A scheduling method for intelligent manufacturing of electric machines based on logistics simulation

A technology of intelligent manufacturing and logistics, applied in the manufacture of computing systems, motor generators, electromechanical devices, etc., can solve problems such as inability to schedule production plans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

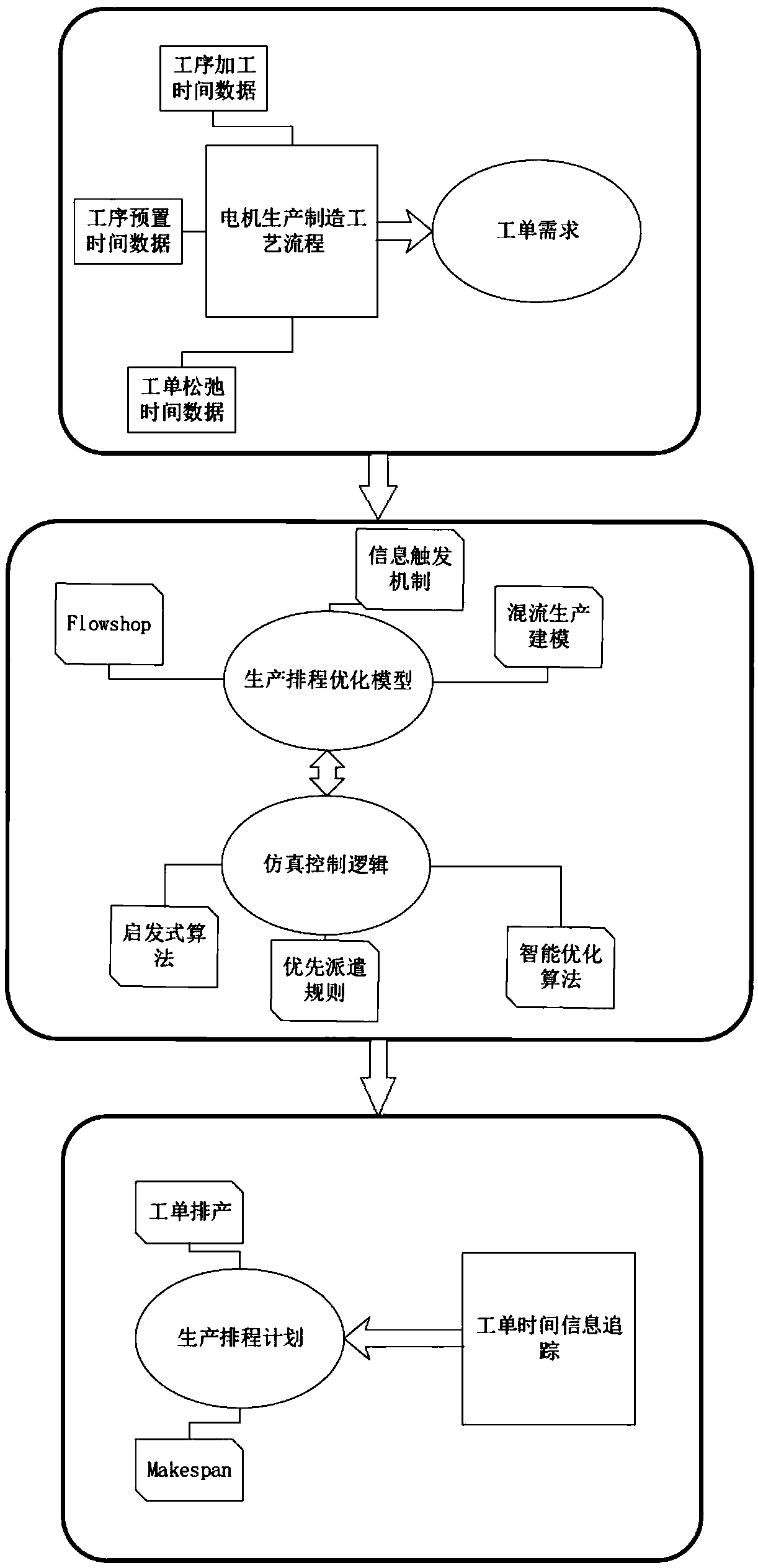

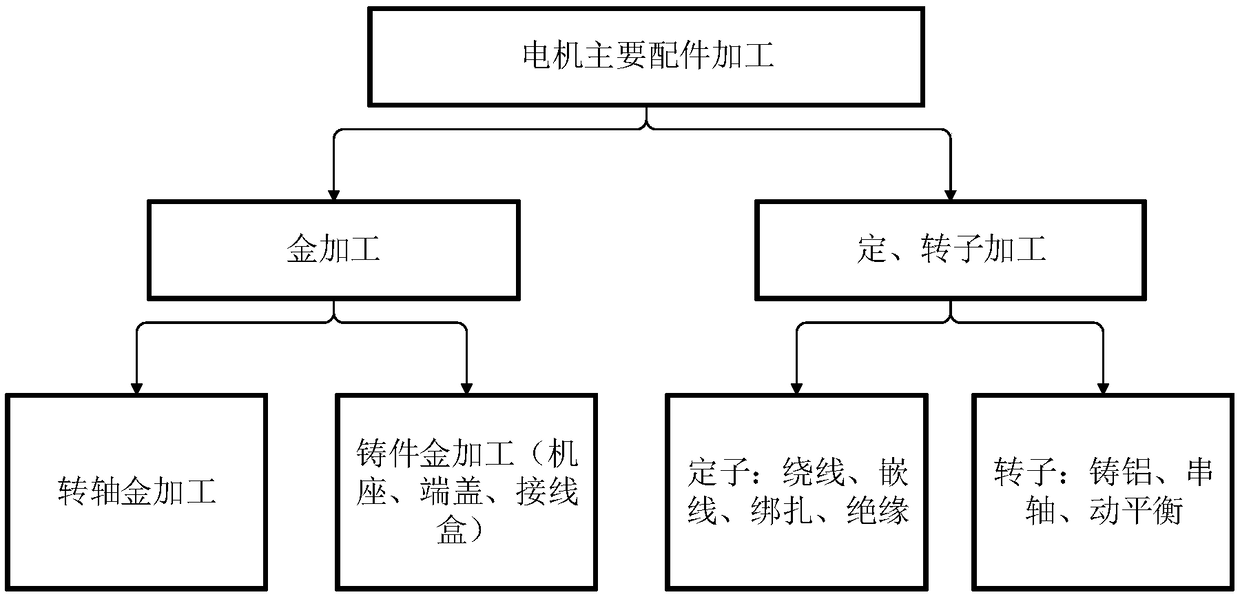

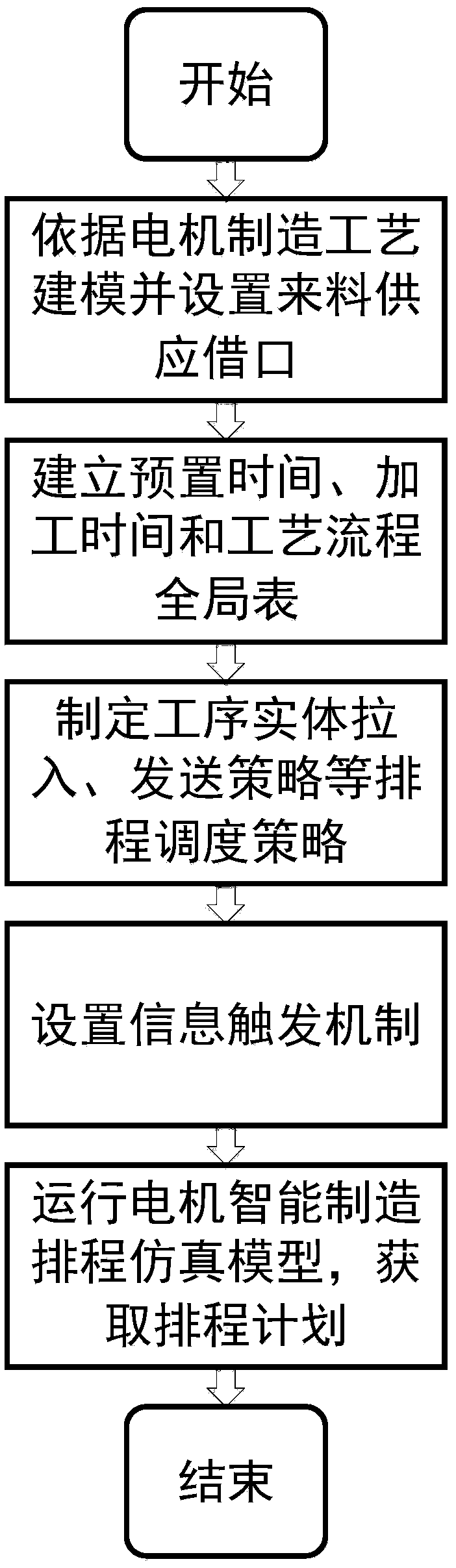

[0035] This example combines the production process of the three-phase asynchronous motor, and uses the logistics simulation system for modeling and simulation analysis, obtains the optimized schedule and total man-hours, and analyzes the conditions of each sub-module and process in the processing process . The block diagram of the entire motor intelligent manufacturing scheduling process is as follows: figure 1 shown. The scheduling modeling and optimization of electric motor intelligent manufacturing is divided into input part, modeling and optimization part and output part. The input part obtains the relevant motor manufacturing process based on work order information query, which mainly includes information such as process preset time, process processing time, and work order slack time. The information in the input part is used for the real-time query of the modeling and optimization part as the basis for optimization. Modeling and optimization Part of the motor manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com