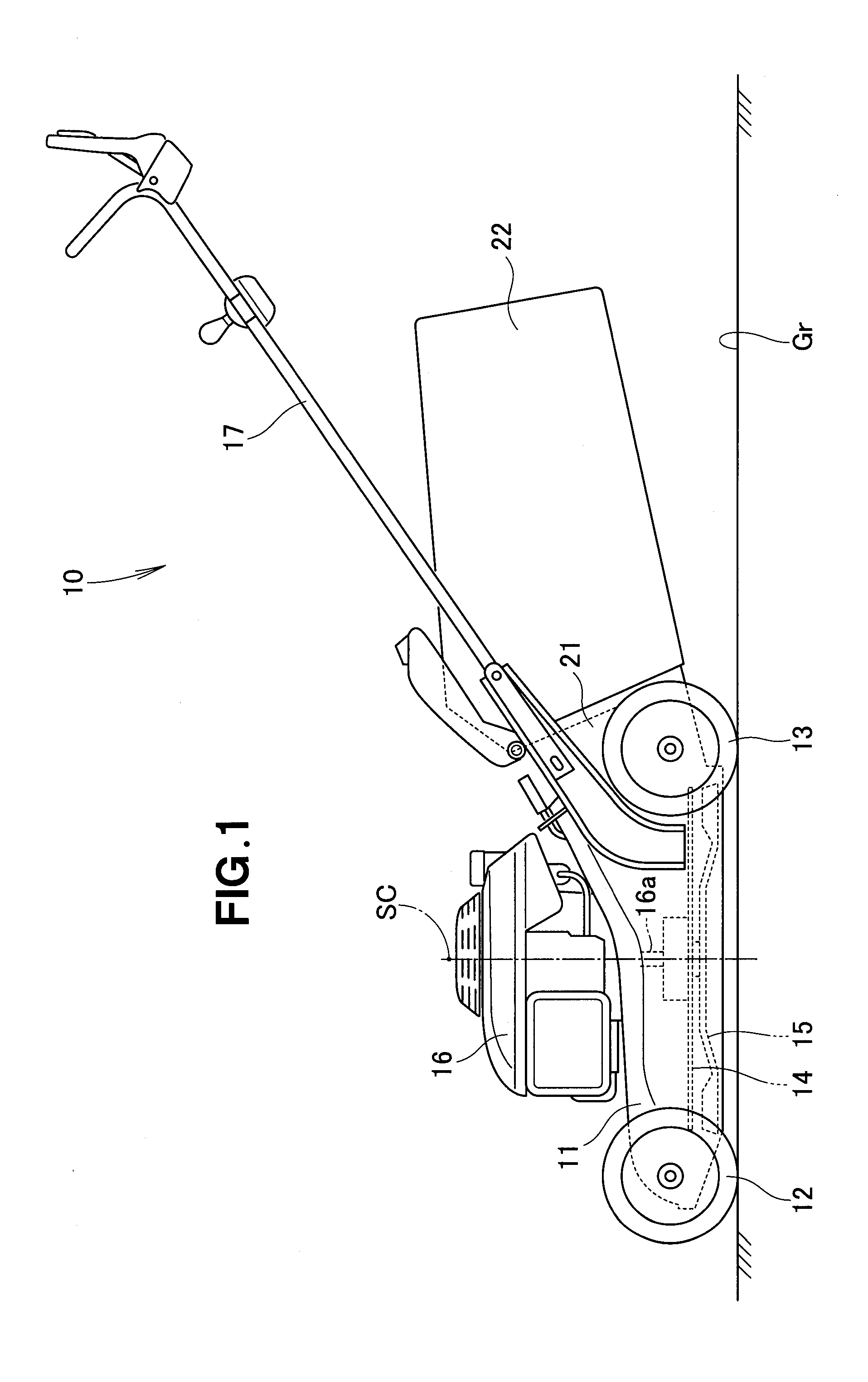

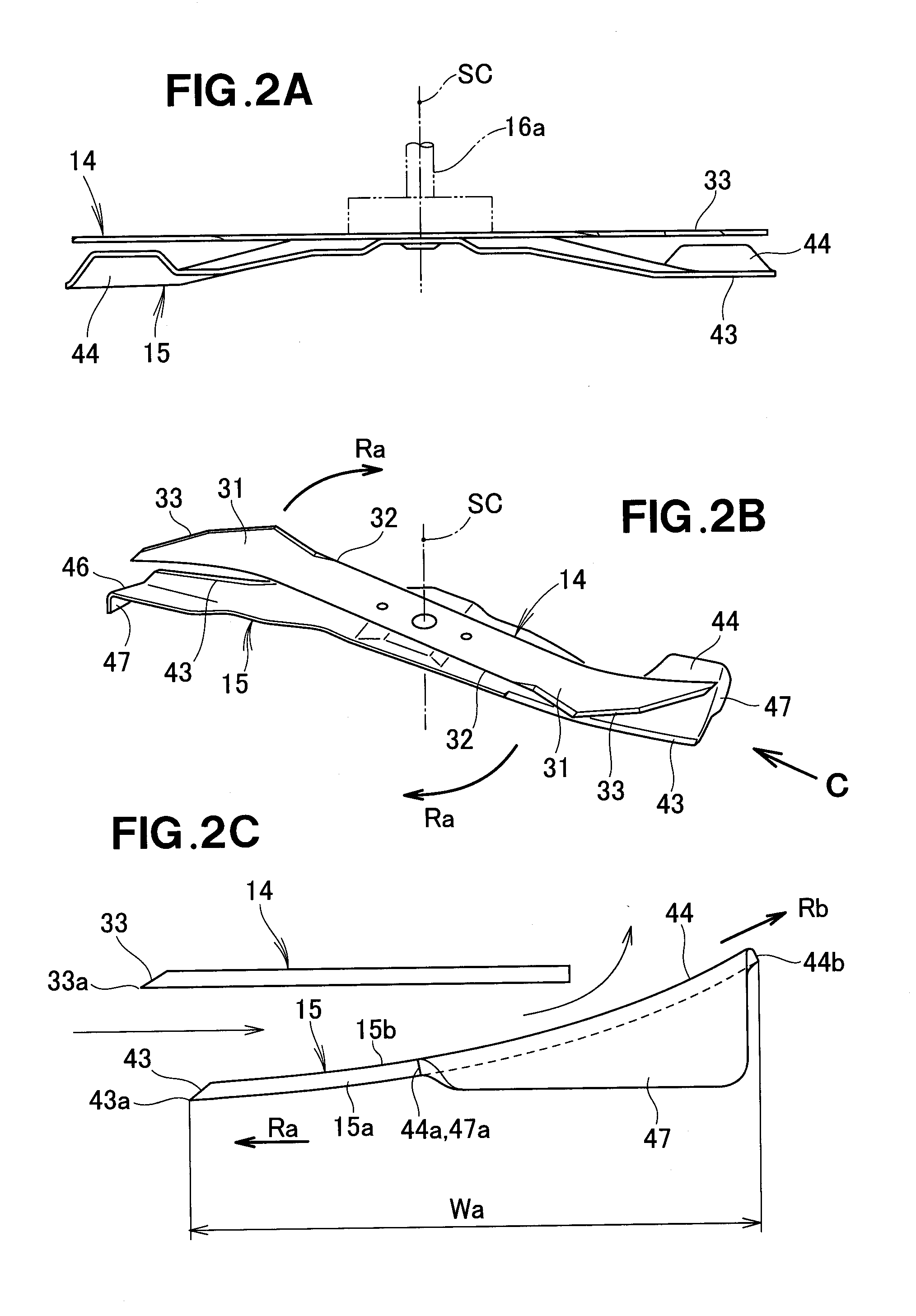

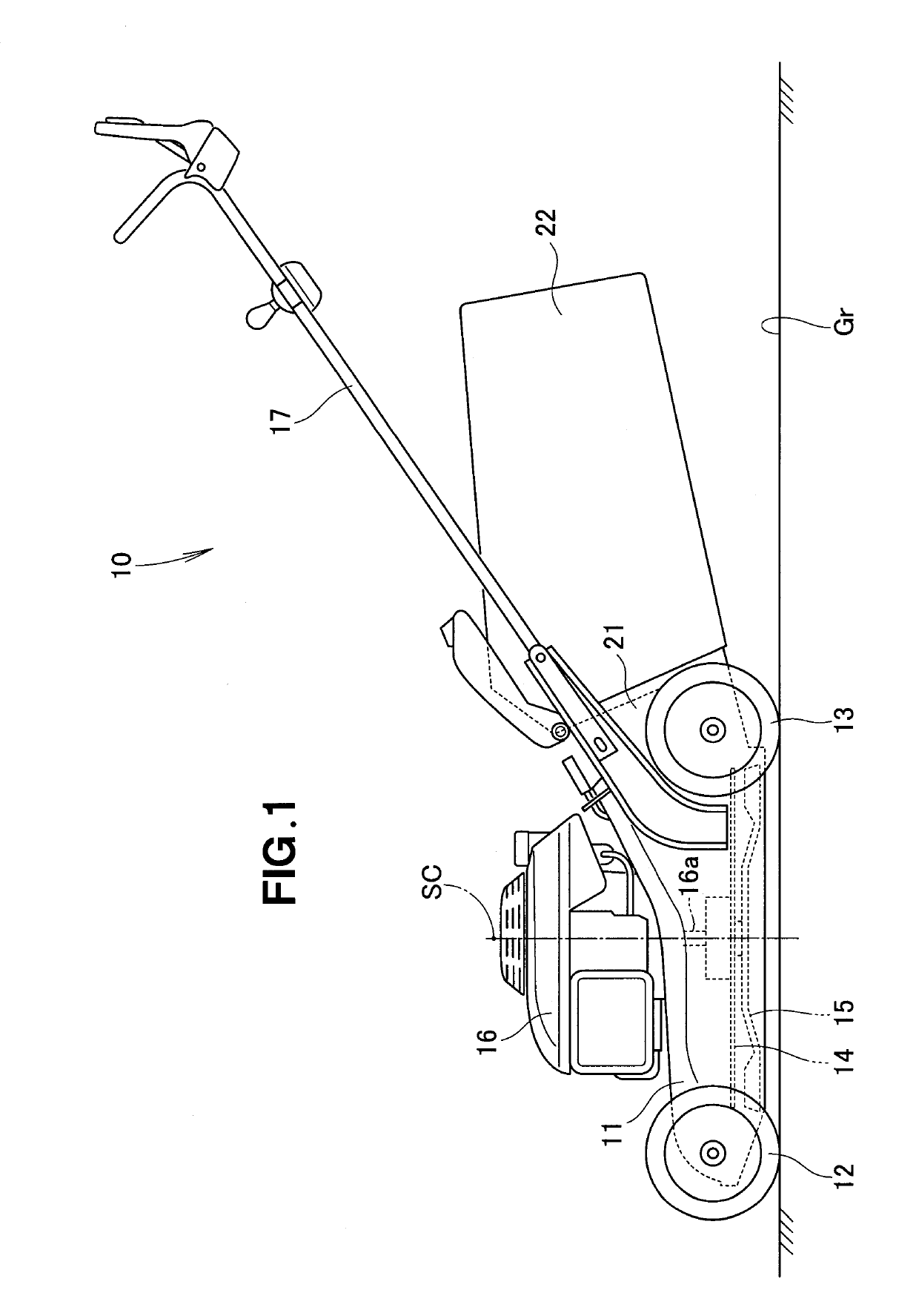

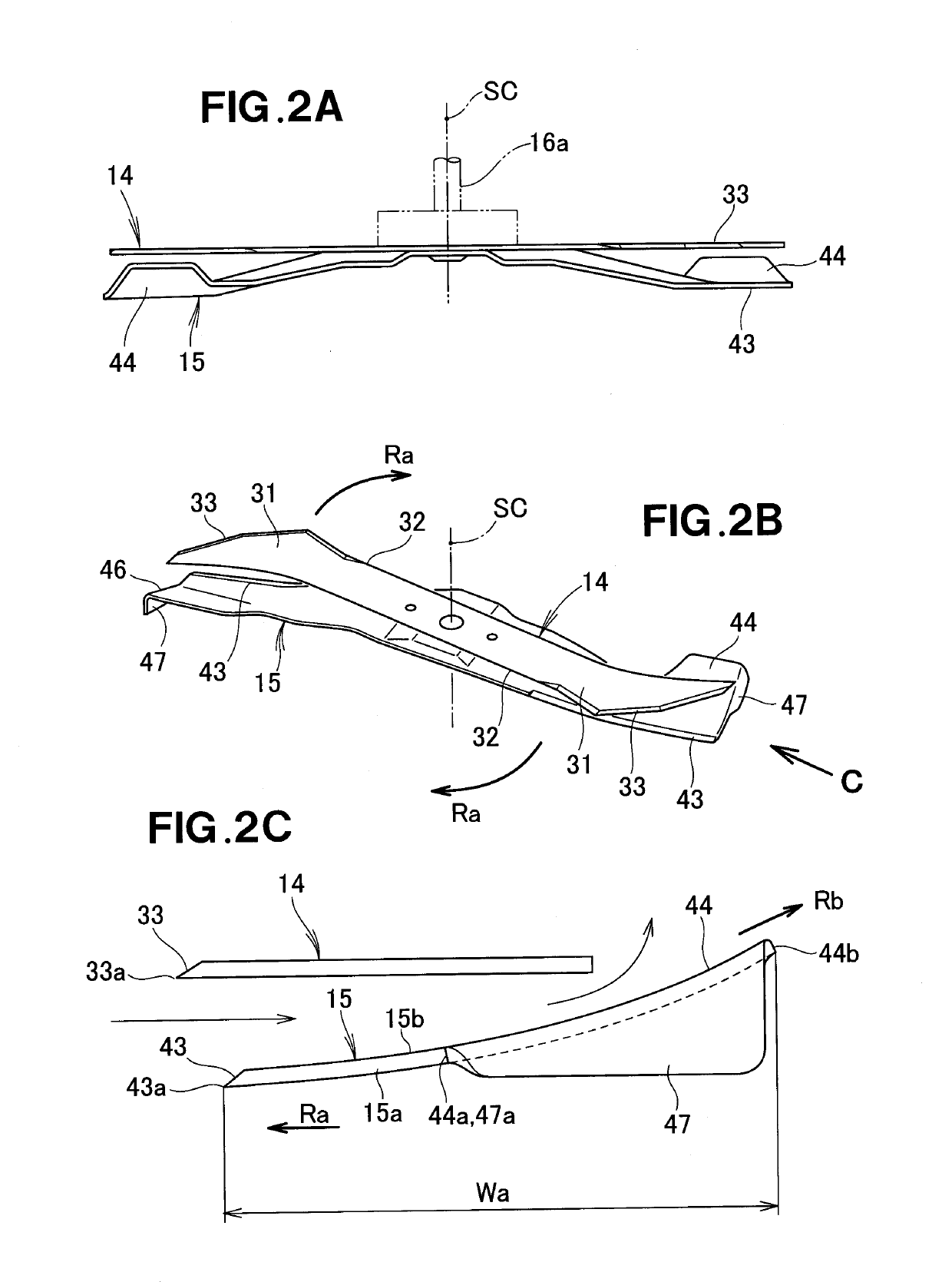

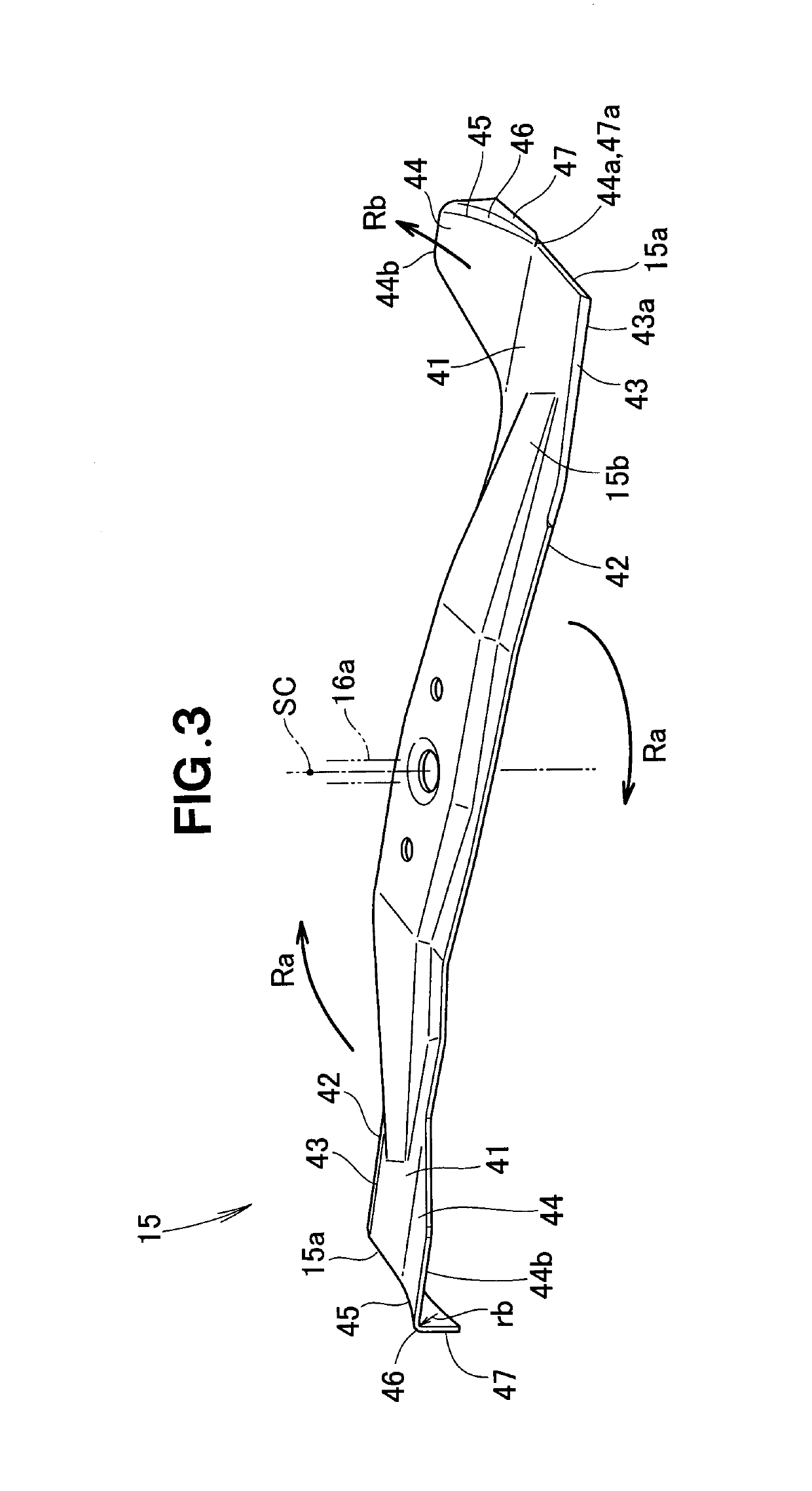

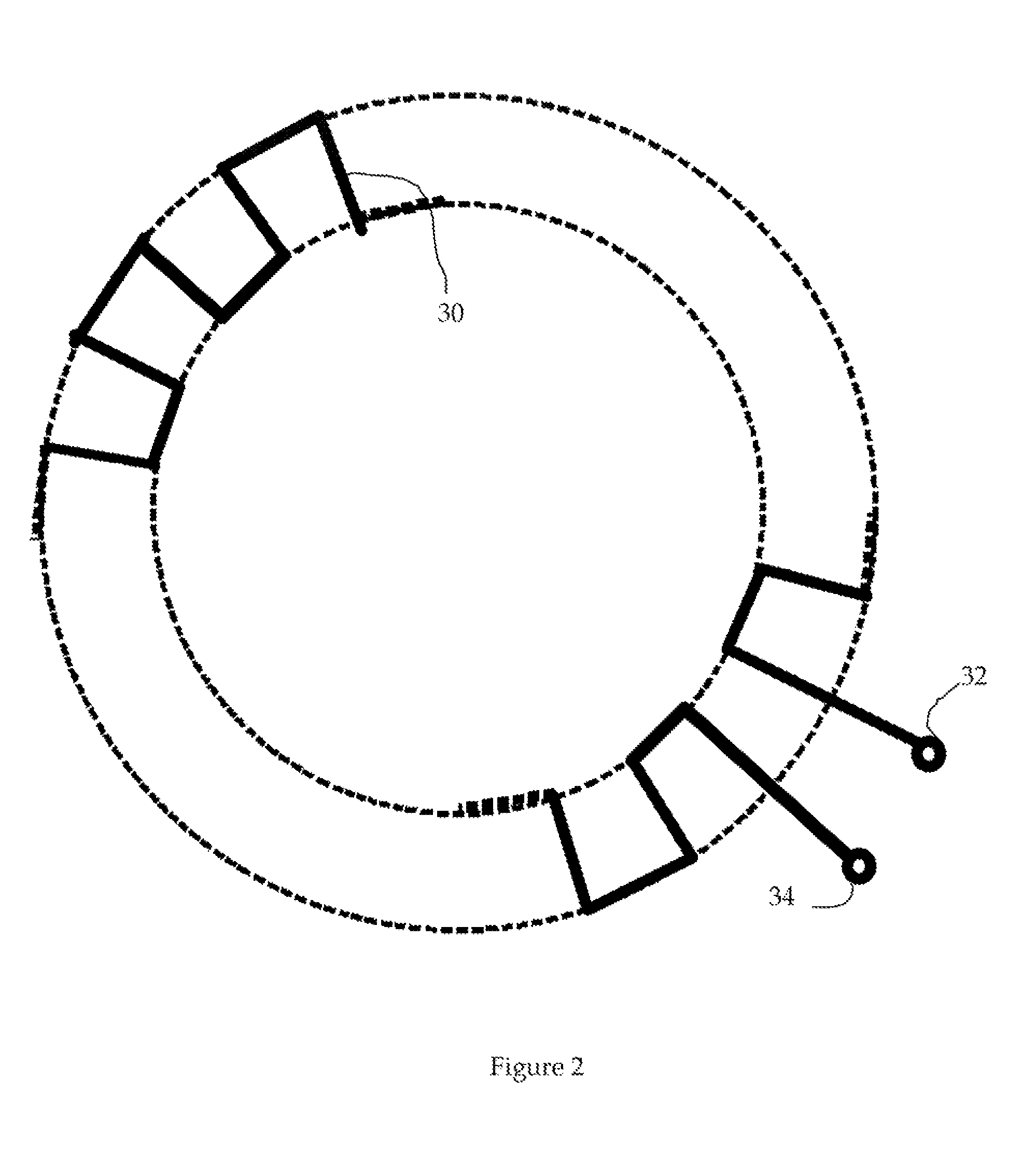

Lawn mower

A lawn mower includes a cutter blade that is an elongated member extending in opposite horizontal directions with respect to a vertical rotation shaft. The cutter blade includes, on each of its longitudinally opposite end portions, a blade section formed along the front edge, in a rotating direction of the cutter blade, of the end portion, and an air lift section extending from the front edge while curving rearward and upward. The air lift section has a vertical downward wing formed integrally thereon and extending downward via a bent section that is bent downward from at least a rear half portion, in the rotating direction, of an outer peripheral edge of the air lift section. The bent section has a radius set to gradually increase as the air lift section curves rearward and upward in the rotating direction.

Owner:HONDA MOTOR CO LTD

Lawn mower cutter blade

A lawn mower includes a cutter blade that is an elongated member extending in opposite horizontal directions with respect to a vertical rotation shaft. The cutter blade includes, on each of its longitudinally opposite end portions, a blade section formed along the front edge, in a rotating direction of the cutter blade, of the end portion, and an air lift section extending from the front edge while curving rearward and upward. The air lift section has a vertical downward wing formed integrally thereon and extending downward via a bent section that is bent downward from at least a rear half portion, in the rotating direction, of an outer peripheral edge of the air lift section. The bent section has a radius set to gradually increase as the air lift section curves rearward and upward in the rotating direction.

Owner:HONDA MOTOR CO LTD

Programming reversible resistance switching elements

ActiveUS8154904B2Save powerShorten the timeRead-only memoriesDigital storageElectrical resistance and conductanceTime efficient

A storage system and method for operating the storage system that uses reversible resistance-switching elements is described. Techniques are disclosed herein for varying programming conditions to account for different resistances that memory cells have. These techniques can program memory cells in fewer attempts, which can save time and / or power. Techniques are disclosed herein for achieving a high programming bandwidth while reducing the worst case current and / or power consumption. In one embodiment, a page mapping scheme is provided that programs multiple memory cells in parallel in a way that reduces the worst case current and / or power consumption.

