Sealing arrangement for pipe expanding machine

A technology of sealing device and tube expander, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve problems such as sealing ring cuts, sealing ring failure, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

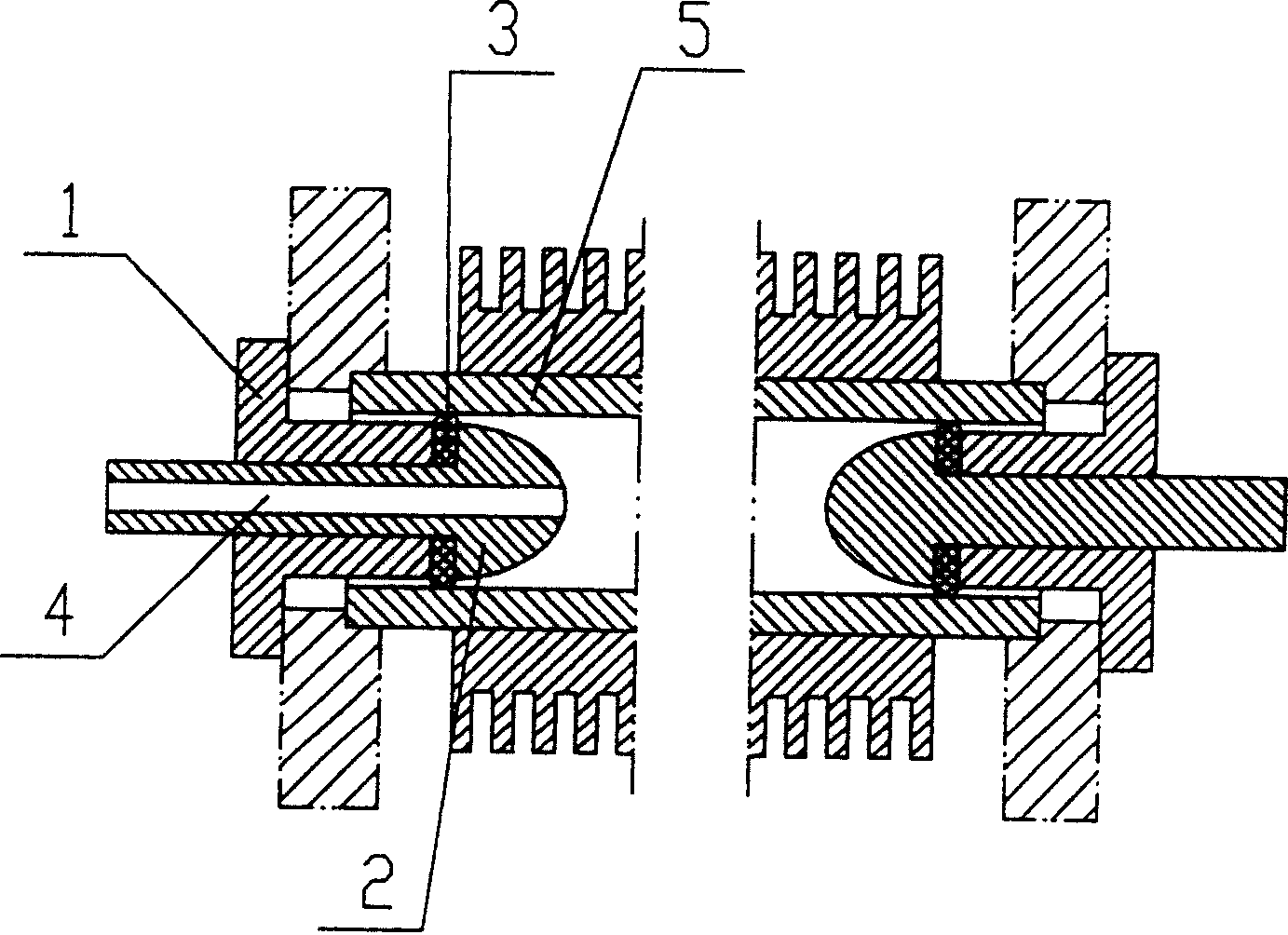

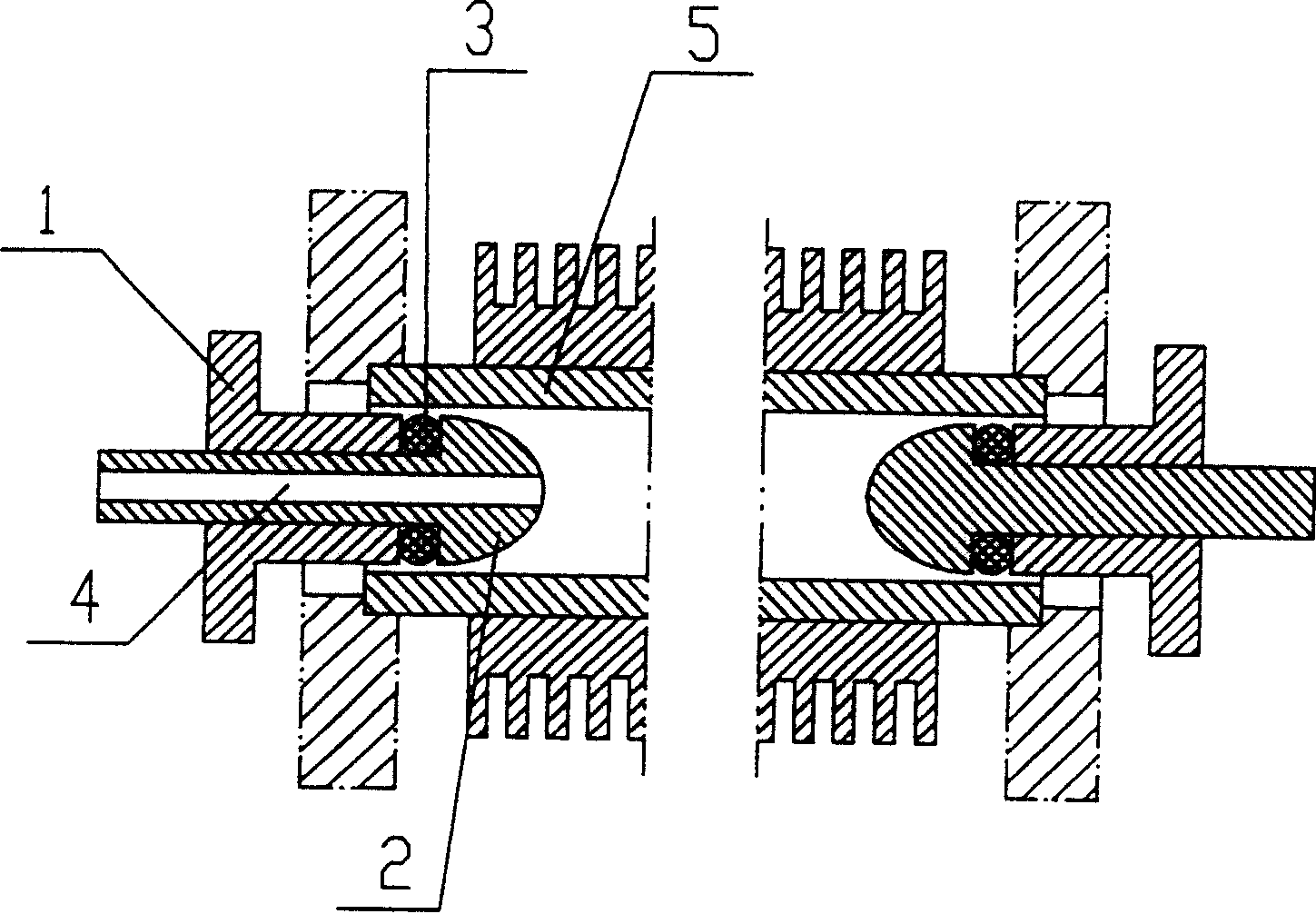

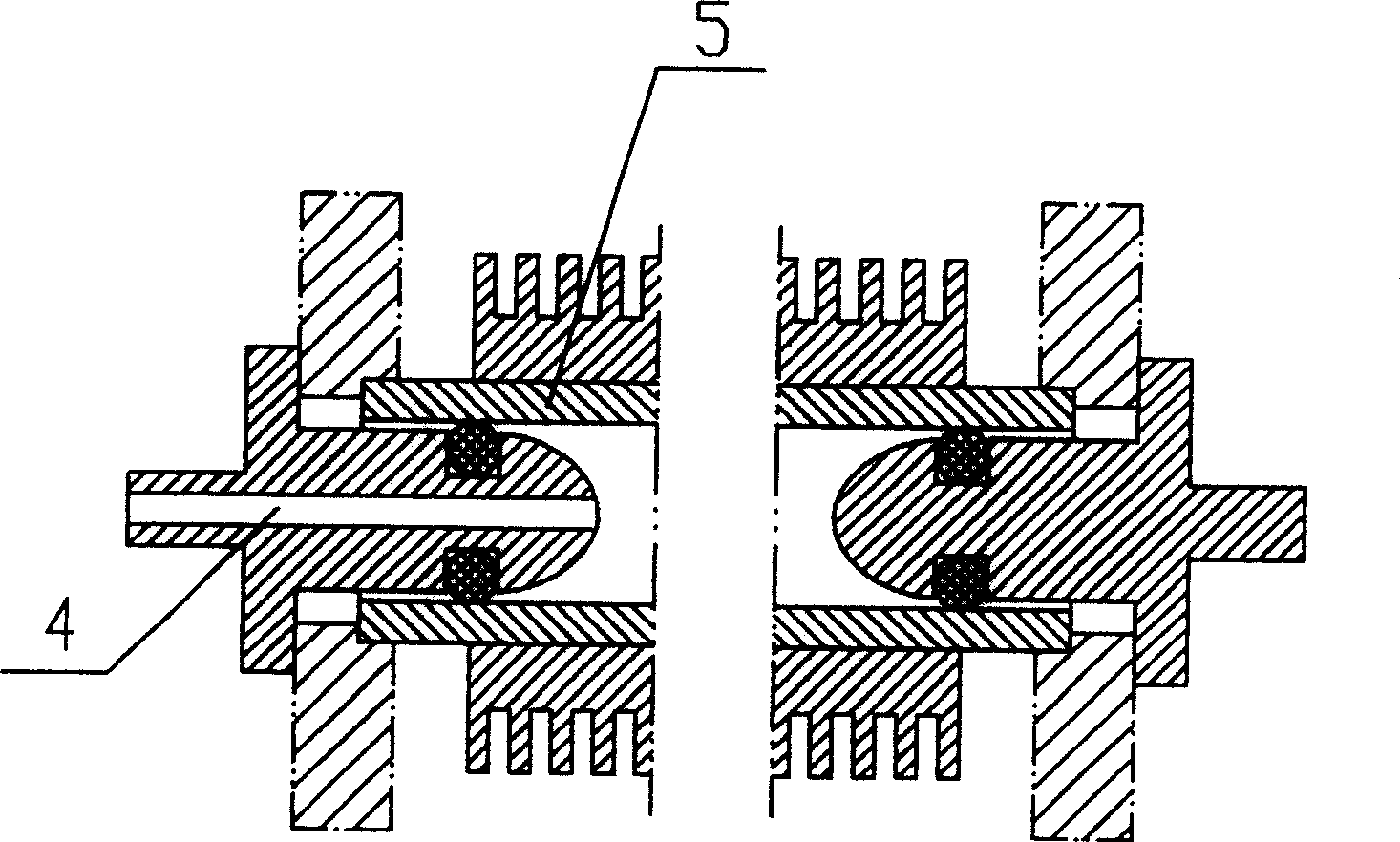

[0010] Such as figure 1 As shown, the sealing device for the tube expander includes a sealing head that can be inserted into the end of the tube to be expanded 5 and a sealing ring 3 arranged in the ring groove of the sealing head. The sealing head is installed in the ring groove of the sealing ring 3, The side away from the free end of the sealing head is divided into two parts, which include the base of the sealing head 1, the bottom surface of the ring groove containing the sealing ring 3 and the extrusion part 2 of the sealing head on the other side, the extrusion part of the sealing head is used as the installation seal The bottom part of the ring groove extends through the base of the sealing head 1 and protrudes out of the base of the sealing head 1, the extruding part 2 of the sealing head can move relative to the base of the sealing head 1, and the outer diameter of the sealing ring 3 is smaller than the pipe to be expanded 5 The inner diameter of the sealing ring 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com