Method for modifying wear resistance and corrosion prevention of metal component surface

A technology for the surface of metal components and workpieces, which is applied in the field of preparation of wear-resistant and anti-corrosion protective layers on the surfaces of metal components, can solve the problems of wear and corrosion, short service life, etc., and achieves the effects of low cost, reduced production cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

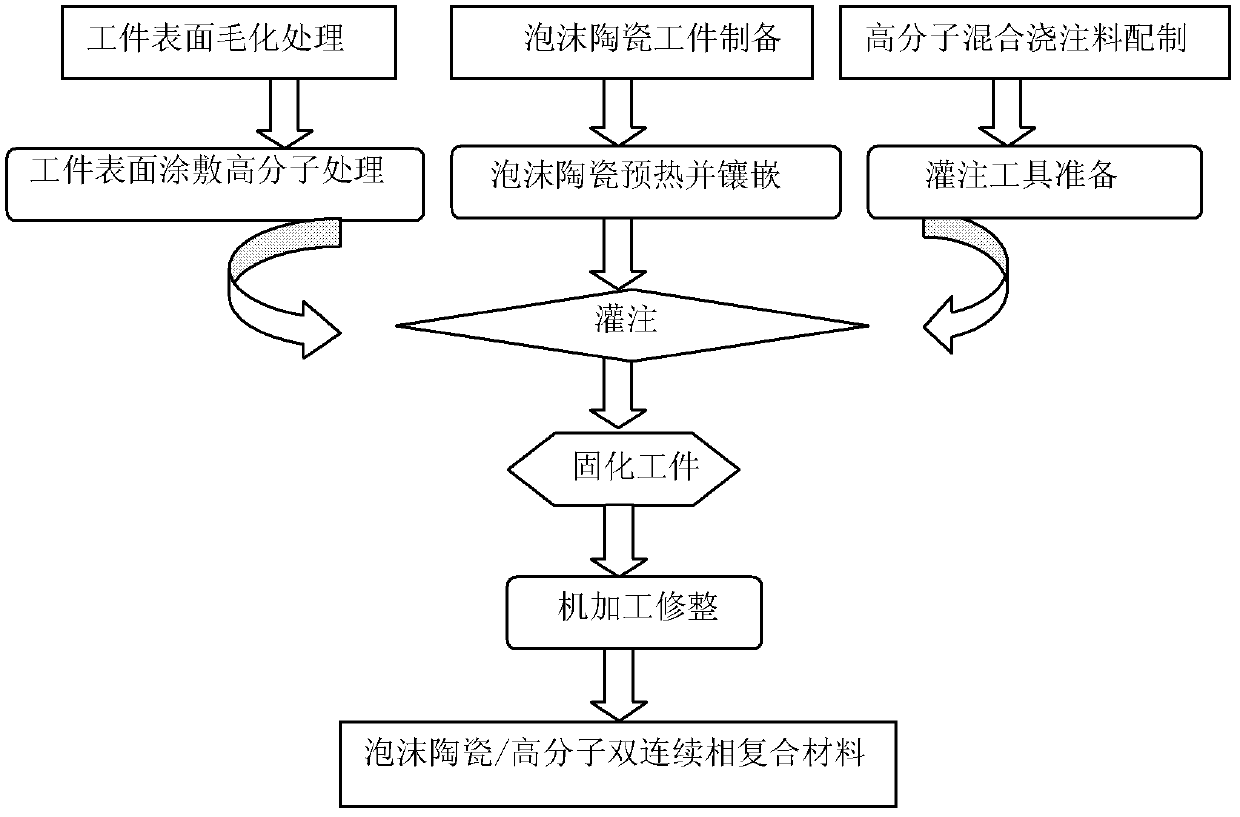

Method used

Image

Examples

Embodiment 1

[0095] Example 1: Wear-resistant and anti-corrosion modification of the inner surface of the metal straight pipe

[0096] ①Texture treatment of inner surface of steel pipe

[0097] Select outer diameter the inside diameter of For the 45# steel pipe with a length of 200mm, the inner surface of the steel pipe is first roughened by sandblasting, and then the inner surface of the steel pipe is machined with annular shallow grooves with a distance of 10mm and a depth of 0.5mm. The significance of surface roughening is to improve the interface bonding. Quality, improve interface bonding strength.

