Automated Guided Vehicle control system

A control system and on-site technology, applied in the field of computer programs, can solve problems such as excessive time consumption, safety accidents, and hidden dangers, and achieve the effects of reducing time, reducing safety accidents, and facilitating management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

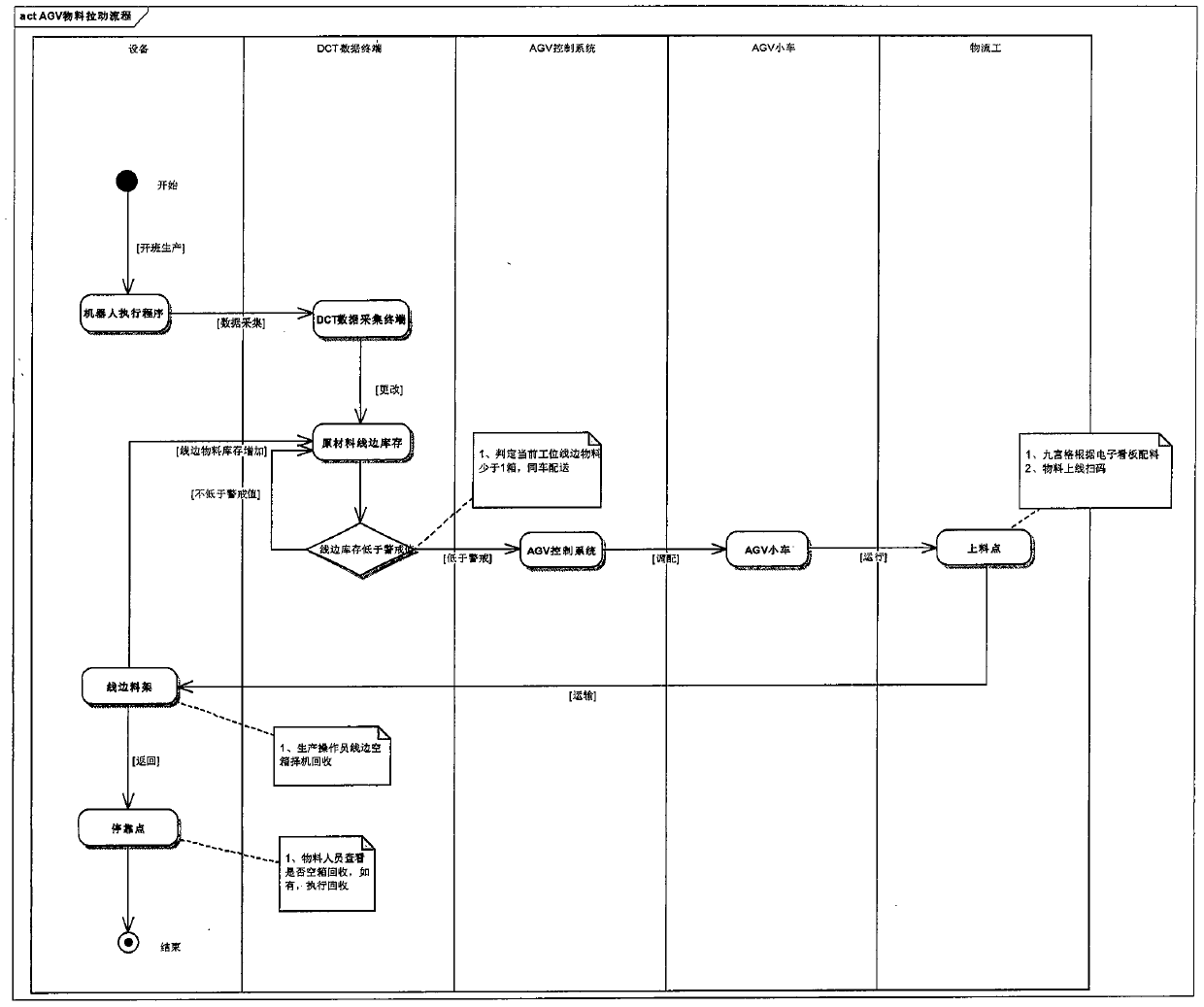

[0053] Configure the dispatching terminal, and dispatching can only be carried out after the test is completed. The AGV system provides two ways of calling materials. In the absence of a third-party system (MES), we use the dispatching terminal to call materials. The dispatching terminal is an industrial touch panel , it communicates with the system through the transparent transmission module, and at the same time sends a material request to the AGV control system. After receiving the material request, the system will send it to the idle AGV car. The AGV car here also communicates with the system through our transparent transmission module. Communicate and receive tasks from the AGV system. The second is that we can send material requests to the AGV trolley through the line-side inventory management in MES. The line-side inventory management calls for materials through material alerts. For example, when the alert value is 20 , to trigger the material-calling task, and the incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com