Automatic carrying device for air conditioner compressor stack separation boards and automatic compressor carrying system

A technology for air-conditioning compressors and handling devices, which is applied in the directions of transportation and packaging, conveyors, stacking of objects, etc., can solve the problems of high labor intensity and low production efficiency, and achieve the effect of improving work efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

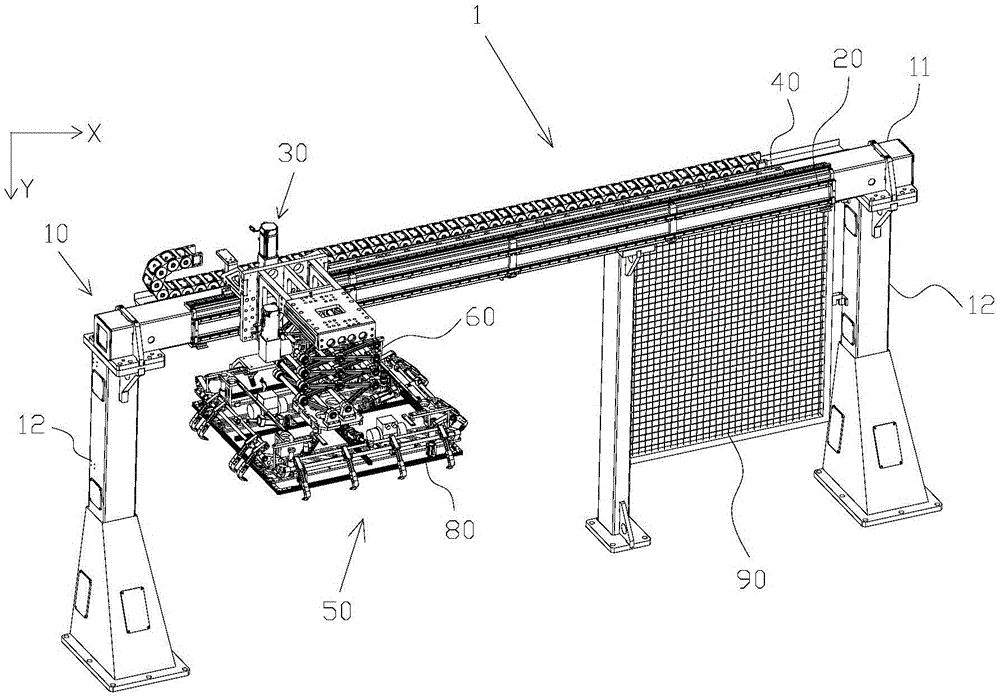

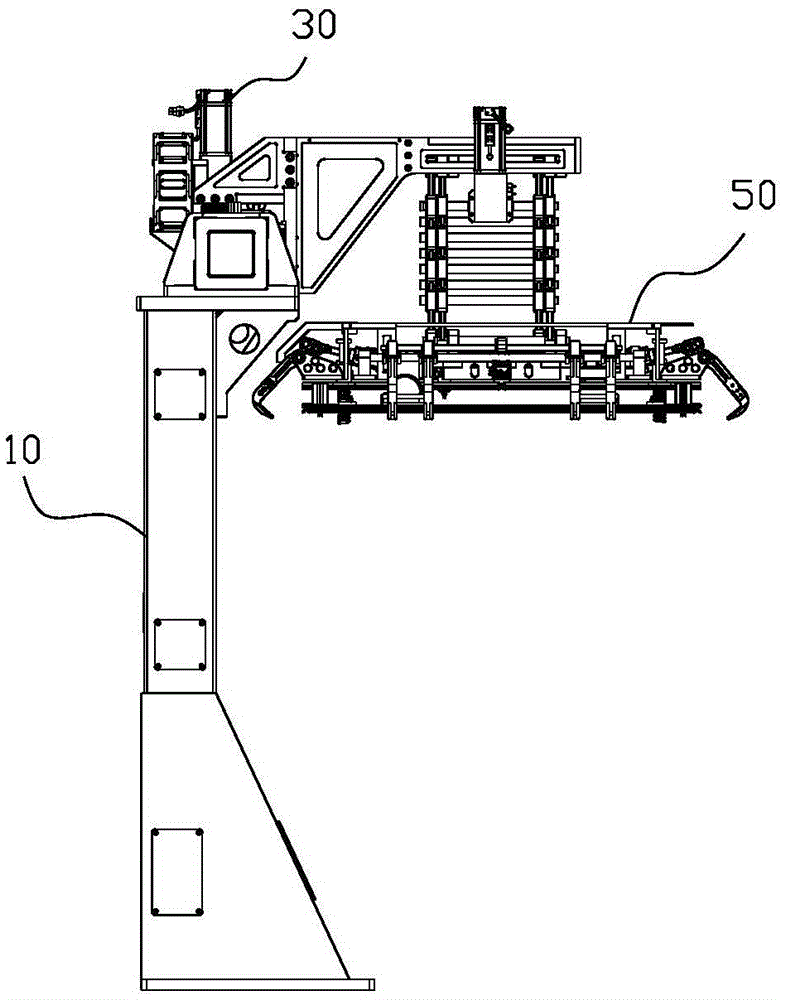

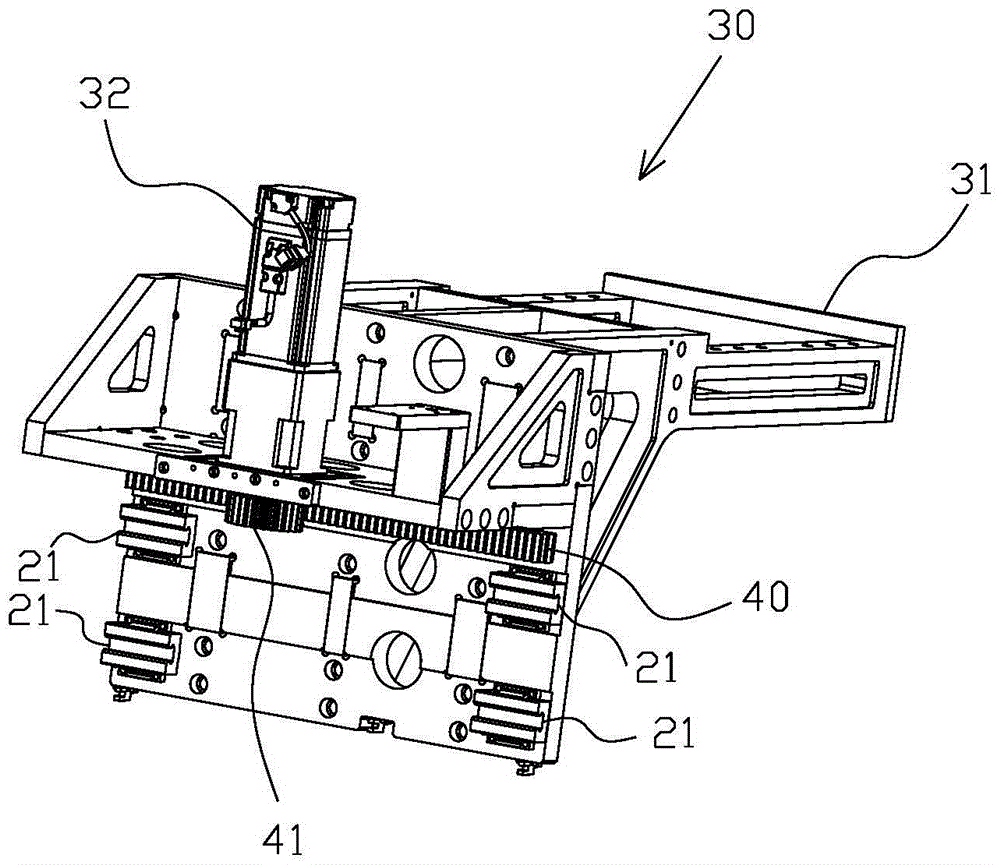

[0036] In order to clearly show the internal structure, figure 1 and figure 2 The three-dimensional schematic diagram and the side schematic diagram of the air-conditioning compressor stacking partition automatic handling device with the shell removed for the present invention, such as figure 1 and figure 2 As shown, the air-conditioning compressor palletizing partition automatic conveying device 1 of the present invention includes: a support mechanism 10 , a driving mechanism 30 and a palletizing partition conveying mechanism 50 . The palletizing partition conveying mechanism 50 is fixedly connected to the driving mechanism 30 , and the driving mechanism 30 is slidably connected to the supporting mechanism 10 .

[0037] The support mechanism 10 includes a beam 11 arranged along the X-axis, and two ends of the beam 11 are respectively provided with pillars 12 arranged along the Y-axis. The guide rail 20 and the rack 40 of the driving mechanism 30 are arranged on the beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com