HUD (Heads-Up Display) digitized boresight method applied to plane general assembly

A general assembly and target calibration technology, which is applied in the field of target calibration, can solve the problems of low degree of automation, inhibition of target calibration accuracy improvement, improvement of target calibration efficiency, and large space occupied by the work site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

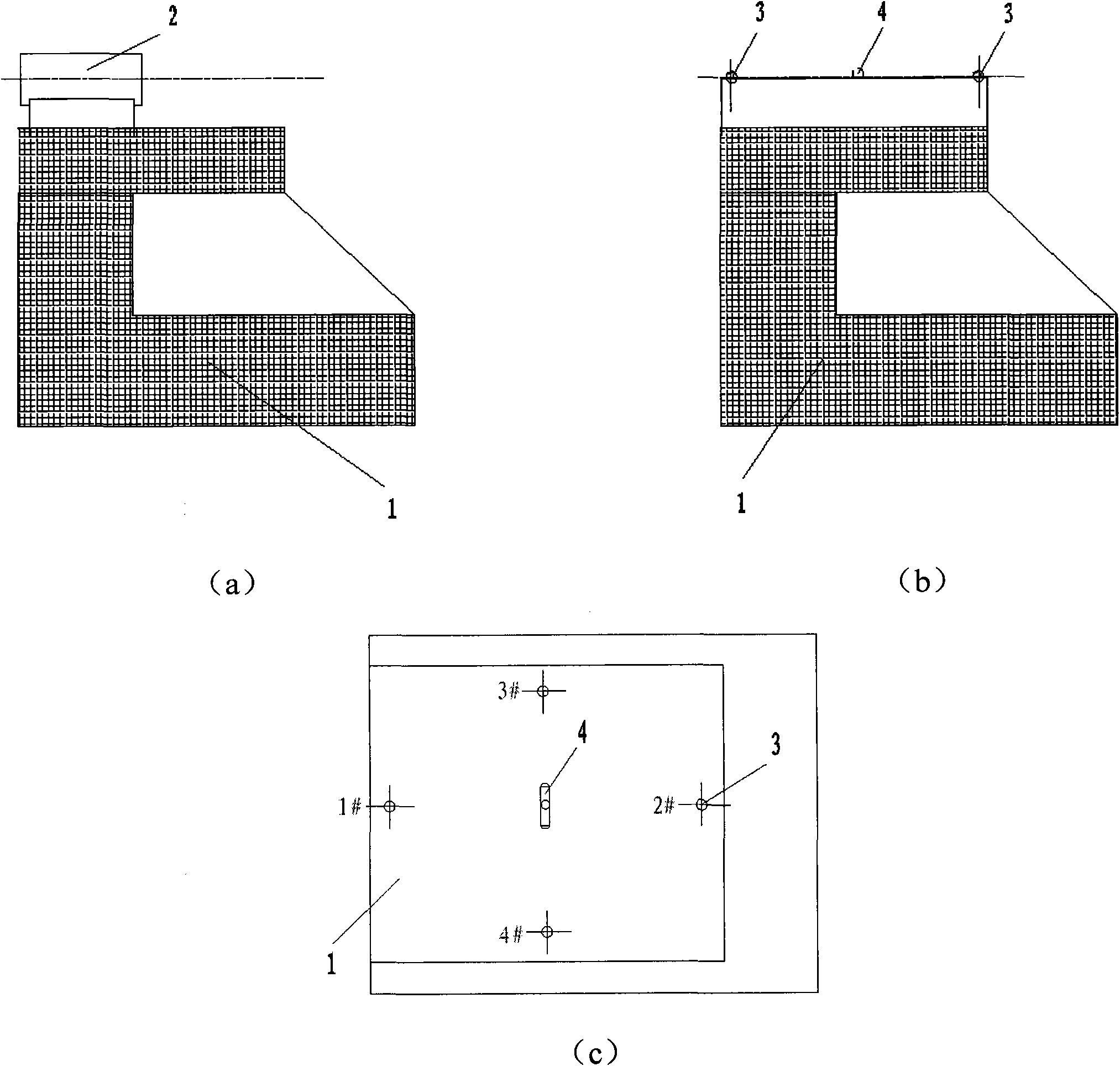

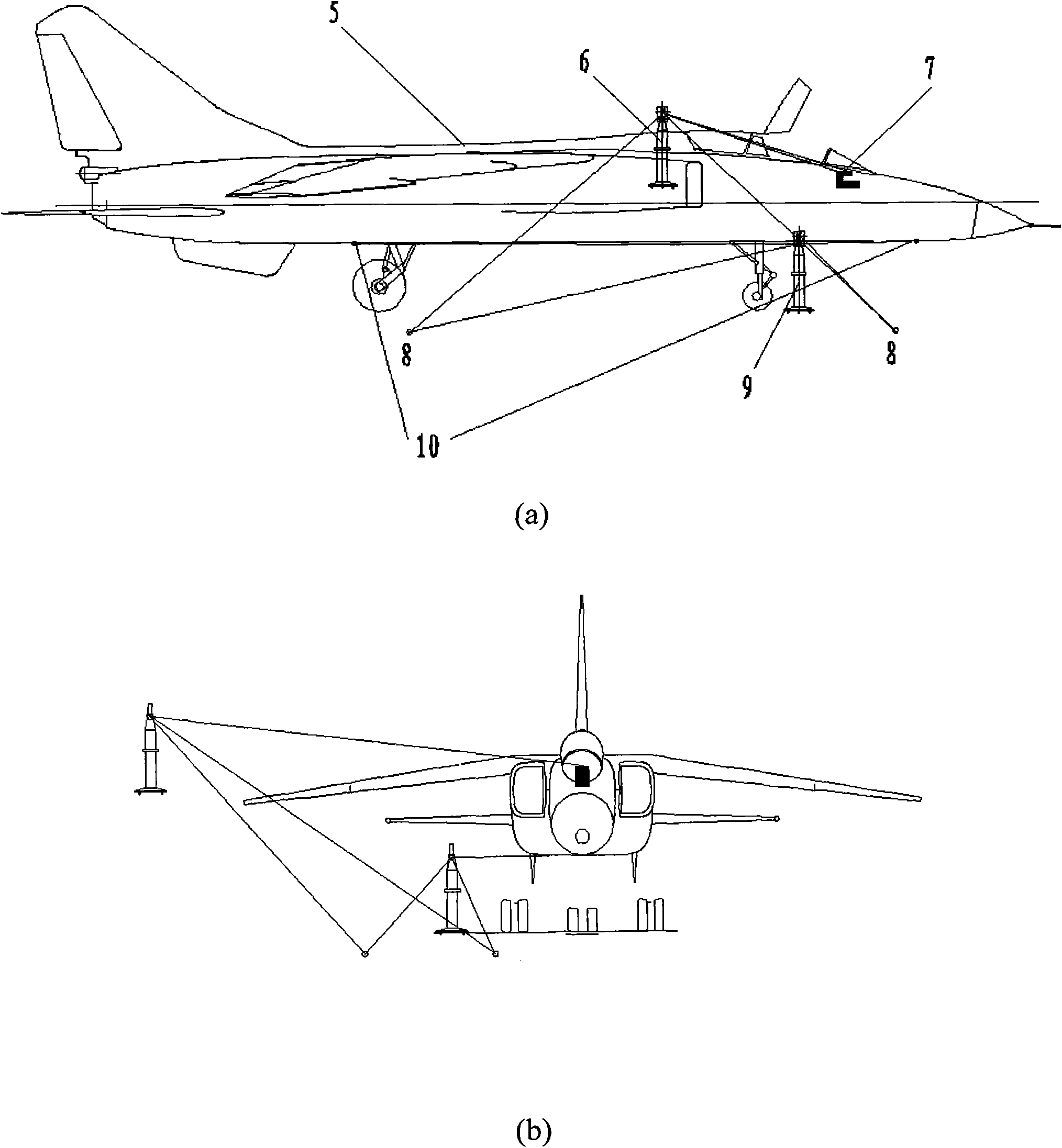