Owner:SANDISK TECH LLC

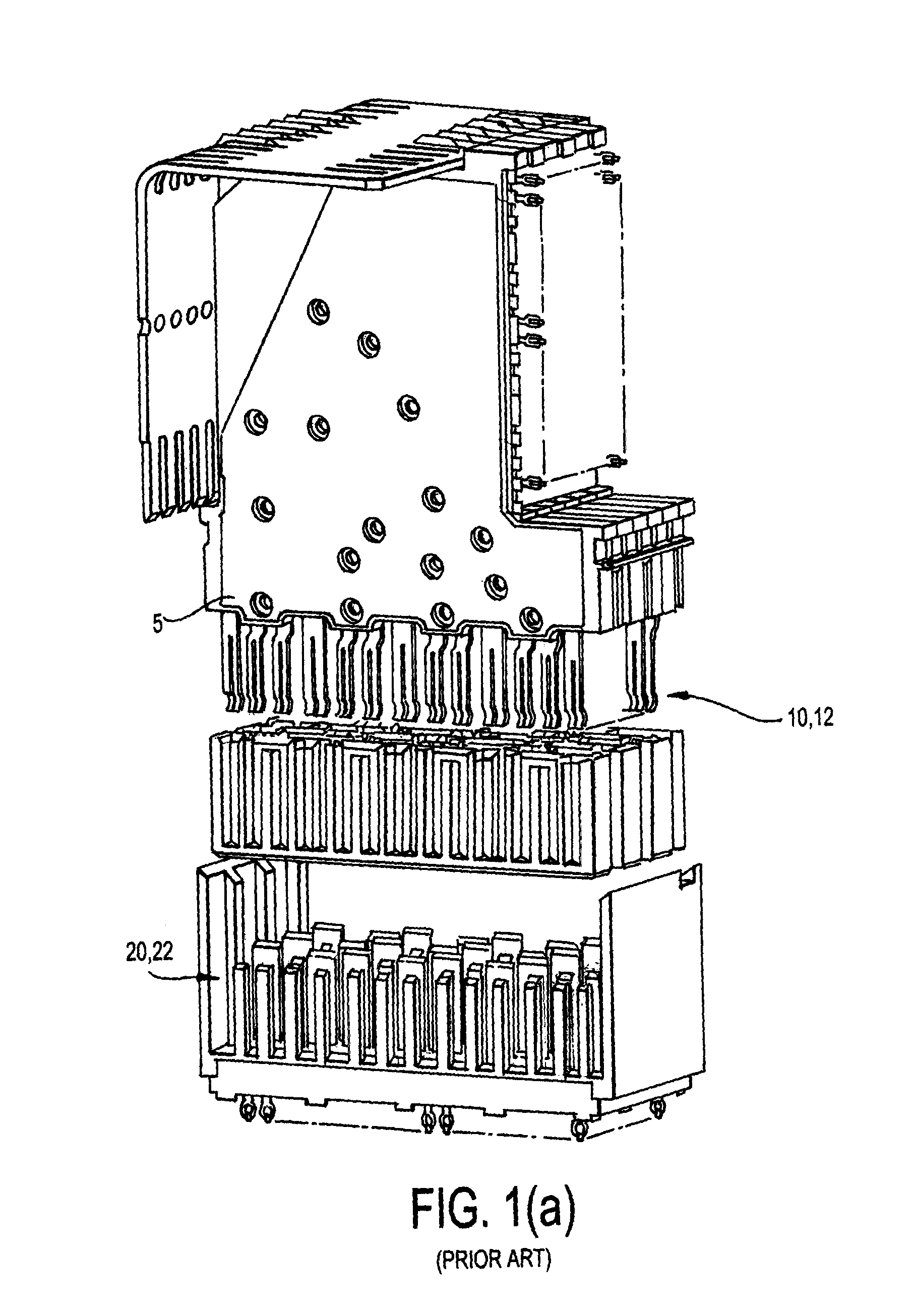

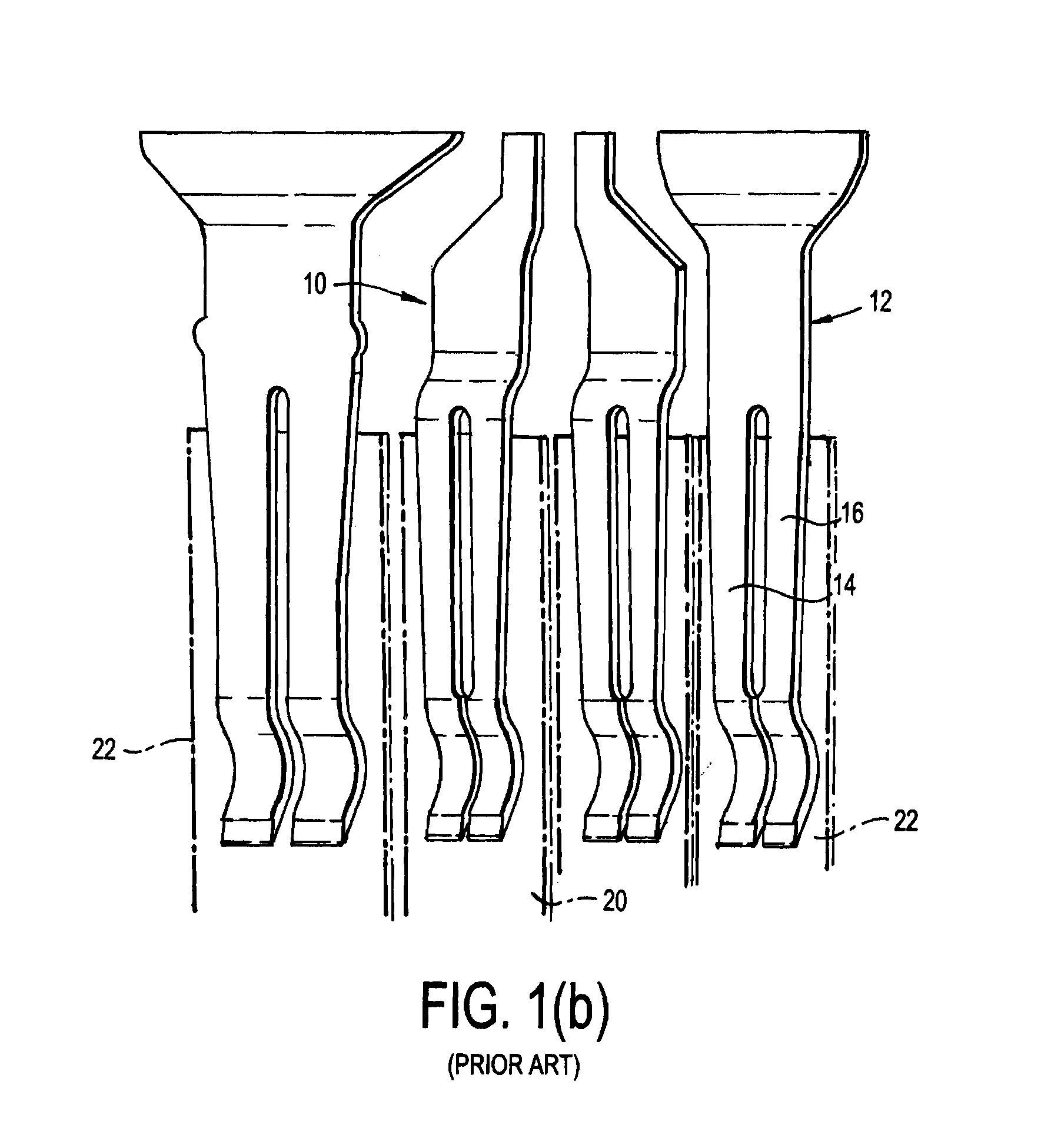

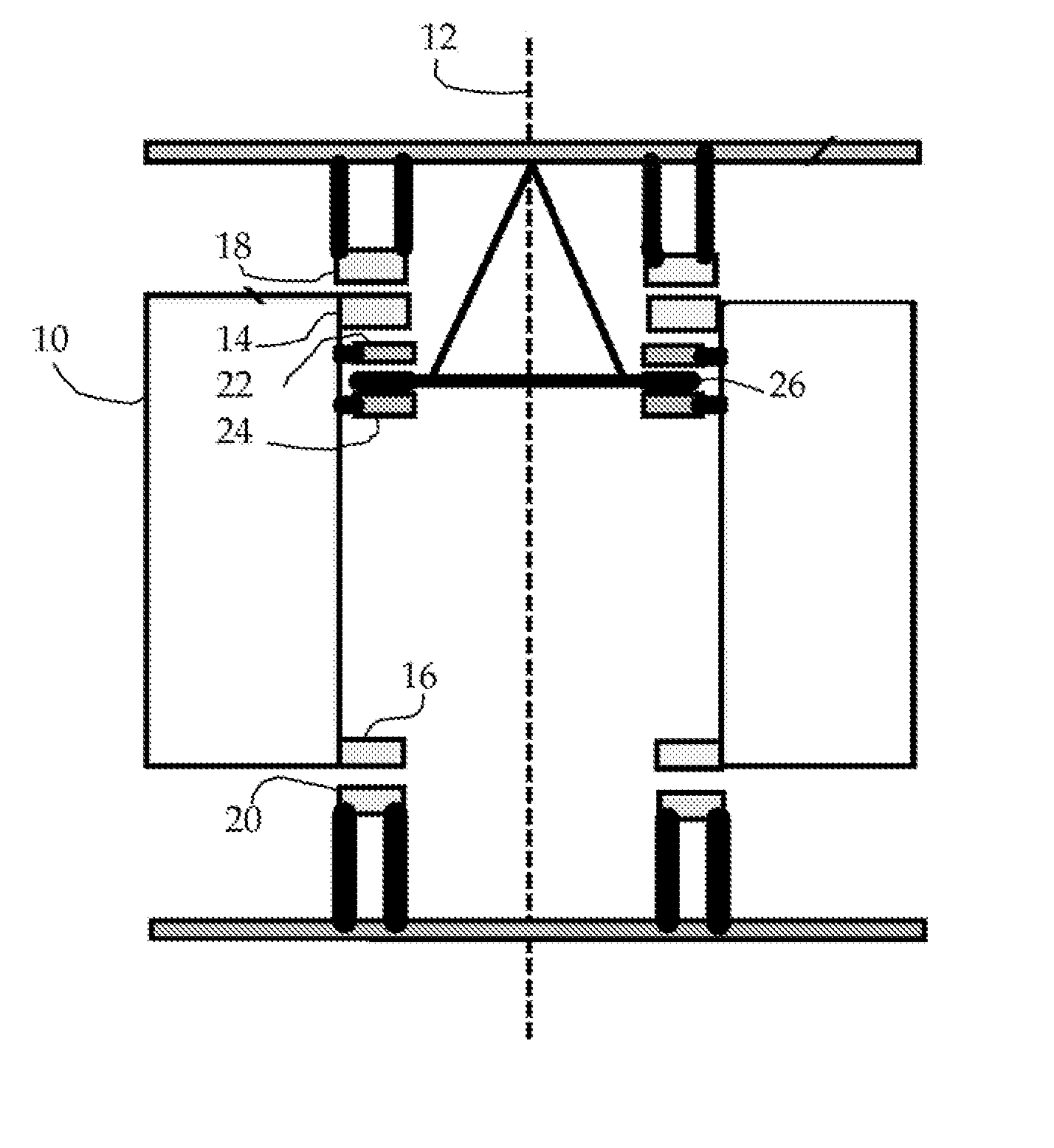

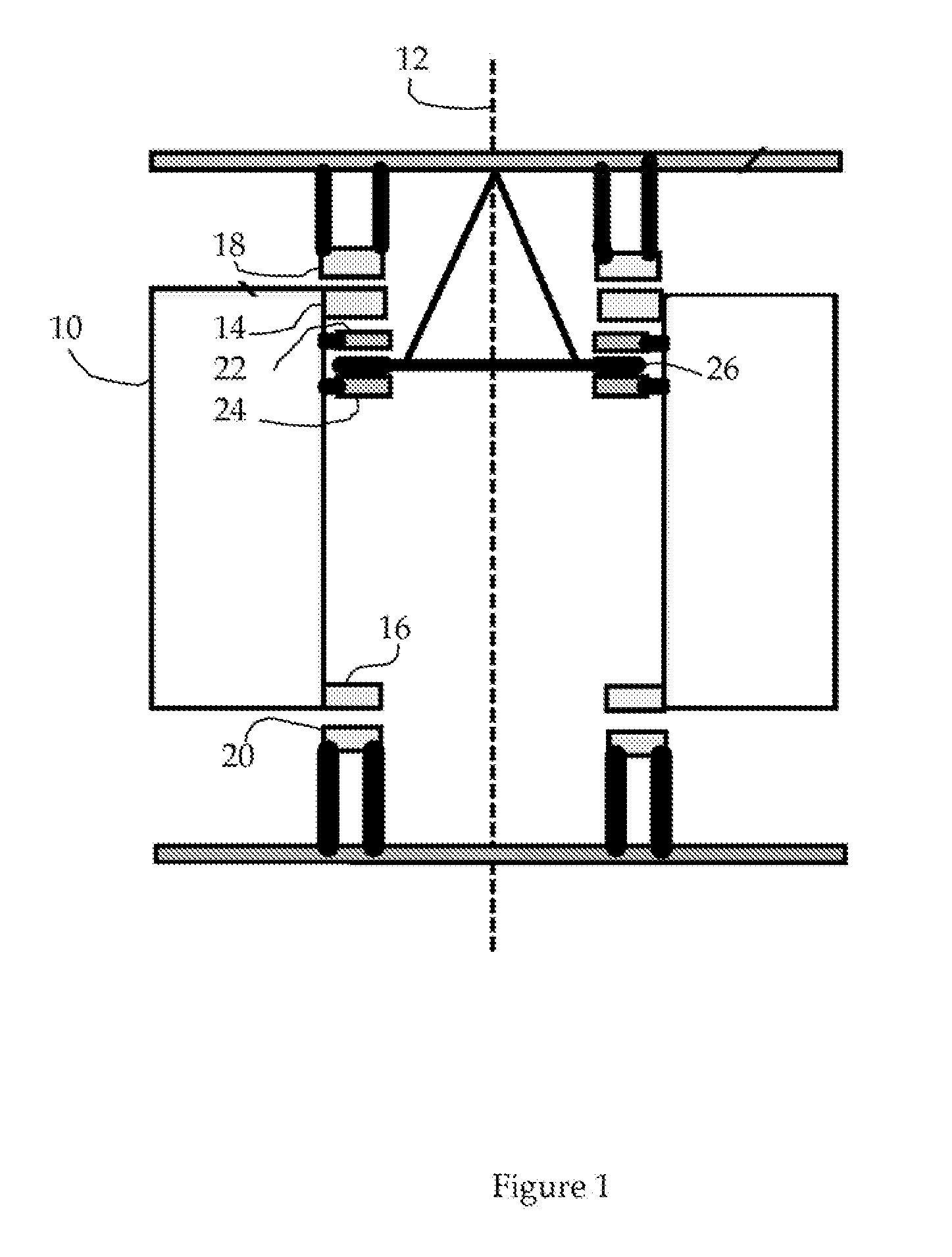

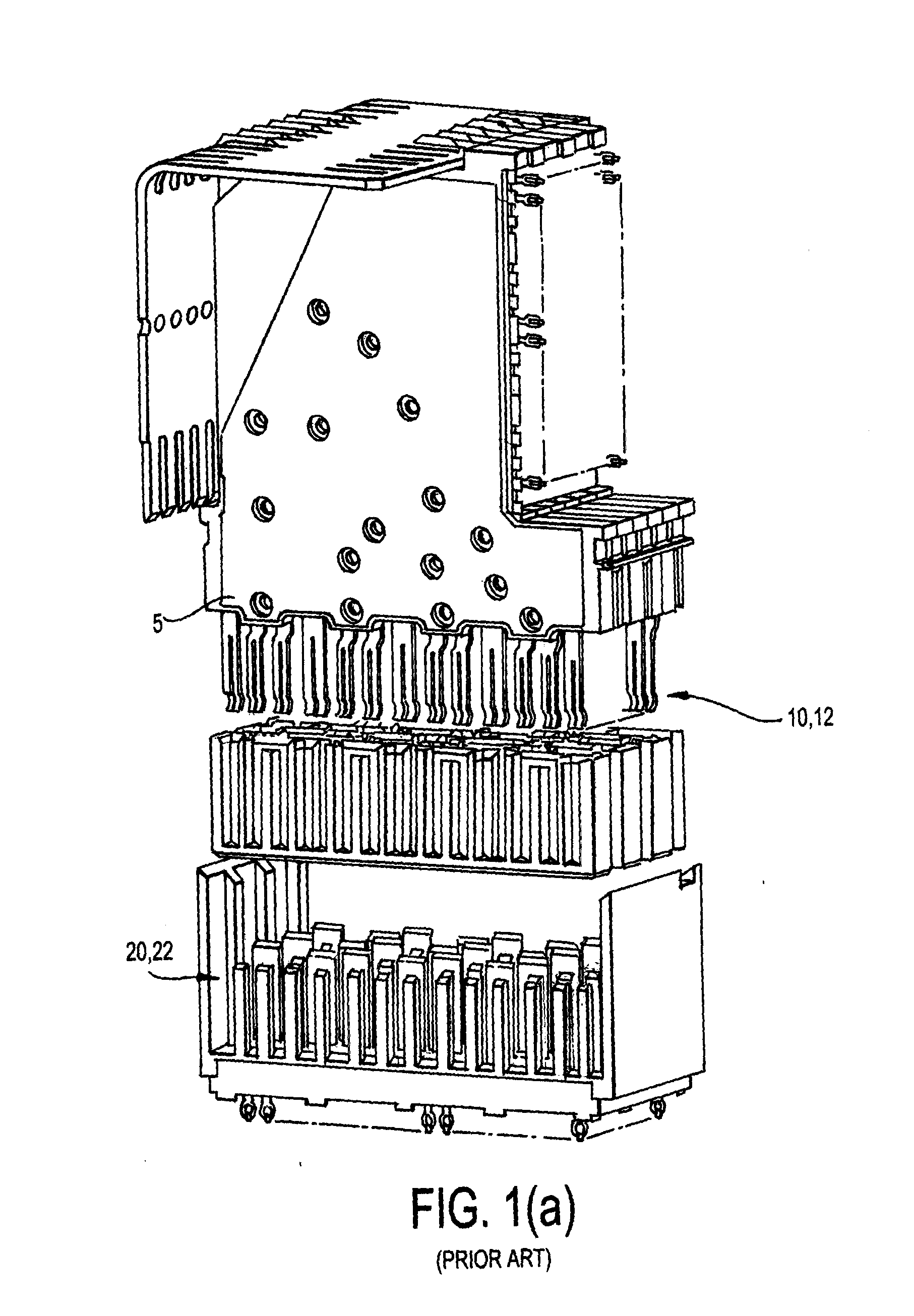

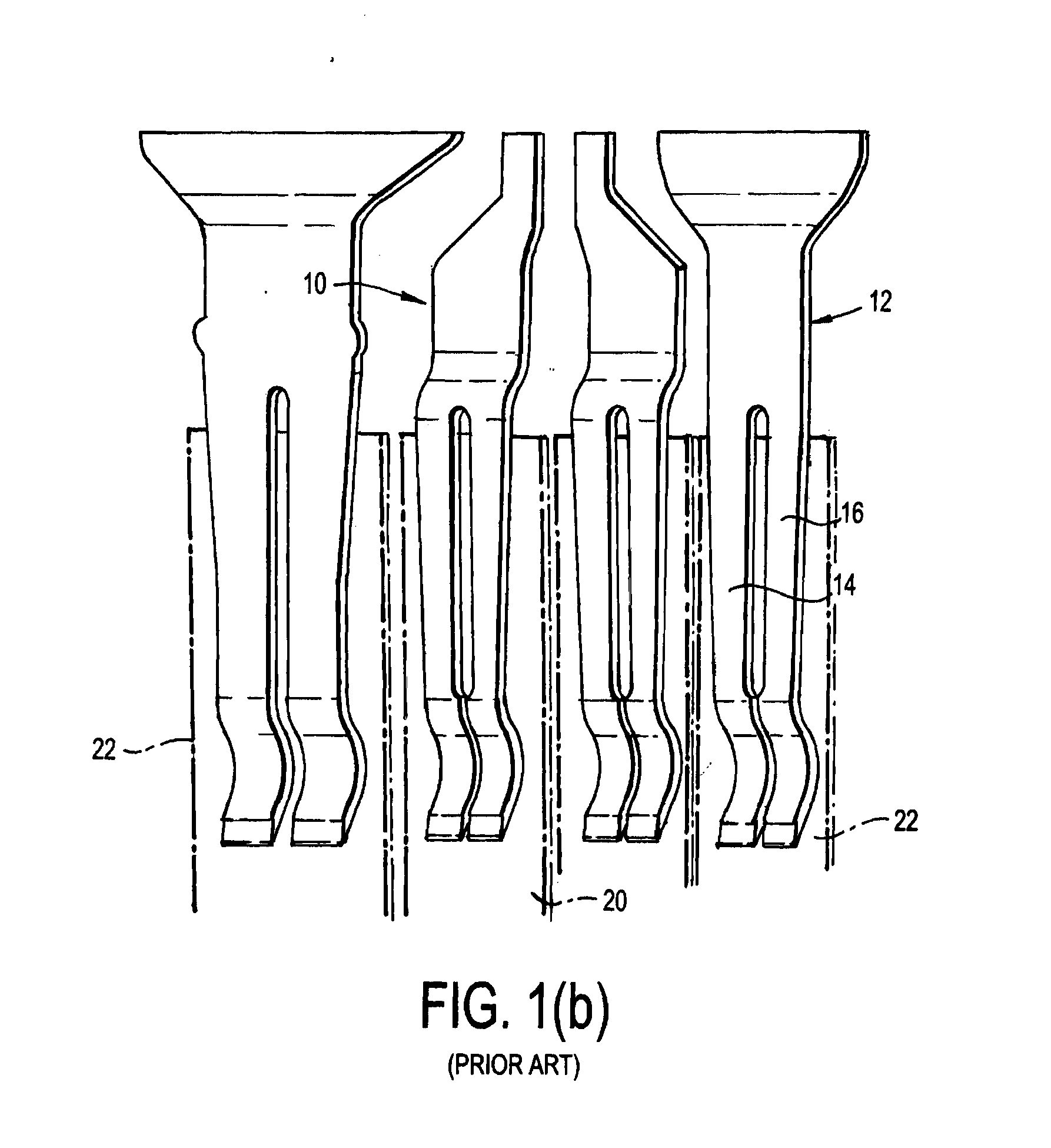

Connector having improved contacts

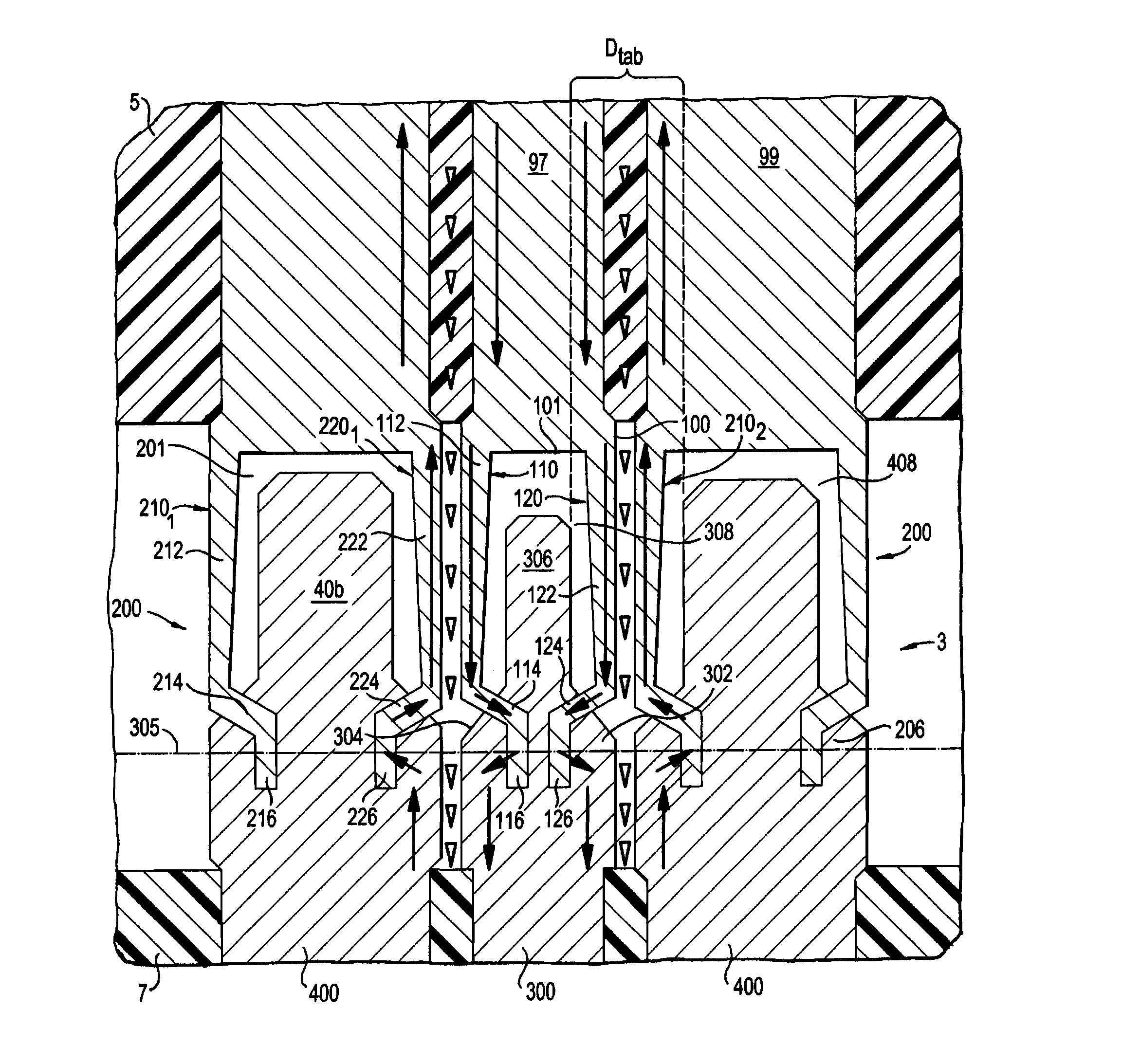

ActiveUS8961227B2Sufficient flexibilityReduce impactElectrically conductive connectionsCoupling contact membersElectrical conductorEngineering

An electrical connector for connecting a conductor of a daughter card connector wafer with a blade in the housing of a backplane connector. The daughter card conductor has a body with two elongated beams extending outward from the body. The two elongated beams each have an outer edge and an inner edge, whereby an opening is defined between the inner edges. The backplane conductor has a body with a narrowed tab portion extending outward from said second conductor body. The narrowed tab portion having outer opposite edges and is sized so that the narrowed tab portion fits between at least a portion of the outer edges of the two elongated beams, and in some cases between at least a portion of the inner edges of the two elongated beams.

Owner:AMPHENOL CORP

Passive magnetic bearing system

InactiveUS8823233B2Minimize currentMinimize powerEngine componentsMechanical energy handlingMagnetic bearingFlywheel energy storage

An axial stabilizer for the rotor of a magnetic bearing provides external control of stiffness through switching in external inductances. External control also allows the stabilizer to become a part of a passive / active magnetic bearing system that requires no external source of power and no position sensor. Stabilizers for displacements transverse to the axis of rotation are provided that require only a single cylindrical Halbach array in its operation, and thus are especially suited for use in high rotation speed applications, such as flywheel energy storage systems. The elimination of the need of an inner cylindrical array solves the difficult mechanical problem of supplying support against centrifugal forces for the magnets of that array. Compensation is provided for the temperature variation of the strength of the magnetic fields of the permanent magnets in the levitating magnet arrays.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

