Fabricated scaffold and using method thereof

A kind of scaffolding and assembly technology, which is applied in the field of assembly scaffolding in shipbuilding, can solve the problems of increasing construction period and occupying a large space, and achieve the effect of reducing time, improving utilization and reducing risk index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

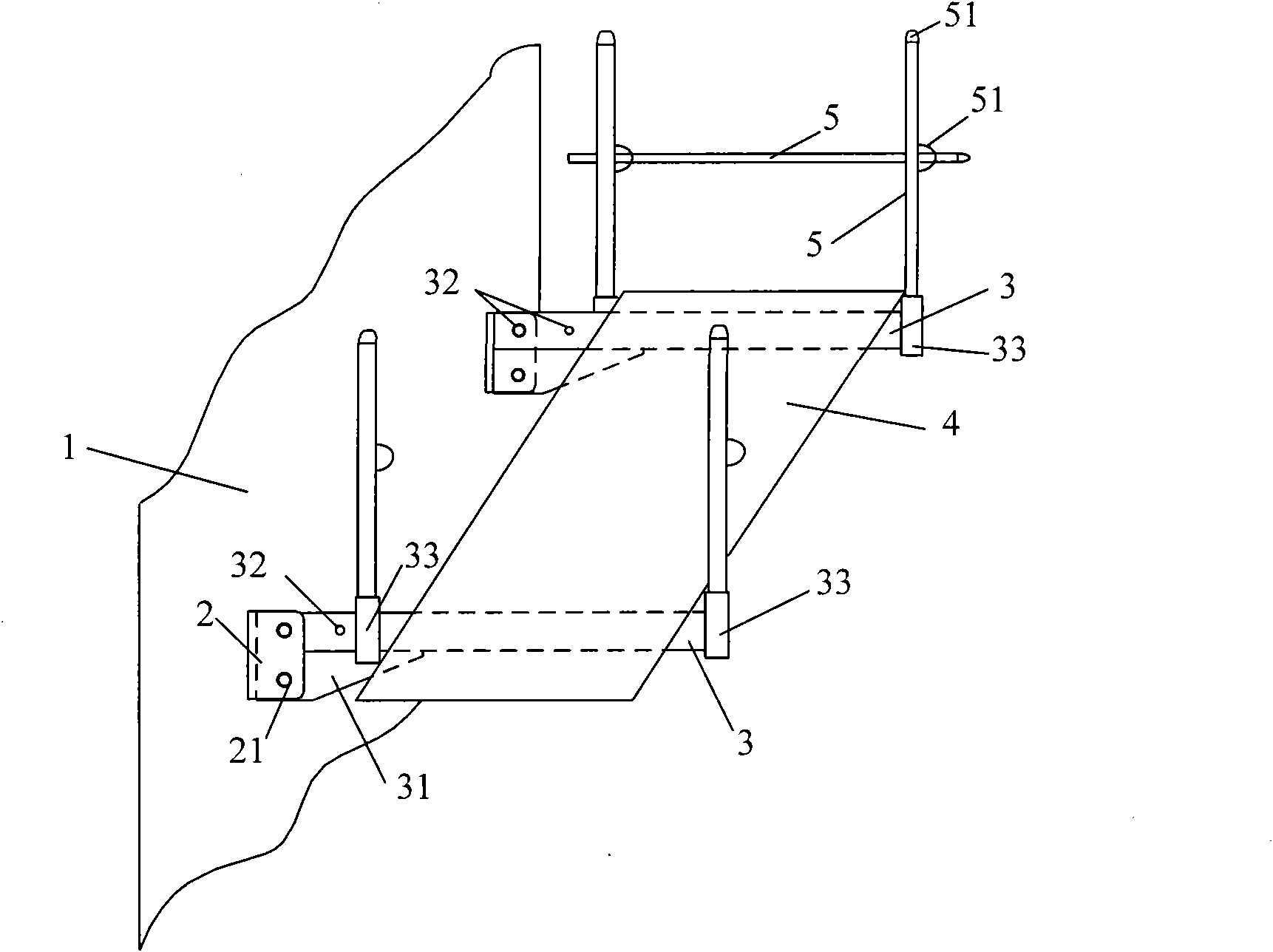

[0038] Such as figure 1 Shown is a perspective view of the assembled scaffolding of the present invention installed on the vertical bulkhead of the cabin. In this embodiment, the assembled scaffold includes two ear plates 2 vertically welded on the bulkhead 1 , the cross section of which is a rectangle, and two first installation holes 21 are provided on the ear plates 2 . Each ear plate 2 is provided with a scaffold cross bar 3 for supporting the scaffolding platform 4, and one end of the scaffold cross bar 3 installed on the ear plate 2 is provided with a second mounting hole 32 matching the first mounting hole 21, and the scaffolding The cross bar 3 is fastened on the lug plate 2 by bolts and kept horizontal to the ground, and a reinforcing rib 31 is also provided at the same end. Both ends of the scaffold cross bar 3 are respectively provided with a hollow column-shaped clamping position 33 for installing the scaffold guardrail 5 , and the scaffold guardrail 5 is provided...