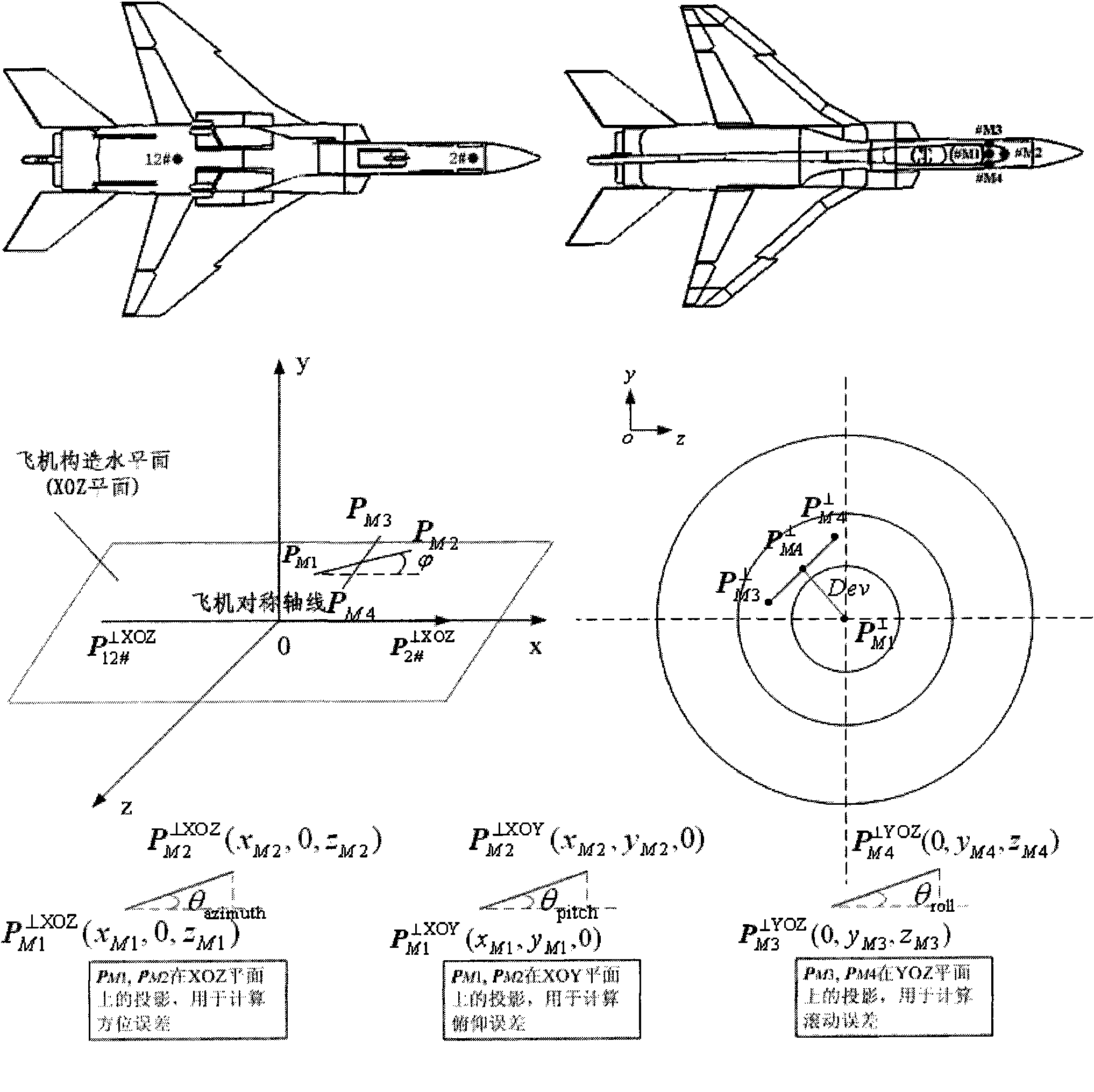

[0073] 1) Level the aircraft, that is, adjust the horizontal and longitudinal directions of the aircraft. The method is: arrange two measuring points symmetrically on the left and right wings of the aircraft. Arrange two measuring points in the direction of the aircraft fuselage, and the height difference between the two points will reach longitudinal leveling within 0.5mm. Secondly, place the laser tracker at the lower station position, and the measurement coordinate system of the laser tracker and the assembly of the lower station Coordinate system 1. Here, the measurement coordinate system of the laser tracker refers to the spatial coordinate system automatically established by default after the laser tracker is turned on, and the assembly coordinate system of the next station refers to the one defined by the designer according to the layout of the general assembly of the aircraft on site. The spatial coordinate system, the method of unifying the two is: by measuring several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com