A production process modeling and product data tracking system

A production process and product data technology, applied in data processing applications, manufacturing computing systems, instruments, etc., can solve problems such as huge quantities, difficult maintenance, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

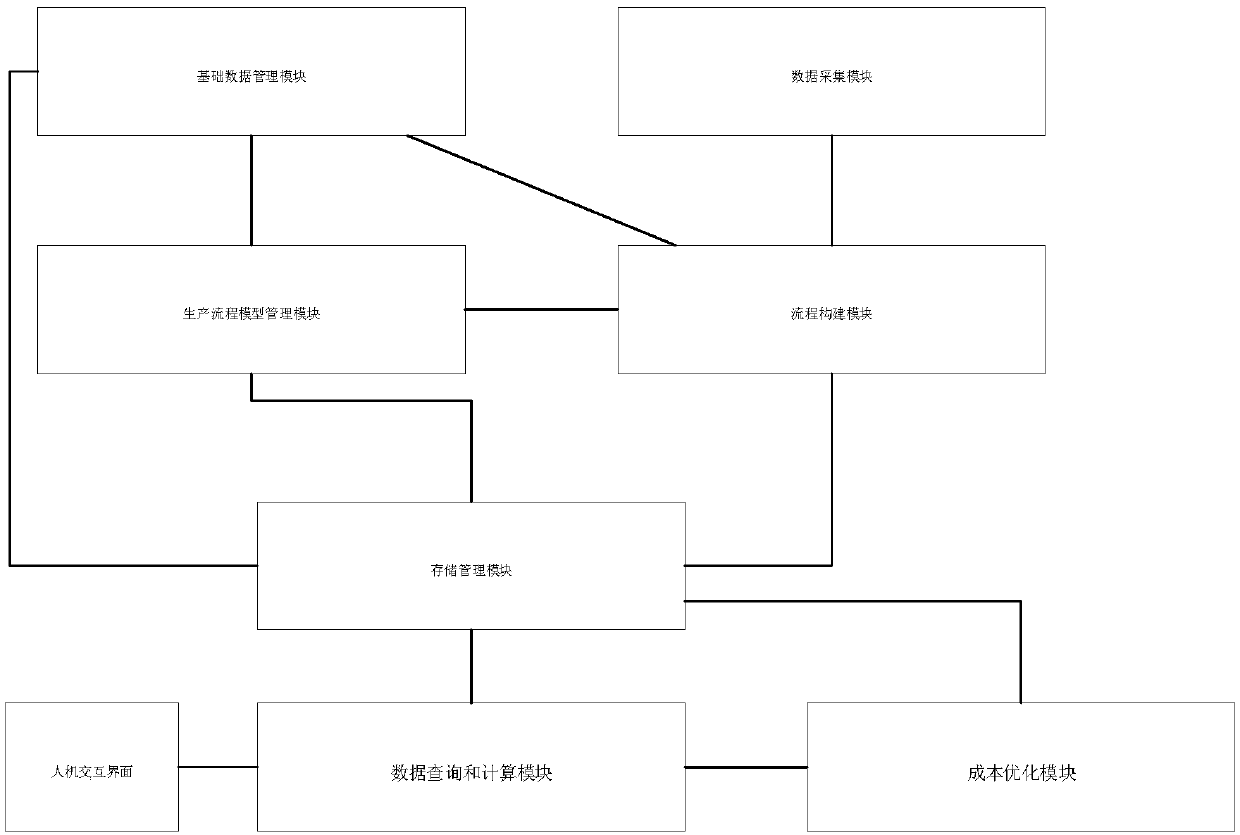

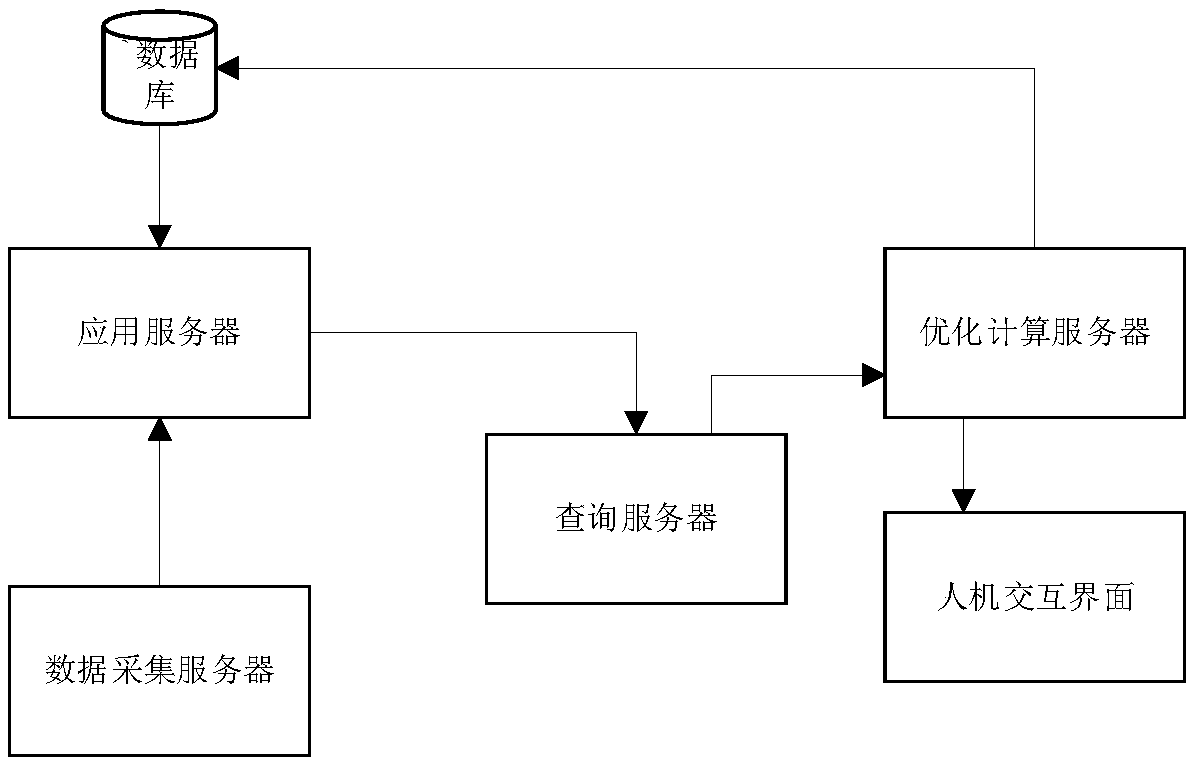

[0029] The present invention includes a production process model management module, a basic data management module, a data acquisition module, a process management module, a data storage module, a process construction module, a data query and calculation module, a cost optimization module, and a human-computer interaction module; these modules are deployed in Computing network nodes that support TCP / IP communicate with each other through network protocols that support TCP / IP. Among them, the basic data management module manages static basic configuration data, including basic information such as production equipment, processes, warehouses, personnel, customers, suppliers, and material BOMs. It is connected to the data storage module and reads and writes data from the data storage module; The production process model management module is connected with the process management module and the data storage module. On the one hand, the generated production process model will be outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com