Antistatic poly vinyl chloride (PVC) conveyer belt

An antistatic and conveyor belt technology, applied in the direction of conveyors, transportation and packaging, synthetic resin layered products, etc., can solve the problems of large amount of antistatic agent and low utilization rate of antistatic agent, and achieve low cost and strong market The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

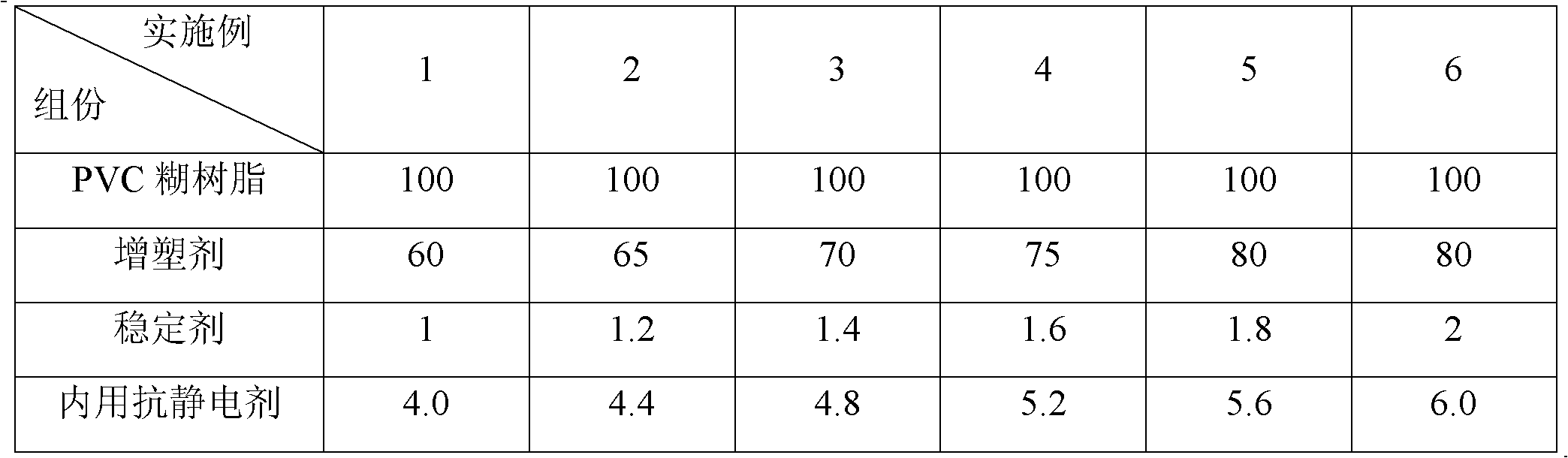

Examples

Embodiment Construction

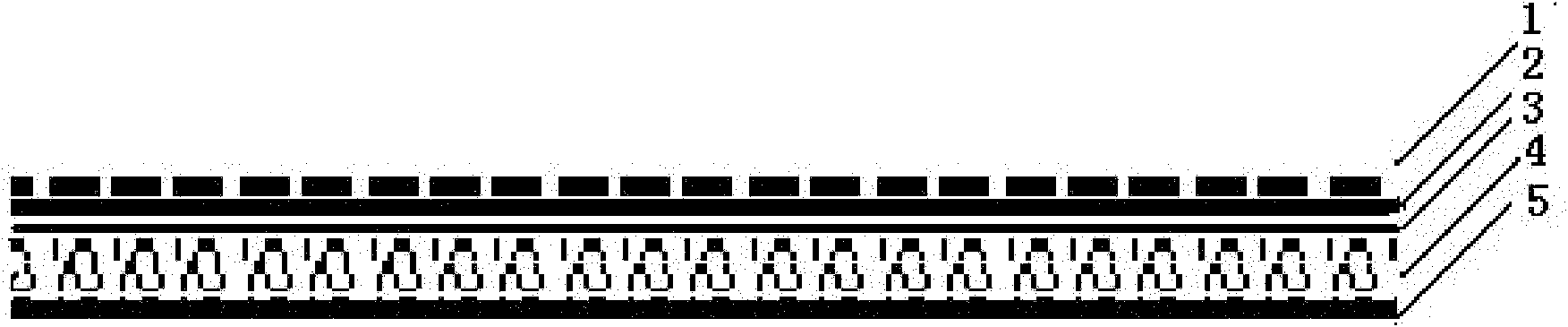

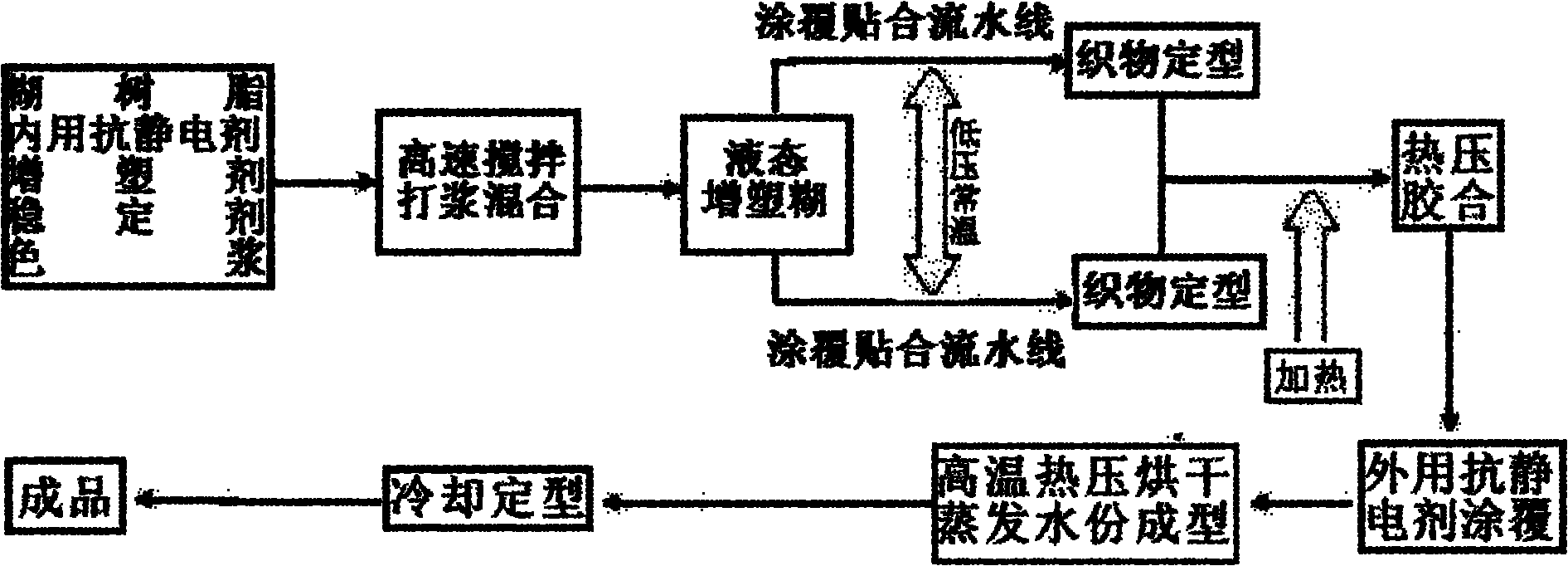

[0014] like figure 1 The shown antistatic PVC conveyor belt, from top to bottom, is an external antistatic agent coating 1, an antistatic coating layer 2, a surface layer 3, a bonding layer 4 and a bottom layer 5, and its manufacturing process is as follows figure 2 shown, where:

[0015] The base material of the surface layer 3 is a fabric doped with 5-10wt% conductive fibers. First, the fabric is shaped, and the surface of the shaped fabric is primed with PVC paste resin; then the upper surface is coated with PVC paste resin containing an internal antistatic agent to form Antistatic coating layer 2, the lower surface is coated with adhesive, and the adhesive is preferably PVC303 adhesive produced by Dongguan Feichuangda Technology Co., Ltd.;

[0016] The base material of the bottom layer 5 is made of fiber fabric, first the fabric is shaped, the surface of the shaped fabric is primed with PVC paste resin, and then the upper surface is coated with PVC303 adhesive;

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com