Embodiment 2

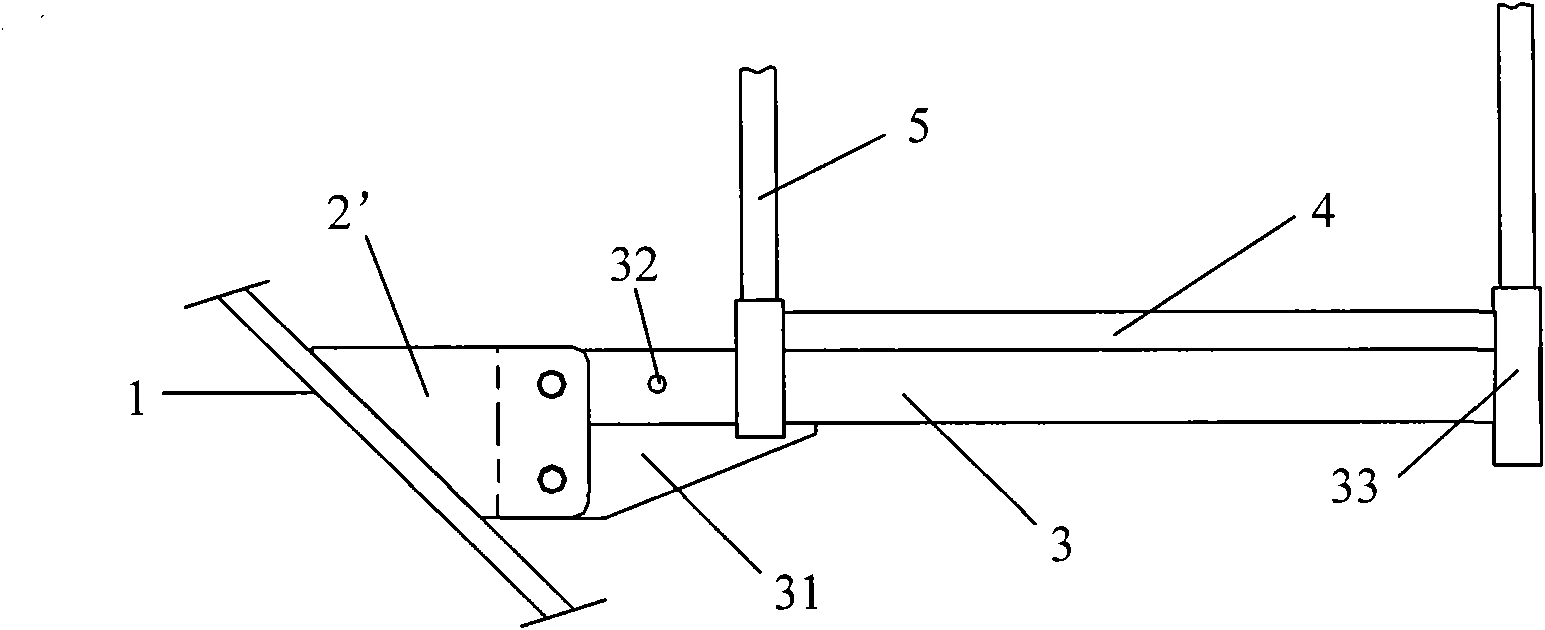

[0040] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that in this example, the bulkhead 1 forms a certain angle with the horizontal plane, so a trapezoidal cross-section is used to replace the lug 2 in Embodiment 1. And keep the scaffolding bar 3 relative to the ground level all the time, and the rest are identical to embodiment 1. It can be seen from this embodiment that the shape of the ear plate can be selected according to the actual situation of its fixed mounting surface, and can be rectangular, trapezoidal or polygonal.

