Architectural ornament material, manufacturing method and manufacturing equipment thereof

A technology for building decoration materials and production equipment, applied in the field of building decoration materials, can solve problems such as easy falling off and inability to play a role, and achieve the effects of reducing bearing capacity, improving human health, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

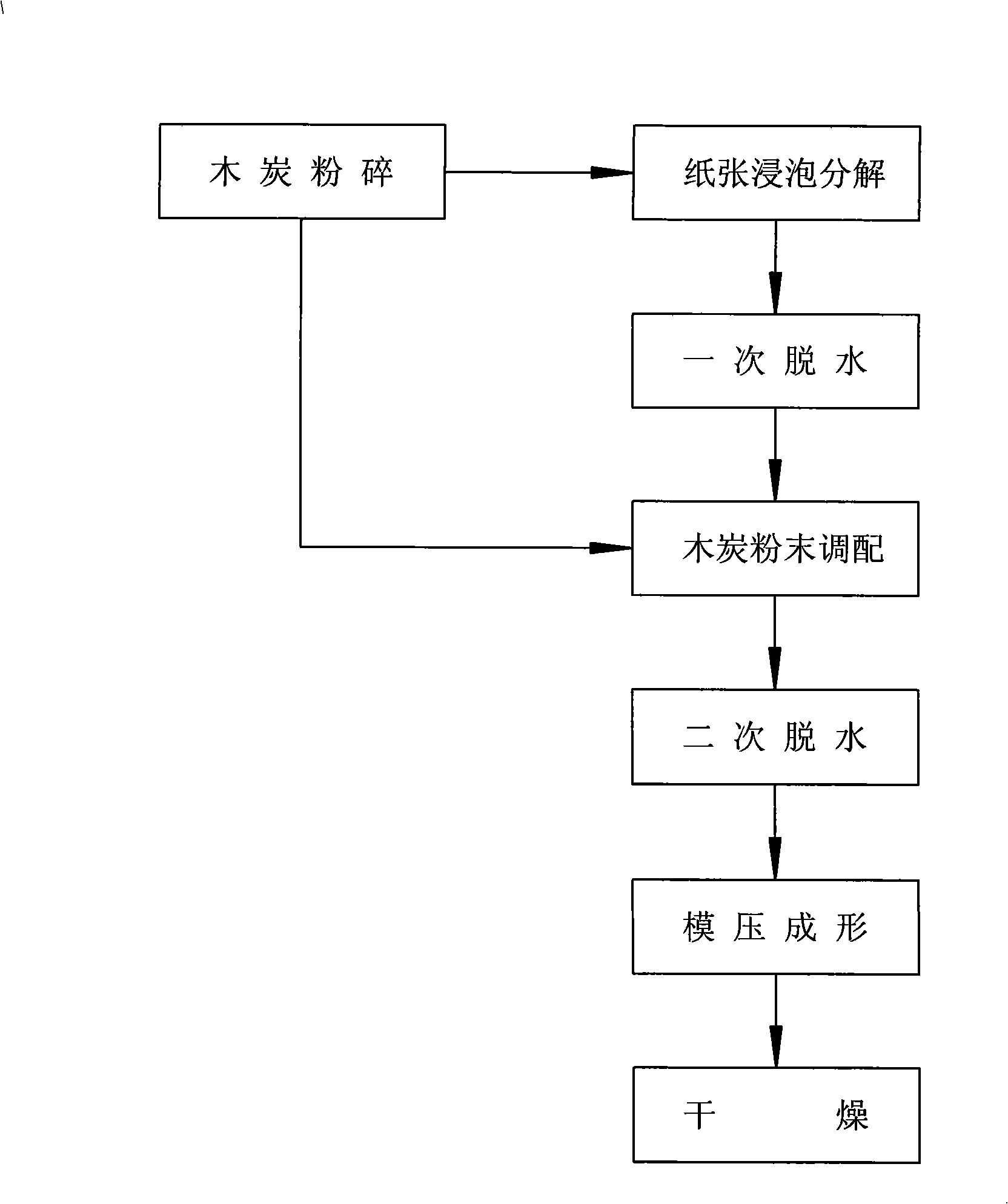

[0035] The processing flow of this embodiment is as follows image 3 Shown:

[0036] a. Take 100g of paper, mix it with about 5-10kg of water phase, make the paper completely swell and become loose, and gradually decompose. In general, recycled printing or packaging paper can be used, but high-quality paper or finished pulpboard can also be used. Although the use of high-quality paper can improve the quality of the product, it will increase the manufacturing cost, so waste paper is mainly used in industrial production. In this way, while ensuring product performance, the effect of resource recycling can also be achieved. After the paper is completely decomposed, it is dehydrated by means of water control or filter screen filtration, leaving only the water-containing paper fibers. If you use high-quality paper, you don't need to completely remove the water, just remove it until the residual water reaches 2-3kg. However, if recycled waste paper is used, it needs to be comple...

