Extruded member of aluminum alloy excelling in flexural crushing performance and corrosion resistance and method for production thereof

A technology for extruded material and aluminum alloy, which is applied in the field of Al-Mg-Si series aluminum alloy extrusion material and its manufacturing field, can solve the problems such as the limitation of improving the bending crushing property, and improve the bending crushing property and corrosion resistance. , The effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

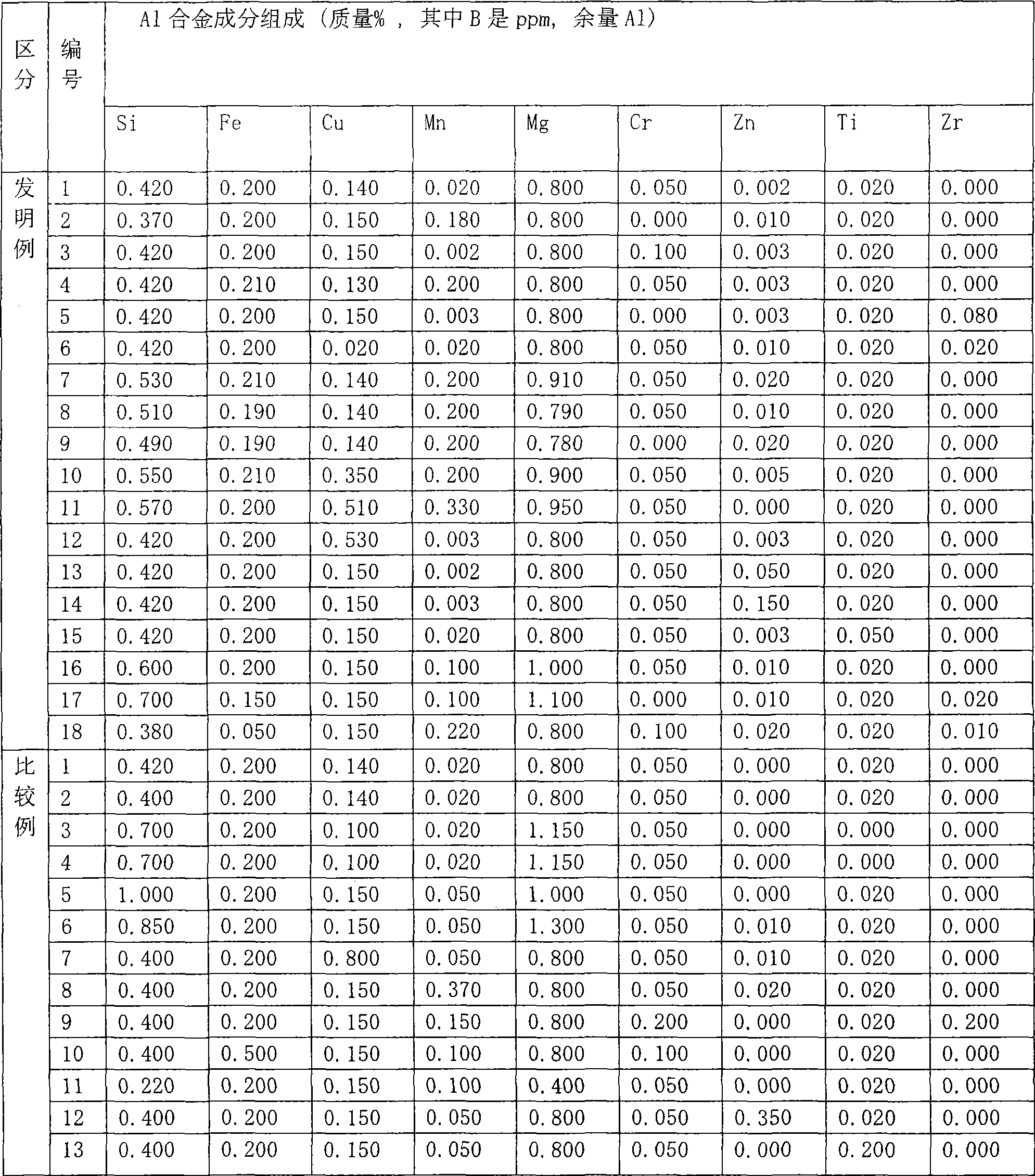

