Plastic-free environment-friendly isolation paper, plastic-free environment-friendly release paper as well as preparation method of plastic-free environment-friendly isolation paper and plastic-free environment-friendly release paper

A technology of release paper and release paper, which is applied in the field of papermaking, can solve the problems of release agent consumption, insufficient production efficiency of release effect, difficulty in meeting production and economic benefits, low biodegradability, etc., and achieve good flatness , high production efficiency and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

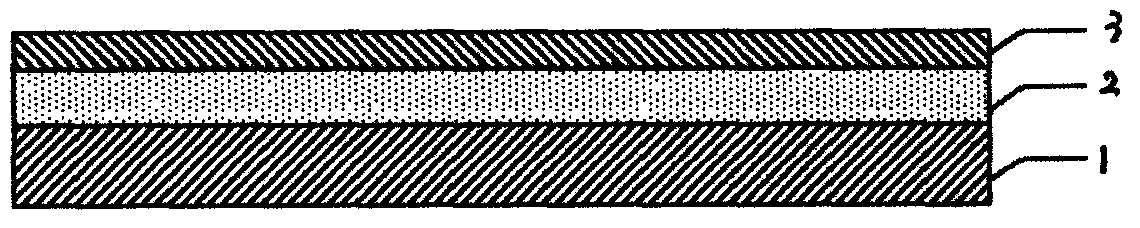

[0043] Such asfigure 1 As shown, the release paper of the present invention is composed of a base paper layer 1 , a precoat layer 2 and a release layer 3 . The base paper layer is conventional 30-60g / m 2 Low weight thin paper (such as release paper, etc.) or 50 ~ 200g / m 2 Cultural paper (such as double-adhesive paper, etc.), the technical indicators are not high.

[0044] The pre-coat is prepared by the following weight of raw materials: water 70g, pigment: kaolin 110g, dispersant: sodium polyacrylate 3g, lubricant: calcium stearate 2g, adhesive: carboxylated styrene-butadiene latex 25g, auxiliary agent: non-silicon Antifoaming agent 0.3g, polyacrylic acid thickener 0.8g. The preparation method of the pre-coat paint is to first add water, dispersant and pigment to disperse at high speed, then add lubricant, adhesive and auxiliary agent, and then mix. According to the characteristics of base paper, kaolin with low price and good covering performance is used as the main compo...

Embodiment 2

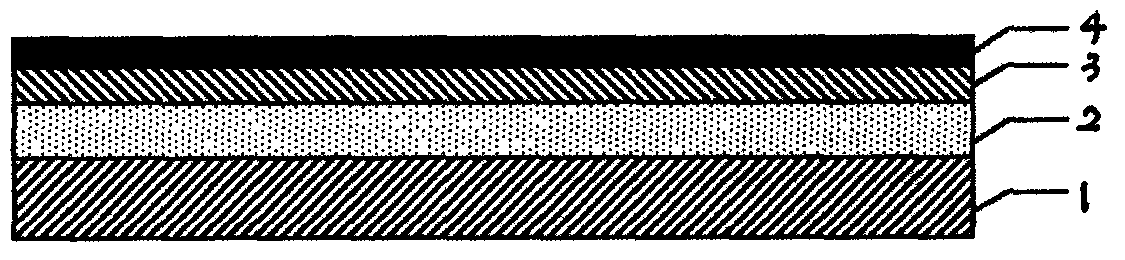

[0054] Such as figure 2 As shown, the release paper of the present invention is composed of a base paper layer 1, a precoat layer 2, an isolation layer 3 and a silicone oil layer 4. The base paper layer is conventional 30-60g / m 2 Low weight thin paper (such as release paper, etc.) or 50 ~ 200g / m 2 Cultural paper (such as double-adhesive paper, etc.), the technical indicators are not high.

[0055] The pre-coat is prepared by the following weight of raw materials: water 70g, pigment: kaolin 110g, dispersant: sodium polyacrylate 3g, lubricant: calcium stearate 2g, adhesive: carboxylated styrene-butadiene latex 25g, auxiliary agent: non-silicon Antifoaming agent 0.3g, polyacrylic acid thickener 0.8g. The preparation method of the pre-coat paint is to first add water, dispersant and pigment to disperse at high speed, then add lubricant, adhesive and auxiliary agent, and then mix. According to the characteristics of base paper, kaolin with low price and good covering performan...

Embodiment 3

[0068] Such as figure 1 As shown, the release paper of the present invention is composed of a base paper layer 1, a precoat layer 2 and a release layer 3, and the base paper layer is selected from a conventional 30-60g / m 2 Low weight thin paper (such as release paper, etc.) or 50 ~ 200g / m 2 Cultural paper (such as double-adhesive paper, etc.), the technical indicators are not high.

[0069] The pre-coat is prepared from the following raw materials by weight: water 75g, pigment: calcium carbonate 50g, kaolin 70g, dispersant: sodium hexametaphosphate 4g, lubricant: zinc stearate 3g, adhesive: polyvinyl alcohol 8g, denatured Starch 40g, additives: polyurethane condensation thickener 1g, amide defoamer 0.1g. The preparation method of the pre-coat paint is to first add water, dispersant and pigment to disperse at high speed, then add lubricant, adhesive and auxiliary agent, and then mix. According to the characteristics of base paper, adjust the ratio of pre-coating, use the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com