Preparation method of graphene composite material for detecting pressure change with high sensitivity

A sensitive detection and composite material technology, which is applied in the field of graphene composite material preparation, can solve the difficulty of single-layer graphene film and achieve the effect of improving hardness and related performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

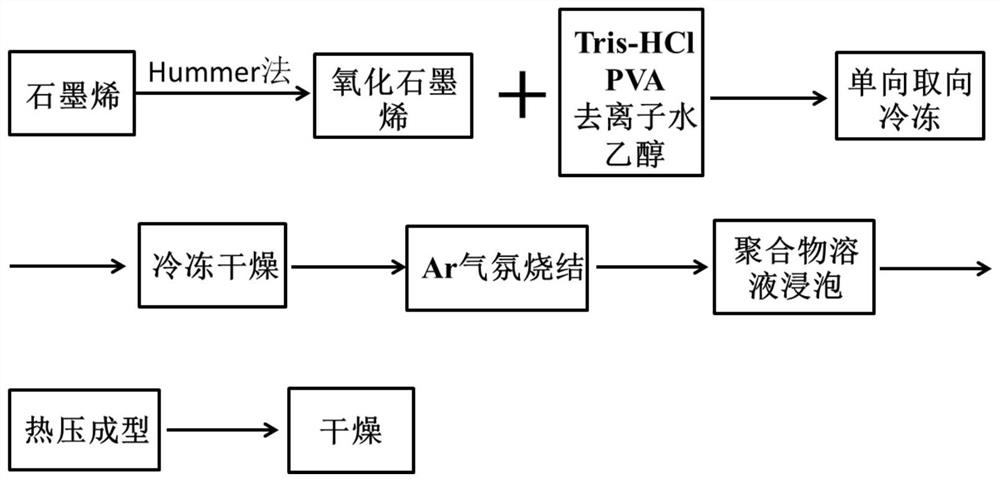

[0029] The invention provides a method for preparing a graphene composite material with high sensitivity to detect pressure changes, the process flow diagram of the preparation method is as follows figure 1 Shown, the component of the graphene oxide suspension used in this preparation method is as follows table 1:

[0030] Table 1 graphene oxide suspension component list

[0031]

[0032] Aqueous polymer solution:

[0033] ①10wt% polyetherimide / dichloromethane (the mass ratio of PEI / DCM is 1:10) solution

[0034] ②10wt% gelatin aqueous solution

[0035] ③10wt% polyvinyl alcohol (PVA) aqueous solution.

Embodiment 1

[0037] Step 1: first prepare graphene oxide from graphene by the Hummer method. The specific method is to add 15g of potassium permanganate powder and 5g of graphene powder in 150ml of concentrated sulfuric acid and stir in an ice-water bath (temperature is lower than 20°C). After 2h oxidation reaction, obtain brown graphene flakes with derivatized carboxylic acid groups on the edge and mainly phenolic hydroxyl groups and epoxy groups on the plane;

[0038] Step 2: Mix graphene oxide, Tris-HCl, PVA and deionized water and then carry out magnetic stirring to prepare graphene oxide containing 30% volume fraction, Tris-HCl with 1% volume fraction, and 1% volume fraction The PVA and the graphene oxide suspension of deionized water with a volume fraction of 68%, then add ethanol and stir;

[0039] Step 3: Perform one-way rapid freezing of the graphene oxide suspension after adding ethanol in a one-way liquid nitrogen freezing device, and put it into a freeze dryer for drying after ...

Embodiment 2

[0047] Step 1: first prepare graphene oxide from graphene by the Hummer method. The specific method is to add 15g of potassium permanganate powder and 5g of graphene powder in 150ml of concentrated sulfuric acid and stir in an ice-water bath (temperature is lower than 20°C). After 2h oxidation reaction, obtain brown graphene flakes with derivatized carboxylic acid groups on the edge and mainly phenolic hydroxyl groups and epoxy groups on the plane;

[0048] Step 2: Mix graphene oxide, Tris-HCl, PVA and deionized water and then carry out magnetic stirring to prepare graphene oxide containing 30% volume fraction, Tris-HCl with 1% volume fraction, and 1% volume fraction The PVA and the graphene oxide suspension of deionized water with a volume fraction of 68%, then add ethanol and stir;

[0049] Step 3: Perform one-way rapid freezing of the graphene oxide suspension after adding ethanol in a one-way liquid nitrogen freezing device, and put it into a freeze dryer for drying after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com