[0098] ② Preparation of foamed silicon carbide ceramic tube

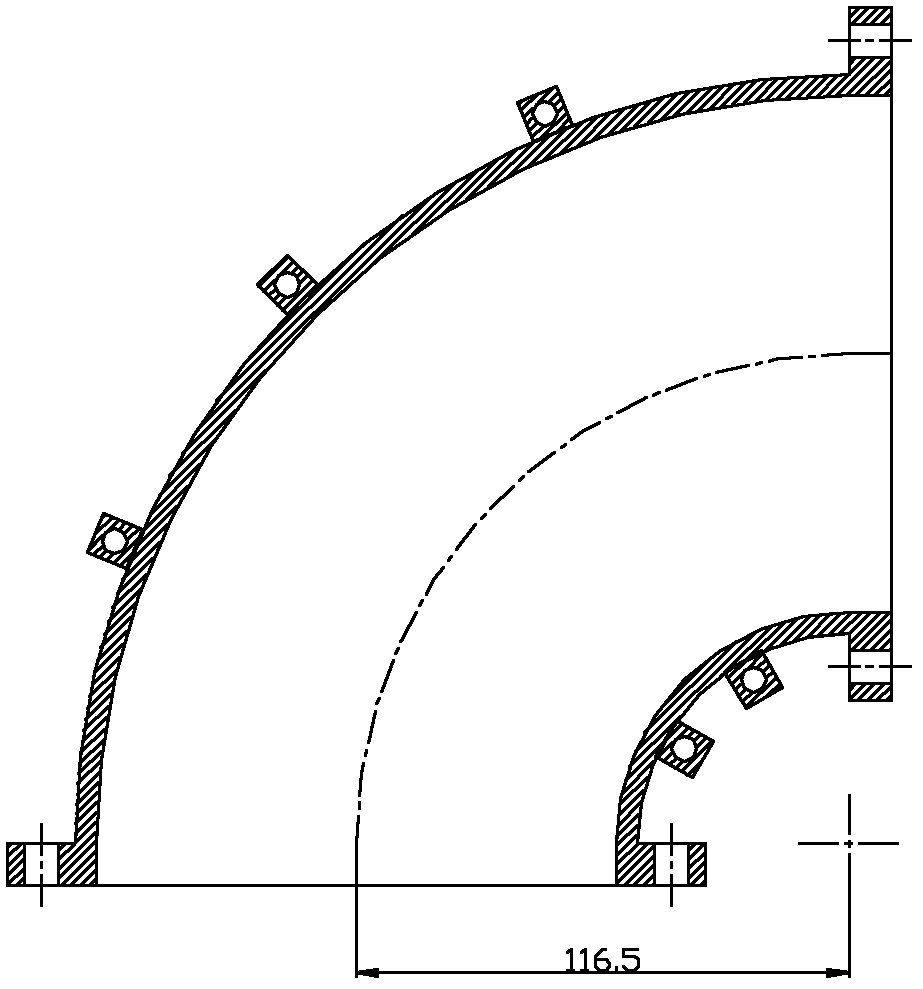

[0099] According to the patent: a high-strength silicon carbide foam ceramics and its preparation method (ZL00110479.9), a silicon carbide foam ceramic tube is prepared, the average size of the mesh is 2.0mm, the volume fraction is 50%, and the size is: outer diameter the inside diameter of The length is 100mm two sect...

Embodiment 2

[0111] Example 2: Wear-resistant and anti-corrosion modification of the inner surface of the metal straight pipe

[0112] The difference from Example 1 lies in the preparation of the resin polymer mixed castable.

[0113] Epoxy resin, SiC micropowder (particle size: 200nm), curing agent polyamide, and diluent acetone were formulated into a slurry according to a certain ratio (Table 2), and stirred evenly.

[0114] Table 2 Polymer mixed castables

[0115]

[0116] Practical application results show that this embodiment is applied to the desulfurization pipeline of a thermal power plant, and its service life is more than 5 times higher than that of the existing rubber lined pipe, which fully shows that the present invention can improve the service life of metal components, reduce production costs, eliminate important role in safety hazards.

Embodiment 3

[0117] Example 3: Wear-resistant and anti-corrosion modification of the inner surface of the metal straight pipe

[0118] The difference from Example 1 lies in the preparation of the polymer mixed castable.

[0119] The neoprene, curing agent, and diluent are formulated into a slurry according to a certain ratio (Table 3), and stirred evenly.

[0120] Table 3 Polymer mixed castables

[0121]

[0122] Practical application results show that this embodiment is applied to the desulfurization pipeline of a thermal power plant, and its service life is more than 5 times higher than that of the existing rubber lined pipe, which fully shows that the present invention can improve the service life of metal components, reduce production costs, eliminate important role in safety hazards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Inner diameter length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com