Embodiment 2

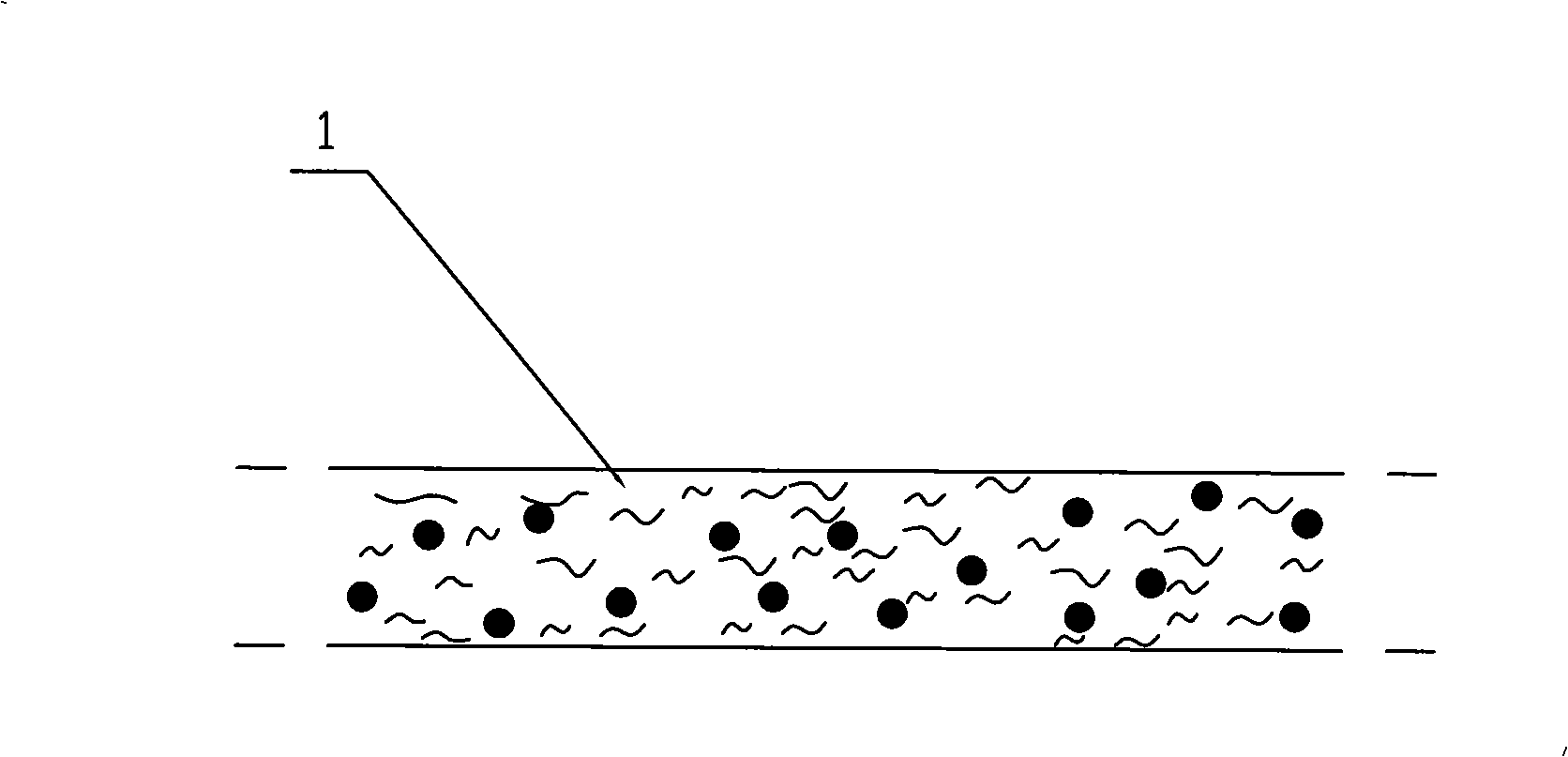

[0042] The method flow is as follows Figure 4 Shown: the step of processing method is the same as embodiment 1, but needs to add loess or volcanic rock powder in step b, to reach the requirement of fire prevention, the addition amount of loess or volcanic rock powder is 300 grams. After processing, it can be formed as figure 1 The shown building decoration material is composed of paper fiber, charcoal powder and loess or volcanic stone powder as the base 1 .