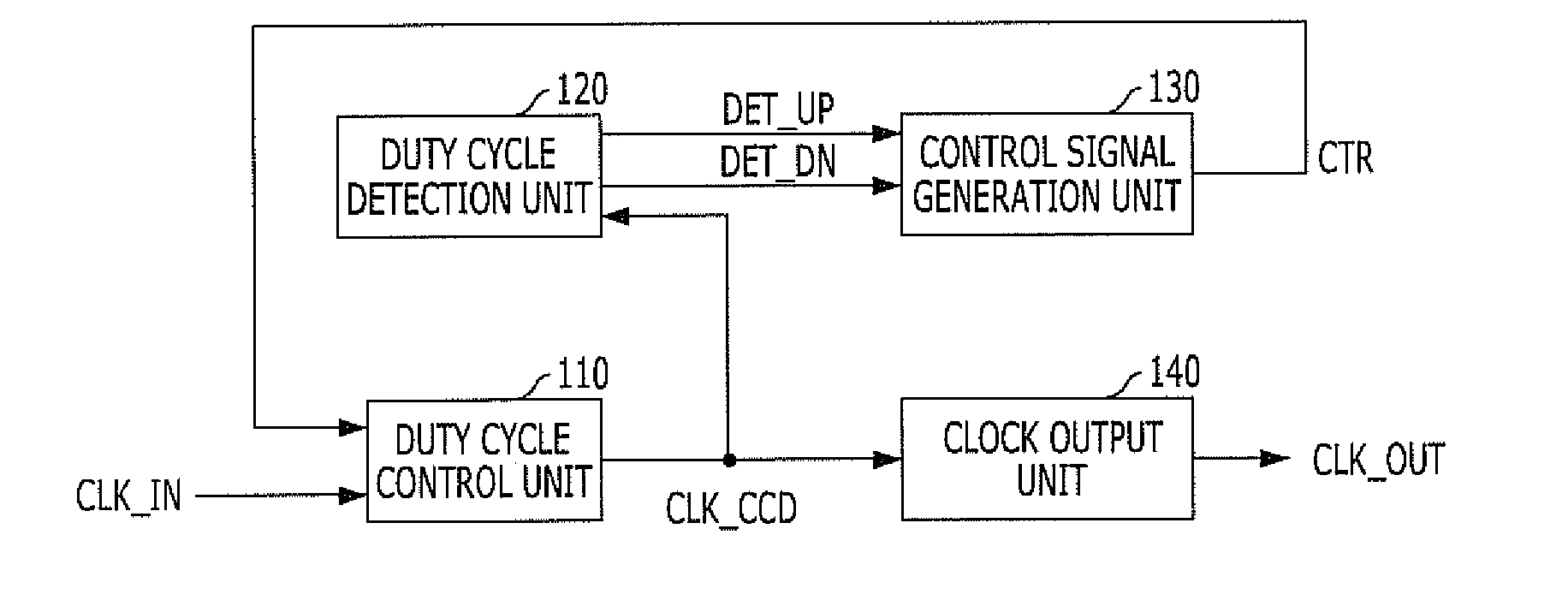

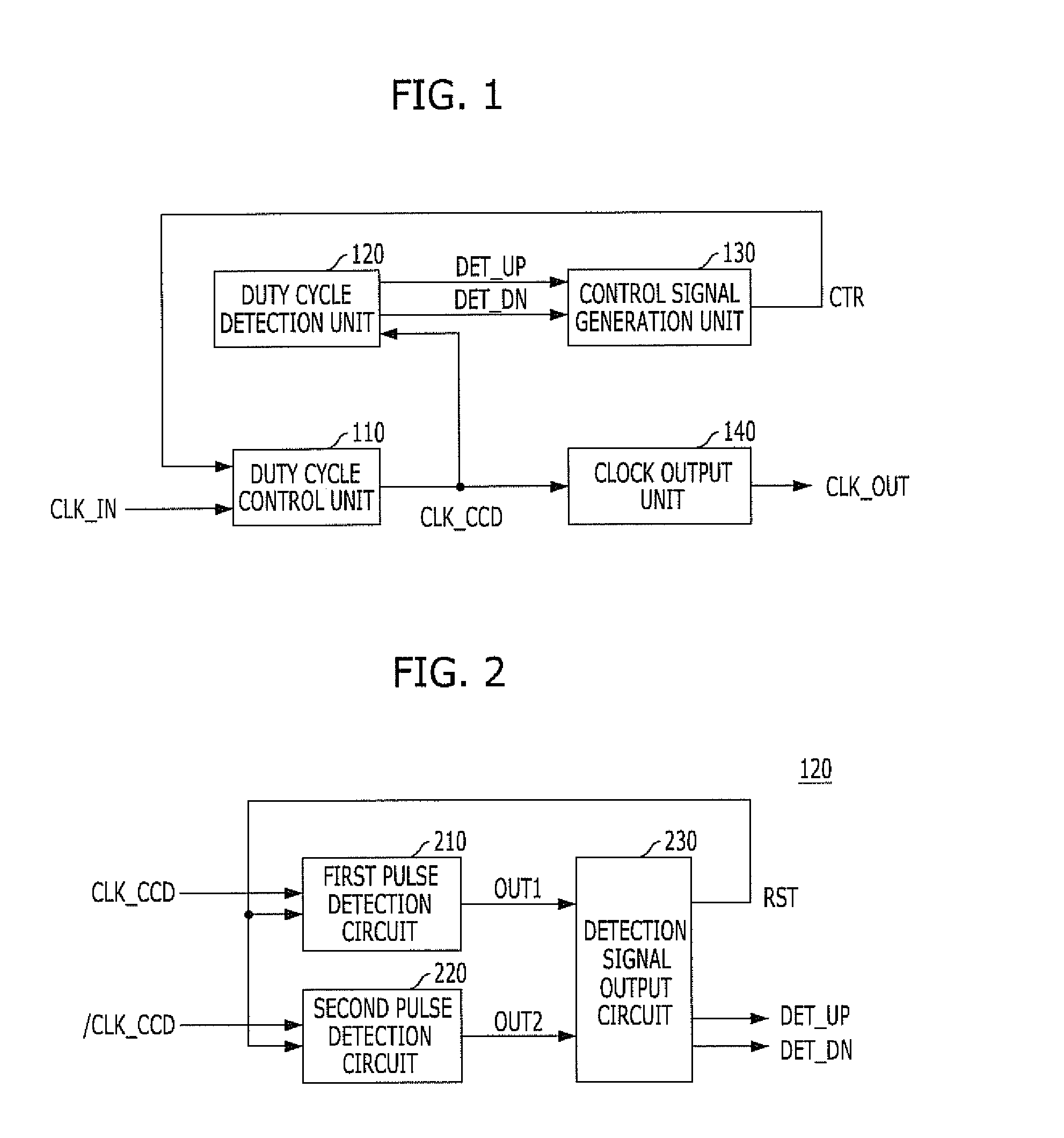

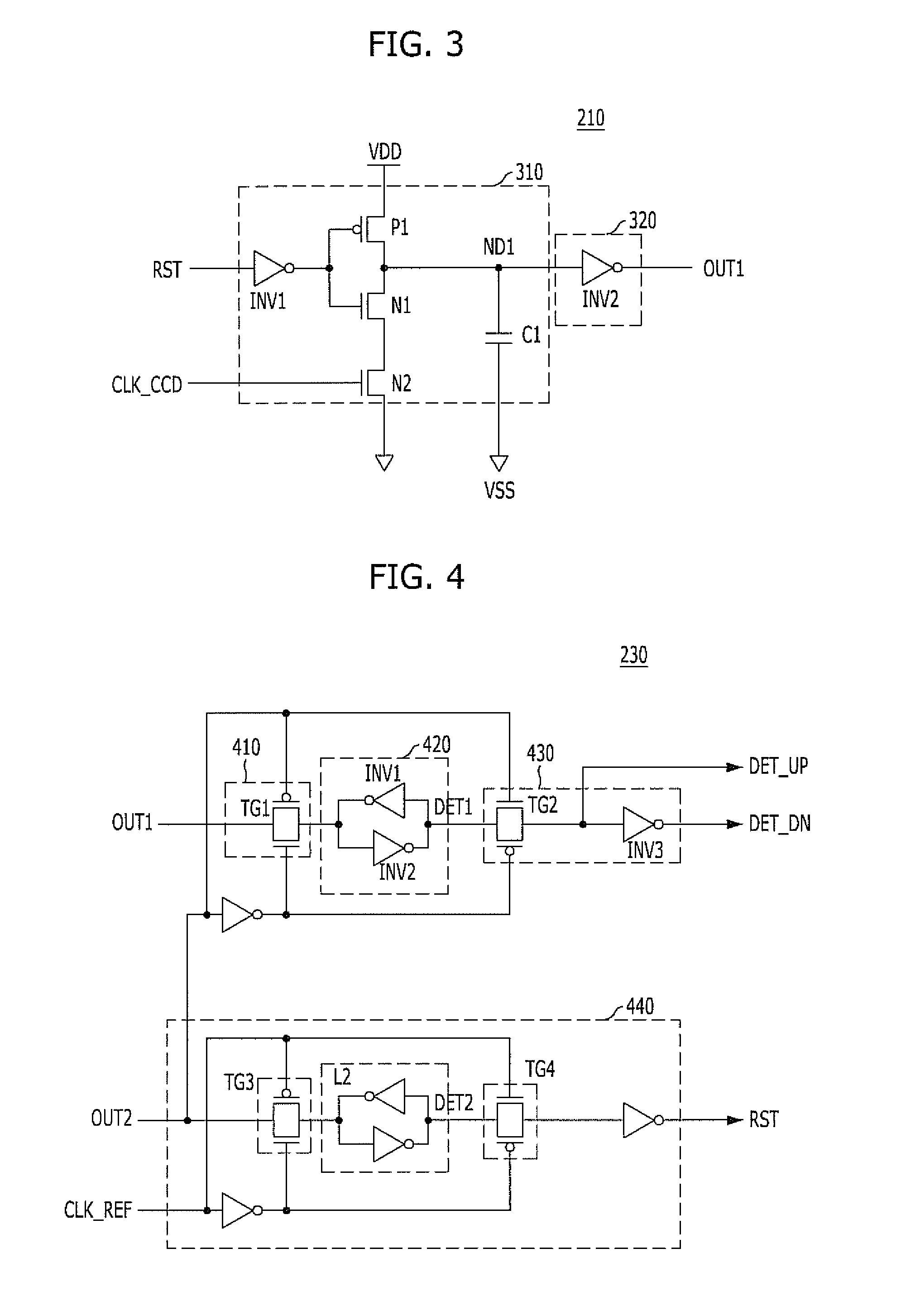

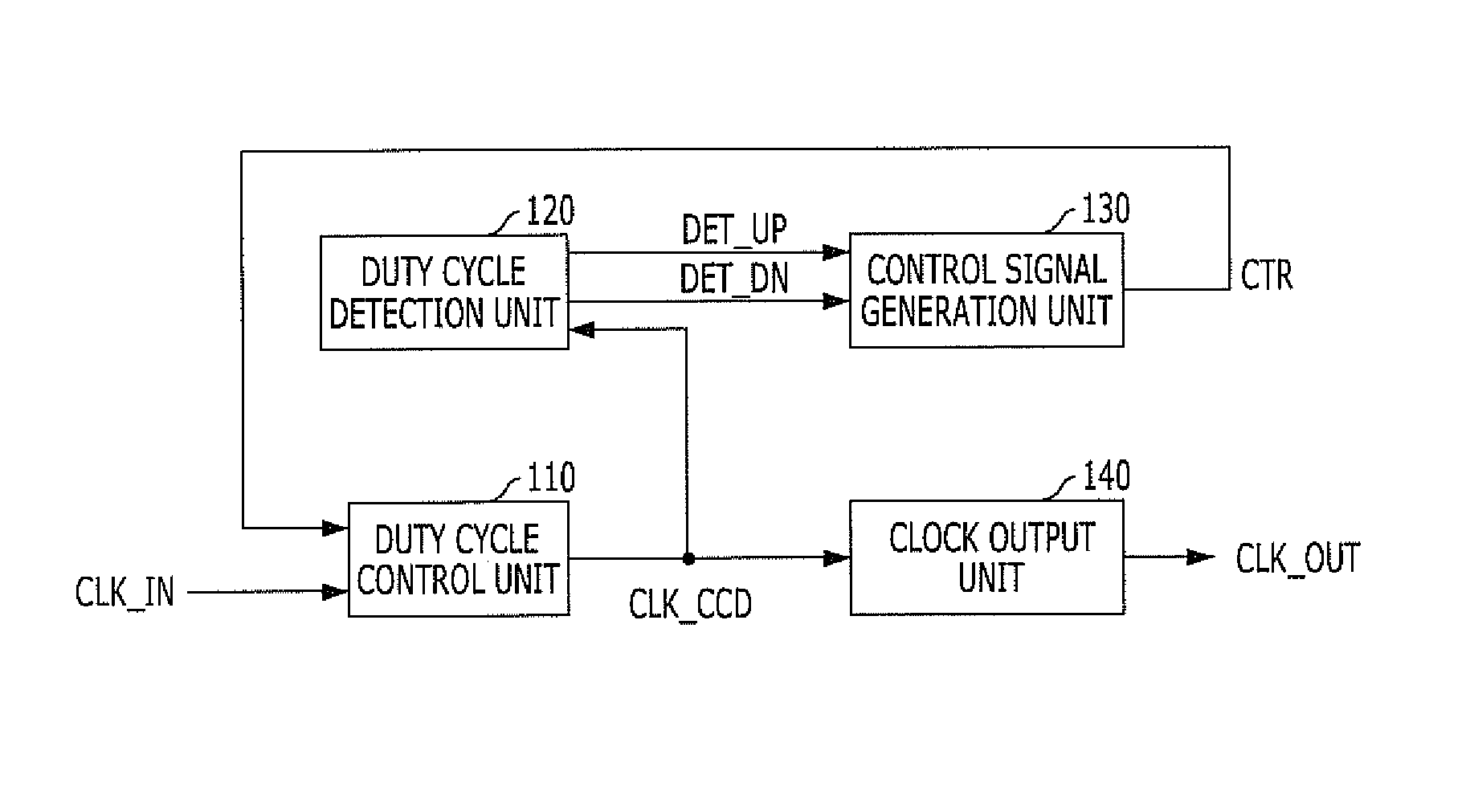

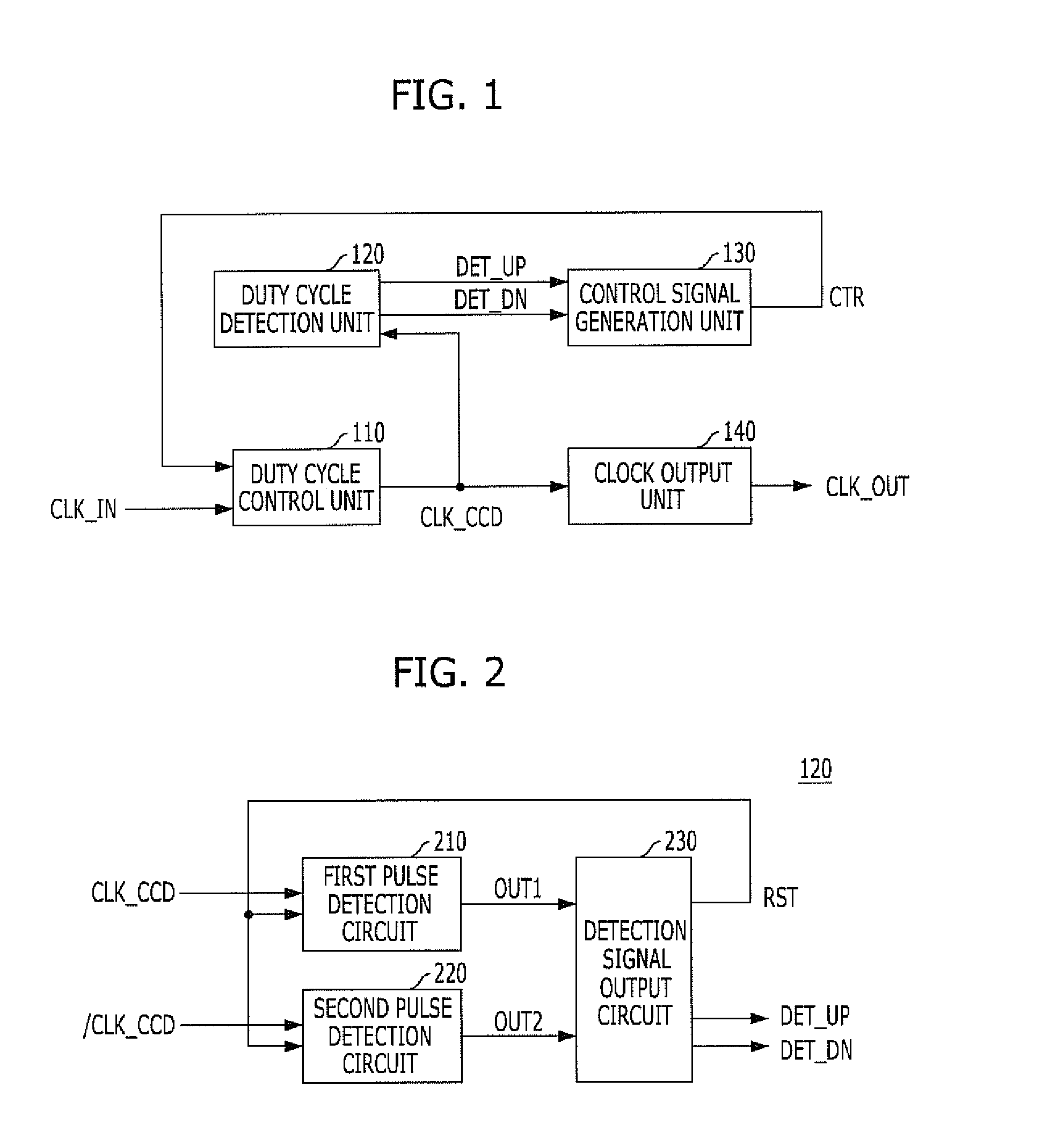

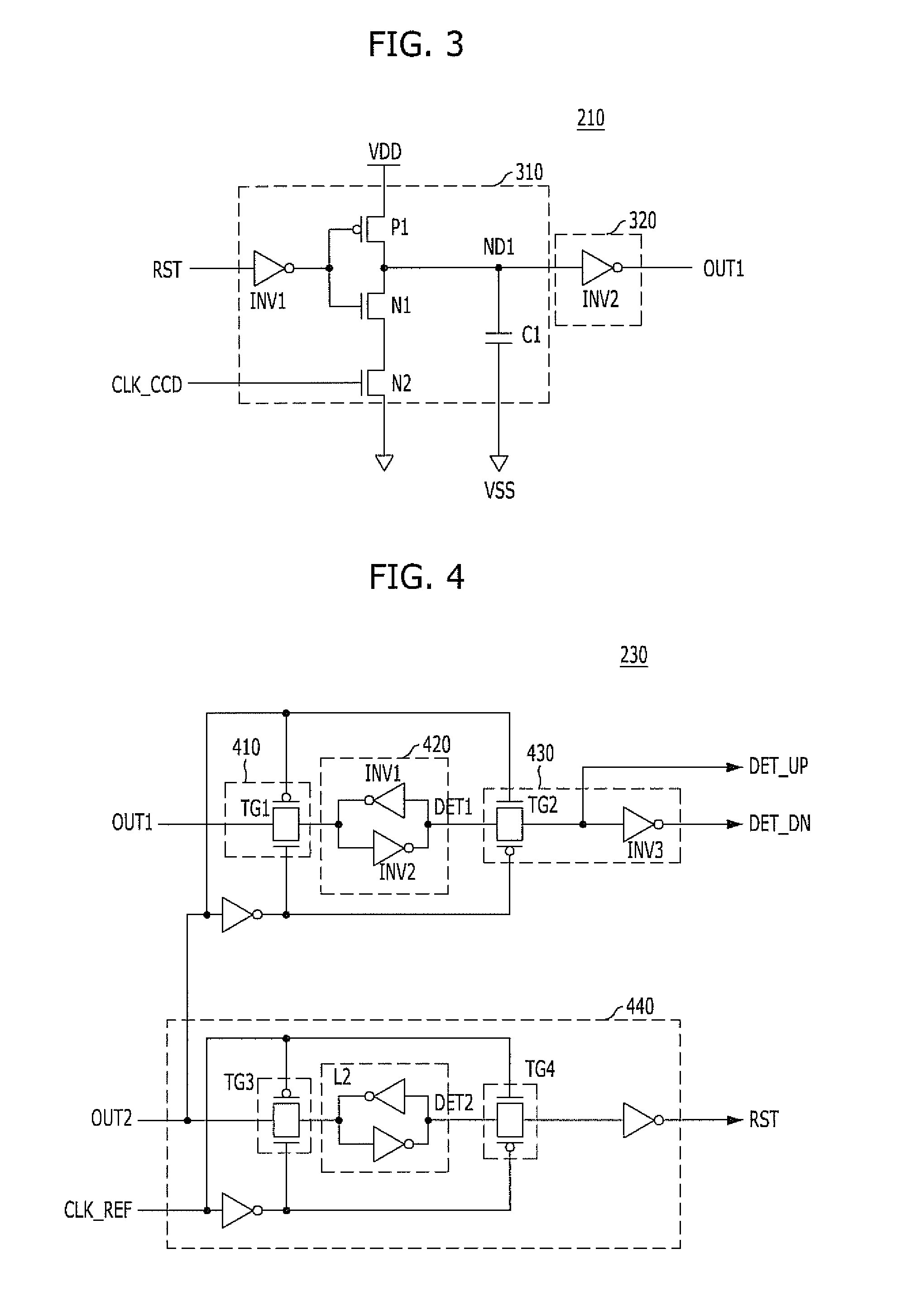

Duty cycle correction circuit

ActiveUS20120154006A1Fast circuit operation rateMinimize circuit areaElectric pulse generatorPulse shapingControl signalEngineering

A duty cycle correction circuit includes a duty cycle control unit configured to generate a corrected clock signal by correcting a duty cycle of an input clock signal in response to a control signal, a duty cycle detection unit configured to detect a duty cycle of the corrected clock signal and output a detection signal, and a control signal generation unit configured to generate the control signal in response to the detection signal.

