Chaos immune algorithm based multi-vehicle assembly line logistics transportation scheduling method

A technology of immune algorithm and scheduling method, applied in logistics, computing, instruments, etc., can solve problems such as increased production costs, affecting the normal production of the assembly line, and inefficient logistics and distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

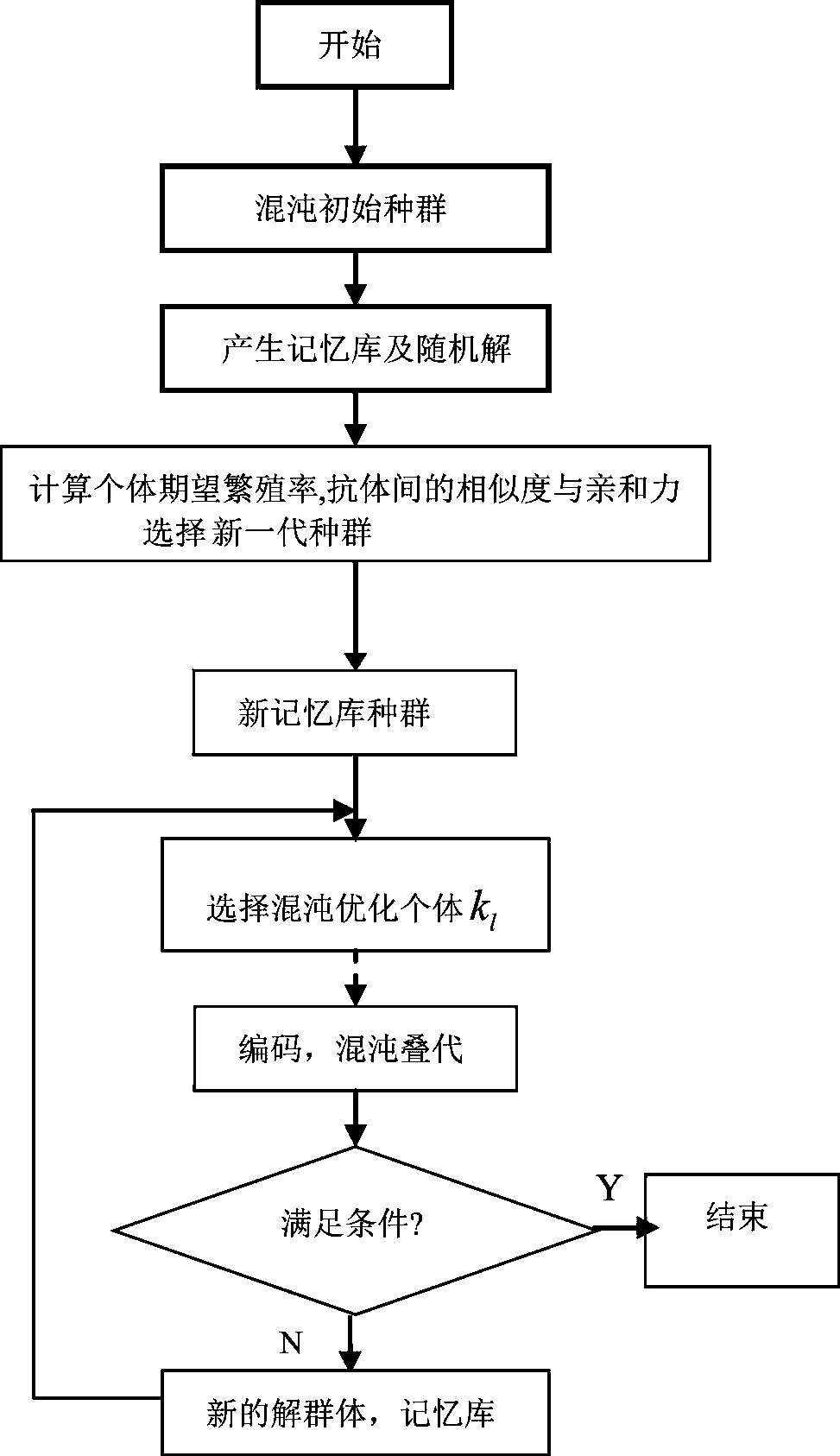

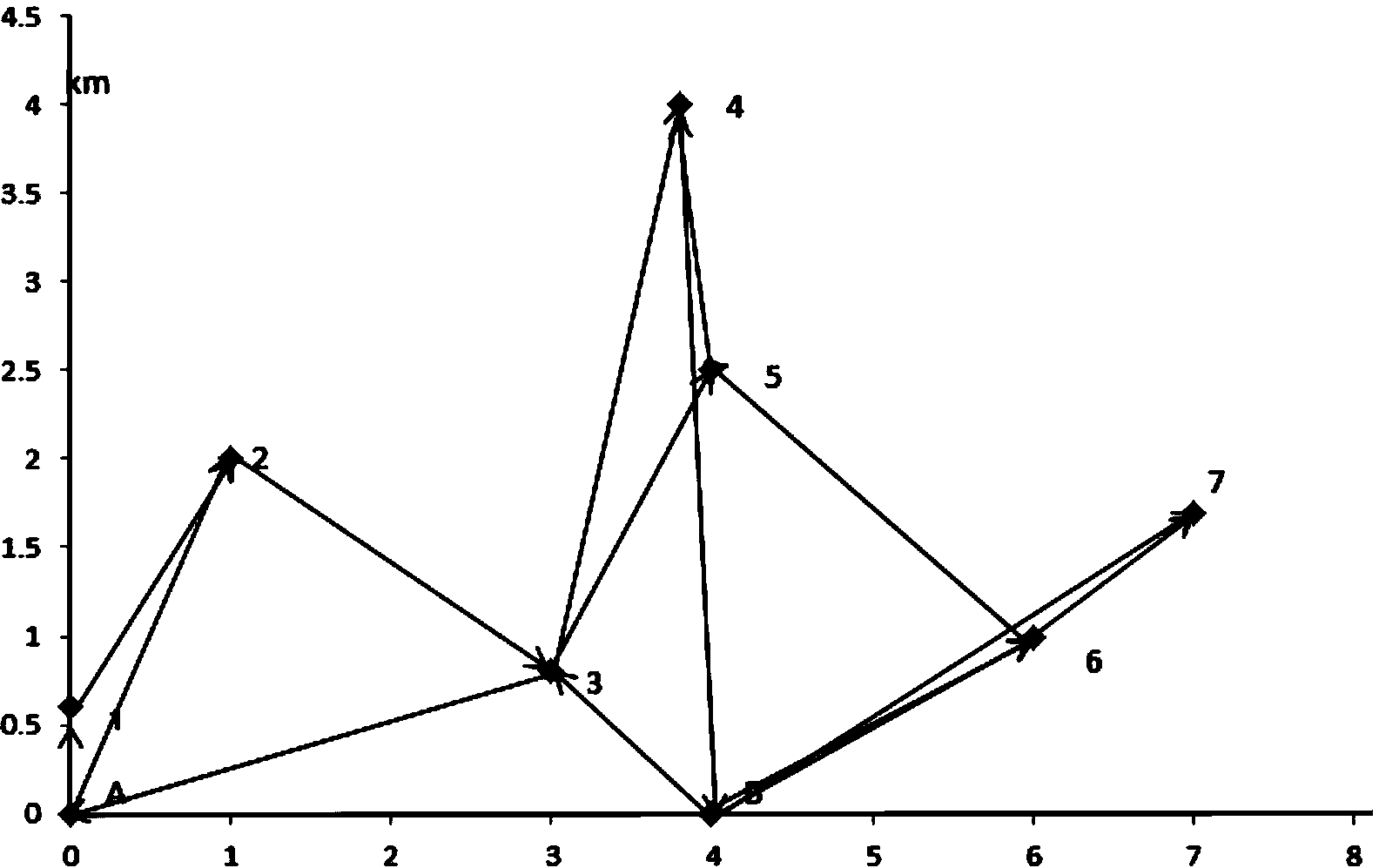

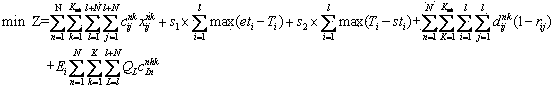

[0032] Such as figure 1 , 2 As shown, a multi-depot multi-model assembly line logistics transportation scheduling optimization method based on chaos immune algorithm. The specific implementation steps are as follows:

[0033] Step 1: Obtain the basic data of the multi-depot multi-model assembly line. There are 7 processes in the assembly line in the attached drawing. The production speed of each process and the coordinates of the distribution material point are known. The two distribution centers can obtain the time window constraints in Attached Table 1 according to the production speed and the initial delivery volume. Attached Table 2 shows the coordinates of the distribution point and distribution center and the weight of the distribution goods. The initial speed of the car is 0.1km / min, and there are two types of vehicles in the yard , , The maximum payload is 0.6 ,vehicle Loading capacity is 0.3 .

[0034] Step 2: Determine the time window process of goods del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com