Production logistics intelligent distribution AGV system based on cloud-station-point architecture, and application thereof

A logistics and intelligent technology, applied in the field of intelligent logistics, can solve the problems of lack of data interaction, inability to carry out centralized monitoring, difficult adjustment and modification of logistics routes in the later stage, and achieve the effect of solving unified deployment and management problems and achieving effective integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

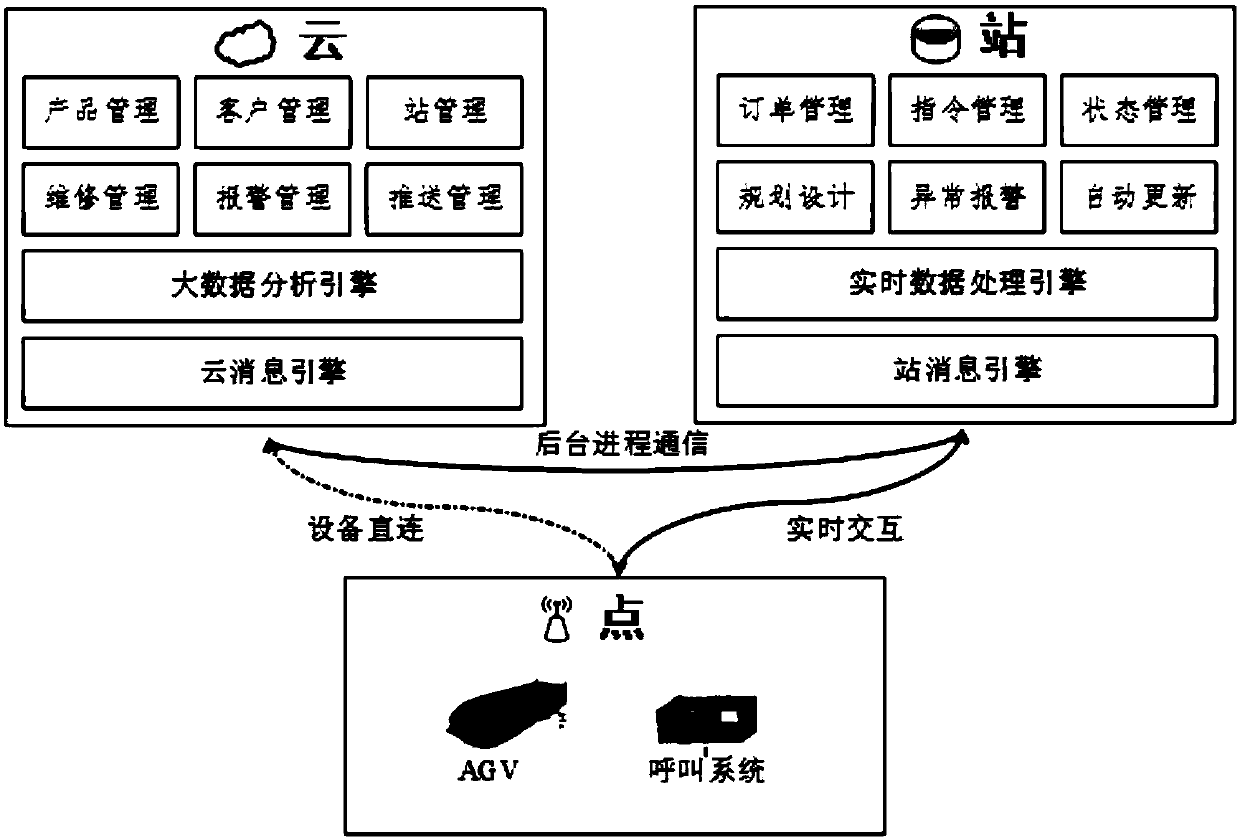

[0033] Such as Figure 1 to Figure 6 As shown, this embodiment provides a production logistics intelligent distribution AGV system based on cloud platform architecture, including cloud platform, station end and point end, and wireless communication technology is used to transmit data information between the three, wherein:

