Wheat cleaning and classifying process for flour milling of stone grinder

A wheat and process technology, applied in the direction of solid separation, grain processing, grain milling, etc., can solve the problems of not applying wheat cleaning and grading and grading processing, affecting the effect of milling process and flour quality, and large differences in the quality of materials entering the mill. , to achieve the effect of improving the grinding effect and flour extraction rate, improving processing accuracy and food safety, and reducing bran stars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

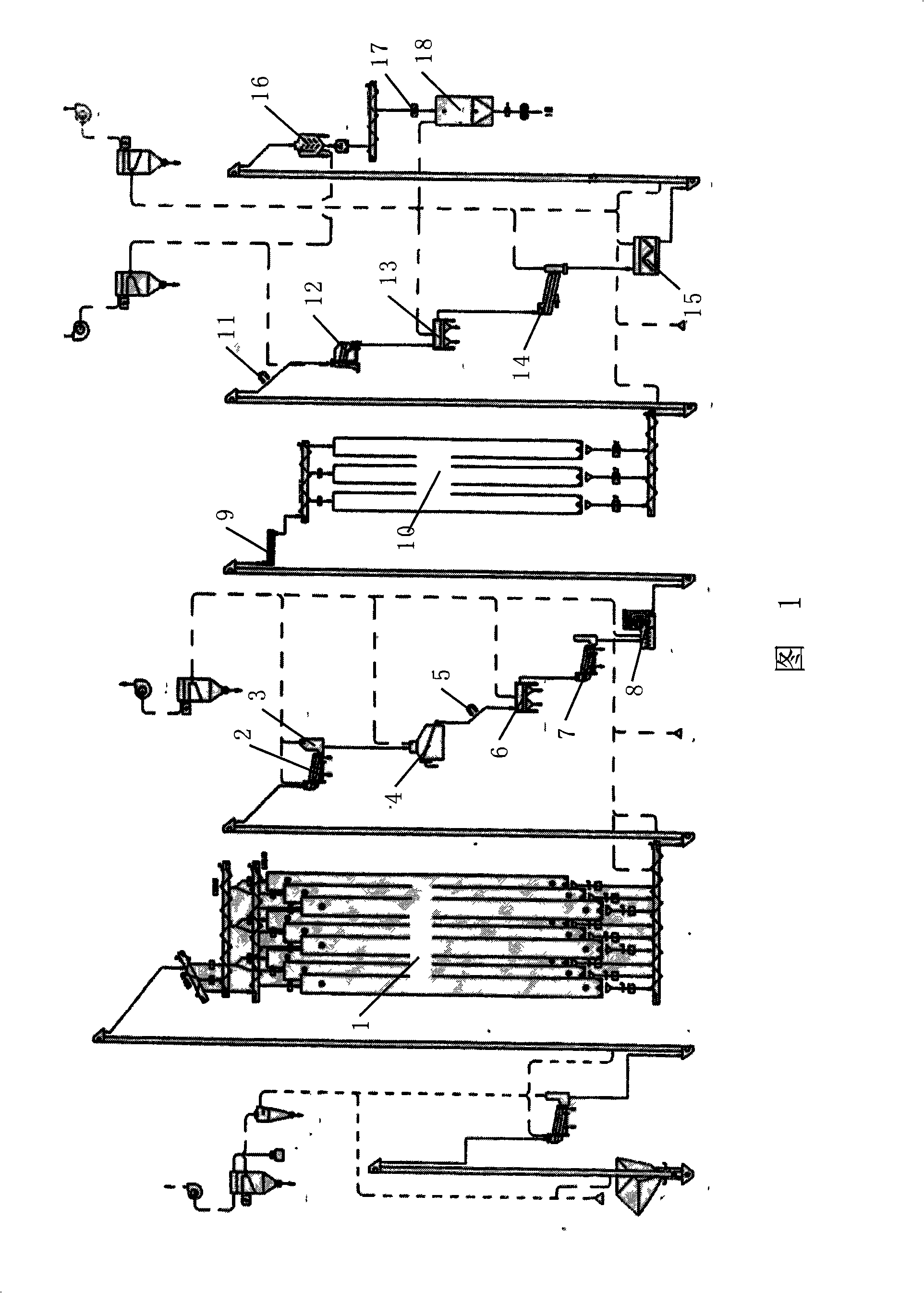

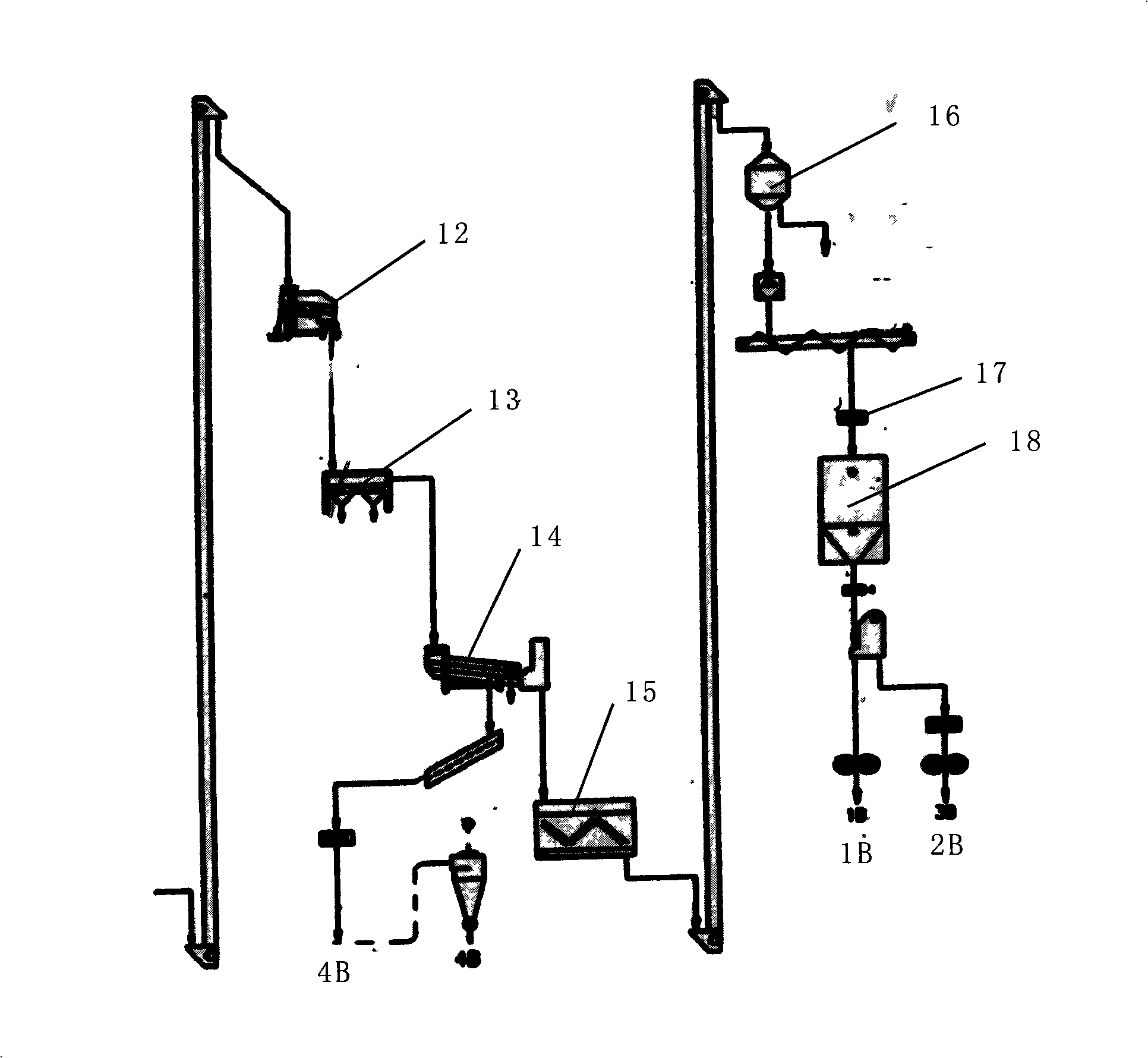

[0016] The stone milling cleaning process of the present invention adopts three sieves, two dozen, two destoners, three magnetic separations, one wheat washing, one wheat brushing with winnowing, and uses classification specific gravity destoner, suction separator and The working principle of the screening equipment is to reasonably clean and grade the wheat.

[0017] The process is to process the wheat that meets the quality of flour processing through the raw grain receiving system, the rough wheat cleaning system, the wheat conditioning system and the wheat cleaning system.

[0018] details as follows:

[0019] First, the wheat that meets the quality of flour processing is removed from the raw grain receiving system to remove large impurities and some impurities and dust, and then enters the wool wheat warehouse 1 for use, and then the wheat of different varieties enters the wool wheat cleaning system after reasonable matching: that is, firstly After the wool wheat is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com