Two-dimensional three-dimensional combined satellite general assembly process planning and simulation method

A technology of process planning and simulation method, applied in the field of satellite final assembly process informatization, can solve the problems of conservative technology, difficult design of process personnel, poor consistency, etc., and achieve the optimization of process planning scheme, the image of process design process and the reduction of dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

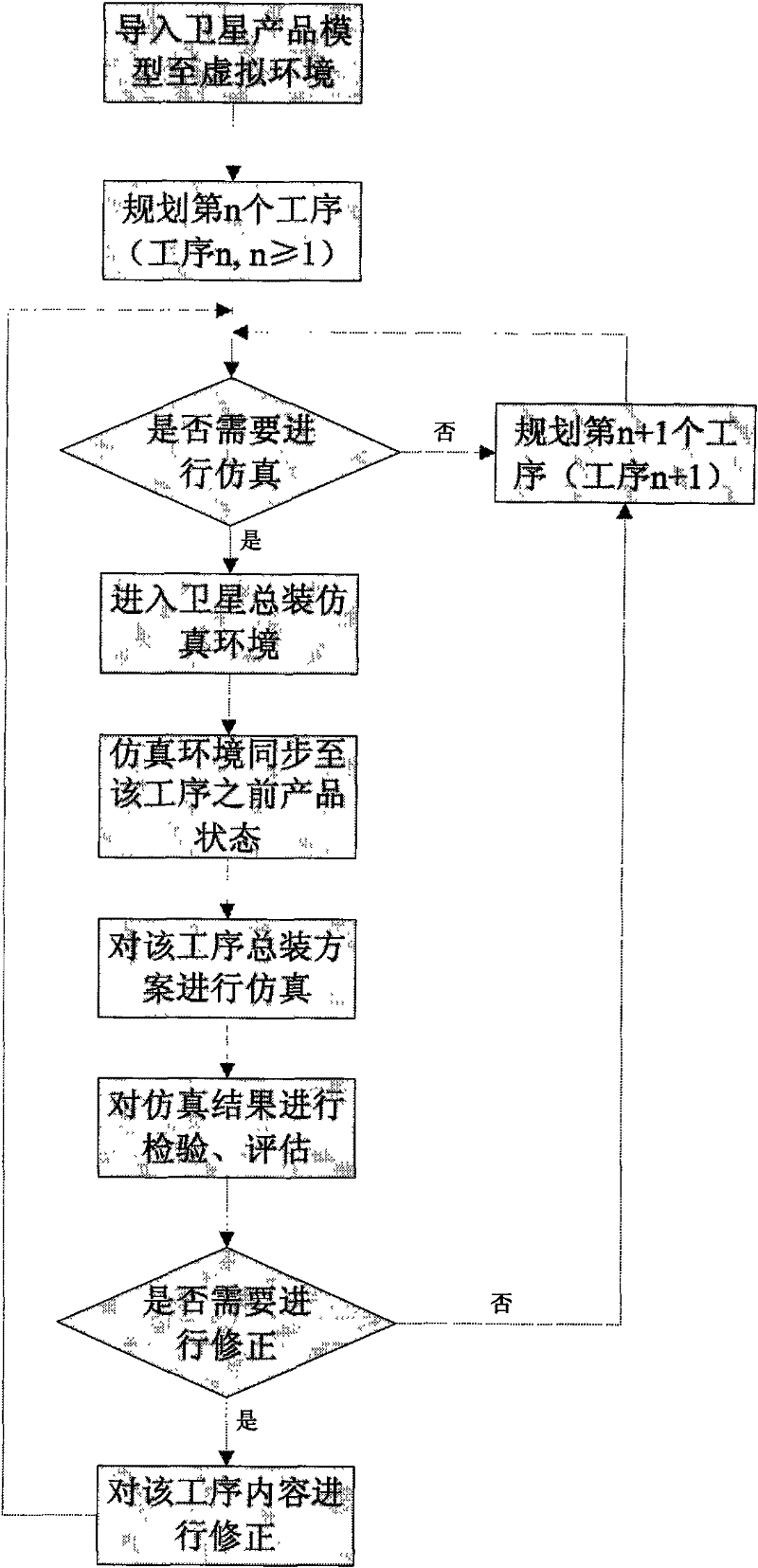

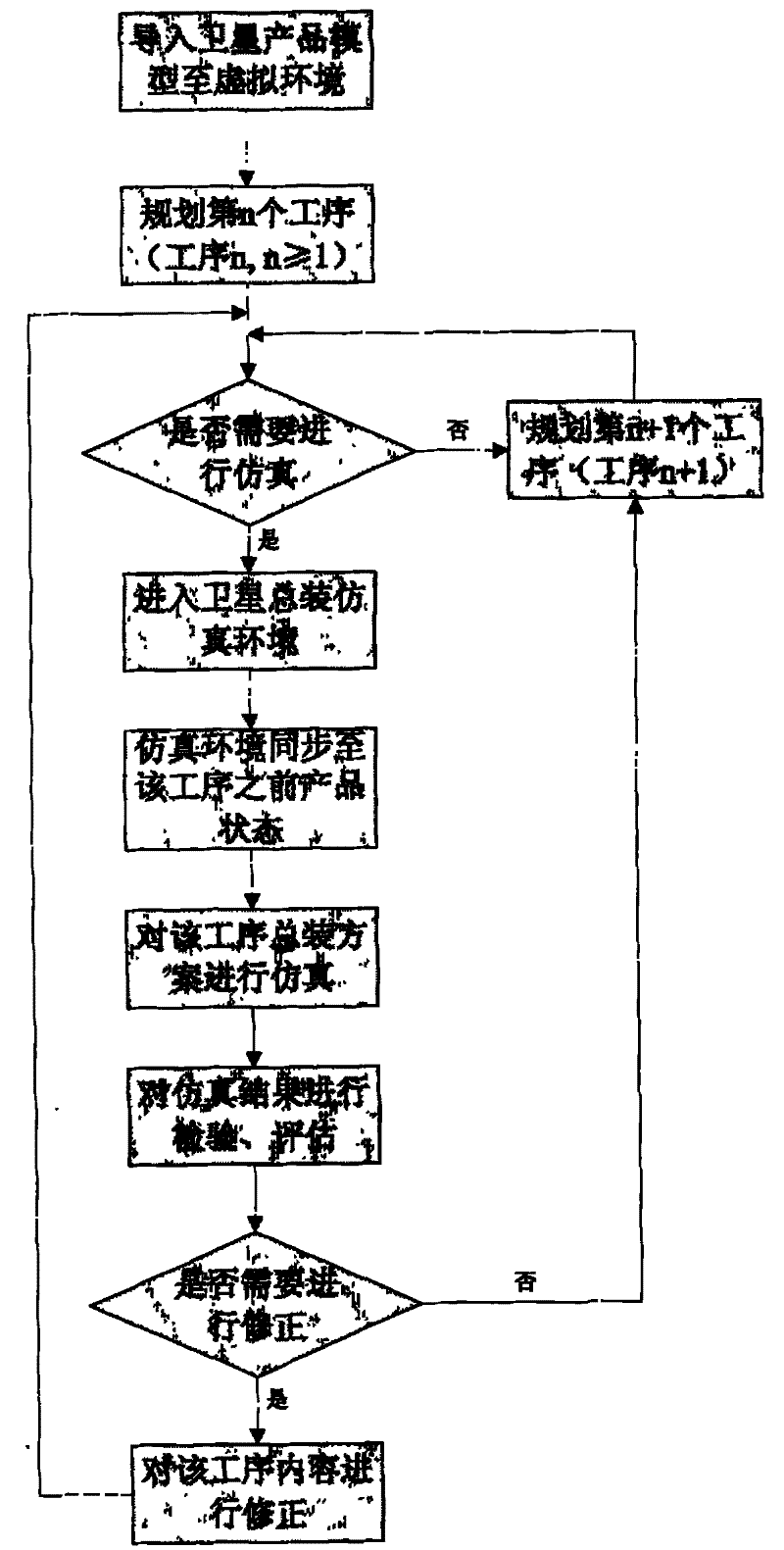

[0009] The realization process of the 2D-3D combined satellite assembly process planning and simulation method is as follows: figure 1 shown.

[0010] Before planning the final assembly process, first import the satellite’s digital parts model into the virtual reality environment, and adjust their specific positions, add process equipment models, tool models, etc., according to the actual assembly environment and resources of the satellite, to build a A realistic virtual satellite final assembly environment, ready for subsequent final assembly simulation operations in this environment.

[0011] The specific methods for satellite assembly process planning and simulation are as follows:

[0012] 1) First analyze the satellite general assembly drawings, general assembly technical documents, etc., plan the operation content of a certain process according to your own experience in model assembly, and determine the operation sequence, operation mode, tooling tools, etc. of the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com