Embodiment 3

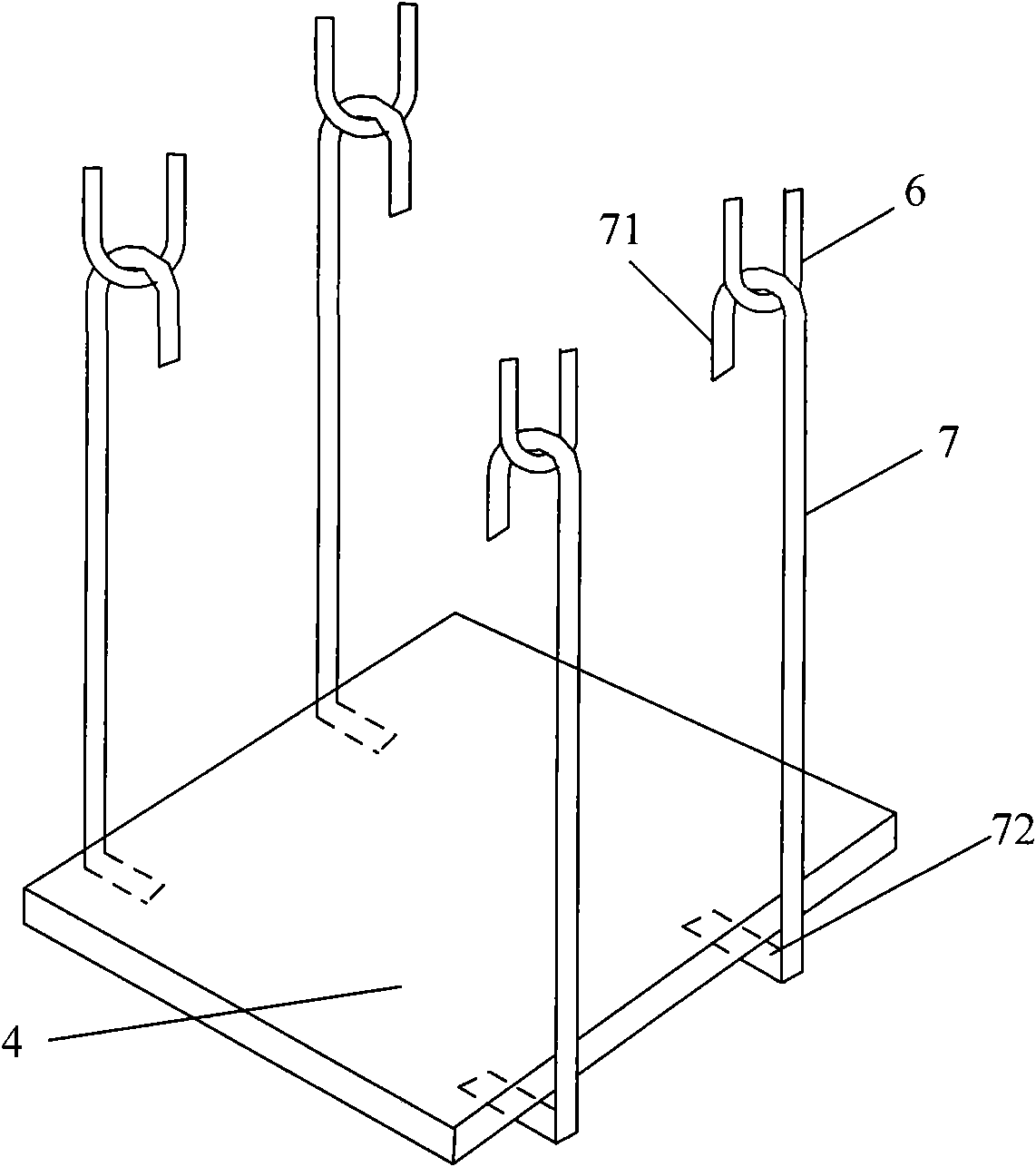

[0042] Such as image 3 As shown, it is a perspective view that the assembled scaffolding among the present invention is installed on the reverse top of the cabin. In this embodiment, the assembled scaffolding includes four rectangularly distributed earrings 6 that are oppositely arranged in pairs. In this embodiment, the earrings 6 are U-shaped, and their open ends are welded to the T row on the reverse top of the cabin. The hanger 7 in this embodiment is made of strip steel, and hangs below the T row through the first bending part 71 hooked in the earring 6 at its upper end. The lower end of each hanger 7 is provided with a second bending portion 72 for supporting the scaffolding platform 4 , and the second bending portion 72 is located directly below the first bending portion 71 and is at a 90° angle to the vertical plane. The scaffolding platform 4 is laid on the four second bending parts 72 .

[0043] Wherein, the length of the hanger 7, that is, the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com