Owner:SK HYNIX INC

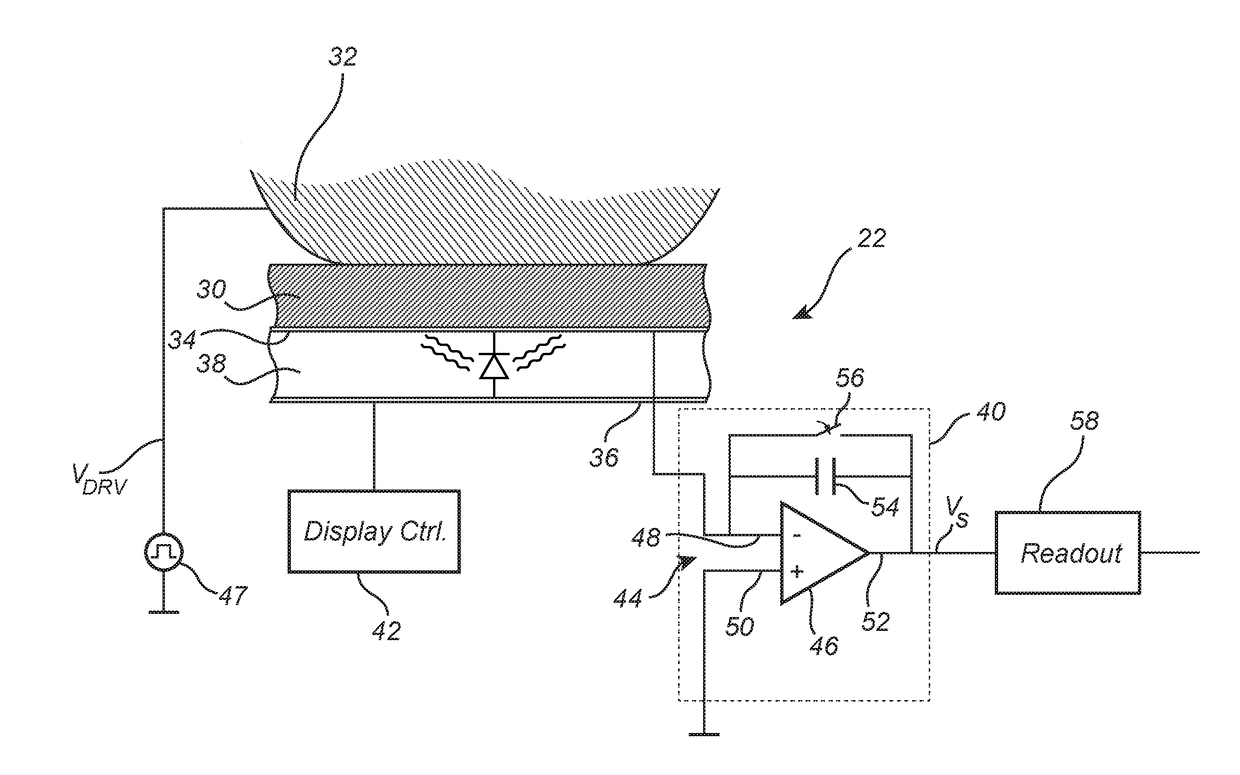

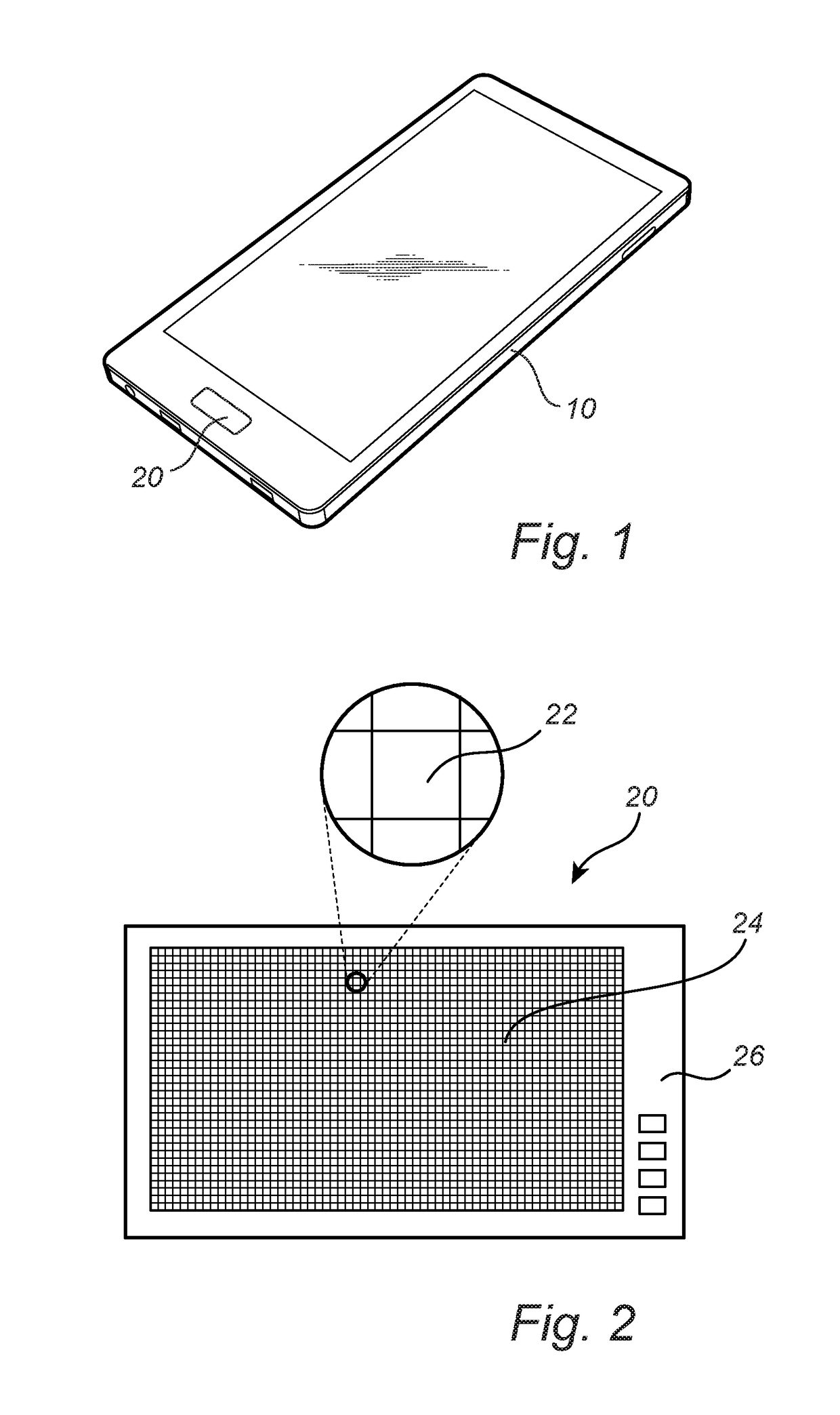

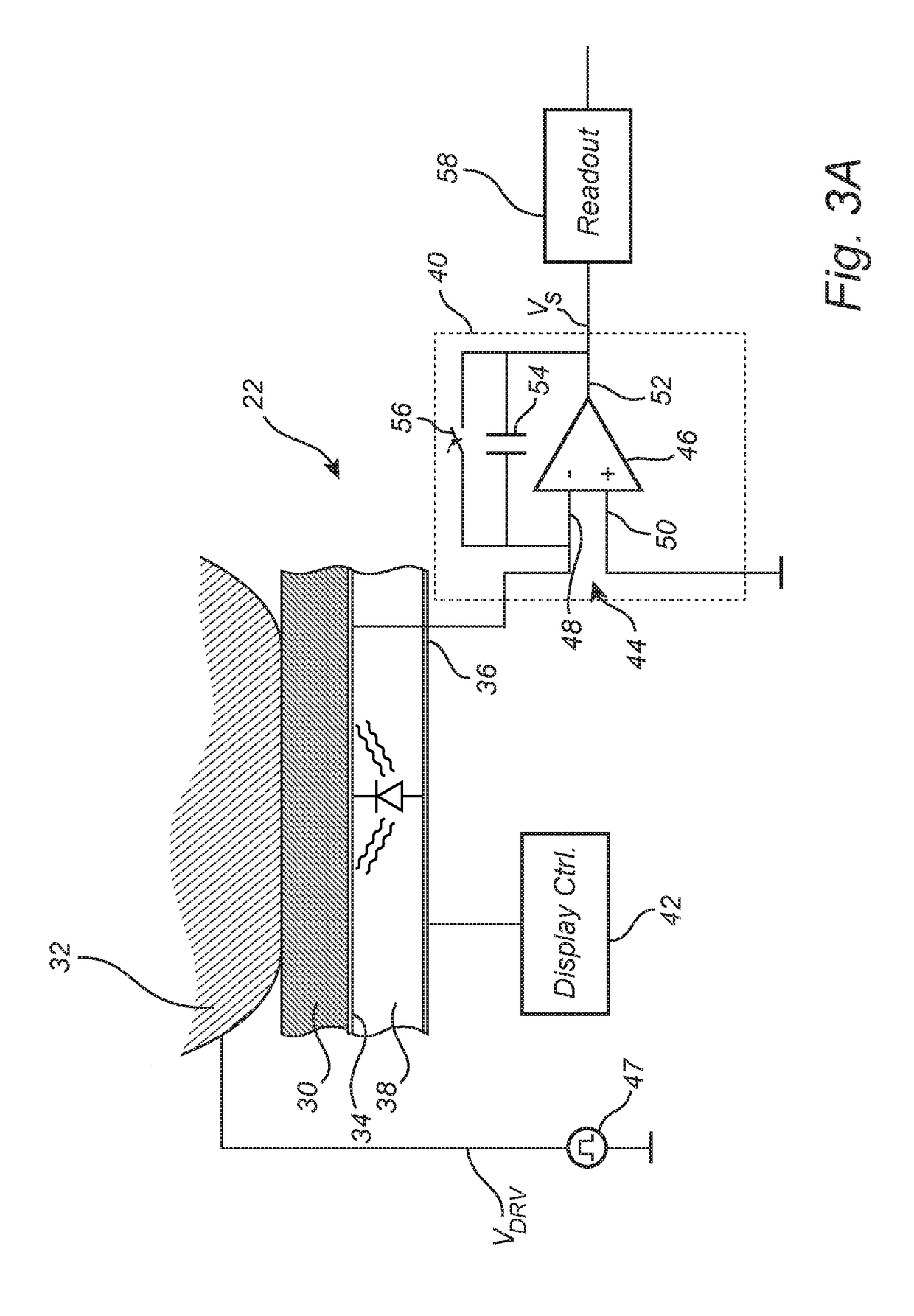

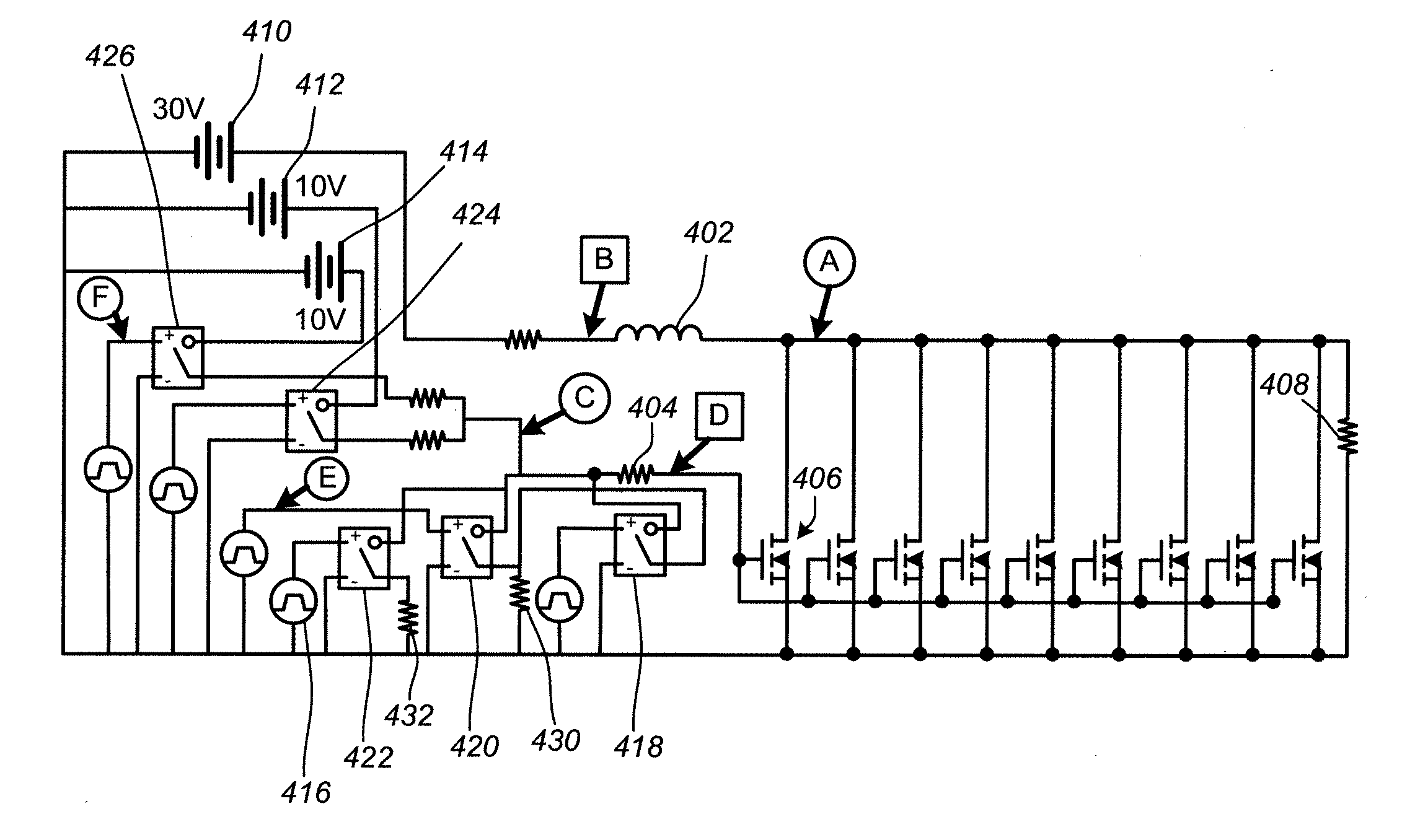

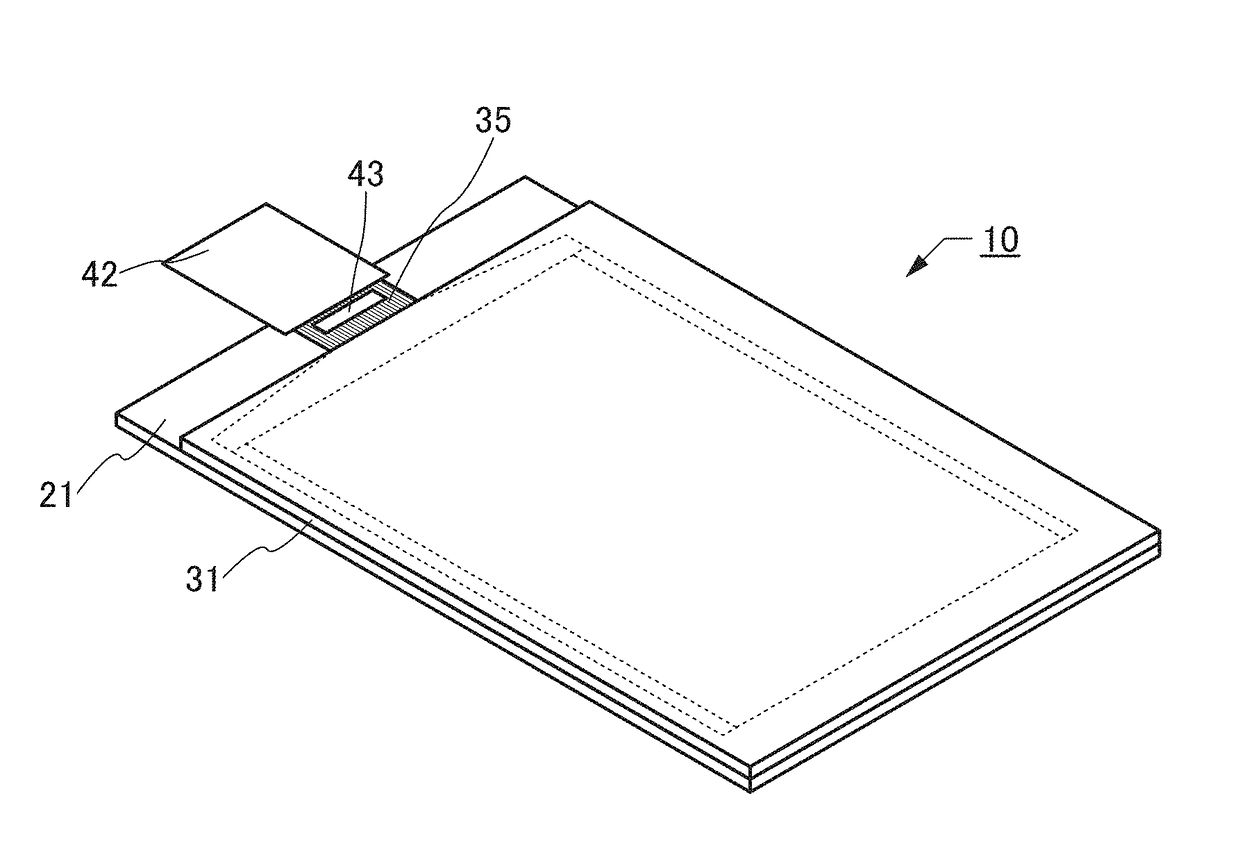

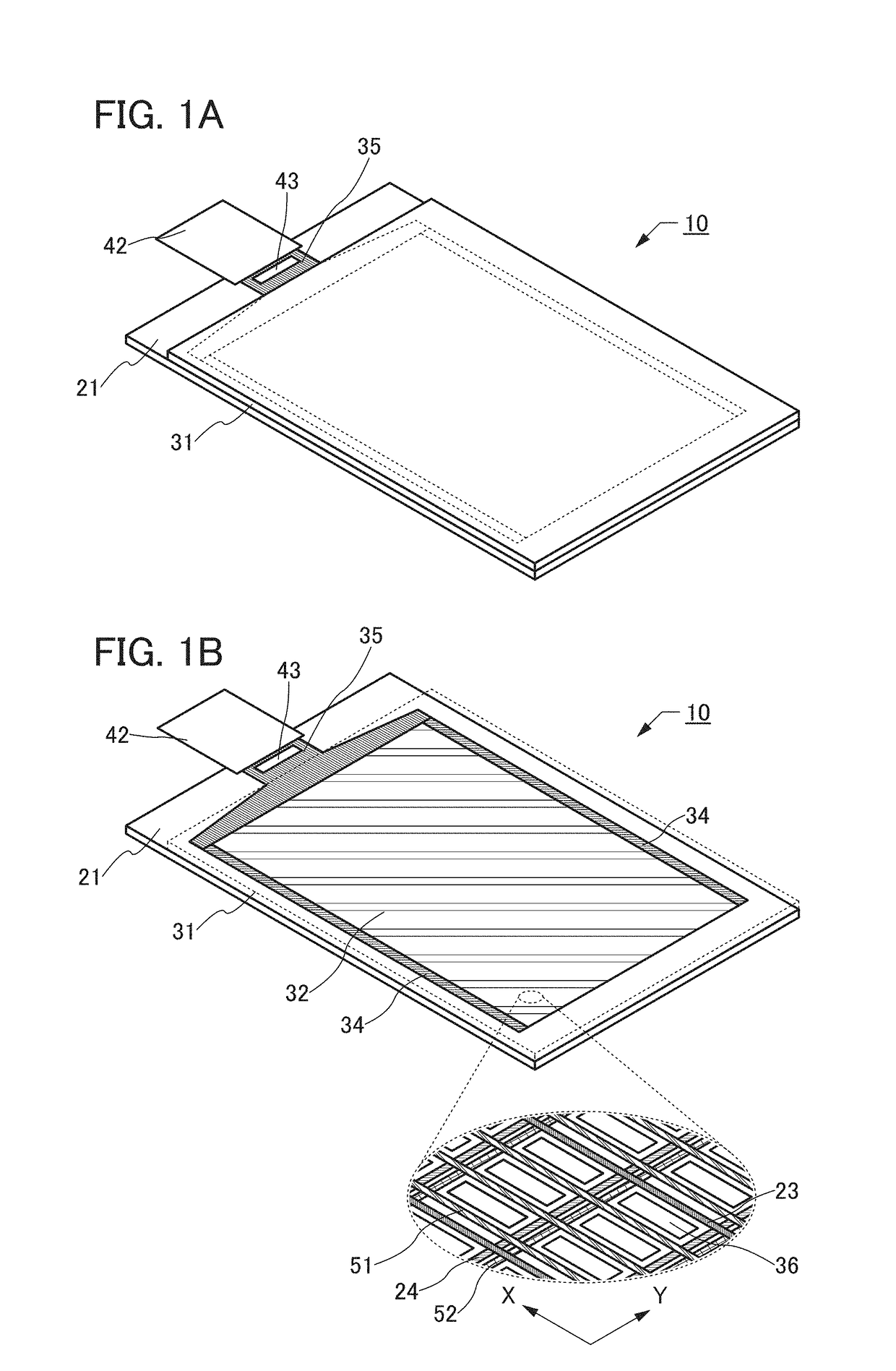

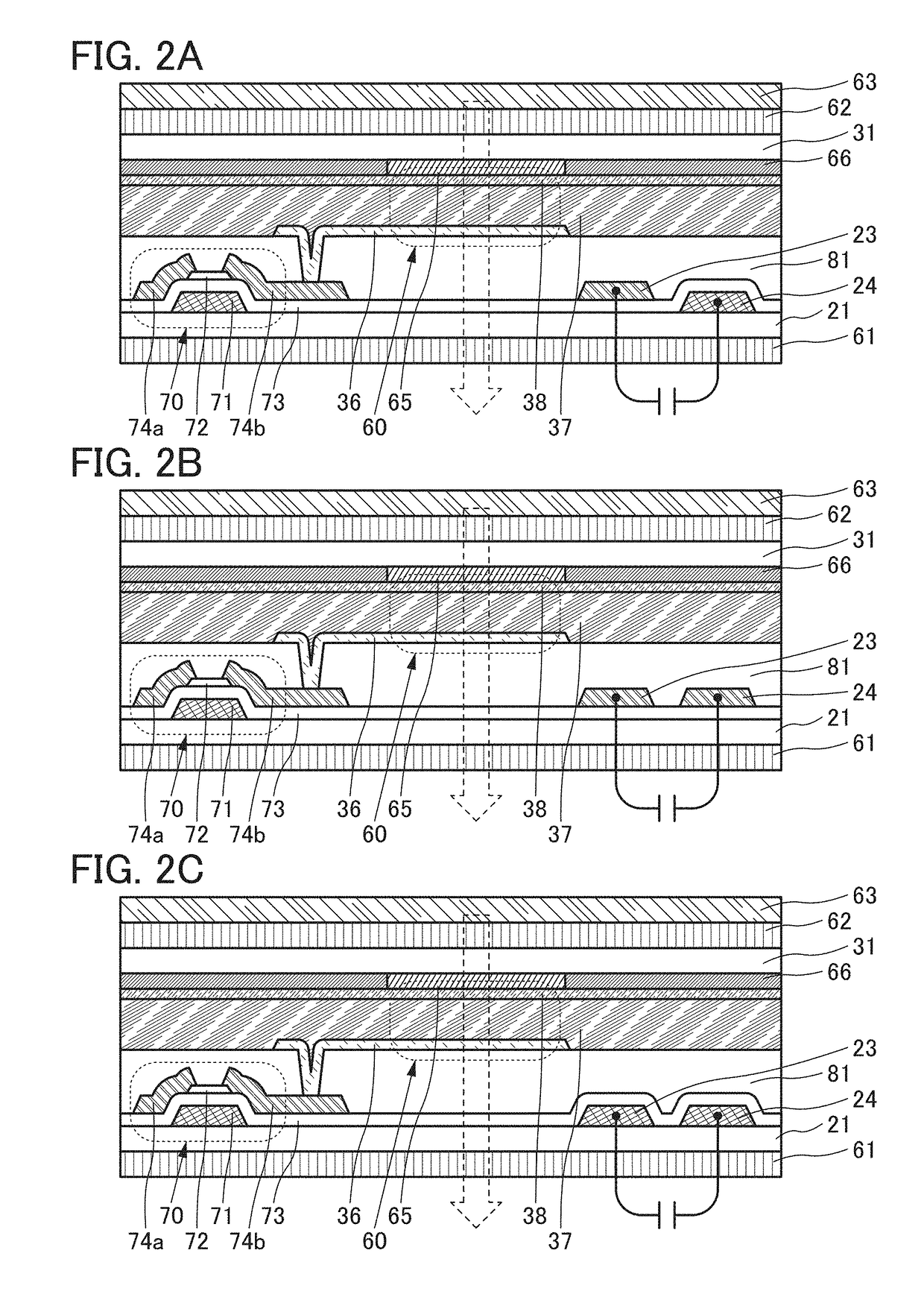

Capacitive fingerprint sensing device comprising display functionality

ActiveUS20180173922A1Minimize currentMinimize light emissionSolid-state devicesPrint image acquisitionSense modeElectrically conductive

A capacitive fingerprint sensing device for sensing a fingerprint pattern of a finger can comprise a plurality of sensing elements. Each sensing element comprises a protective dielectric top layer to be touched by the finger; a first electrode comprising an optically transparent electrically conductive sensing structure arranged underneath the top layer; fingerprint sensing circuitry connected to the first electrode and configured to provide an analog sensing signal indicative of a distance between the finger and the sensing structure, a second electrode arranged underneath the first electrode; an organic light emitting layer arranged between the first and second electrodes; display element control circuitry connected to the second electrode and configured to control a display element comprising the first and second electrodes and the organic light emitting layer; and a switching mechanism configured to switch the sensing element between a fingerprint sensing mode and a display mode.

Owner:FINGERPRINT CARDS ANACATUM IP AB

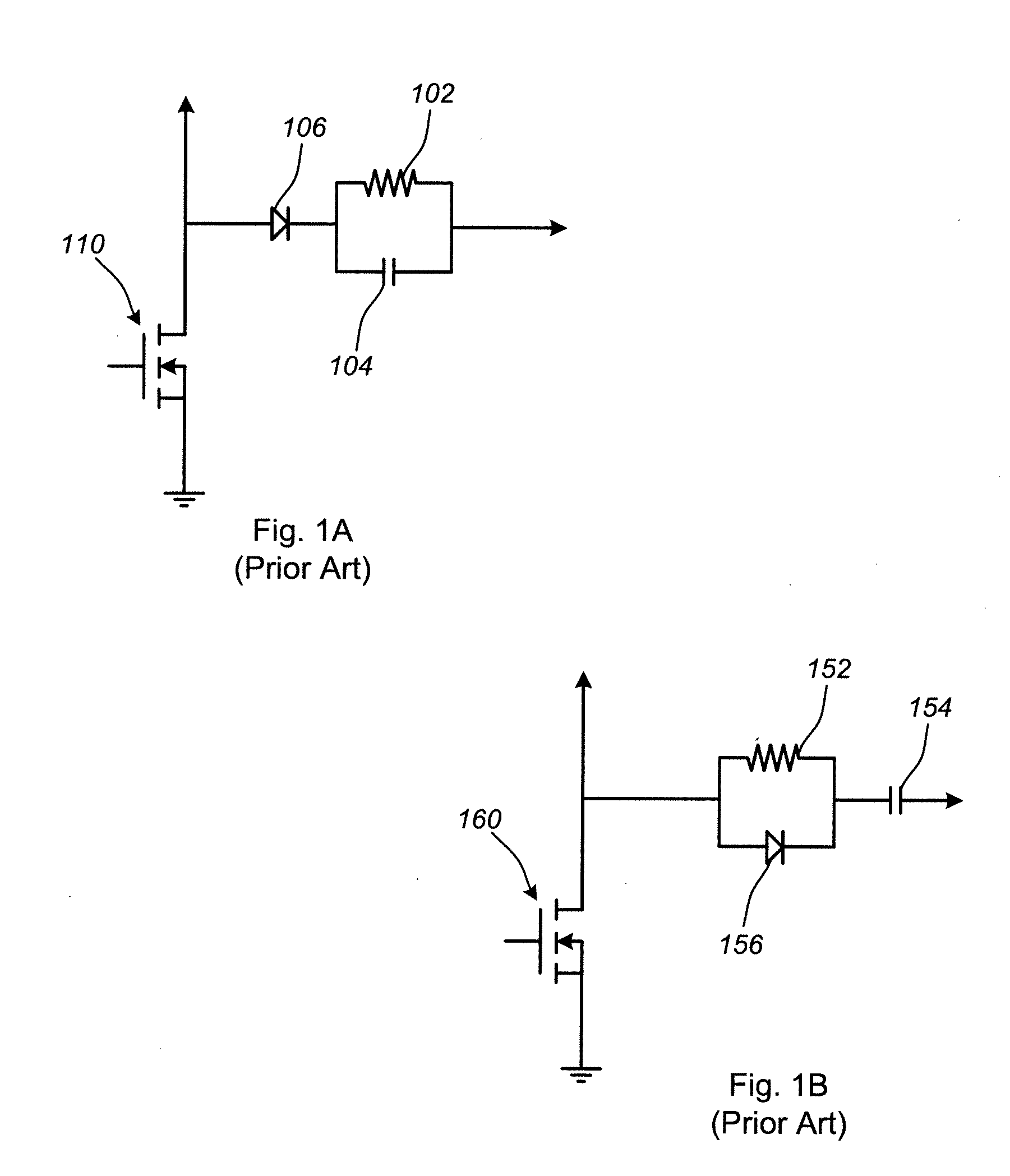

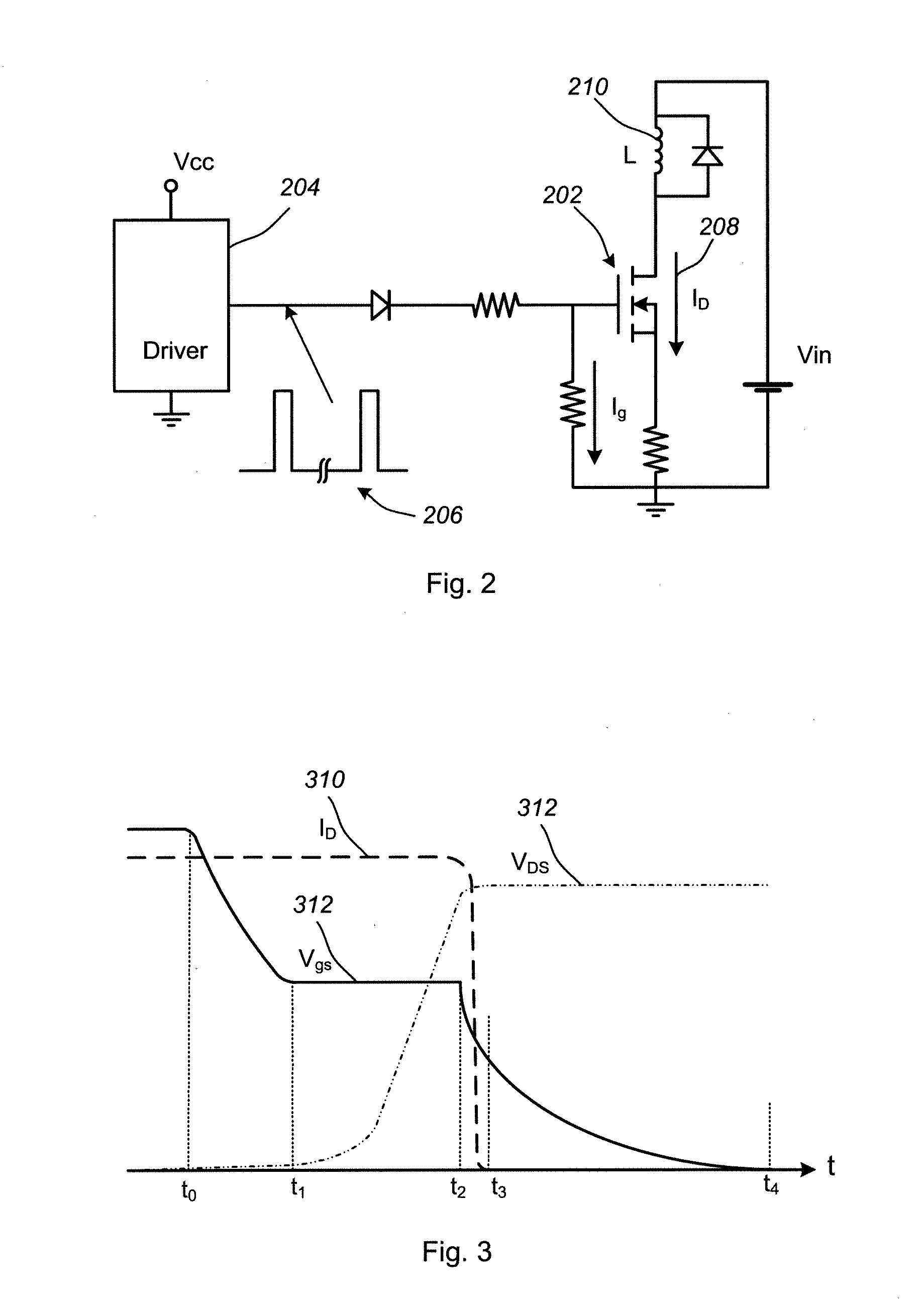

Optimal mosfet driver circuit for reducing electromagnetic interference and noise

InactiveUS20110273220A1Minimize currentMinimize voltageTransistorElectronic switchingDriver circuitMOSFET

A system and method of controlling the primary switching FET turn-on and turn-off profiles in a switching power converter suppresses voltage and current spikes, reduces power consumption, and reduces system switching time. A combination of fast and slow shunt circuits is used to control current flow through the primary switching FET. The FET switching rate is slowed during the period of maximum current change to limit the magnitude of switching spikes and is allowed to proceed rapidly at other times to reduce switching time and power consumption.

Owner:SEMTECH CORP

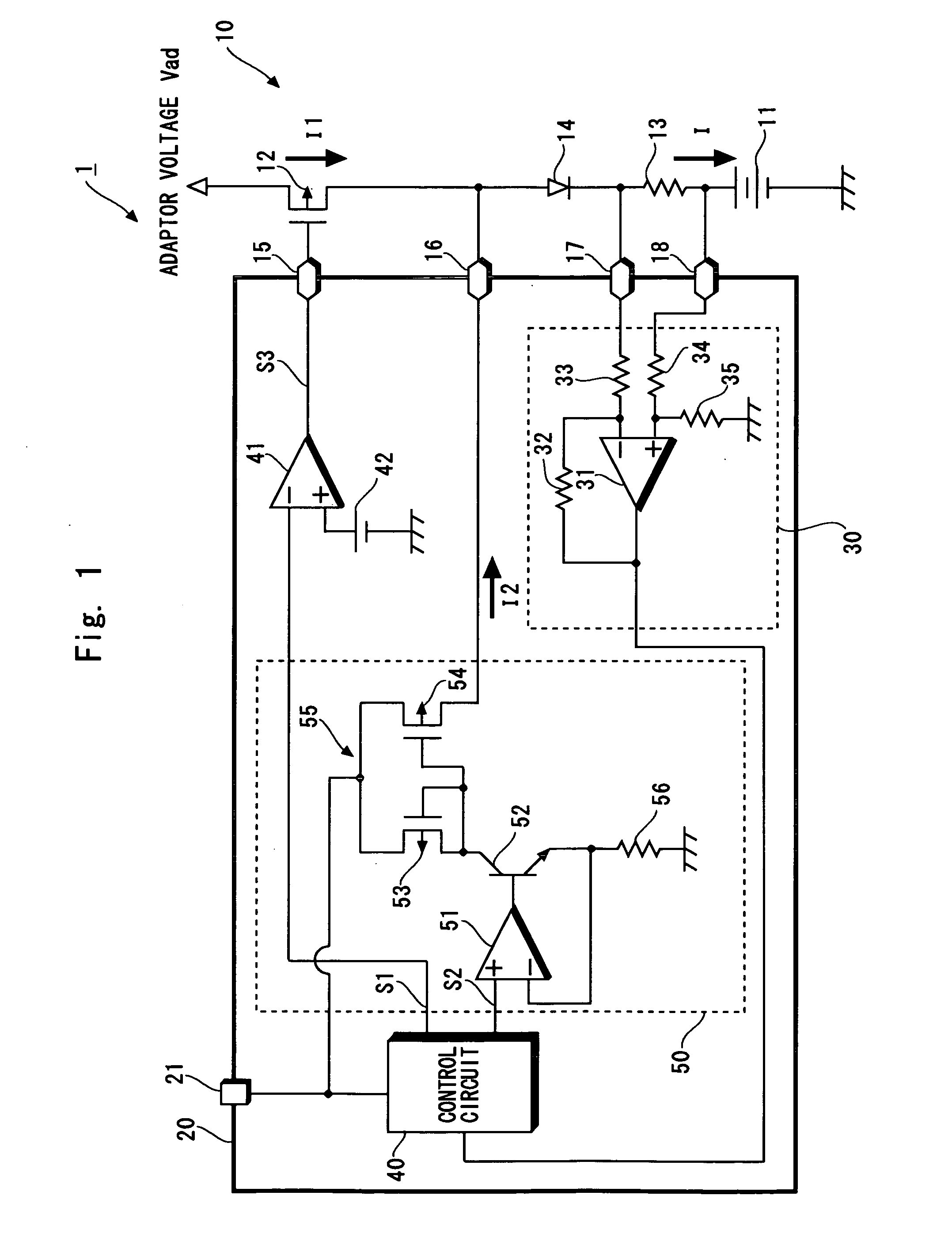

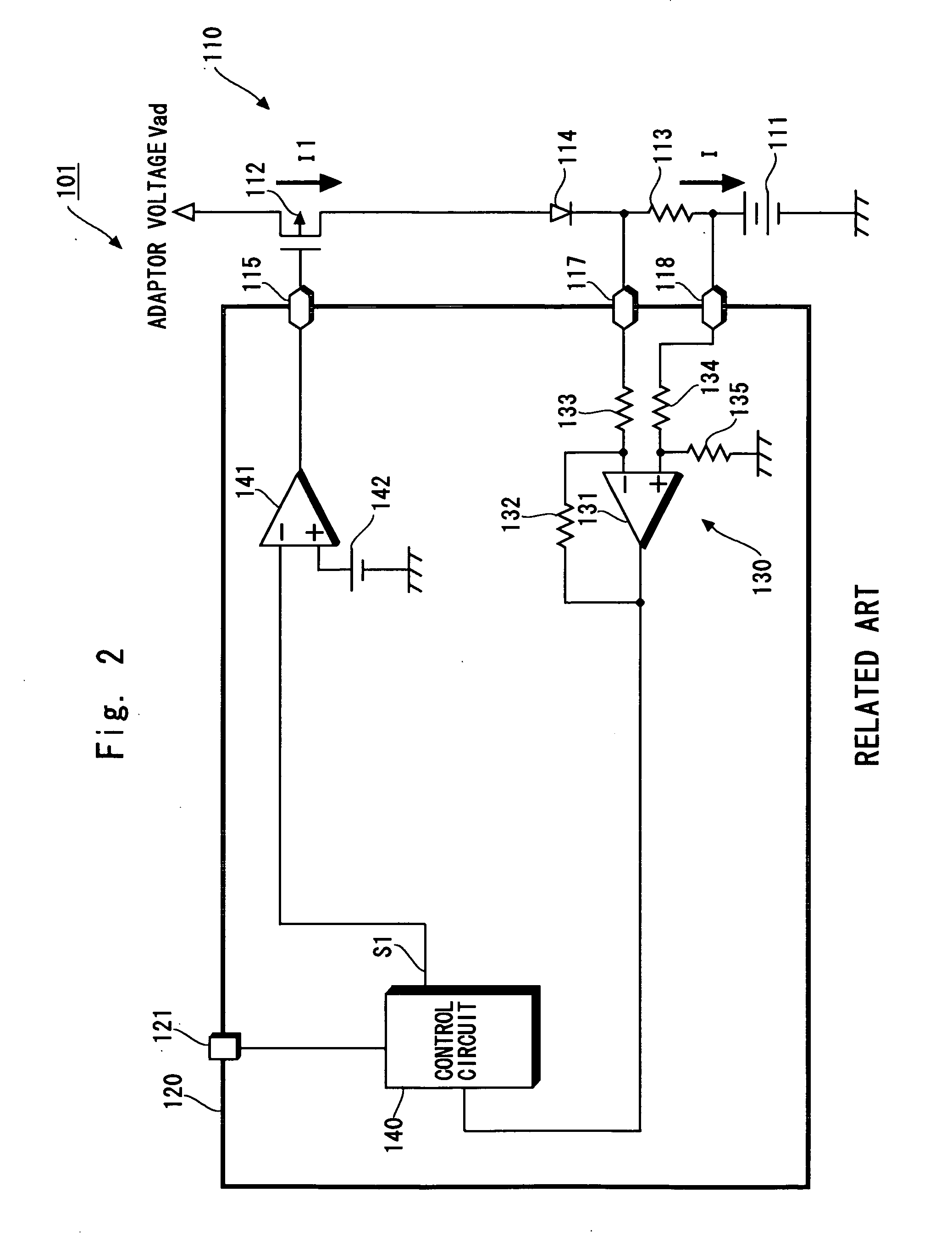

Charger and integrated circuit

InactiveUS20060076928A1Minimize currentSuppress heat generationBatteries circuit arrangementsElectric power transfer ac networkIntegrated circuitCharge current

A charger of the present invention includes a charging transistor and a charging integrated circuit. The charging transistor is series-connected with a secondary battery to supply a charging current to the secondary battery. The charging integrated circuit is incorporated into a package having a higher heat releasability than that of the charging transistor. The charging integrated circuit controls the charging transistor and besides, supplies a charging current to the secondary battery. For this purpose, the charging integrated circuit includes a current source supplying this charging current. The charging current from the current source is supplied to the secondary battery together with the charging current from the charging transistor to charge the secondary battery.

