Material flow simulation optimization method in steel making-continuous casting production based on target guiding

An optimization method and logistics technology, applied in the information field, can solve problems such as limitations, lack of mutual evolution mechanism, lack of analysis methods for simulation results, etc., to achieve the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

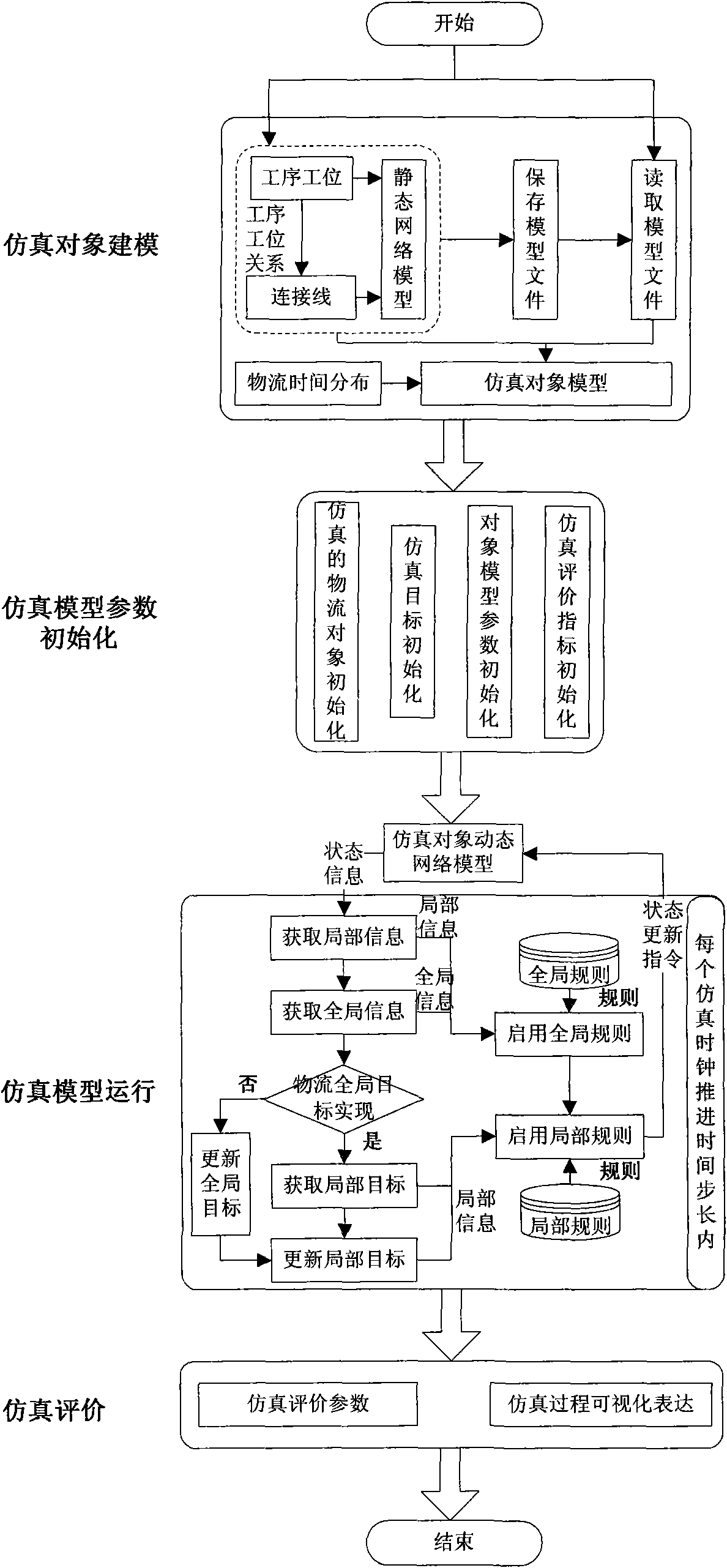

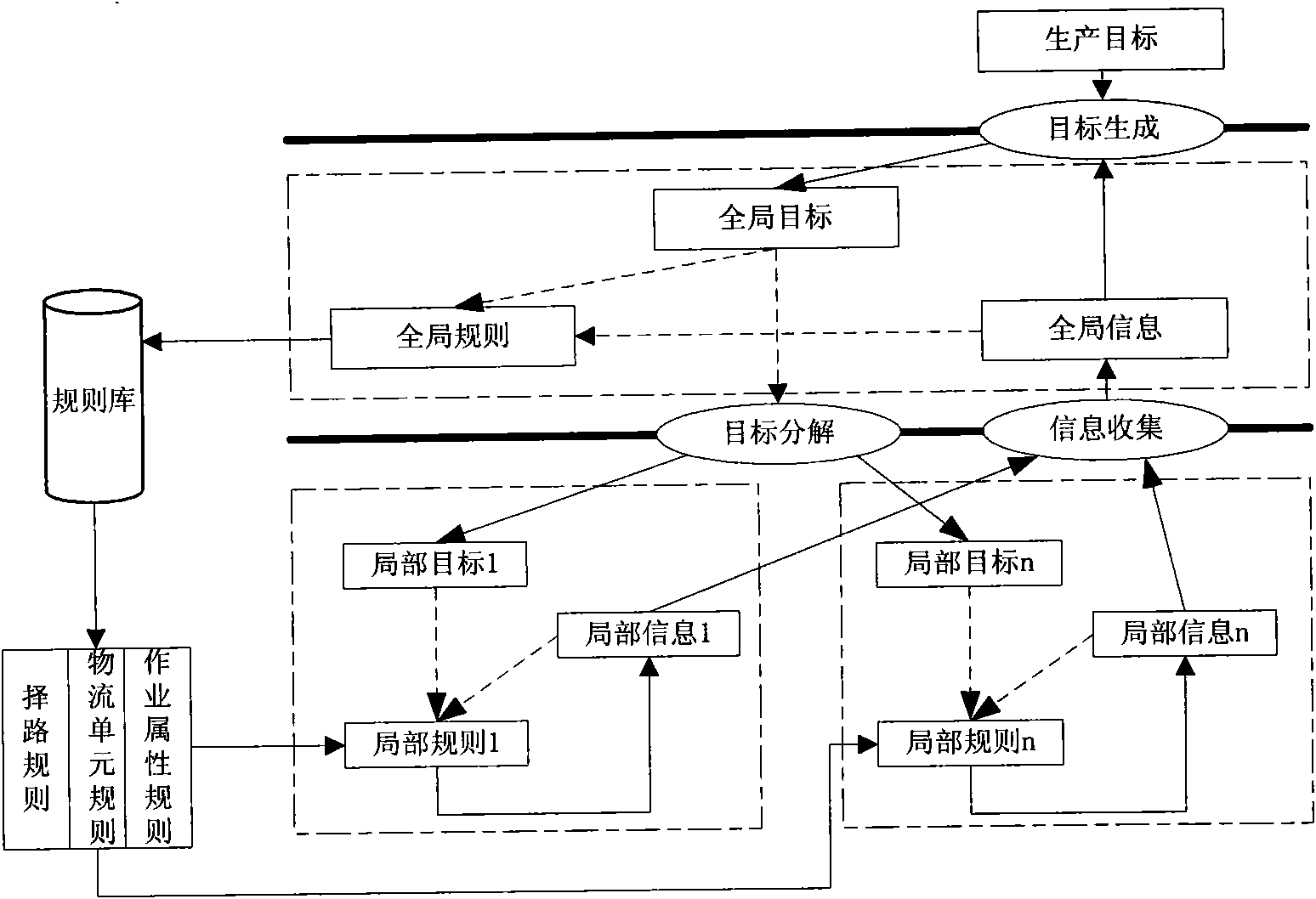

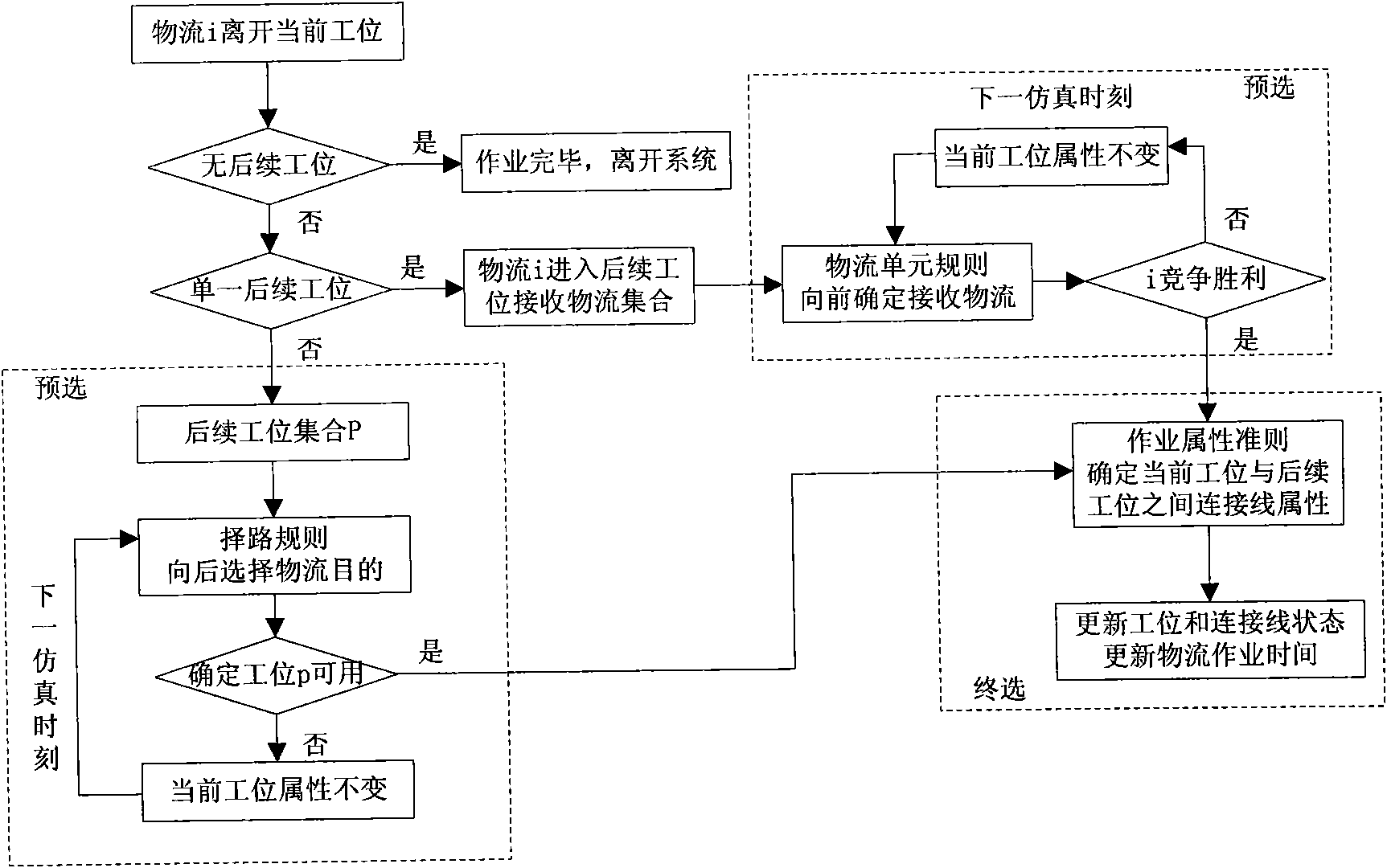

[0039] The present invention first abstracts the production process and the logistics operation in the production process into a static network model represented by the process station and the connecting line between the stations, and the simulation object model of the main production logistics running in the model network, and the operation of the logistics at the station Time and transit times are described by various probability distributions or production statistics. The realization of the final production goal of the system is taken as the global goal of the simulation model system (such as the continuous casting of the continuous casting machine), and the control principle of the realization of the production goal is taken as the global rule (such as the control principle of the continuous casting of the continuous casting machine), and the global goal and the rule The partial target is obtained by decomposing it backwards in time, and the information related to the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com