High-toughness nanofiber-reinforced rubber-base 3D printing material and preparation method thereof

A nanofiber and reinforced rubber technology, applied in the field of nanofiber reinforced rubber-based 3D printing materials and their preparation, can solve the problems of low strength, low efficiency, long cycle, etc., and achieve the effect of high bonding strength and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a high-toughness nanofiber-reinforced rubber-based 3D printing material, comprising the steps of:

[0031] 1), the preparation of mixing rubber:

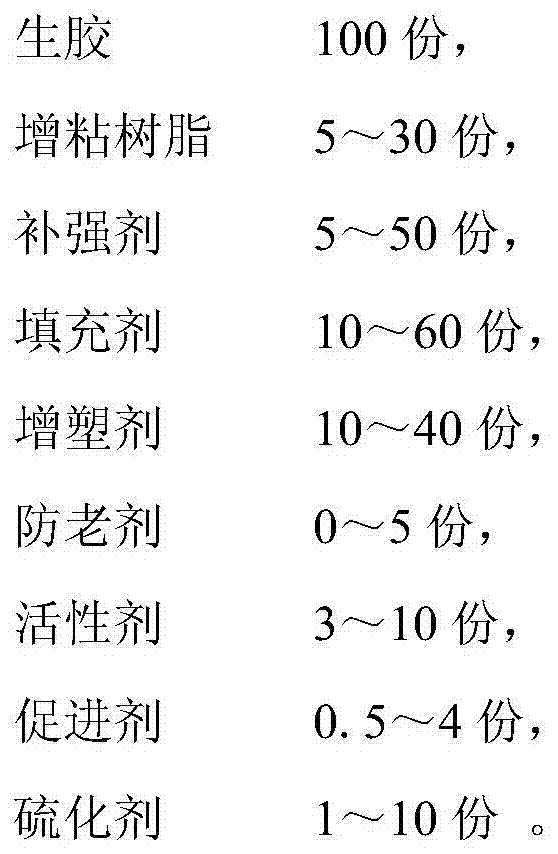

[0032] parts by mass

[0033]