[0034] - cloud platform, described cloud platform comprises the cloud server of ring network and operation data analysis and decision-making system;

[0035] -Station end, the station end includes a plurality of AGV dispatching subsystems, each AGV dispatching subsystem corresponds to a factory area, each AGV dispatching subsystem includes at least one station server responsible for AGV vehicle dispatching in the corresponding factory area, and multiple station servers are distributed In multiple workshops, generally speaking, one workshop corresponds to one station server;

[0036] - point end, the point end includes a plurality of AGV vehicles under eac...

Embodiment 2

[0045] A production logistics intelligent distribution AGV system based on a cloud platform architecture, the system architecture is as described in Embodiment 1, the difference is that the cloud server also includes: a Hadoop module for data integration, storage and analysis; a resource management module YARN module; use Zookeeper for scheduling; use HDFS to store data uploaded by the station-side database in Hadoop files; use HBase and Redis to store data; use MapReduce for offline computing, Spark for real-time computing; use Hive to realize data warehouse construction, MLlib Perform data analysis.

[0046] Managers or users can access the cloud server logged in to the cloud platform through the terminal platform to monitor or view all data information in the AGV system or the operation of each station and point in real time, and can also modify or issue the AGV through the terminal platform The task command of the vehicle, so as to realize the control of the AGV vehicle at...

Embodiment 3

[0048] As described in Embodiment 2, a method of operating an AGV system for intelligent distribution of production logistics based on a cloud platform architecture, its specific working process is as follows:

