Spacecraft equipment pose information measuring method based on six-freedom-degree laser tracking target

A technology of laser tracking and measurement method, applied in measurement devices, measurement instruments, instruments, etc., can solve the problems of low measurement efficiency, difficult measurement, and many occupations, achieve high measurement accuracy, and reduce the occupation rate of measurement personnel and equipment. , Improve the effect of on-site measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but this is only exemplary and not intended to limit the protection scope of the present invention.

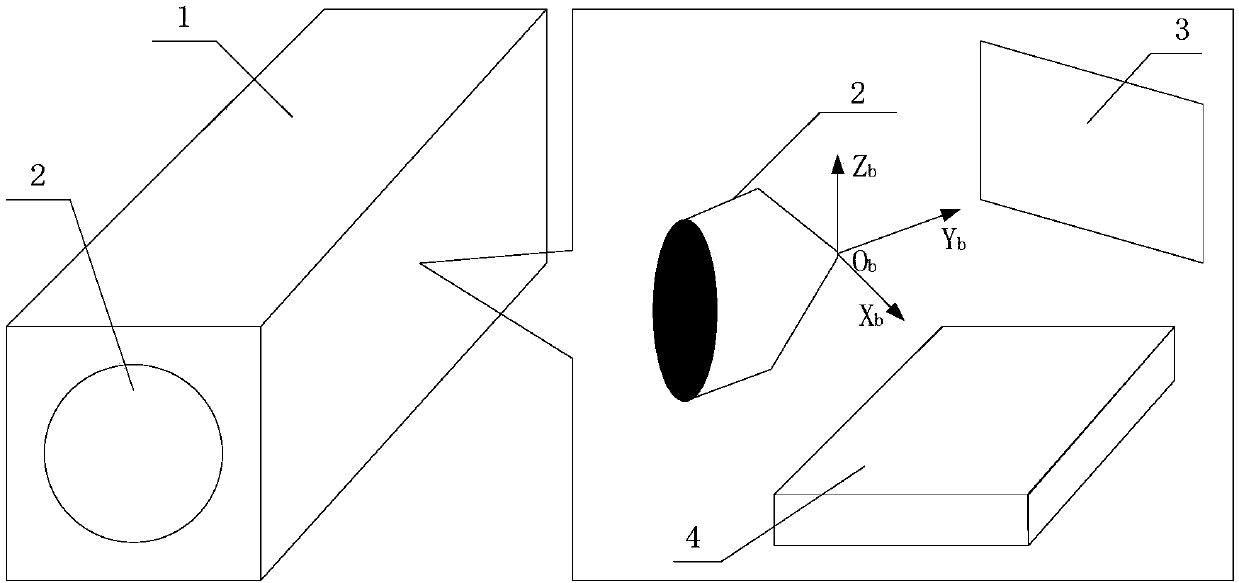

[0030] see image 3 , image 3Shows the schematic diagram of the composition of the six-degree-of-freedom laser tracking target in the method of the present invention; wherein, the six-degree-of-freedom laser tracking target in the method of the present invention: consists of a corner cube prism, an area array camera and a horizontal inclinometer, the angle of the corner cube prism There are small cuts at the cone. The measurement laser of the laser tracker or total station passes through the corner cube prism of the cooperative target for tracking and measurement, and most of the light is returned by the original path, which is no different from ordinary prism measurement, and the other part is received by the rear imaging system through the cutout. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com