Coated steel bar and preparation method thereof

A coating and steel bar technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., to achieve the effects of good film-forming properties, improved hardness, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

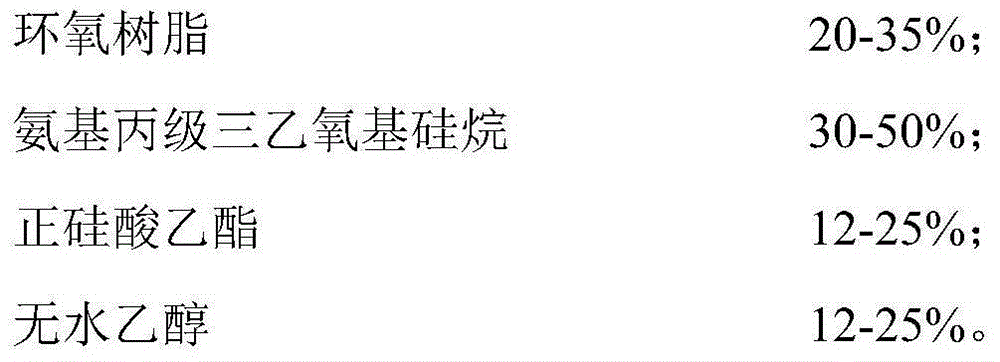

[0031] The coating steel bar of this embodiment, the coating material on its surface is made of following components and weight percentage thereof:

[0032]

[0033] The epoxy resin is epoxy resin GY2600 from CIBA Company, Eq=0.25.

[0034] The mass content of the aminopropyl triethoxysilane is more than or equal to 98%.

[0035] The mass content of the tetraethyl orthosilicate is 28%.

[0036] According to the above ratio, mix epoxy resin, tetraethyl orthosilicate TEOS, and ethanol (transparent liquid) into the glass reactor, stir pneumatically, and circulate water at a temperature of 20-30°C. After constant temperature, start to add aminosilane (aminopropyl Grade triethoxysilane), after a few minutes (can be 1-10 minutes), the temperature rises to 35°C, and the rate of addition is controlled to keep the temperature below 40°C for reaction, and then keep warm for 4 hours after the dropwise addition to obtain the above coating Material.

[0037] Then follow the steps bel...

Embodiment 2

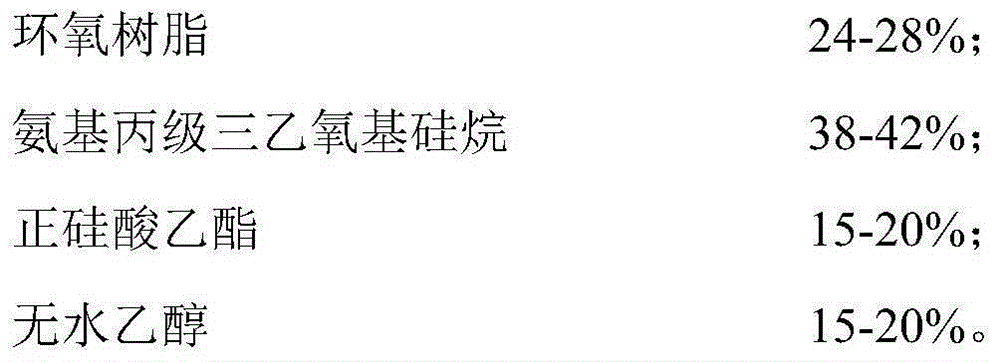

[0043] The coating steel bar of this embodiment, the coating material on its surface is made of following components and weight percentage thereof:

[0044]

[0045] The epoxy resin is epoxy resin GY2600 from CIBA Company, Eq=0.25.

[0046] The mass content of the aminopropyl triethoxysilane is more than or equal to 98%.

[0047] The mass content of the tetraethyl orthosilicate is 28%.

[0048] Follow the steps below to apply the above coating materials to the surface of the reinforcement:

[0049] Step 1, sandblasting to make the surface roughness of the steel bar 3.0-3.5 μm;

[0050] Step 2, remove the sand and dust on the surface of the steel bar to ensure that the surface of the workpiece is clean and free of oil or other foreign matter;

[0051] Step 3, uniformly coat the surface of the steel bars treated in the above step 2 with a dry film thickness of 5-15 μm;

[0052] Step 4: Curing at room temperature for 0.5-1 hour, and then keeping at 150°C-180°C for 30-60 mi...

Embodiment 3

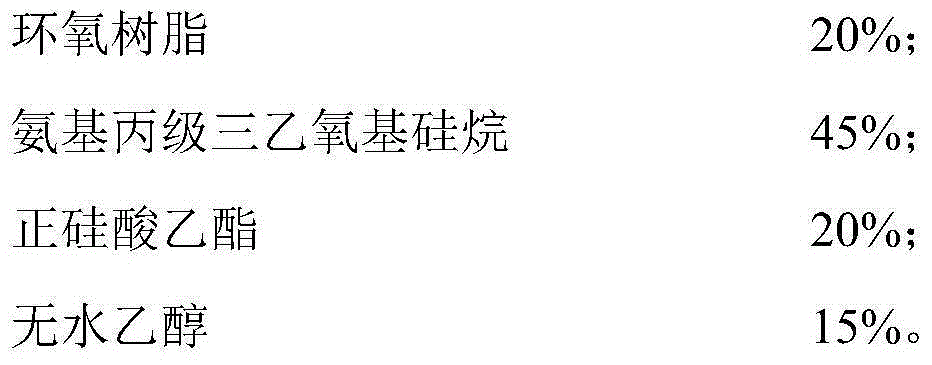

[0054] The coating steel bar of this embodiment, the coating material on its surface is made of following components and weight percentage thereof:

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com