Embodiment 3

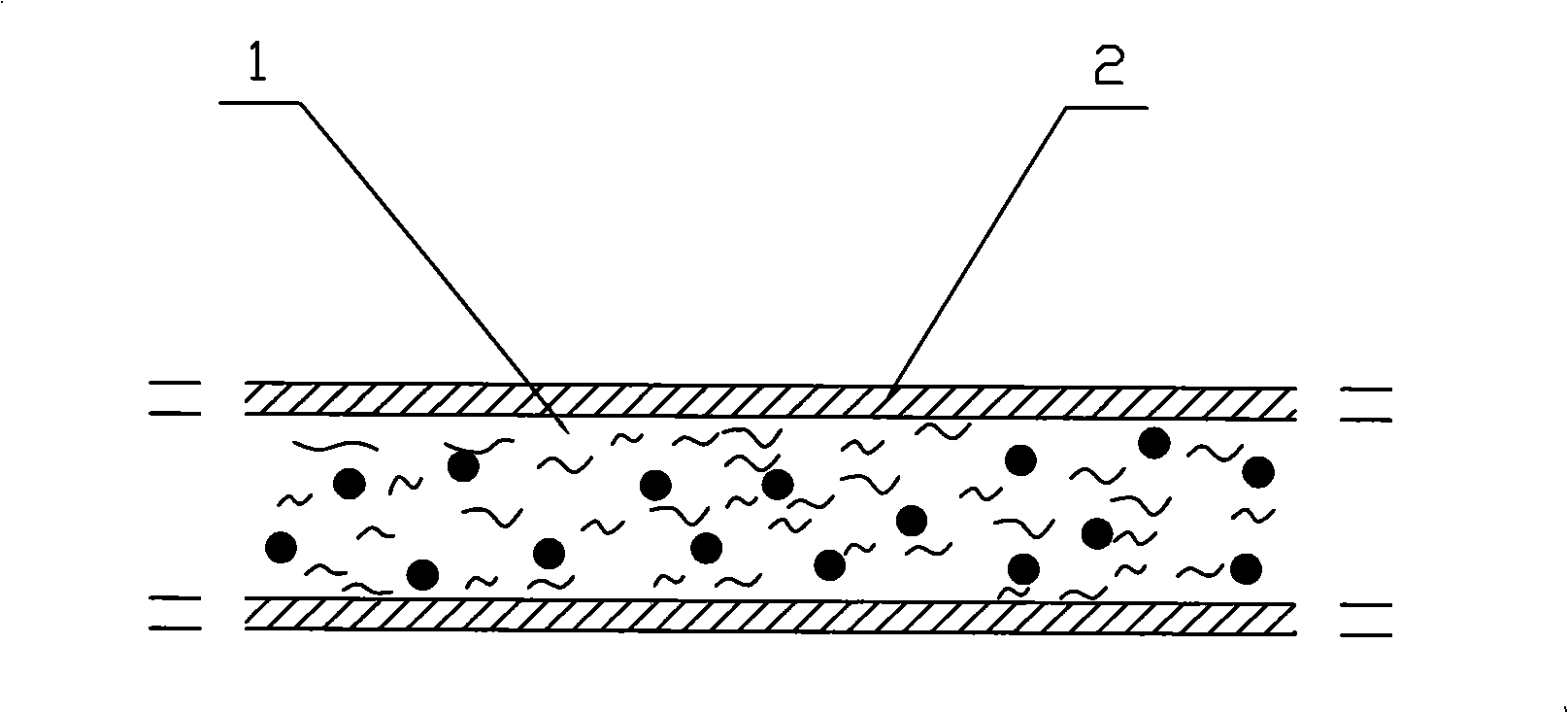

[0044] The method flow is as follows Figure 5 As shown: the steps of the processing method are basically the same as in embodiment 1 or embodiment 2, except that a decorative layer 2 is adhered to the side of the blank of the substrate 1 formed in step c, such as the upper and lower surfaces of the plate, the outer surface of the block, etc. The decorative layer 2 can be decorative paper, woven cloth or non-woven cloth, which can prevent the leakage of charcoal powder while protecting the surface and strengthening the hardness, and complete the treatment of the external packaging. After processing, it can be formed as figure 2 The shown building decoration material is composed of paper fiber, charcoal powder and loess or volcanic stone powder and has a decorative layer 2 on the surface of a substrate 1 .

[0045]The production equipment shown in Figure 6 can be used, that is, a hopper 3 is provided, and a mesh conveyor belt 5 driven by a pair of conveying rollers 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com