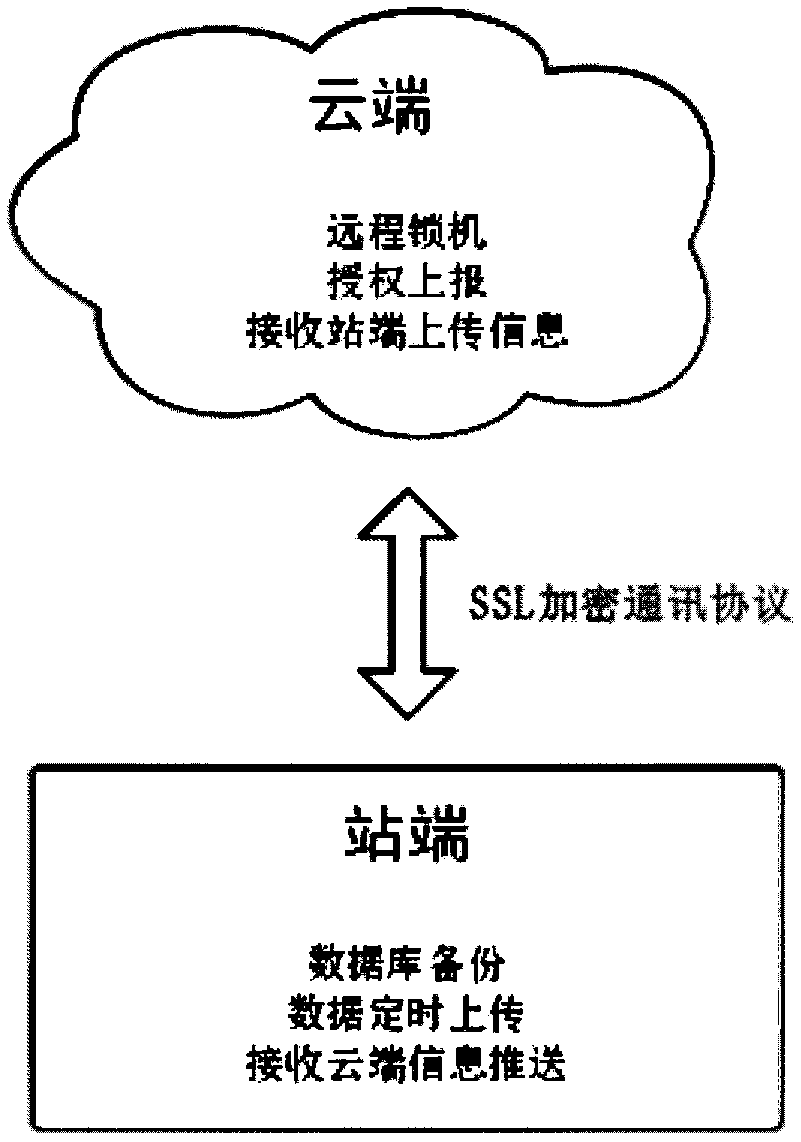

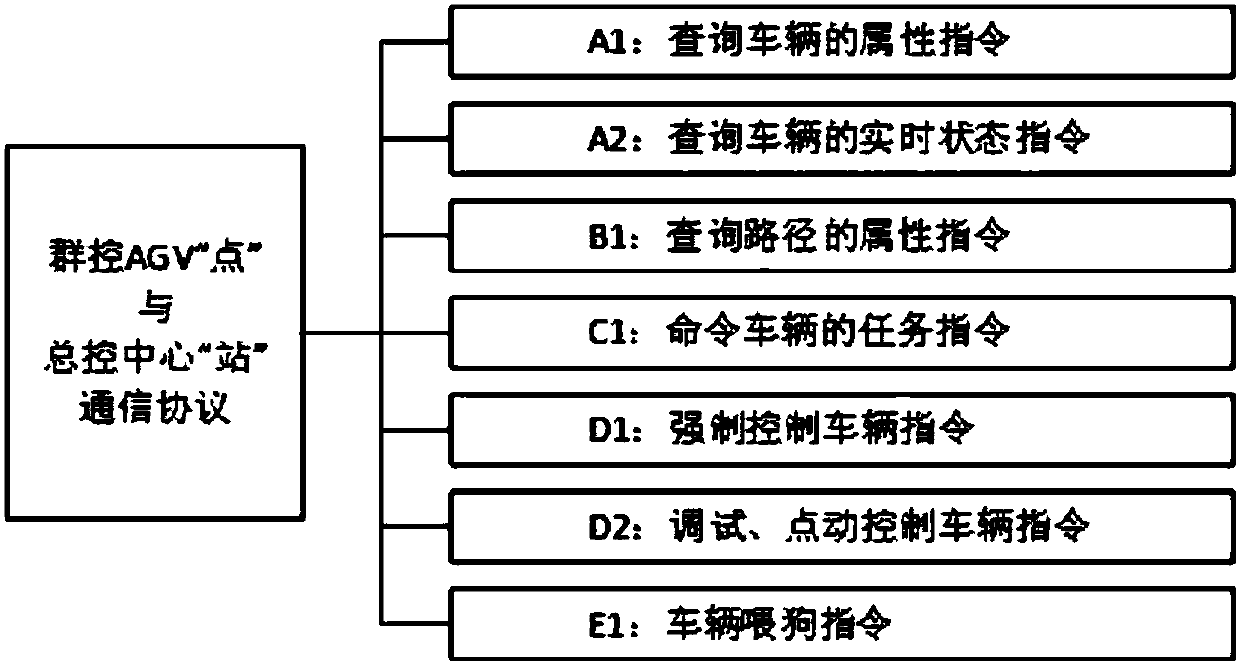

[0049] The station-side AGV dispatching subsystem sends task instructions to multiple AGV vehicles under their corresponding factory areas. After the AGV controller on the AGV vehicle receives the task instruction sent by the station server through the wireless communication module, the AGV controller controls the operation of the AGV vehicle. ; During the operation of the AGV vehicle, it regularly sends the operation information of the AGV vehicle to the station server, and the AGV dispatching subsystem at the station uses wireless communication technology to transmit the data information mastered by the AGV dispatching subsystem to the cloud platform in real time. The mobile phone and computer can log in to the cloud server of the cloud platform to view information an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com