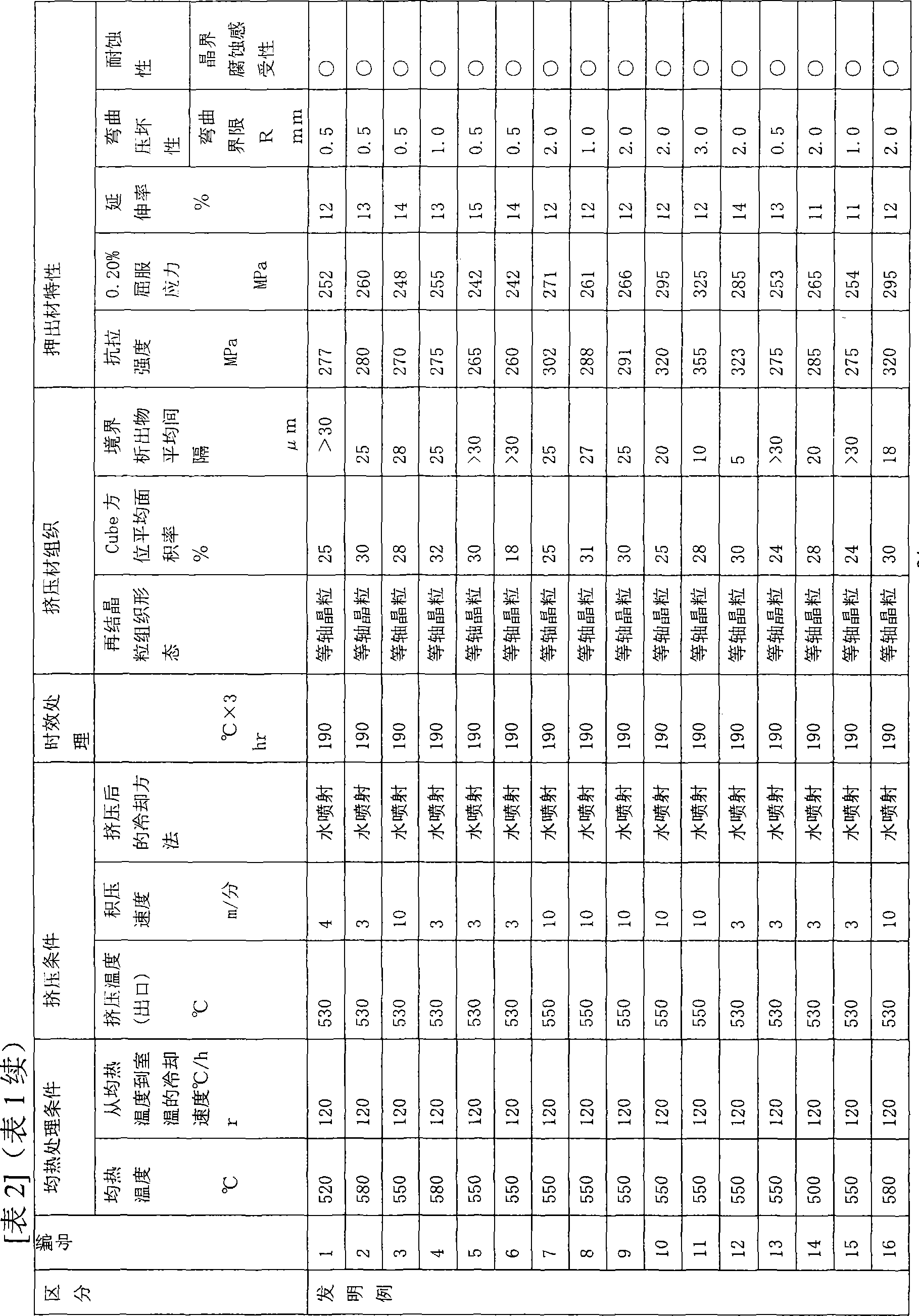

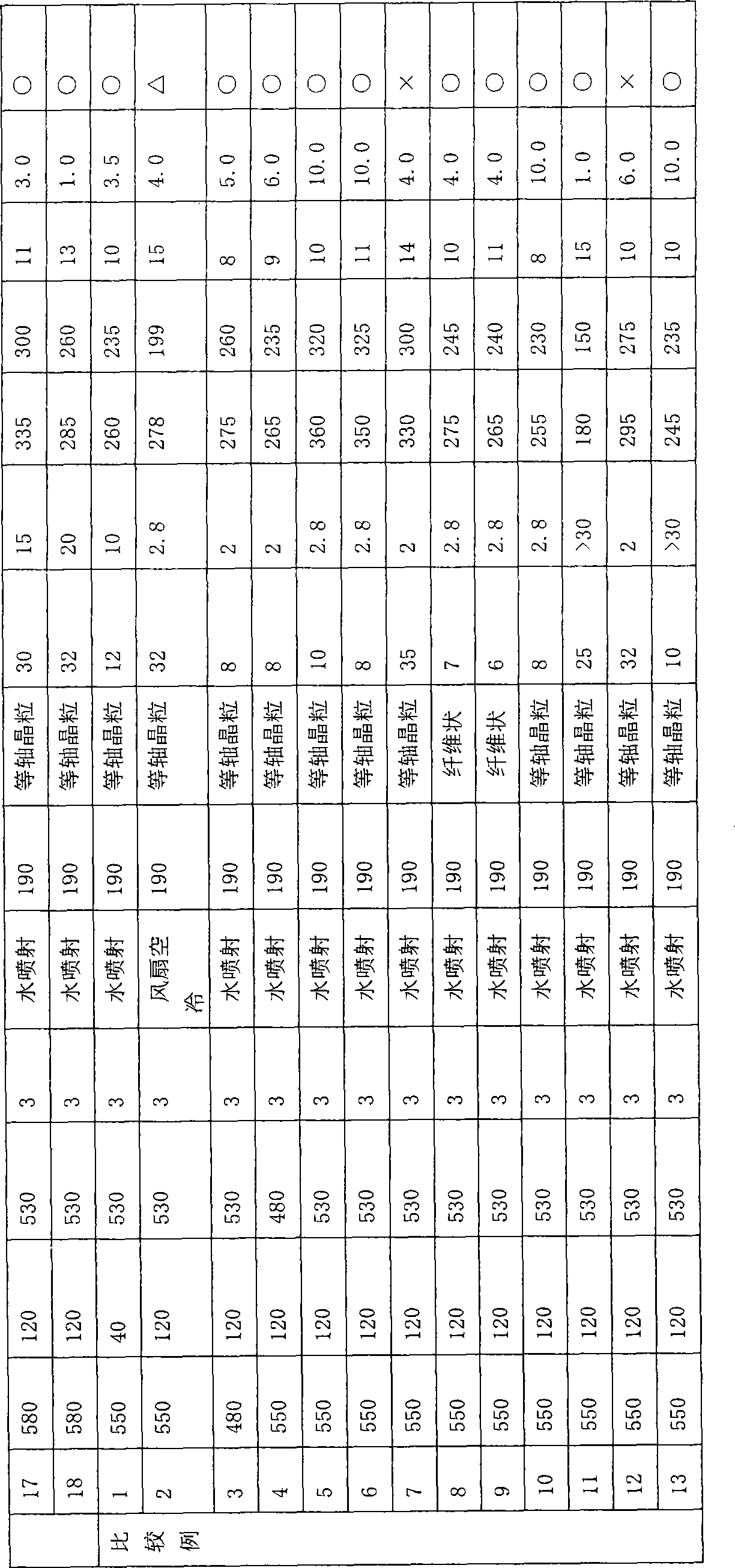

[0115] Next, examples of the present invention will be described. In the composition of each component shown in Table 1, a 6000-series aluminum alloy extruded material with Japanese cross-section was produced under the conditions shown in Table 2, and as shown in Table 2, the structure of the extruded material was investigated, and its characteristics were investigated ( Mechanical properties, bending crush resistance, corrosion resistance). In addition, in each example in Table 1 except Comparative Example 5, the contents of Mg and Si all satisfy the preferred relationship of Mg(%)≥1.73×Si(%)-0.4 or Mg(%)≥1.73×Si(%)-0.2 .

[0116] More specifically, the extruded material was produced by solution casting various billets of aluminum alloys having the compositions shown in Table 1. After the homogenization heat treatment was performed at each temperature shown in Table 2, this billet was once cooled to room temperature at the average cooling rate (° C. / hr) shown in Table 2. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com