Fault early warning method for production logistics conveying equipment

A technology of fault warning and equipment, applied in the field of intelligent system technology application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

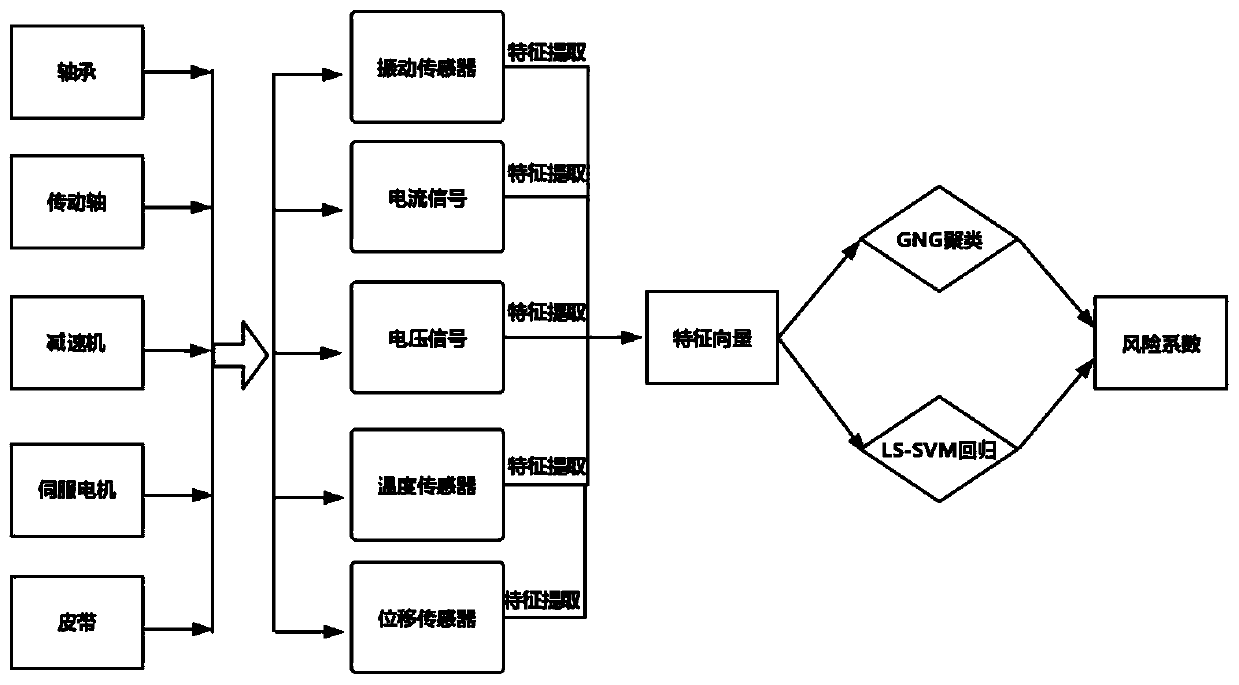

[0063] In this embodiment, the equipment used in the production of automobile assembly lines is taken as an example to illustrate the method for early warning of failures of conveying equipment for automobile assembly in the present invention, such as figure 1 As shown, the steps are as follows.

[0064] Step 1. Data collection: Use sensors to collect state data of the main parts of the equipment used in production, including the vibration acceleration signals of the two bearings and the reducer, the displacement of the belt, etc.;

[0065] Step 2, extracting feature parameters: different feature extraction techniques are used for feature extraction for different data.

[0066] Step 3, data dimension reduction: take the average value of the devibration effective value and the peak value, and then synthesize a feature vector, so that the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com