Owner:RENESAS ELECTRONICS CORP

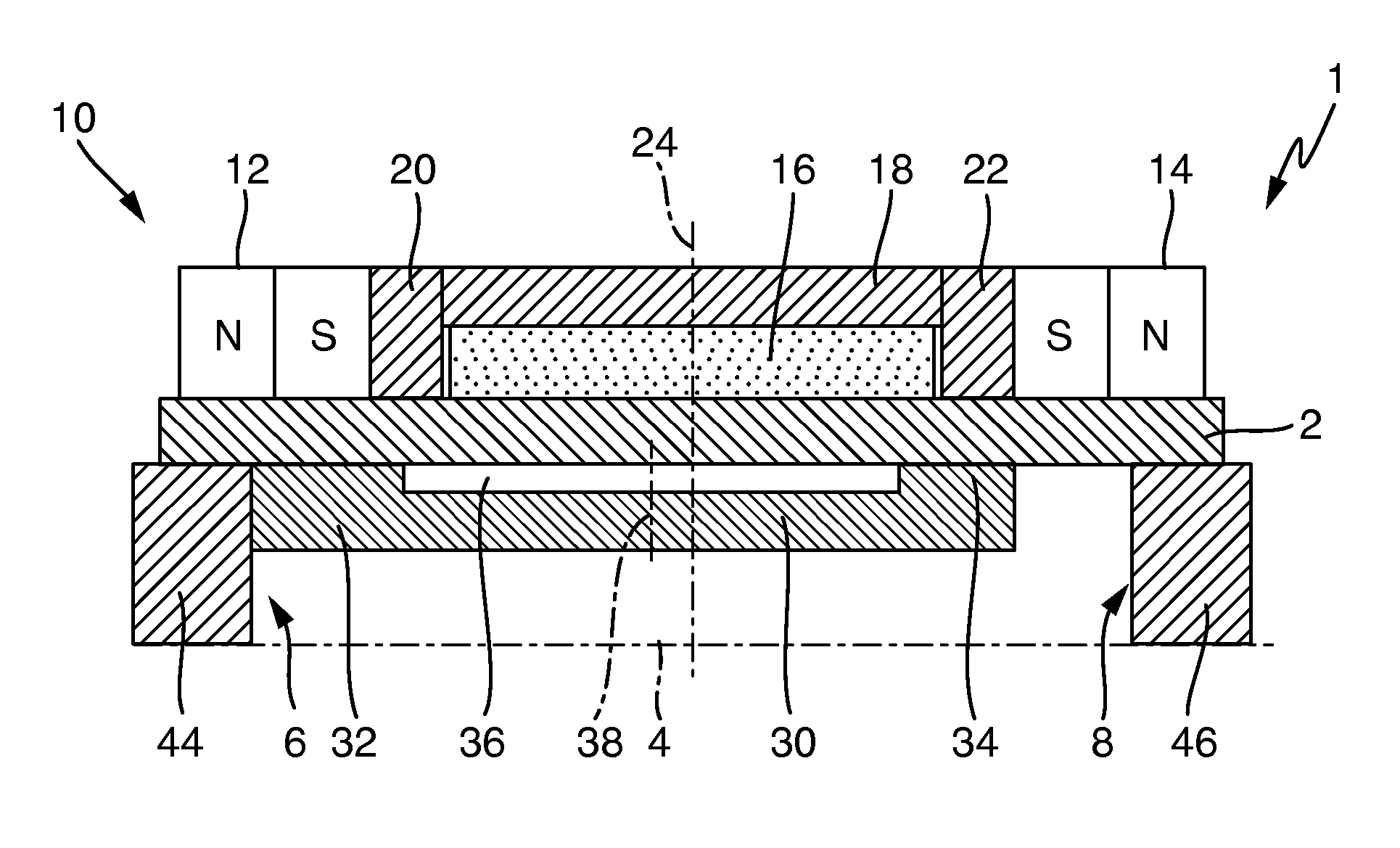

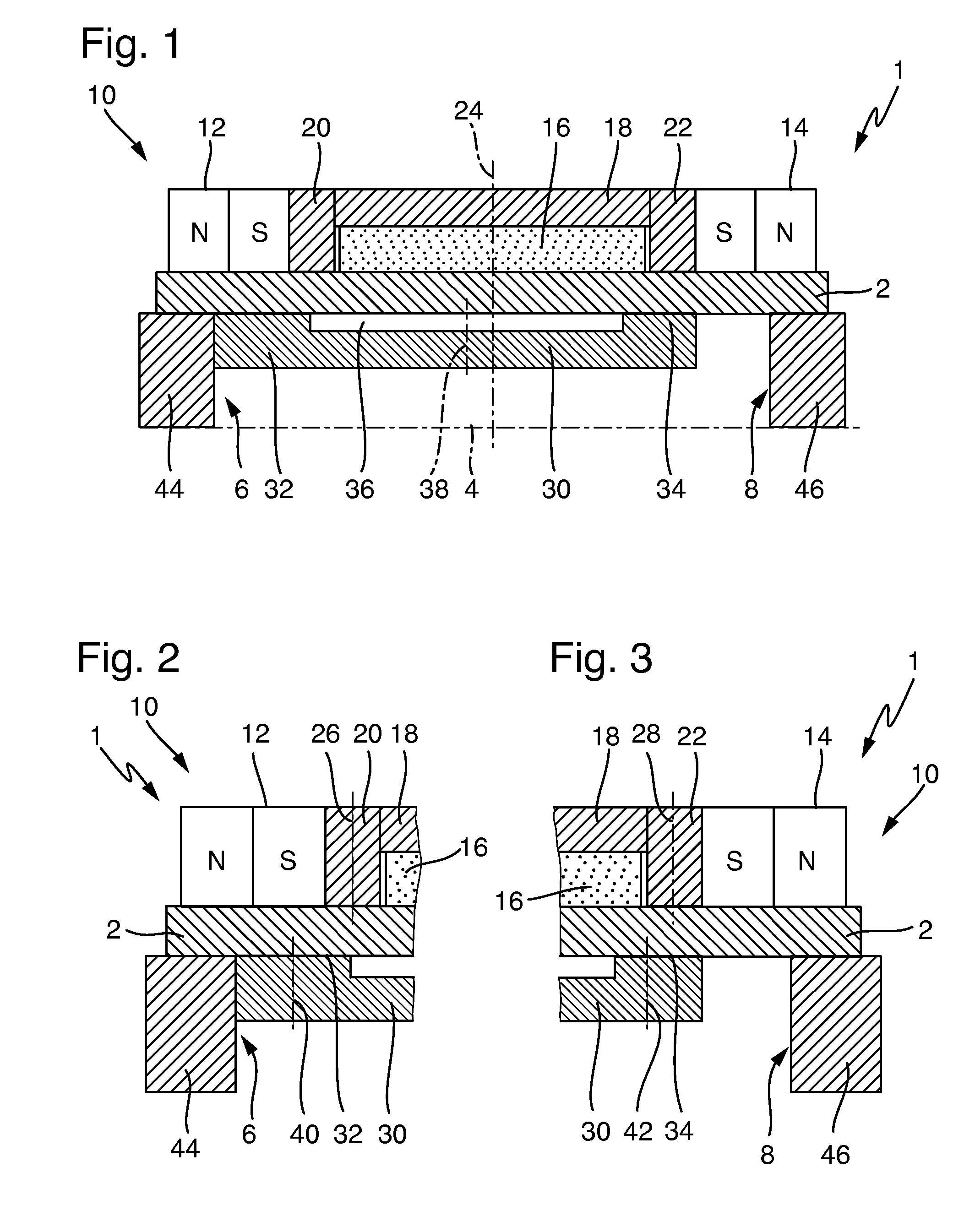

Bistable electromagnetic actuator and surgical instrument

InactiveUS20150340937A1Switching force can be increasedAdjust balanceMagnetsMagnetic circuit stationary partsEngineeringElectromagnetic actuator

A bistable electromagnetic actuator including: a tube; a stator arranged outside the tube, and a rotor mounted in the tube so as to be displaceable axially in the longitudinal direction, is the rotor being at least partially formed of one or more of a paramagnetic and ferromagnetic material, the rotor being reversibly moved between a first position and a second position by applying an electromagnetic field. Wherein the stator includes: two ring permanent magnets that are axially polarized in opposite directions, a coil for generating the electromagnetic field, and a magnetic return element having two stator pole shoes. Wherein, the magnetic return element with the stator pole shoes encloses the coil, one of the stator pole shoes is arranged on each of two sides of the coil between the coil and ring permanent magnets, the rotor has two rotor pole shoes, and an axial width of the stator pole shoes is smaller than an axial width of the rotor pole shoes.

Owner:OLYMPUS WINTER & IBE

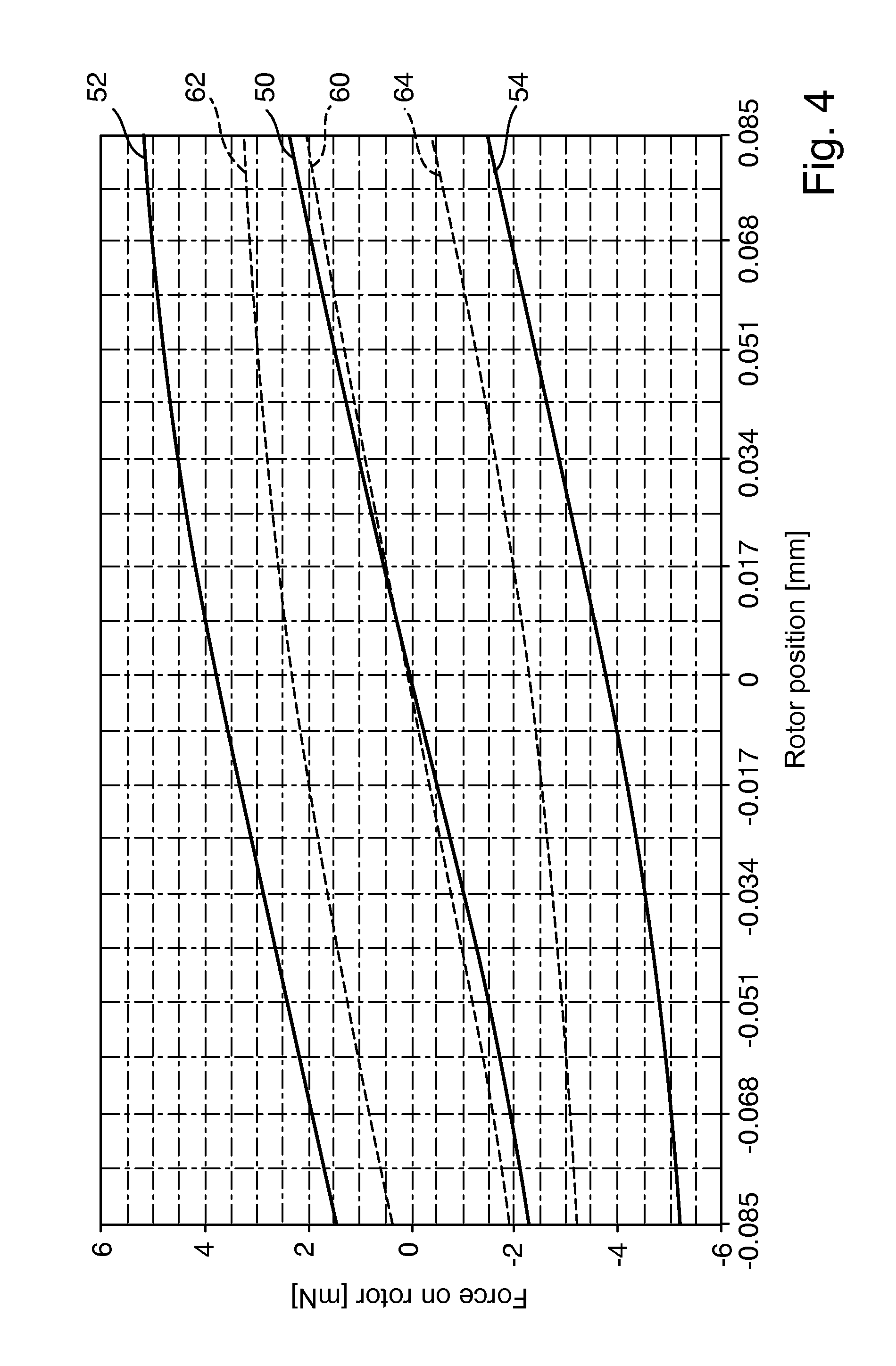

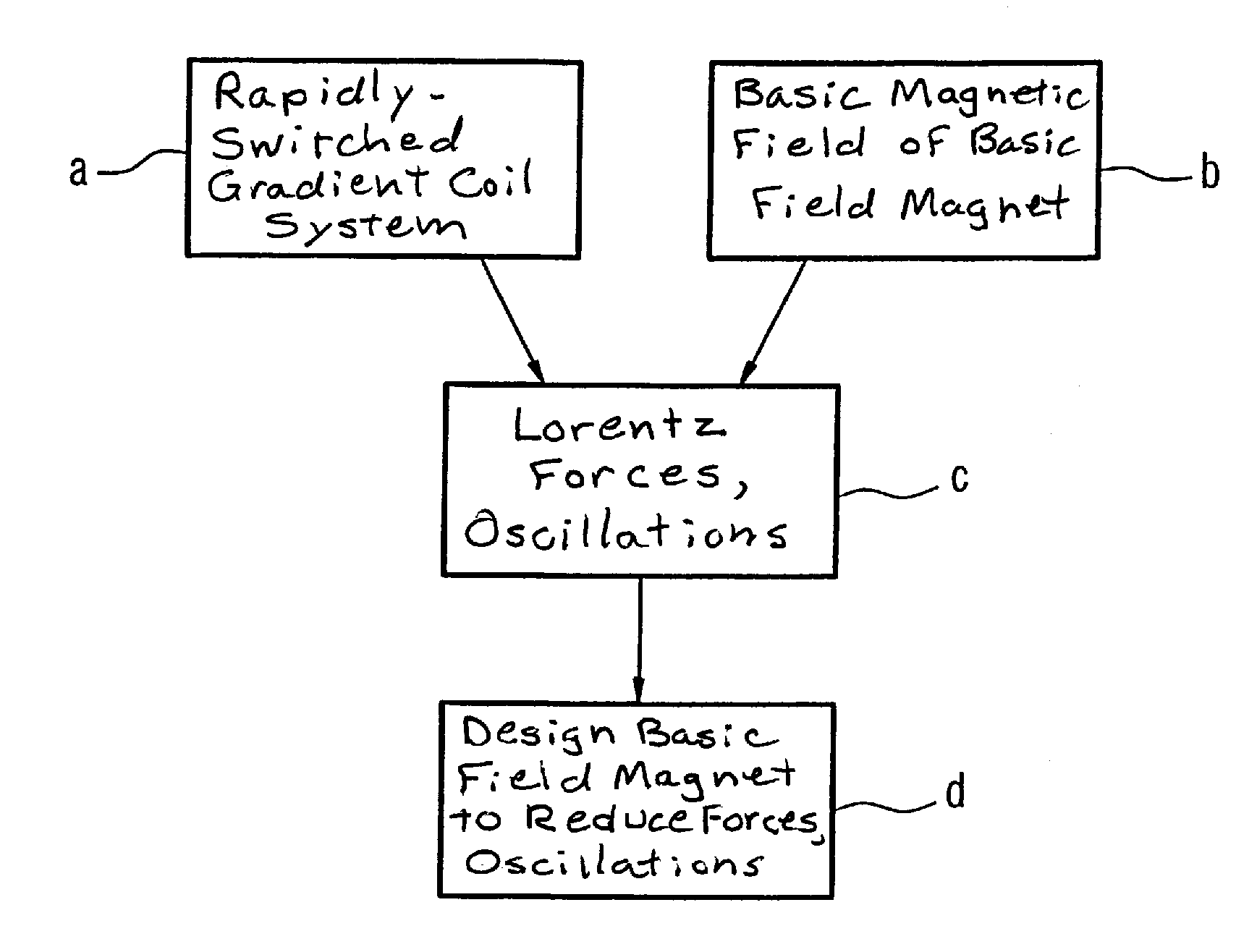

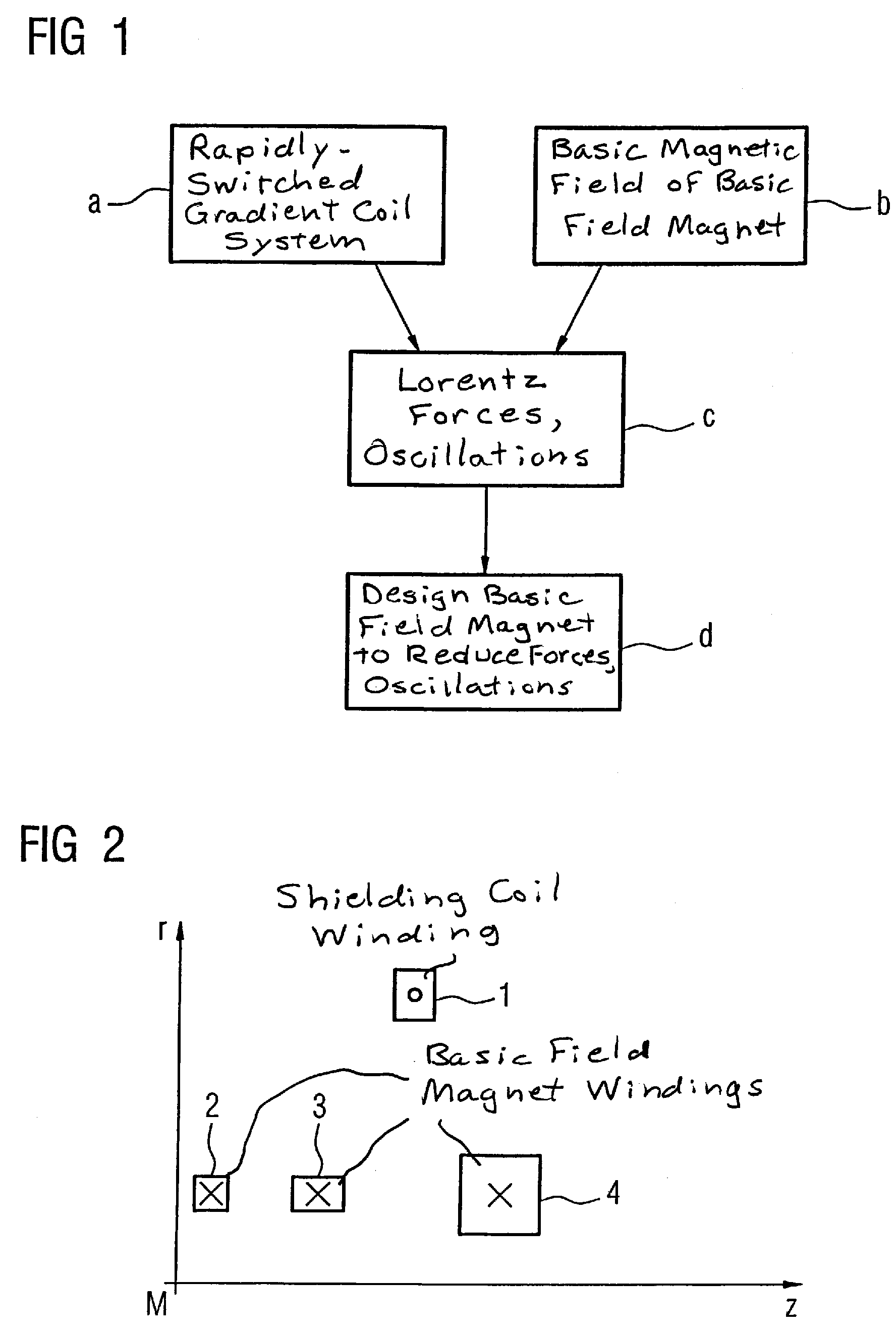

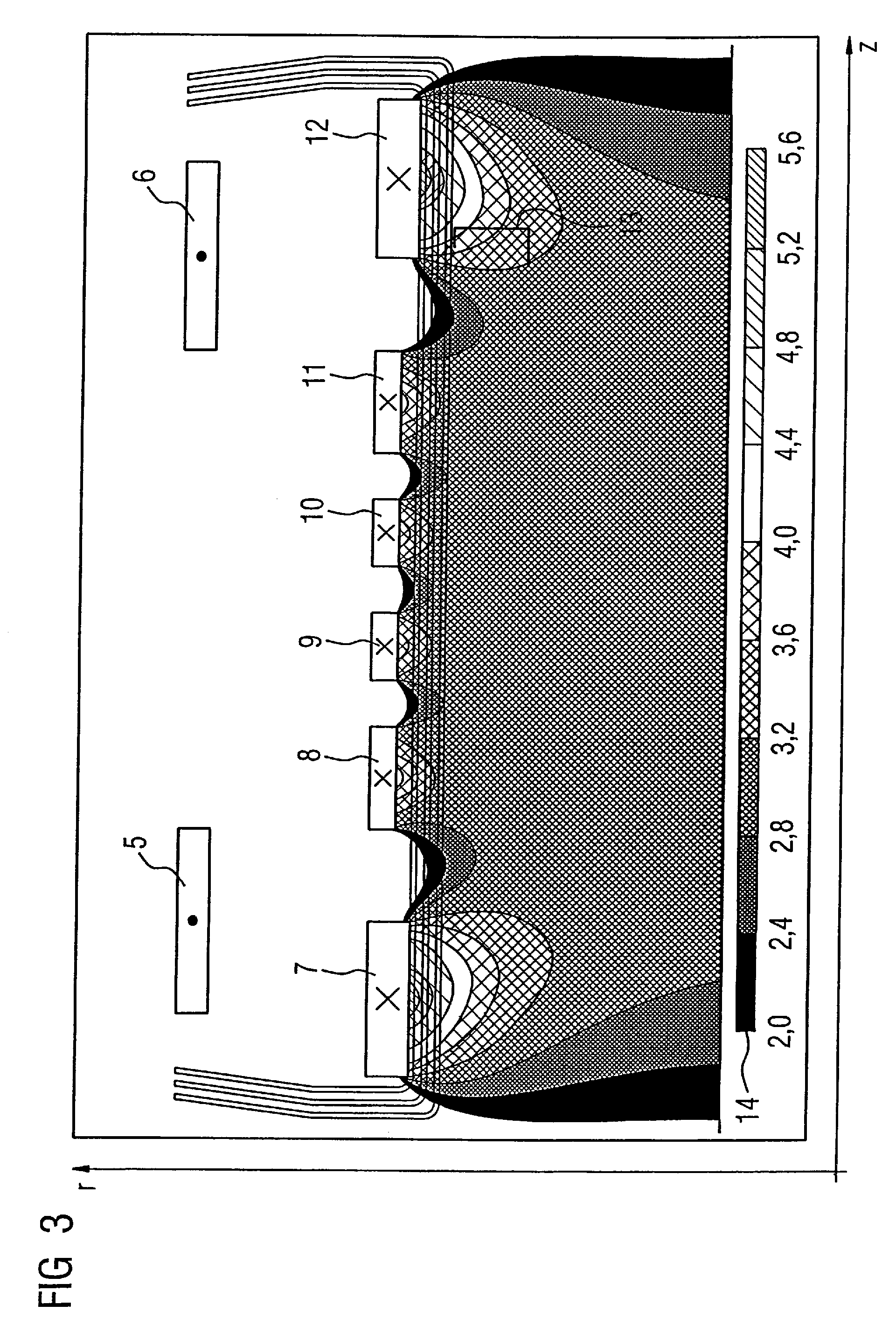

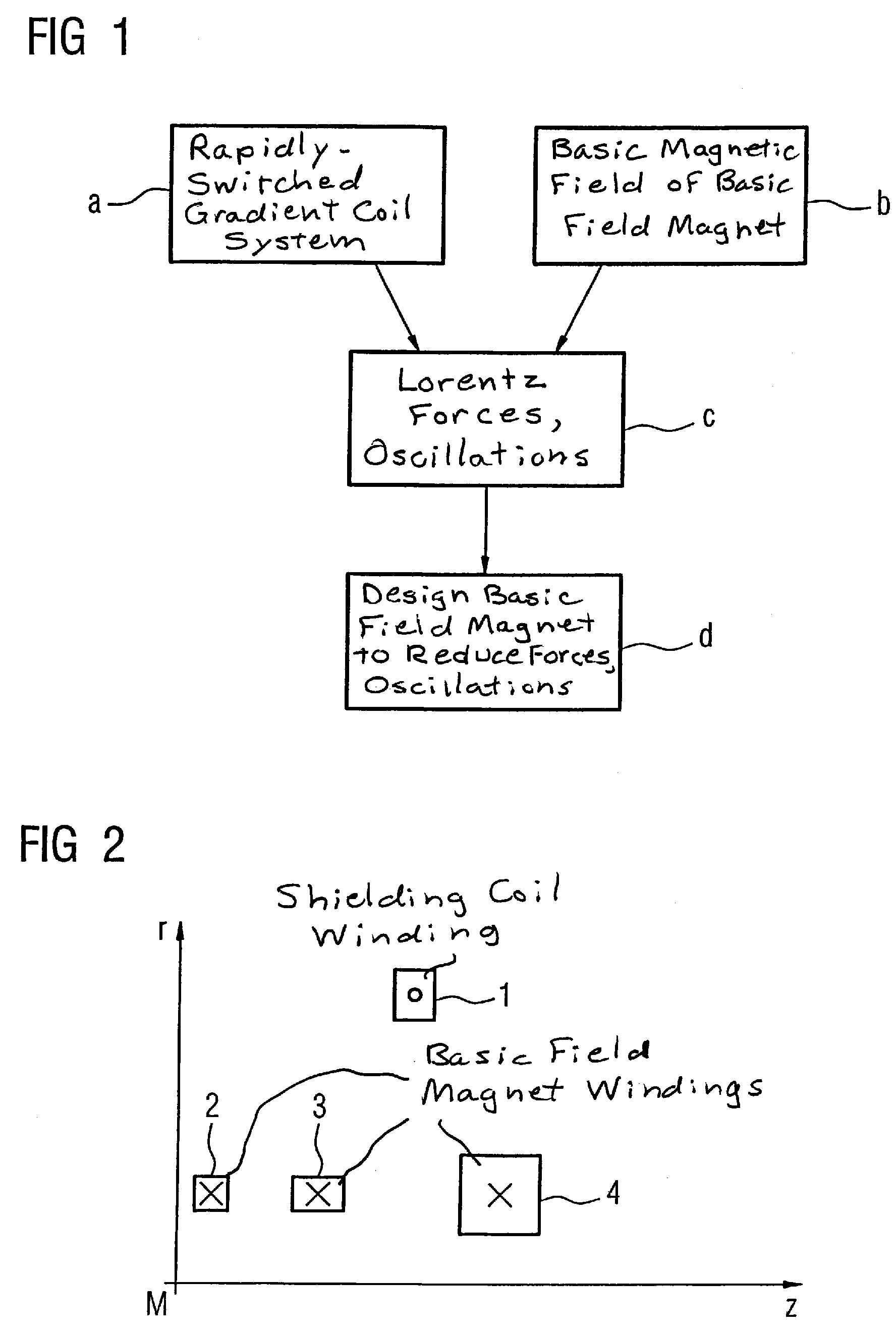

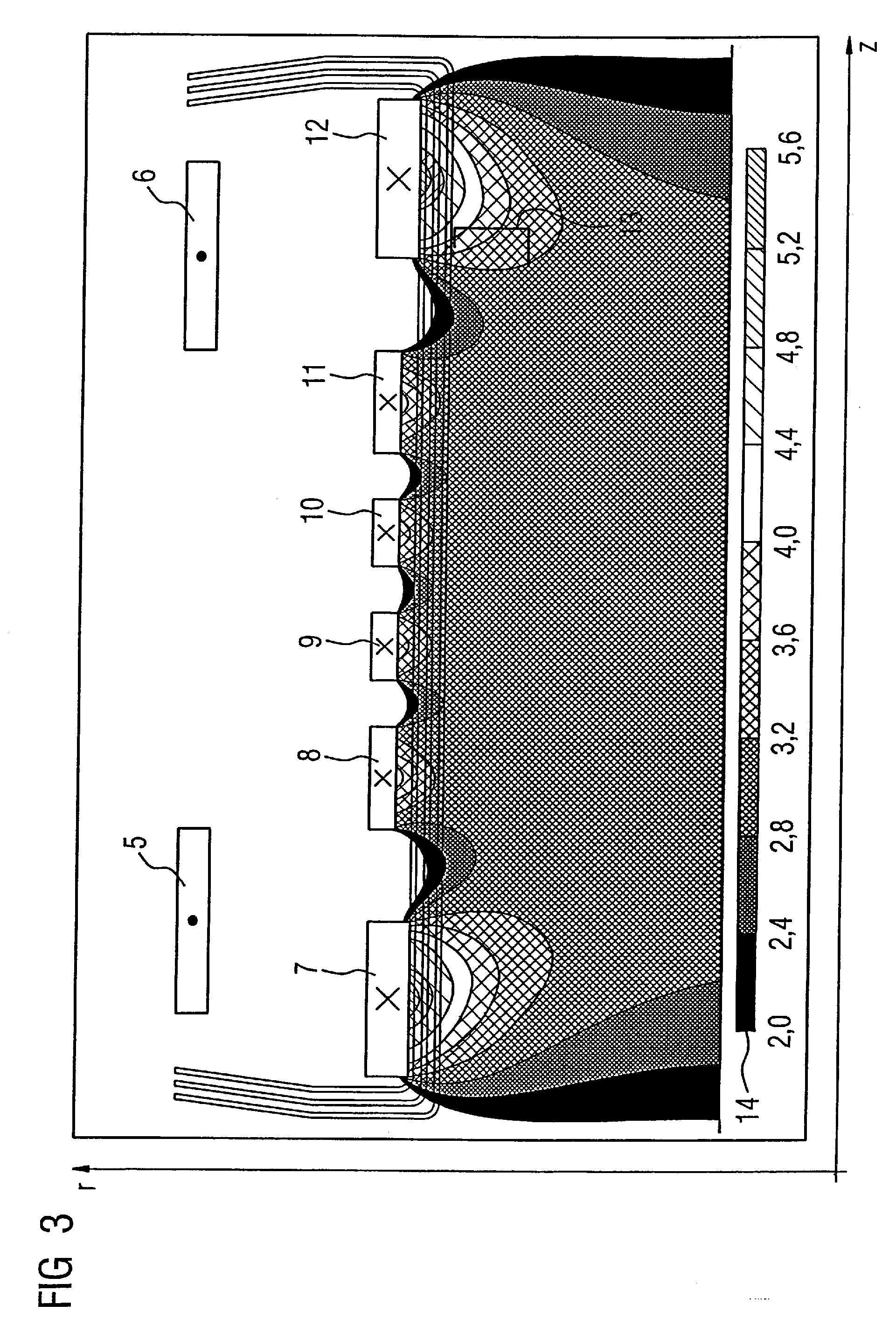

Method to determine the design of a basic magnet of a magnetic resonance apparatus with at least one gradient coil system

ActiveUS7755358B2Minimize currentNoise minimizationMagnetic measurementsElectric/magnetic detectionResonanceAtomic physics

