Stainless steel with ultraviolet-proof function and preparation method thereof

An anti-ultraviolet and anti-ultraviolet coating technology, applied in the field of stainless steel, can solve the problems that stainless steel does not have anti-ultraviolet function, shorten the service life of stainless steel, and do not have sterilization function, etc., and achieve the effect of preventing loss, improving hardness and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

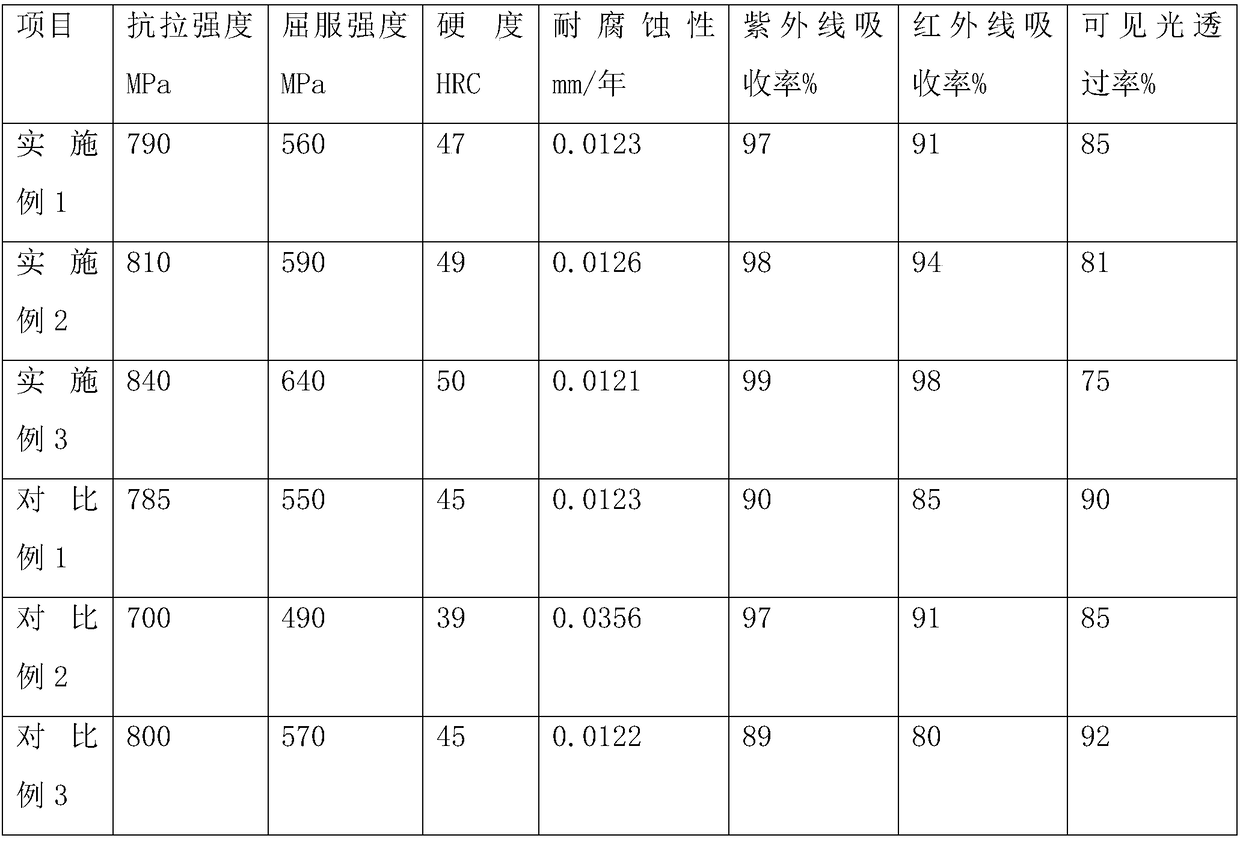

Examples

Embodiment 1

[0032] A stainless steel with anti-ultraviolet function. The stainless steel includes the following components in parts by weight: C: 0.03%, Si: 0.03%, Mn: 1.1%, P: 0.013%, S: 0.01%, Cr: 18%, Ni: 8%, N: 0.01%, Nb: 0.8%, Tl: 3%, the balance is iron and other unavoidable elements;

[0033] The stainless steel surface is coated with an anti-ultraviolet coating, and the coating includes the following components by weight: 12 parts of water-based rosin resin emulsion, 15 parts of polyethylene terephthalate, 6 parts of silver-based antibacterial masterbatch, triallyl iso 4 parts of cyanuric acid ester, 7 parts of palmimidopropyl betaine, 25 parts of anti-ultraviolet silicone oil, 5 parts of dispersant, 5 parts of dihydroxy polymethyl vinyl siloxane, 1 part of coupling agent, acidified graphite 10 parts, 35 parts of water, 5 parts of water repellent.

[0034] The preparation method of silver-based antibacterial masterbatch is as follows:

[0035] Take 5% by weight of nano-silver io...

Embodiment 2

[0050] A stainless steel with anti-ultraviolet function. The stainless steel includes the following components in parts by weight: C: 0.05%, Si: 0.06%, Mn: 1.4%, P: 0.023%, S: 0.02%, Cr: 19%, Ni: 9.5%, N: 0.03%, Nb: 1.05%, Tl: 5%, the balance is iron and other unavoidable elements;

[0051] The stainless steel surface is coated with an anti-ultraviolet coating, and the coating includes the following components by weight: 14 parts of water-based rosin resin emulsion, 17.5 parts of polyethylene terephthalate, 8 parts of silver-based antibacterial masterbatch, triallyl iso 6 parts of cyanuric acid ester, 9 parts of palmitamidopropyl betaine, 30 parts of anti-ultraviolet silicone oil, 10 parts of dispersant, 7.5 parts of dihydroxy polymethyl vinyl siloxane, 3 parts of coupling agent, acidified graphite 15 parts, 40 parts of water, 10 parts of water repellent.

[0052] The preparation method of silver-based antibacterial masterbatch is as follows:

[0053] Take 10% by weight of n...

Embodiment 3

[0068] A stainless steel with anti-ultraviolet function. The stainless steel includes the following components in parts by weight: C: 0.07%, Si: 0.009%, Mn: 1.7%, P: 0.033%, S: 0.03%, Cr: 20%, Ni: 11%, N: 0.05%, Nb: 1.3%, Tl: 7%, the balance is iron and other unavoidable elements;

[0069] The stainless steel surface is coated with an anti-ultraviolet coating, and the coating includes the following components by weight: 16 parts of water-based rosin resin emulsion, 20 parts of polyethylene terephthalate, 10 parts of silver-based antibacterial masterbatch, triallyl iso 8 parts of cyanuric acid ester, 11 parts of palmimidopropyl betaine, 35 parts of anti-ultraviolet silicone oil, 15 parts of dispersant, 10 parts of dihydroxy polymethyl vinyl siloxane, 5 parts of coupling agent, acidified graphite 20 parts, 45 parts of water, 15 parts of water-repellent agent.

[0070] Preferably, the preparation method of the silver-based antibacterial masterbatch is as follows:

[0071] Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com