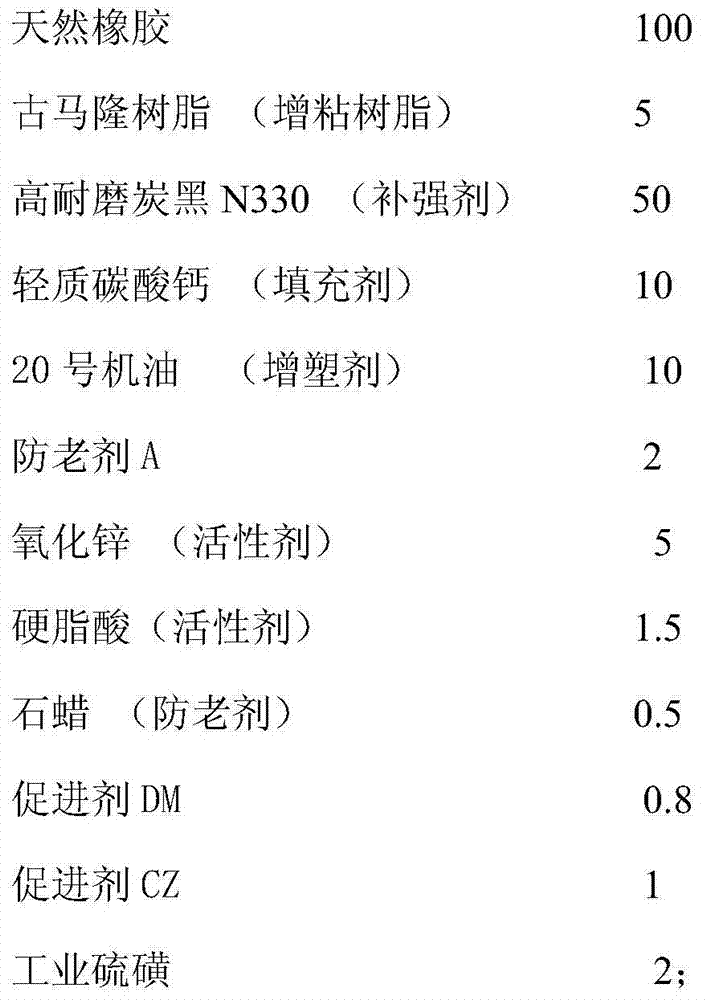

[0034] Add natural rubber and coumarone resin to the open mixer at a temperature of 50-70°C for mastication. After the Mooney viscosity of the masterbatch of natural rubber and coumarone resin reaches 40-70, add Anti-aging agent A, paraffin, zinc oxide, stearic acid, accelerator DM, accelerator CZ, after the above is completely mixed into the rubber, then add high wear-resistant carbon black N330, light calcium carbonate, No. 20 engine oil, wait for the above to be completely mixed After the rubber, industrial sulfur is added at the end. After the sulfur is mixed into the rubber, it needs to be thinly passed 3 to 5 times, so that the compounding agent can be evenly dispersed in the rubber, and the mixed rubber can be obtained;

[0035] 2), Preparation of thermoplasti...

Embodiment 2

[0041] A method for preparing a high-toughness nanofiber-reinforced rubber-based 3D printing material, comprising the steps of:

[0042] 1), preparation of mixed rubber

[0043] parts by mass

[0044]

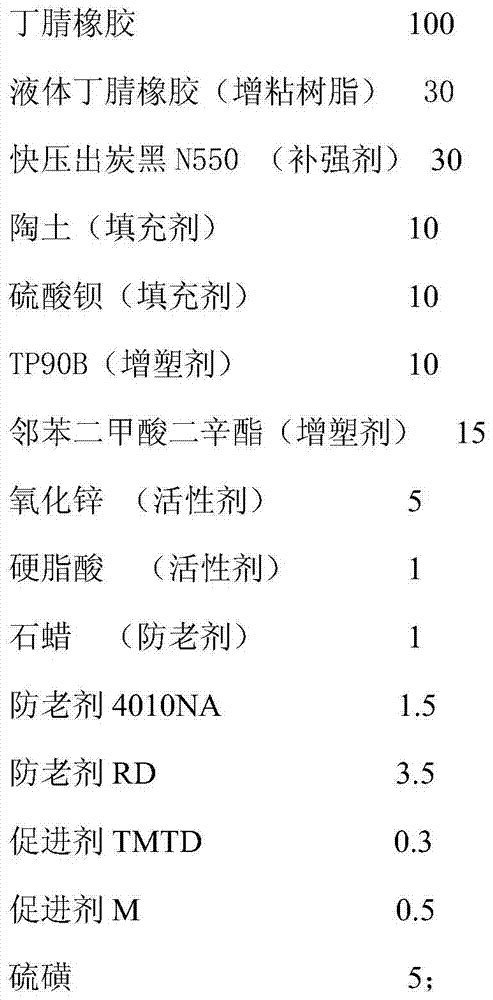

[0045] Add nitrile rubber and liquid nitrile rubber to the open mill at a temperature of 50-70°C for mastication, and when the Mooney viscosity of the masterbatch of nitrile rubber and liquid nitrile rubber reaches 40-70, feed it to the open mill Add anti-aging agent 4010NA, anti-aging agent RD, paraffin, zinc oxide, stearic acid, accelerator TMTD, accelerator M, after the above ingredients are completely mixed into the rubber, then add quick-pressed carbon black N550, clay, barium sulfate, TP90B, dioctyl phthalate, after the above compounding agent is completely mixed into the rubber, add sulfur at last, after the sulfur is mixed into the rubber, it needs to be thinly passed 3 to 5 times, so that the compounding agent is evenly dispersed in the rubber, and the obtained Mi...

Embodiment 3

[0052] A method for preparing a high-toughness nanofiber-reinforced rubber-based 3D printing material, comprising the steps of:

[0053] 1), preparation of mixed rubber

[0054] parts by mass

[0055]

[0056]

[0057] Add neoprene and coumarone resin to the open mill at a temperature of 50-70°C for mastication. After the Mooney viscosity of the masterbatch of chloroprene rubber and coumarone resin reaches 40-70, put it into the open mill. Add anti-aging agent AW, anti-aging agent MB, paraffin, stearic acid, accelerator TMTD, accelerator NA-22, accelerator TETD, after the above ingredients are completely mixed into the rubber, then add medium particle thermal carbon black N990, White carbon black, heavy calcium carbonate, titanium dioxide, dioctyl sebacate, dibutyl phthalate, after the above compounding ingredients are completely mixed into the rubber, finally add zinc oxide, magnesium oxide, wait for zinc oxide, magnesium oxide After the rubber is mixed, it needs to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com