Owner:SIEMENS HEALTHCARE GMBH

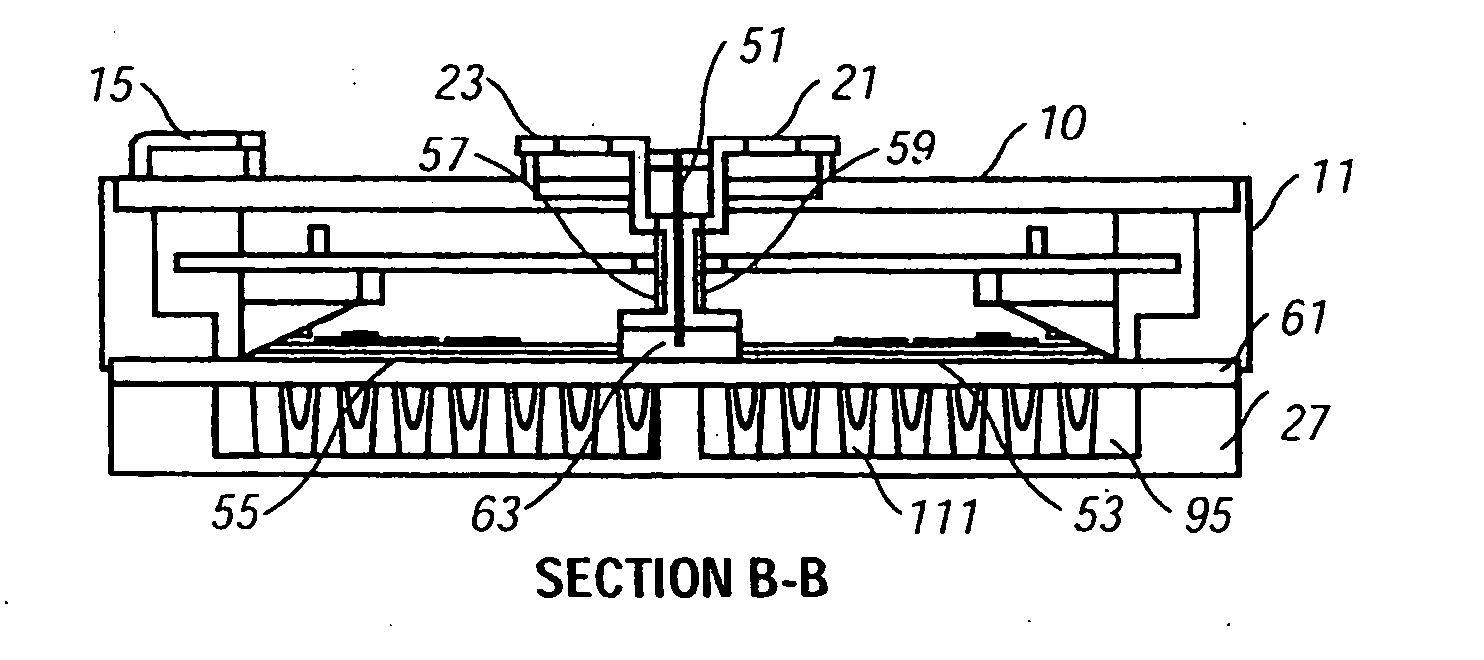

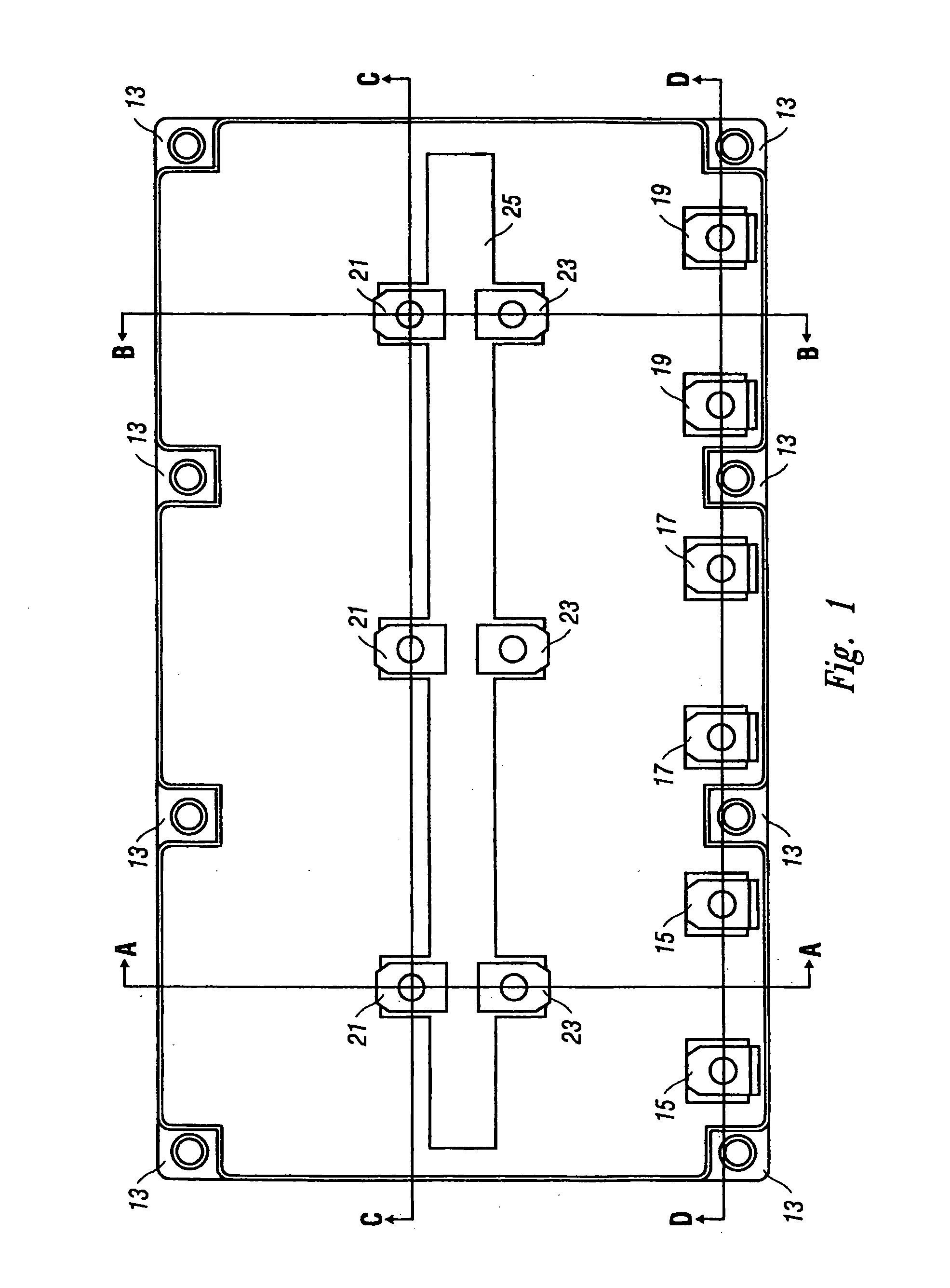

Leadframe-based module DC bus design to reduce module inductance

InactiveUS20060028806A1Reduce lossMinimize currentFinal product manufactureConversion constructional detailsEmbedded systemDC-BUS

A DC bus for use in a power module has a positive DC conductor bus plate parallel with a negative DC conductor bus plate. One or more positive leads are connected to the positive bus and are connectable to a positive terminal of a power source. One or more negative leads are connected to the negative bus and are connectable to a negative terminal of a power source. The DC bus has one or more positive connections fastenable from the positive bus to the high side of a power module. The DC bus also has one or more negative connections fastenable from the negative bus to the low side of the power module. The positive bus and negative bus permit counter-flow of currents, thereby canceling magnetic fields and their associated inductances, and the positive and negative bus are connectable to the center portion of a power module.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

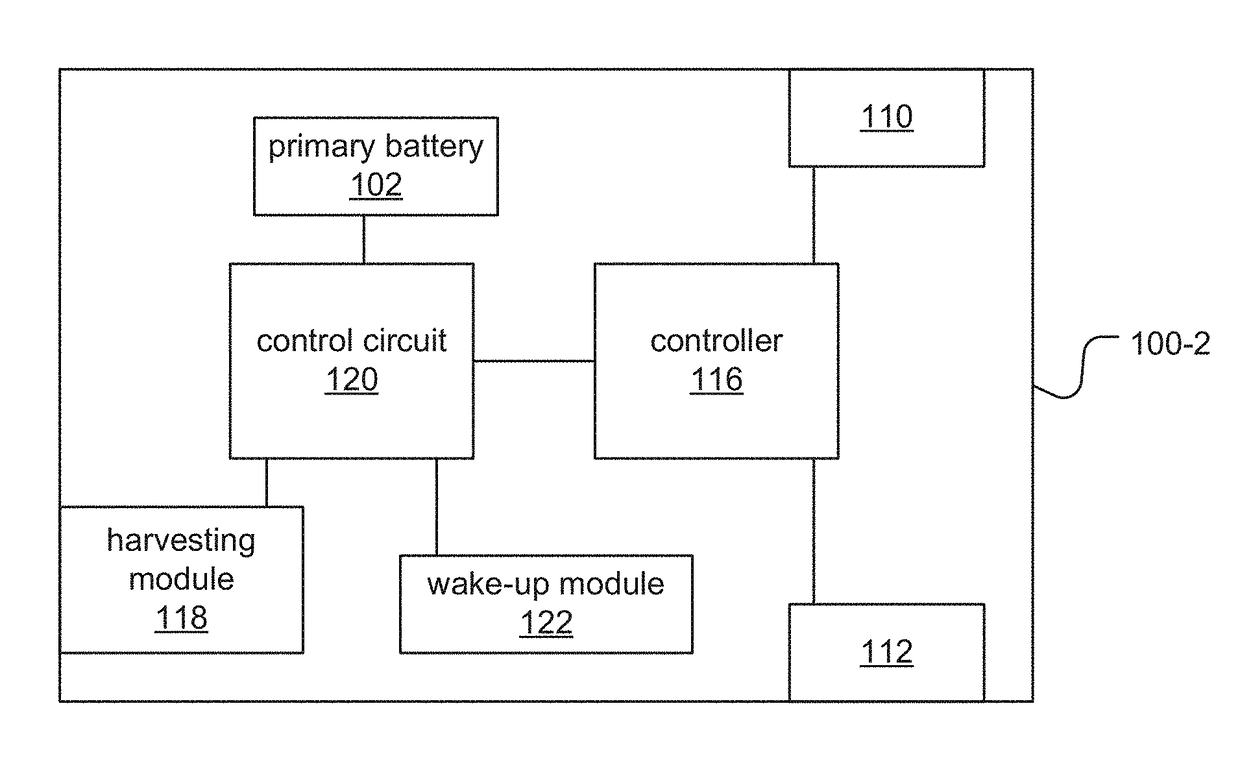

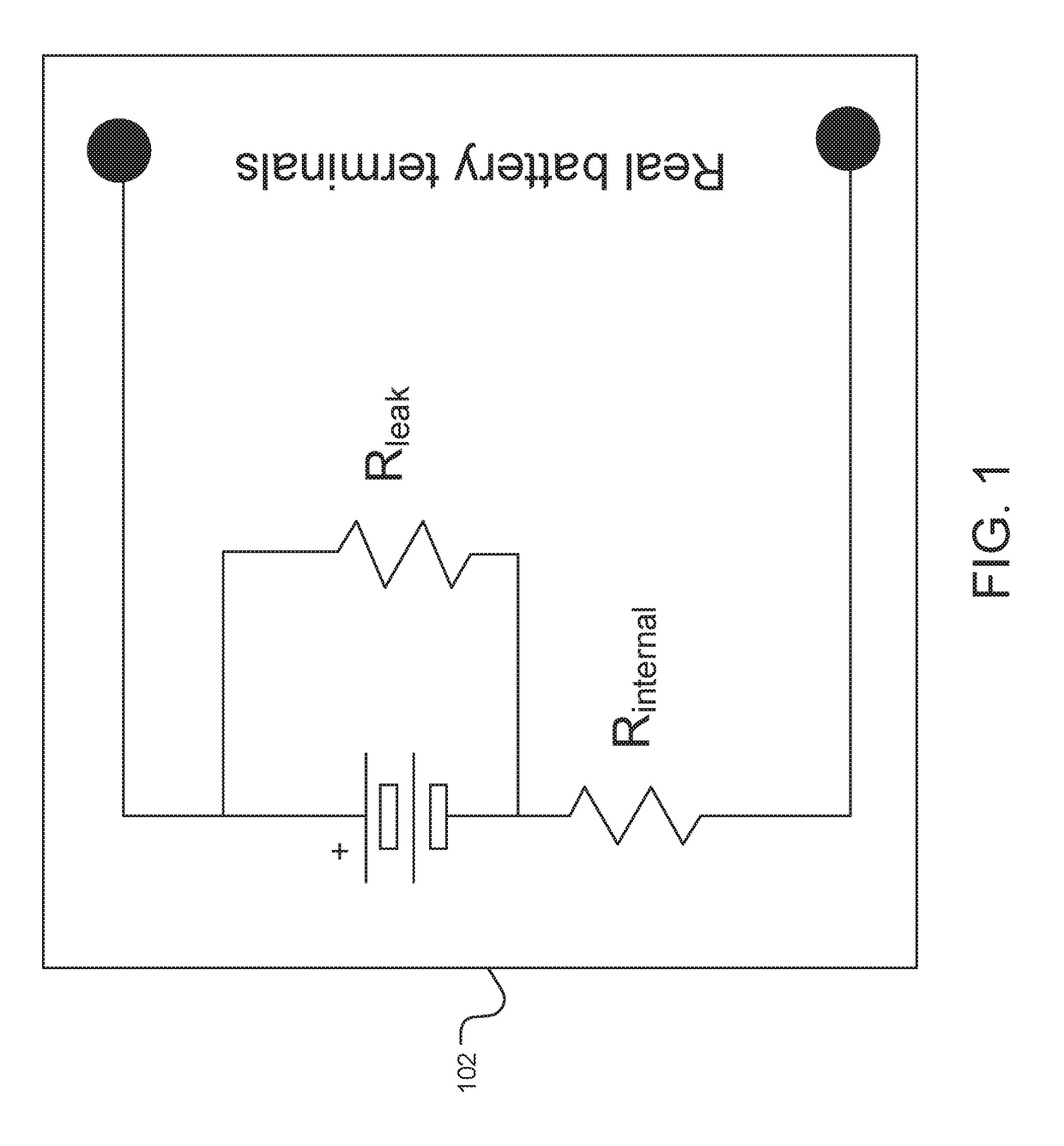

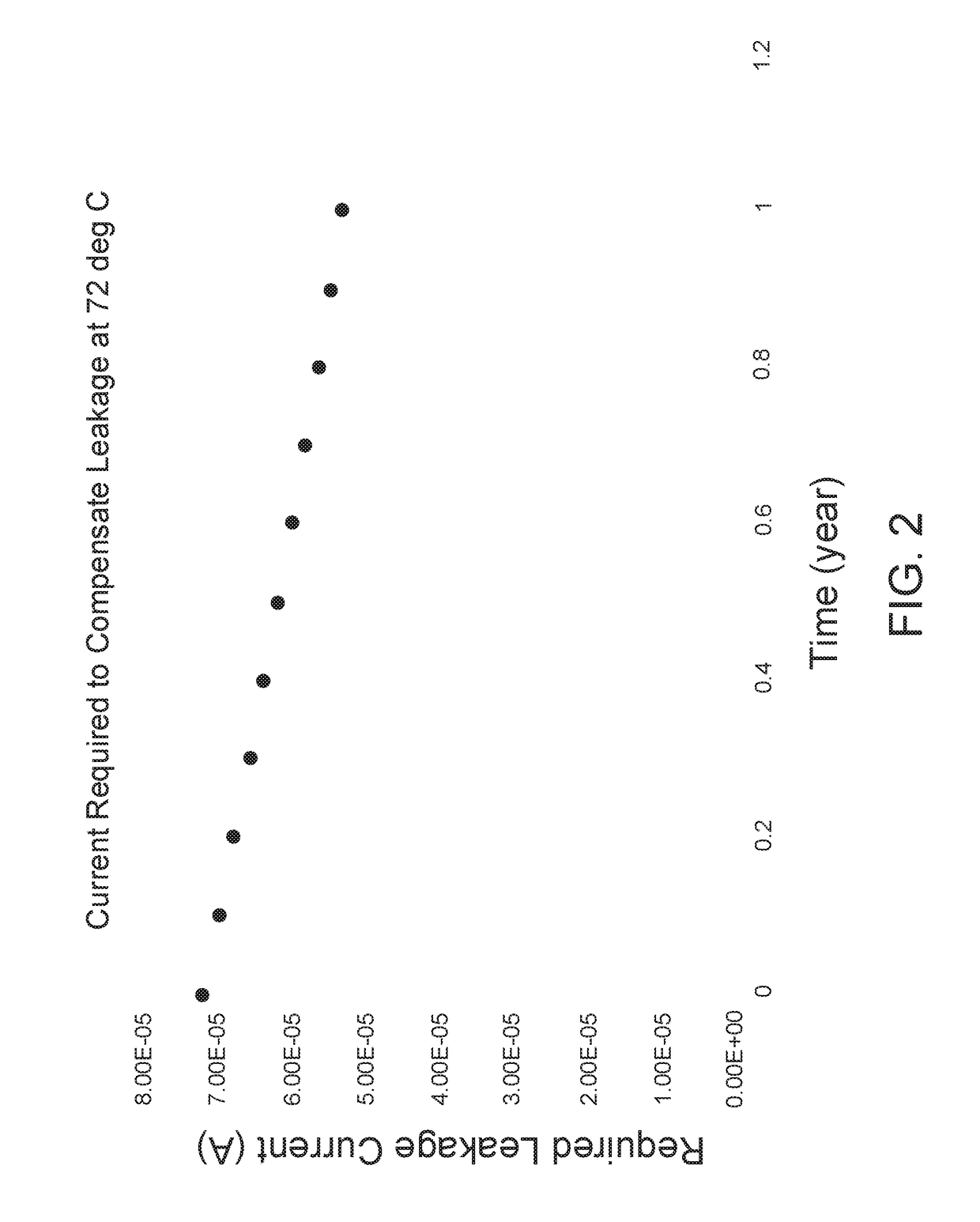

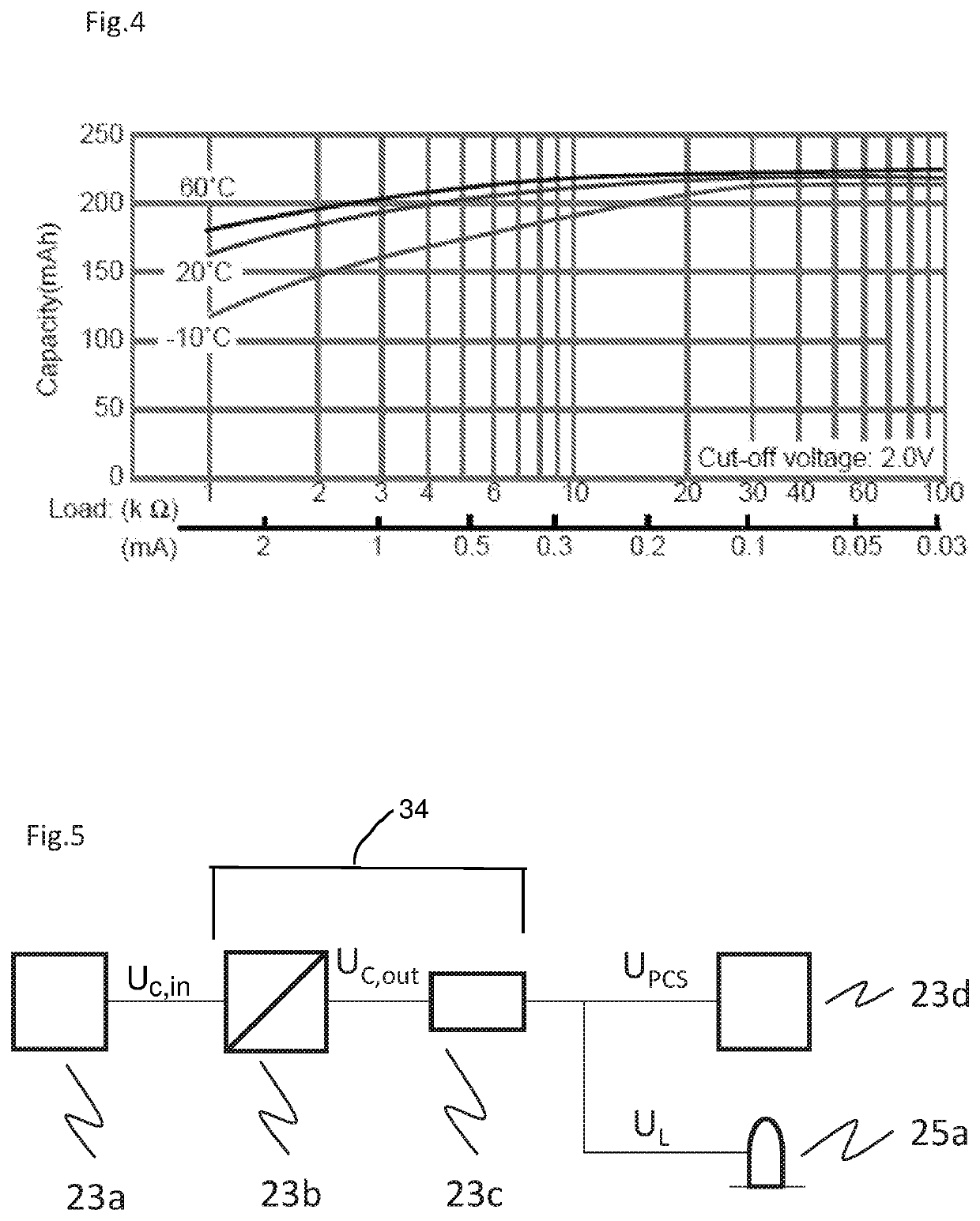

Method for Preventing High Temperature Self Discharge in Primary Battery

InactiveUS20170271688A1Minimize currentReduce self dischargeSurveyThermoelectric device with peltier/seeback effectEnergy harvestingElectrical battery

A discharge prevention system for a primary battery comprises an energy harvesting module that produces energy from an environment and a control circuit for applying electrical current to the primary battery from the energy harvesting module to prevent or reduce self-discharge. This system will prevent or reduce rapid self-discharge at high temperatures in lithium-based primary batteries, for example. It can significantly extend the operating lifetime of such batteries operating at high temperature, particularly in applications where battery power is used intermittently. Specifically, a very low current is supplied to the primary battery at high temperature, significantly extending its storage lifetime. In some cases, depending on the current characteristics of the battery, the energy associated with the bias current can be in the same order of magnitude as the energy that would be lost by self-discharge, but in many cases it is much lower. This bias current “biases” the battery in such a way that self-discharge current of the primary battery is minimized.

Owner:CHARLES STARK DRAPER LABORATORY

Connector having improved contacts

ActiveUS20120202395A1Strong couplingSufficient flexibilityElectrically conductive connectionsCoupling contact membersElectrical conductorEngineering

An electrical connector for connecting a conductor of a daughter card connector wafer with a blade in the housing of a backplane connector. The daughter card conductor has a body with two elongated beams extending outward from the body. The two elongated beams each have an outer edge and an inner edge, whereby an opening is defined between the inner edges. The backplane conductor has a body with a narrowed tab portion extending outward from said second conductor body. The narrowed tab portion having outer opposite edges and is sized so that the narrowed tab portion fits between at least a portion of the outer edges of the two elongated beams, and in some cases between at least a portion of the inner edges of the two elongated beams.

Owner:AMPHENOL CORP

Duty cycle correction circuit

ActiveUS8451037B2Simple internal structureRun fastElectric pulse generatorPulse shapingControl signalEngineering

A duty cycle correction circuit includes a duty cycle control unit configured to generate a corrected clock signal by correcting a duty cycle of an input clock signal in response to a control signal, a duty cycle detection unit configured to detect a duty cycle of the corrected clock signal and output a detection signal, and a control signal generation unit configured to generate the control signal in response to the detection signal.

