Friction adjustable power roller feeding channel

A power roller and friction technology, applied in the direction of roller table, transportation and packaging, can solve the problems of surface wear of parts and roller wear, and achieve the effect of improving the efficiency and level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

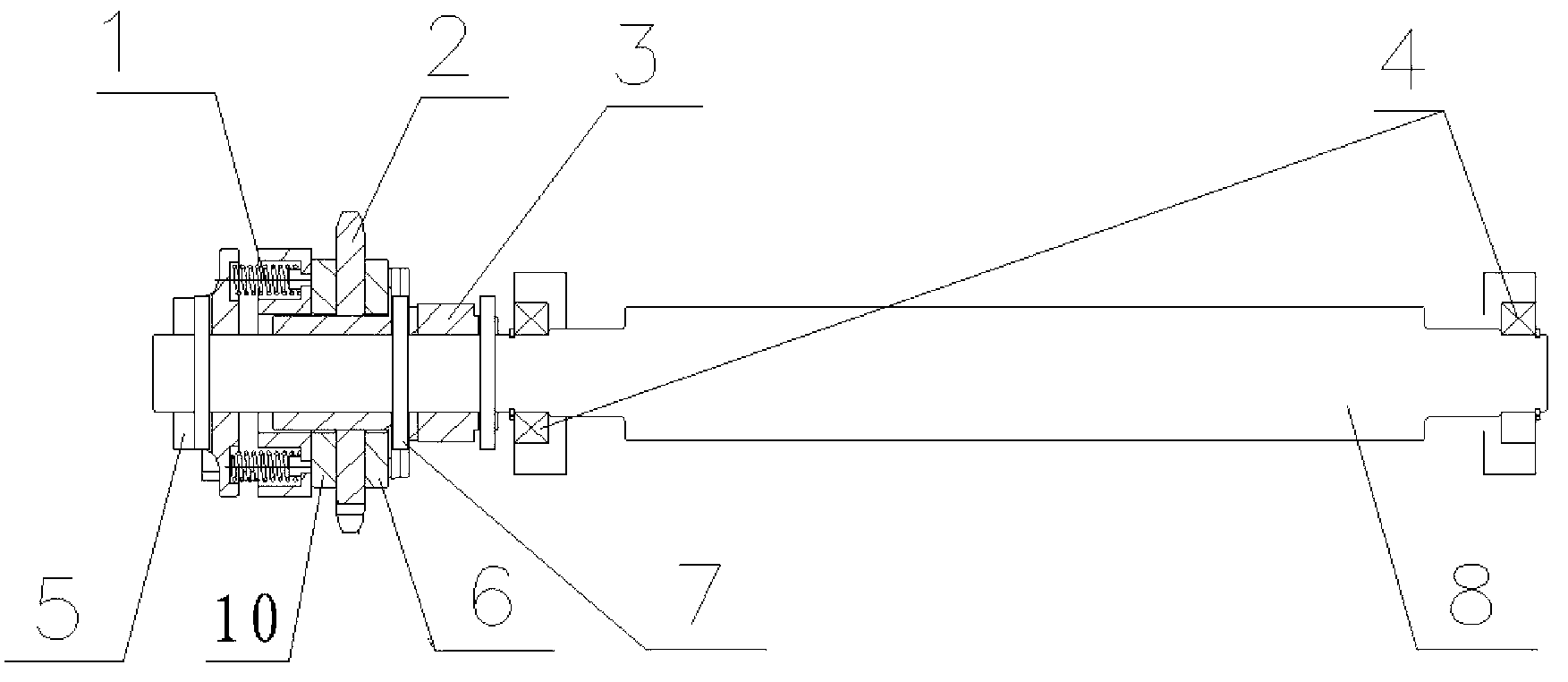

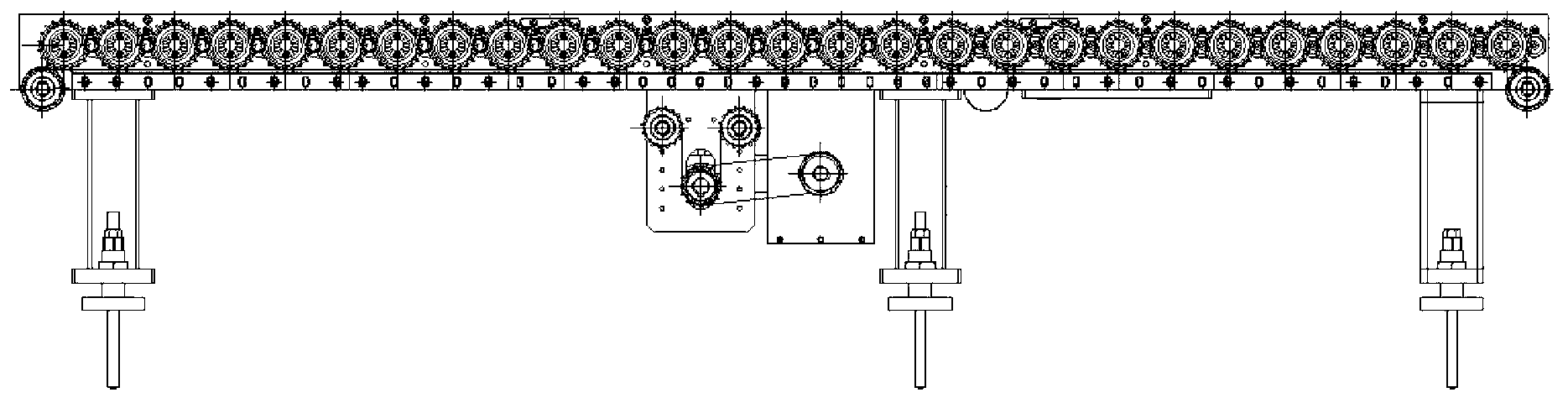

[0014] Such as figure 1 , 2 As shown, the present invention is a friction-adjustable power roller feedway, which includes several roller units and driving motors installed on the frame, and the driving motors are connected to the roller units through a chain drive to drive the rollers. The unit rotates to convey materials, wherein the roller unit includes a transmission shaft 8 installed on two bearings 4, and a baffle 7, a first friction plate 6, a transmission shaft 8 are installed on the outside of one of the bearings 4 in sequence The sprocket 2, the second friction plate 10, the spring 1 and the adjustment sleeve 5, wherein the baffle plate 7 is fixed on the transmission shaft 8, and the first friction plate 6, the transmission sprocket 2 and the second friction plate 10 all have gaps with the transmission shaft 8 Cooperate, the adjustment sleeve 5 is detachably installed on the transmission shaft 8 through a fastener, such as a straight pin, and the two ends of the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com