Biohaydite filter material and its prepn

A technology of biological ceramsite and filter material, which is applied in the direction of ceramic products, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of insufficient surface roughness, small amount of microbial immobilization, and low immobilization rate, and achieve aeration The effect of small bubble resistance, high hardness, and improved degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

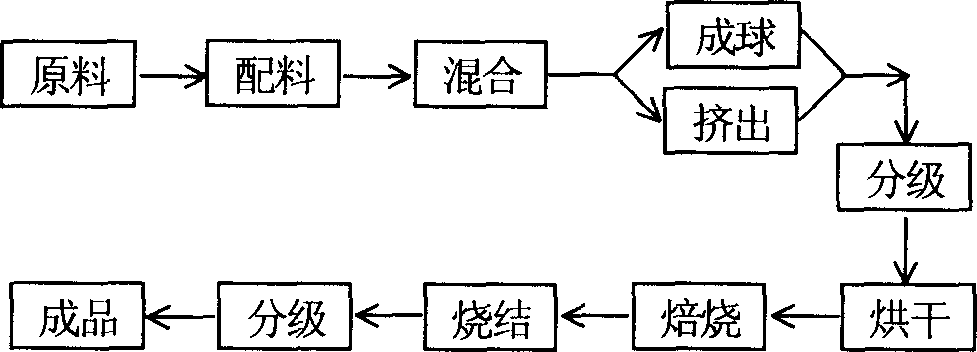

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment 1: The bio-ceramsite filter material of this embodiment is composed of 30-40wt.% shale, 30-45wt.% fly ash, 10-20wt.% sludge, 3-8wt.% pore former and 0.5 ~2wt.% binder is made, in which the chemical composition of shale, fly ash and sludge is shown in Table 1.

[0009]

[0010] In this embodiment, the pore-forming agent is coal powder; the binder is carboxymethyl cellulose.

specific Embodiment approach 2

[0011] Specific embodiment two: this embodiment is different from specific embodiment one in that the bio-ceramsite filter material is composed of 34wt.% shale, 35wt.% fly ash, 15wt.% sludge, and 5wt.% pore former And 1wt.% binder made.

specific Embodiment approach 3

[0012] Specific embodiment three: this embodiment is different from specific embodiment one in that the bio-ceramsite filter material is composed of 30wt.% shale, 40wt.% fly ash, 20wt.% sludge, and 8wt.% pore former And 2wt.% binder made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com