Owner:SK HYNIX INC

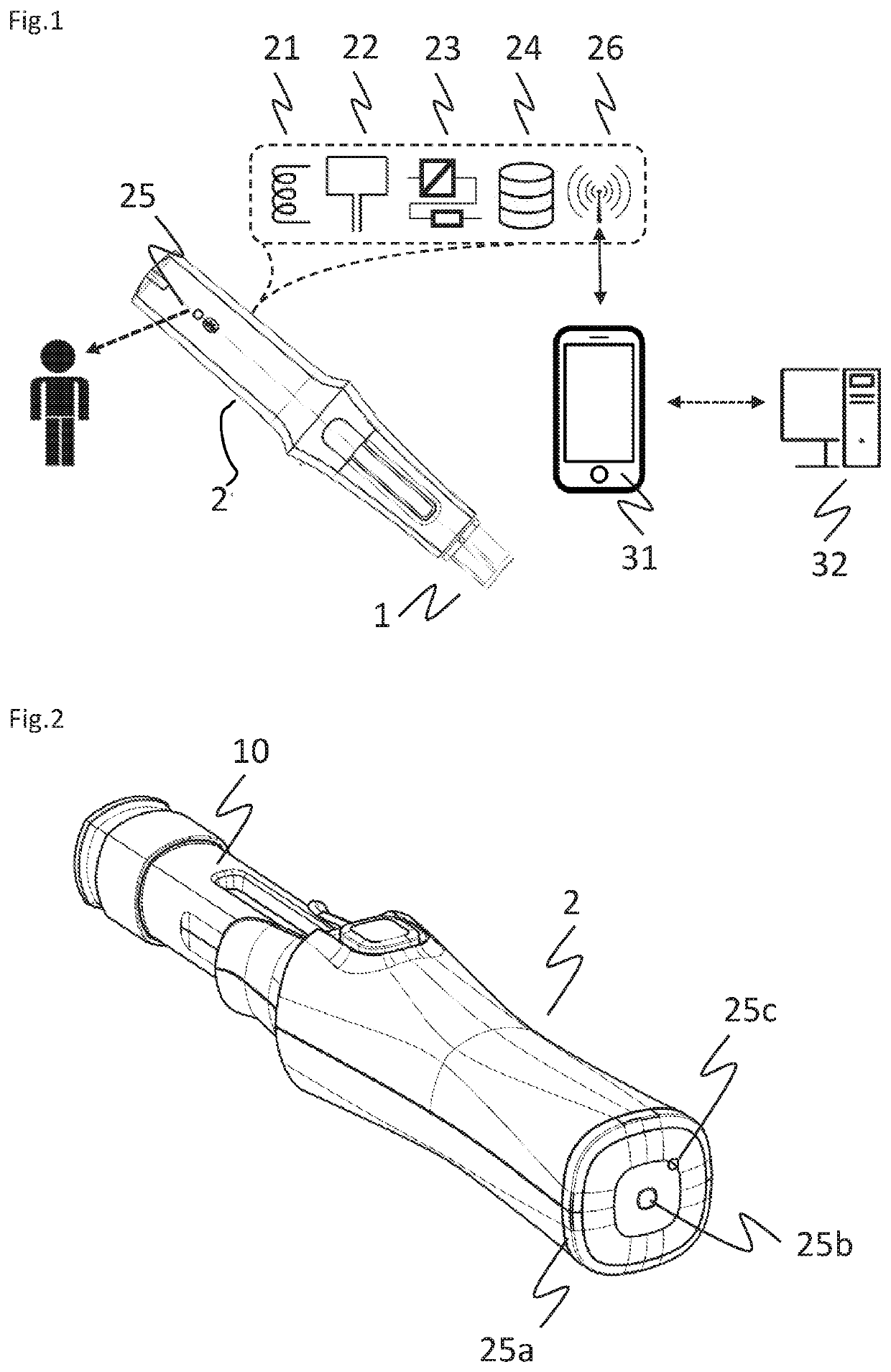

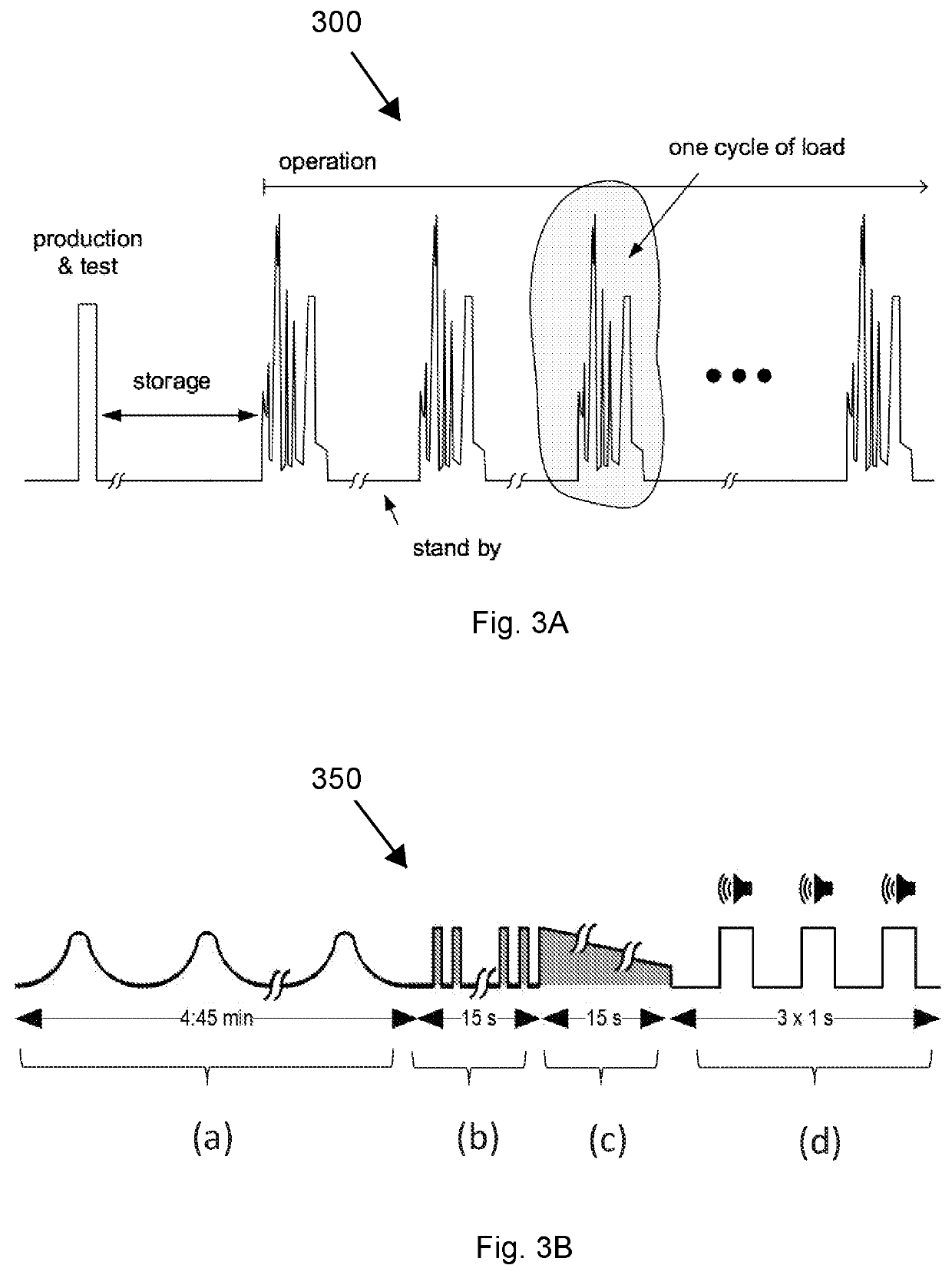

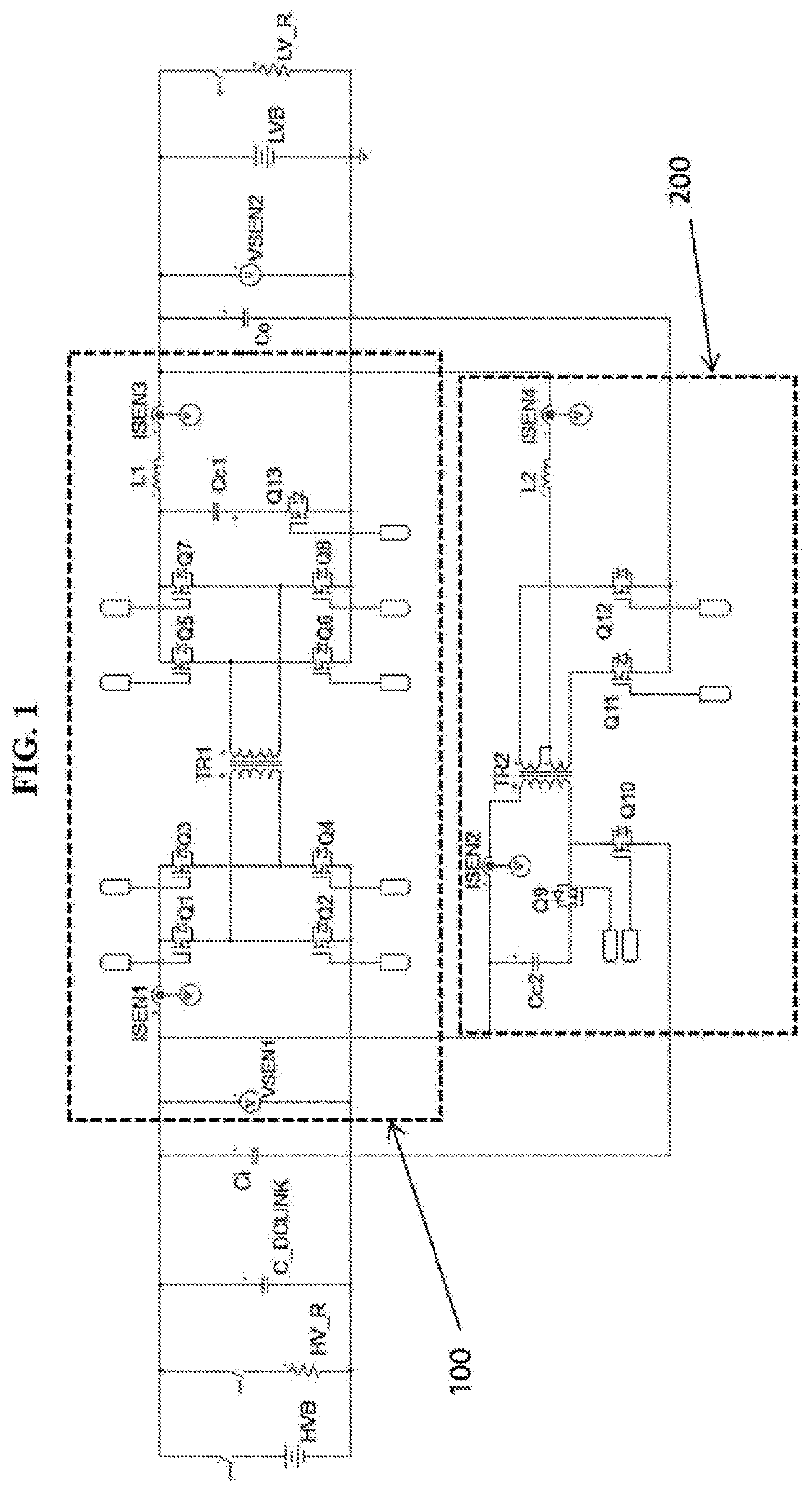

Power supply for drug delivery systems

PendingUS20210008294A1Lower efficiencyMinimize currentMedical devicesIntravenous devicesDrug deliveryConverters

A space-saving, autonomous power supply enables a monitoring unit to monitor a minimum number of delivery events of a drug delivery device. The monitoring unit has delivery status sensing means for monitoring a device delivery status, a status indicator with an indicator element such as an LED controllable to indicate delivery or module status to a user, and a power supply supplying power to the status sensing means and status indicator of the monitoring unit. The power supply has a peak current source, in particular a rechargeable battery or accumulator, providing a load current for operating the status sensing means and status indicator of the monitoring unit. The power supply has a recharge circuit with a converter and a charging resistor for providing a limited recharge current to the peak current source, plus a recharge source for repeatedly providing an optimized recharge source current to the recharge circuit.

Owner:YPSOMED AG

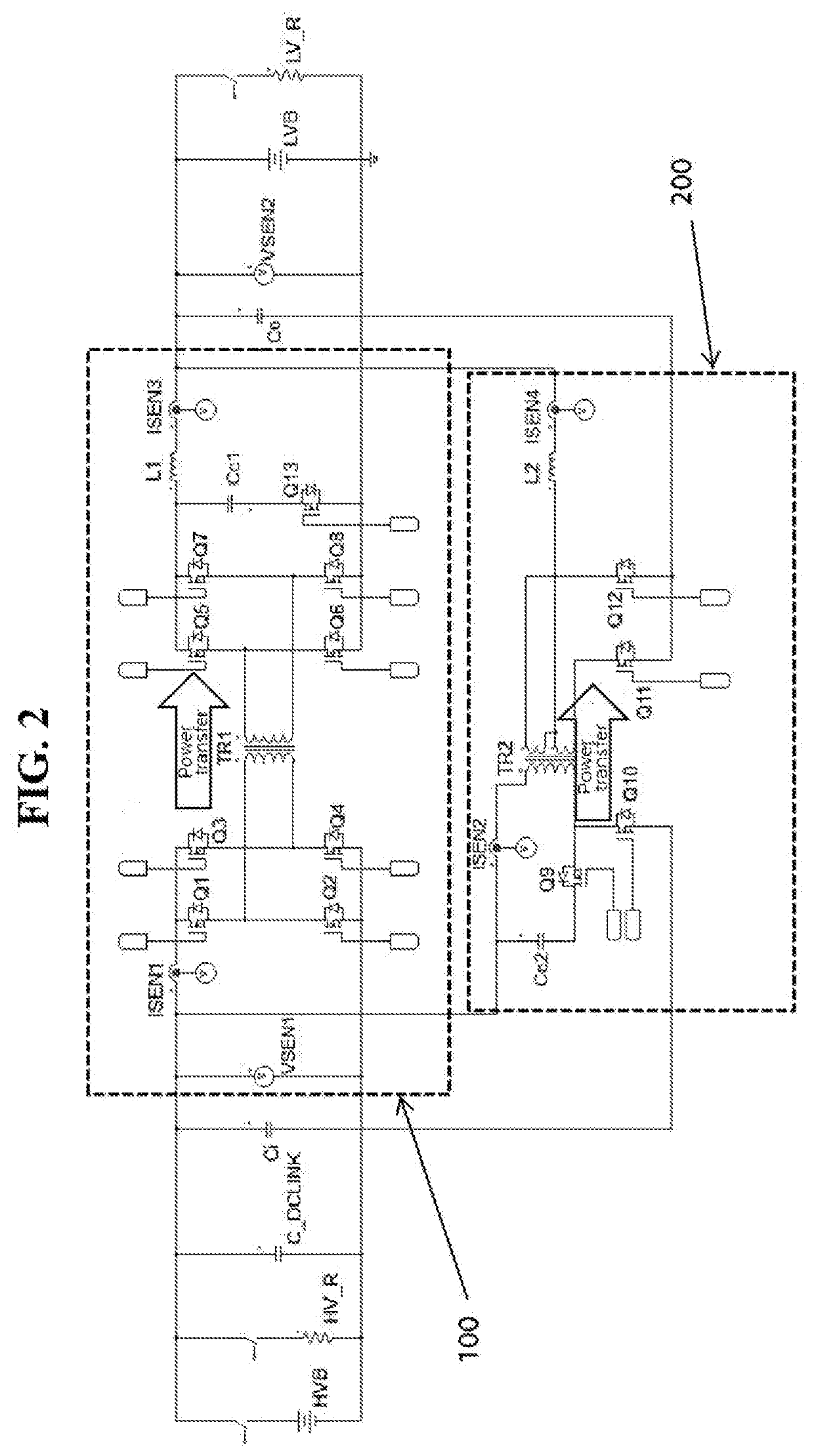

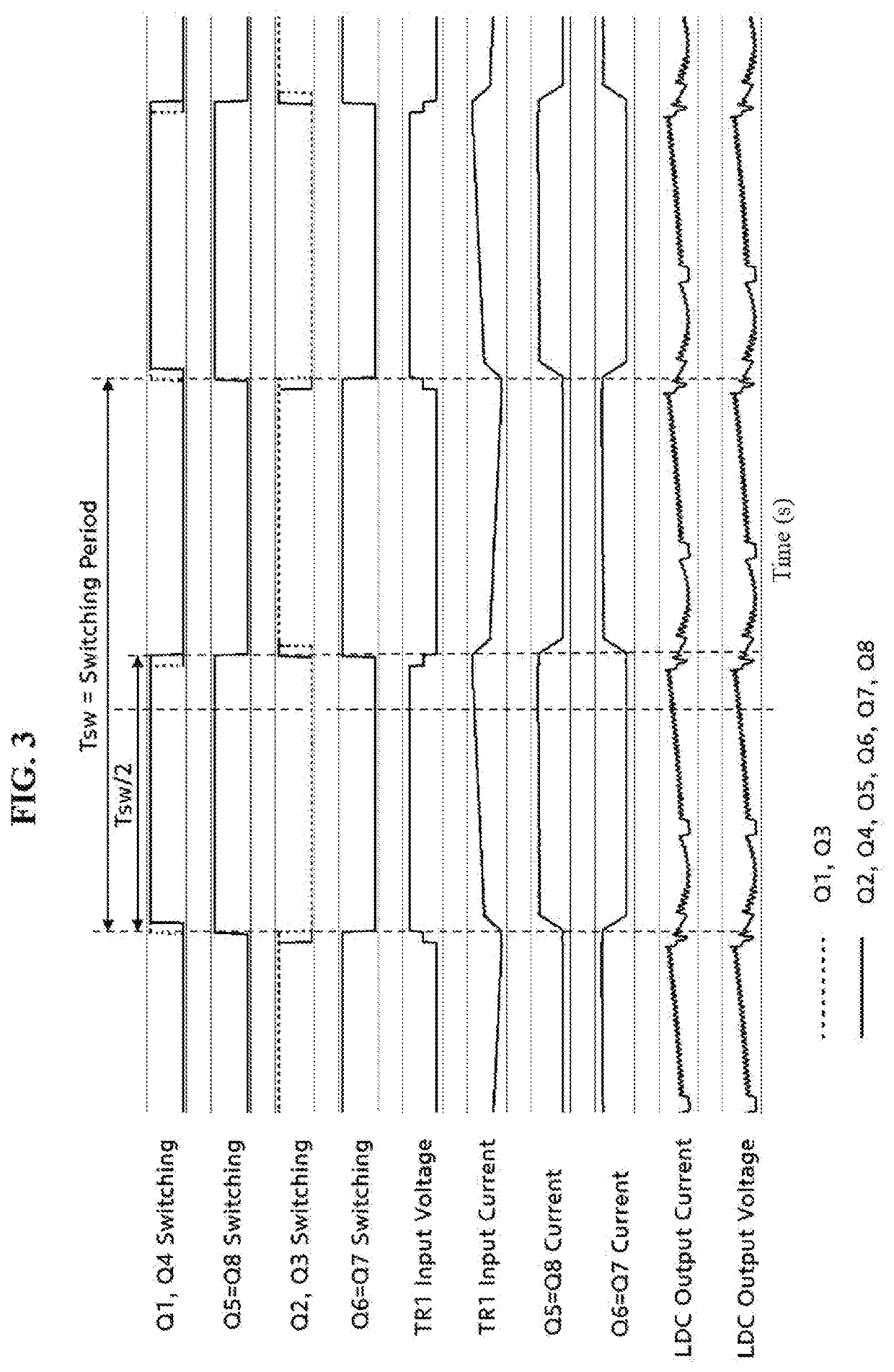

Large capacity bidirectional isolated dc-dc converter and control method thereof

ActiveUS20220200454A1Minimizing semiconductor power lossLow rateHybrid vehiclesDc-dc conversionConvertersActive clamp

Provided is a new LDC to satisfy the recent requirements for a bidirectional large-capacity isolated LDC (DC-DC converter). The present disclosure provides a new bidirectional isolated LDC, in which two converters with different power circuit topologies operate in parallel in order to enable both buck mode and boost mode. The two applied converters are a phase-shift full-bridge converter with full-bridge synchronous rectification and an active-clamp forward converter. According to the present invention, it is possible to achieve the advantages of both a phase-shifted full-bridge converter with full-bridge synchronous rectification applied and an active clamping forward converter. Thus, it is to possible to minimize output voltage and current ripples, thereby improving the quality of the LDC output power while minimizing electromagnetic waves generated while a product is operating.

Owner:HYUNDAI MOBIS CO LTD

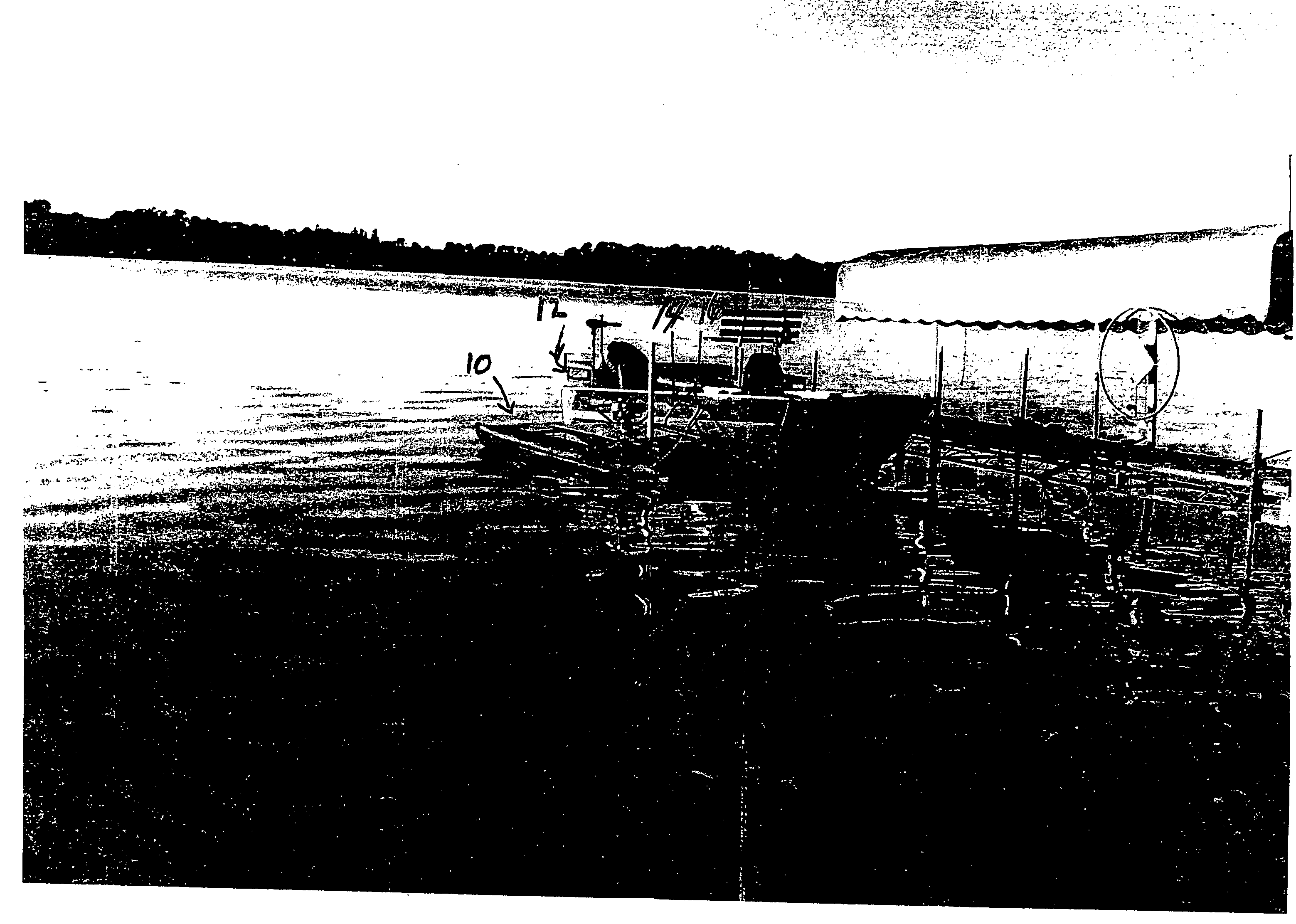

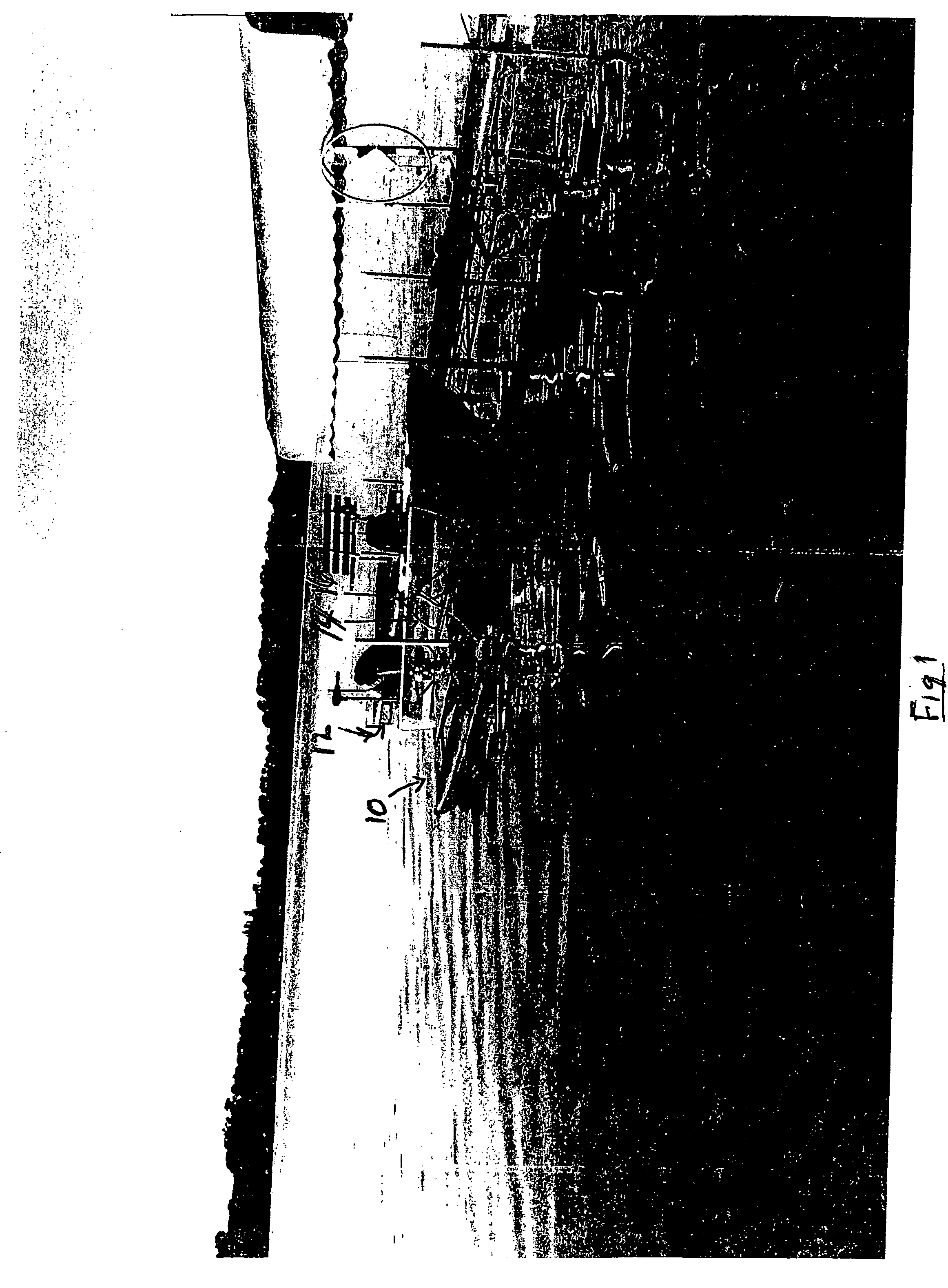

Aquatic vegetation groomer

An aquatic vegetation cutting and removal system is disclosed which is a self-contained floating system having a depth-variable cutting assembly operated in conjunction with a rake device which gathers and removes detached aquatic weeds or other vegetation. The system may be large enough to have a rider-operator or small and light enough to be easily portable.

Owner:LIEN DOUGLAS E

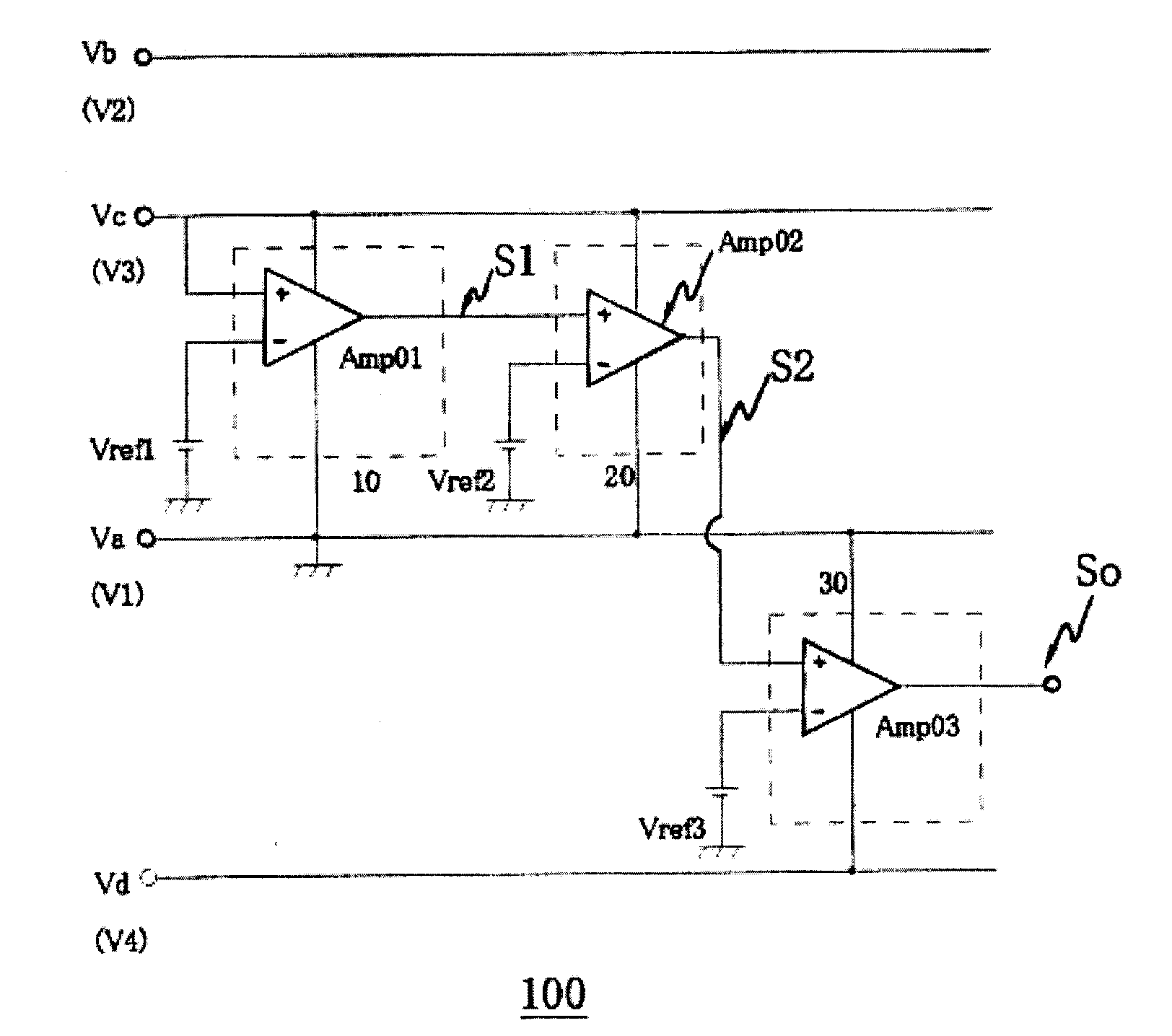

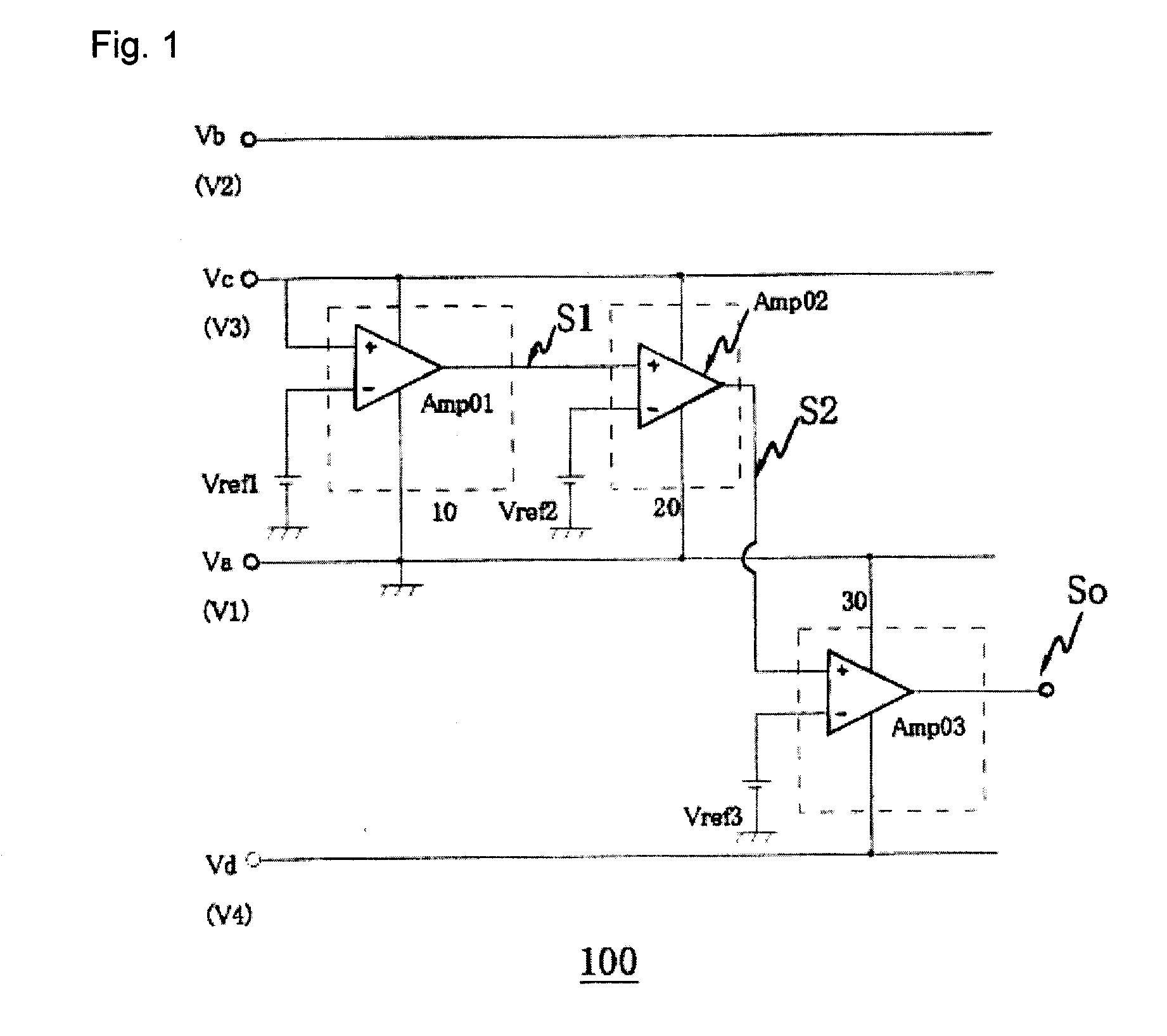

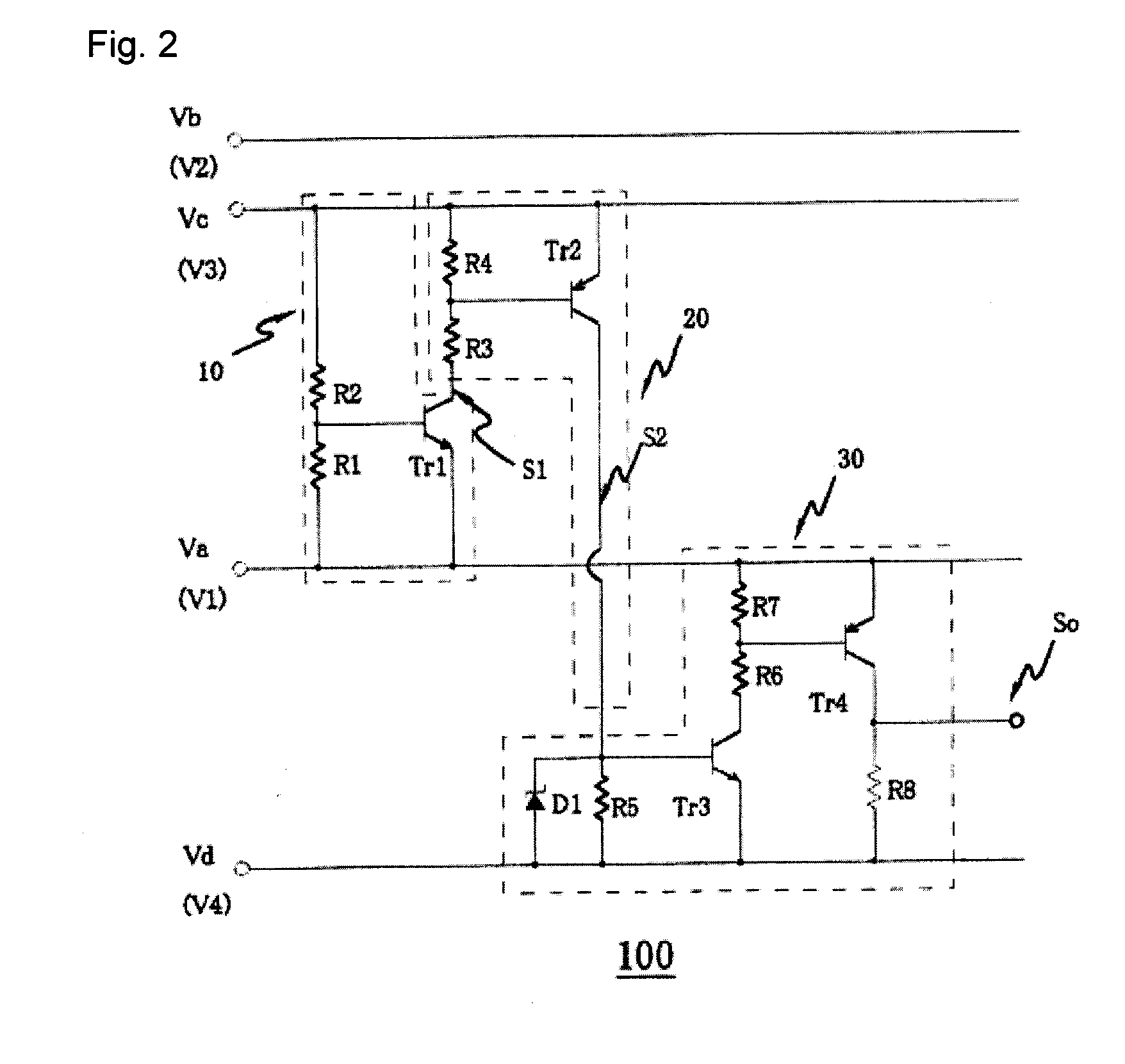

Semiconductor device, and power supply device and image pickup device using the same

InactiveUS20070205809A1Designing be facilitateMinimize currentMultiple input and output pulse circuitsPulse shapingElectronic circuitEngineering

An electronic circuit includes a semiconductor device which has an internal circuit that uses a positive power supply voltage and a negative power supply voltage, and which controls the operation of the above-mentioned internal circuit by an external input. The semiconductor device includes an input signal detection circuit that operates using a voltage that is input into the external input, and a signal output circuit which outputs a signal that controls the negative power supply voltage applied to the internal circuit in accordance with an output of the input signal detection circuit. The circuit can switch a negative-side circuit on and off without depending on a positive power supply voltage and also without depending on the order of starting a positive power supply voltage and a negative power supply voltage.

Owner:ROHM CO LTD

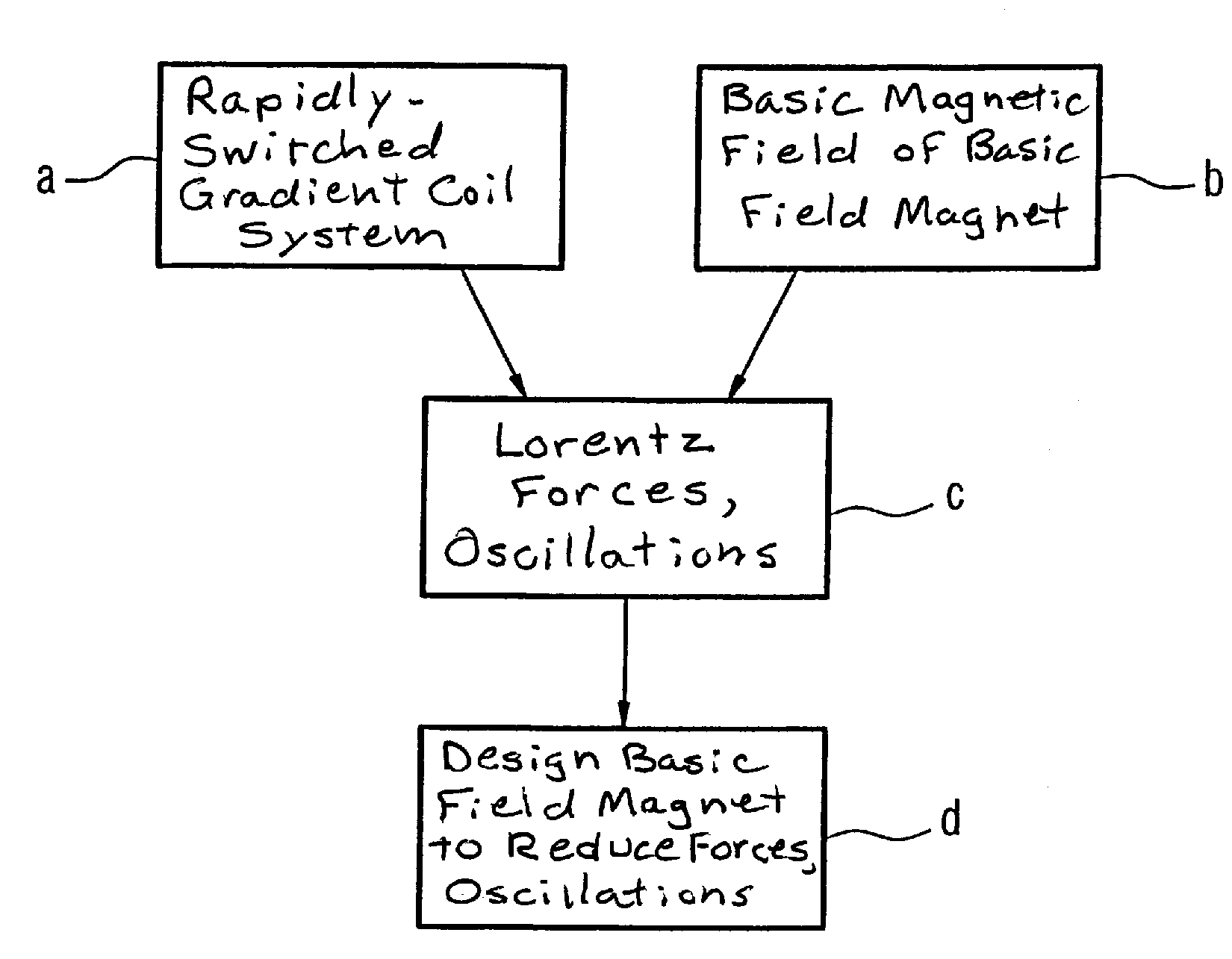

Method to determine the design of a basic magnet of a magnetic resonance apparatus with at least one gradient coil system

ActiveUS20090295519A1Minimize currentNoise minimizationMagnetic measurementsElectric/magnetic detectionResonanceAtomic physics

The method for determination of the design of the basic magnet of a magnetic resonance apparatus with at least one gradient coil system, the design of the basic magnet is determined by taking into consideration forces acting on the at least one gradient coil system that may lead to vibrations of the gradient coil system due to switching processes of the gradient coil system in the field of the basic magnet.

Owner:SIEMENS HEALTHCARE GMBH

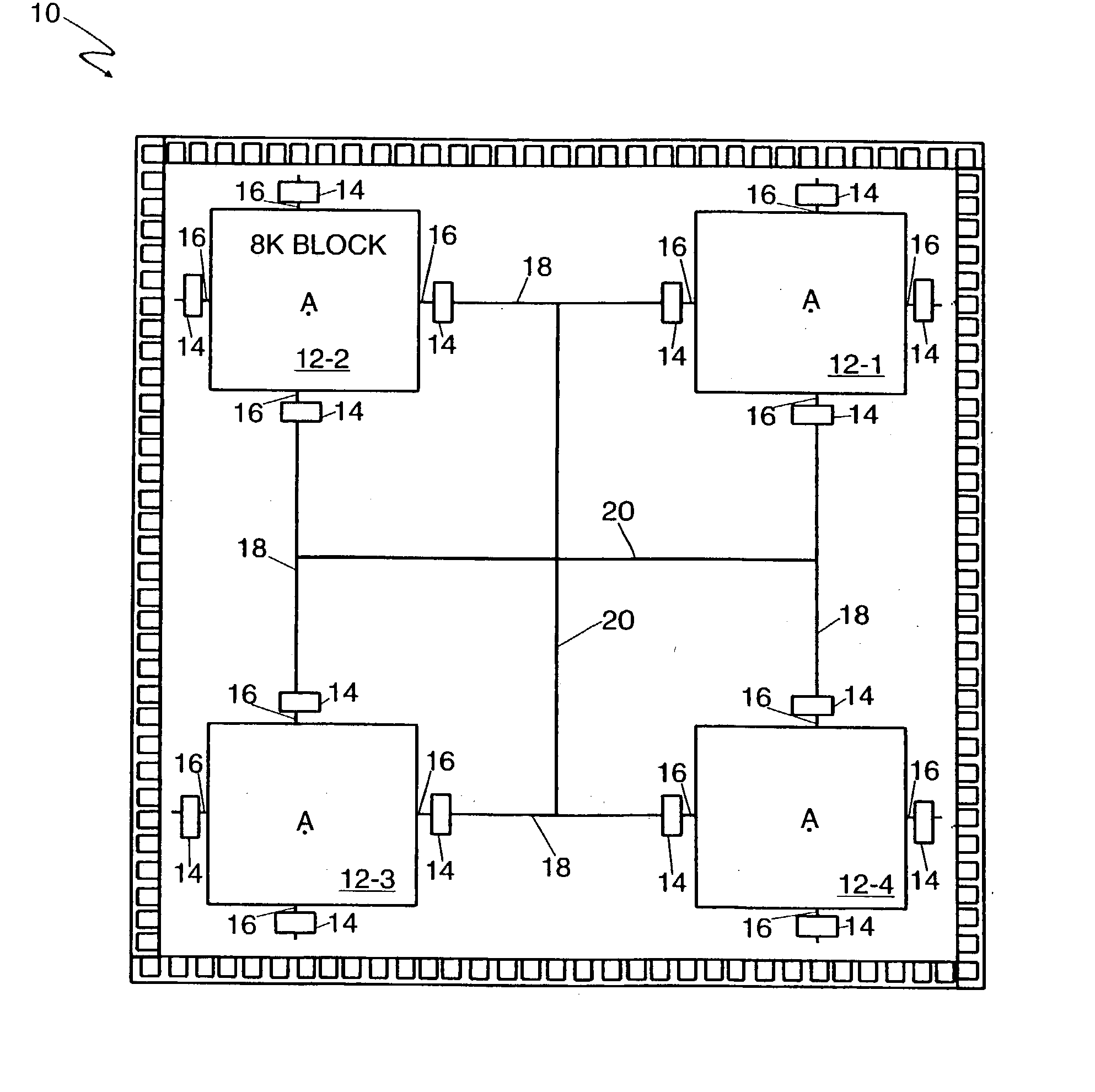

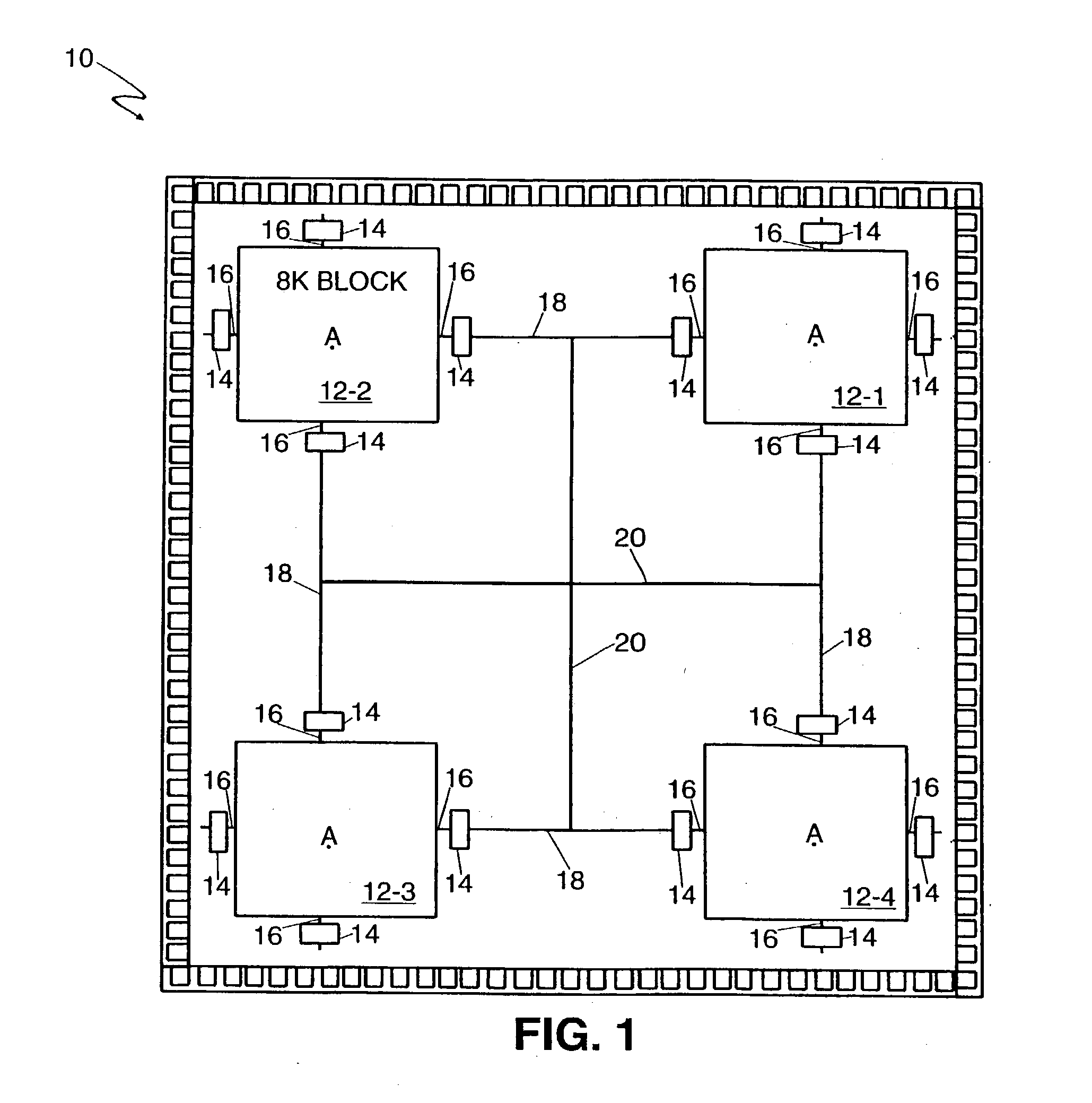

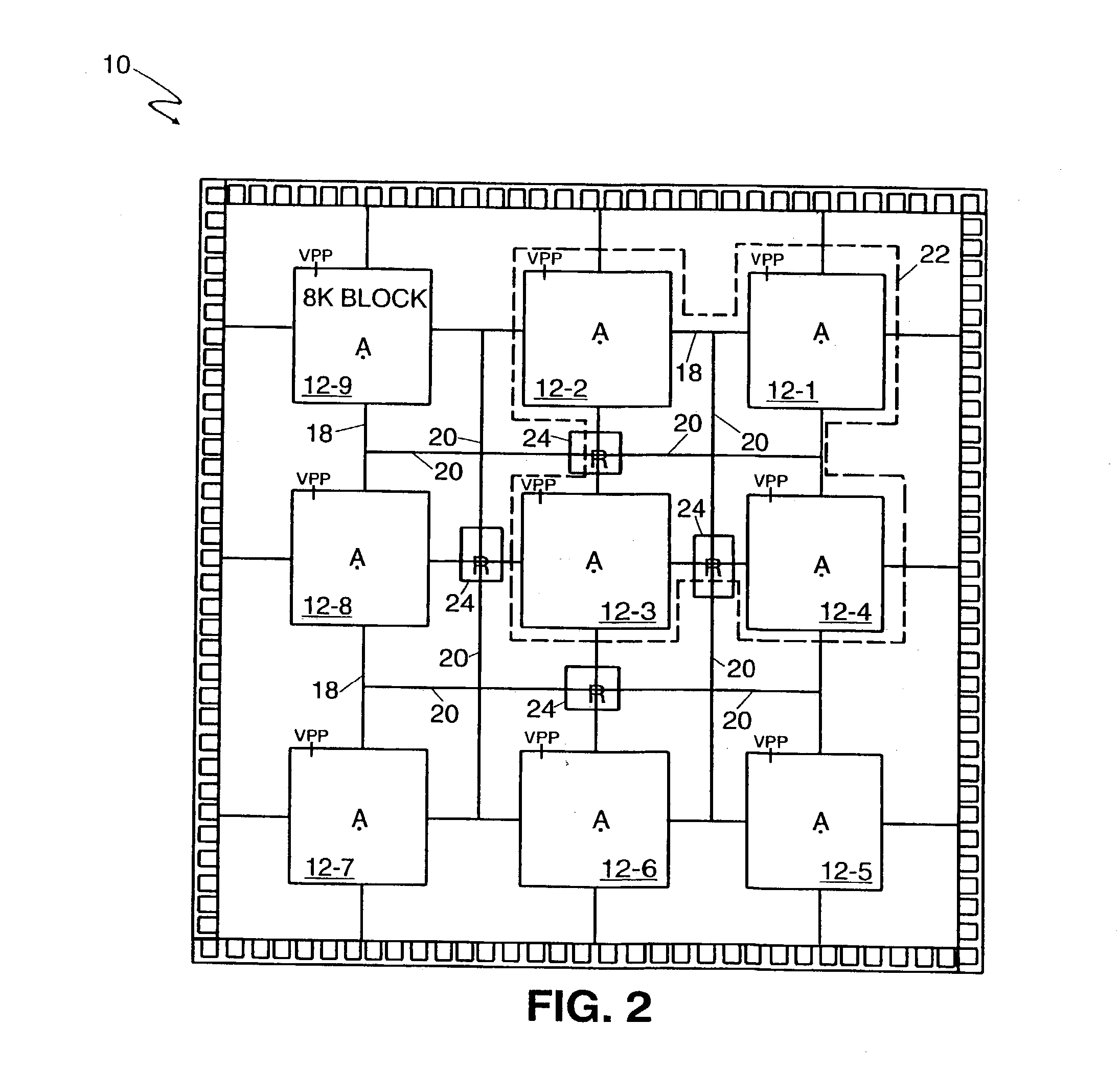

High density antifuse based partitioned FPGA architecture

InactiveUS20030201792A1Shorten programming timeReduce standby currentSolid-state devicesLogic circuits using elementary logic circuit componentsFpga architectureHigh density

An antifuse based FPGA architecture is partitioned into repeatable blocks of logic modules to reduce the programming time of the array and to minimize parasitic capacitance and current leakage in the array. With repeatable blocks the size of the FPGA may be made larger with minimal changes to the architecture. Disposed along the edges of each repeatable block are bidirectional buffer banks for connecting to adjacent blocks and to an interconnect matrix that is connectable to blocks other than adjacent blocks. Disposed at regular intervals in the interconnect matrix are repeater buffers to limit the number of antifuses on a given track of the interconnect matrix, to minimize RC delay, and to avoid violating the Ipeak limit.

Owner:MICROSEMI SOC

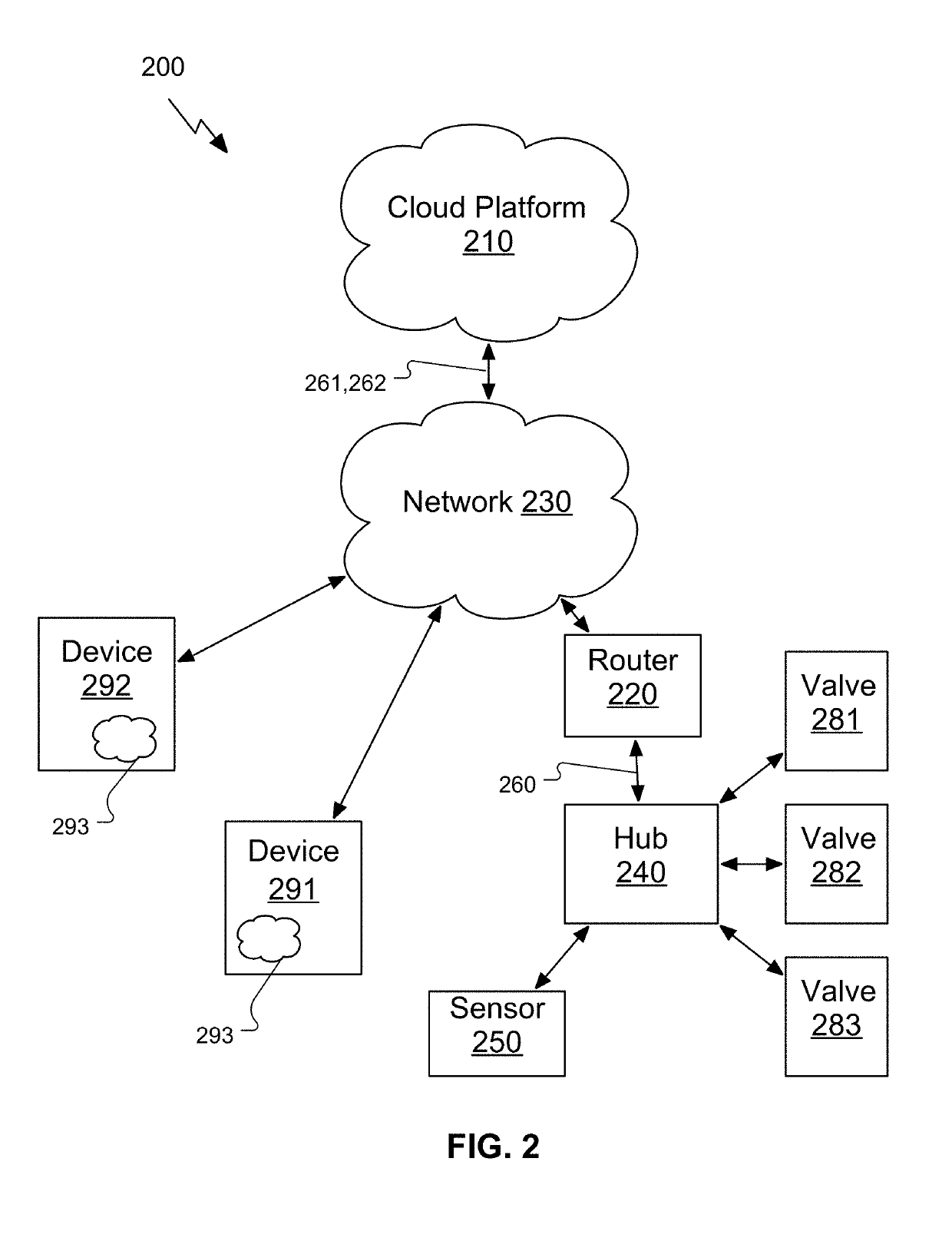

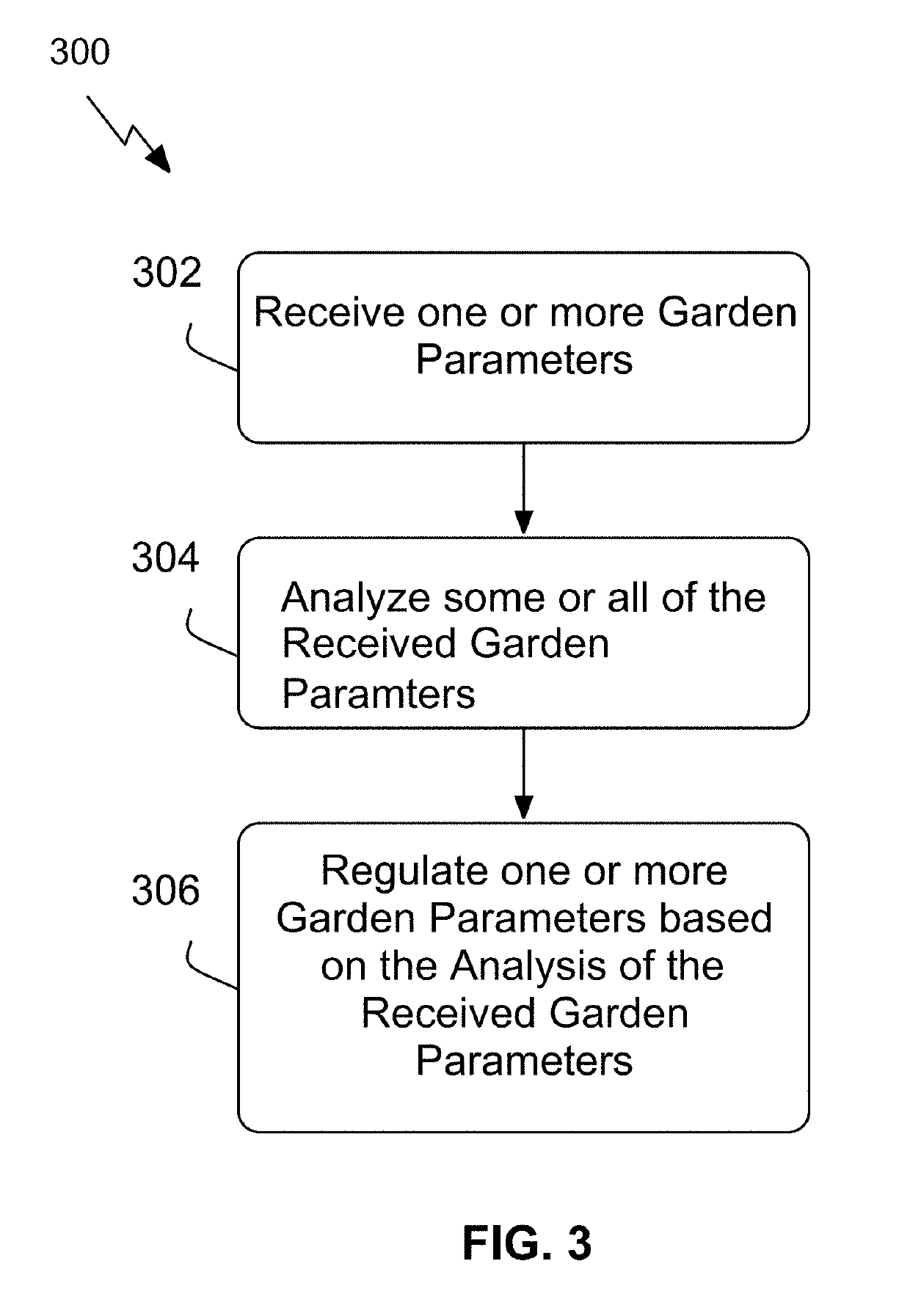

Sensing system and method for use in electromagnetic-absorbing material

ActiveUS11445274B2Minimize currentMinimize voltagePulse generatorParticular environment based servicesCarrier signalEnvironmental engineering

Owner:GROGURU

Sensing system and method for use in electromagnetic-absorbing material

ActiveUS10502865B2Minimize currentMinimize voltageProgramme controlTransmission systemsAudio power amplifierCarrier signal

Owner:GROGURU

Uninterruptible Power Supply

InactiveUS20170331327A1Minimize currentPrevent rotational energy transferEmergency power supply arrangementsFlywheelDynamo

An uninterruptible power supply (UPS) is disclosed, comprising an electric generator, a flywheel configured to store a rotational energy and coupled to the electric generator through a gear mechanism, a mechanical motor mechanically coupled to rotate the flywheel, and a control unit. The control unit is configured, upon detecting utility line failure, to cause the gear mechanism to transfer rotational energy stored in the flywheel to the electric generator and to cause the mechanical motor to rotate the flywheel so as to preserve the flywheel ability to transfer rotational energy to the electric generator until a backup generator achieves the adequate speed for driving the electric generator.

Owner:ENERGO ON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com