Solar cell module with integrated optimizer

A technology of solar cell components and optimizers, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of reducing system power generation performance, reducing system reliability, and no power output, etc., to achieve improved reliability, simple structure, and improved The effect of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

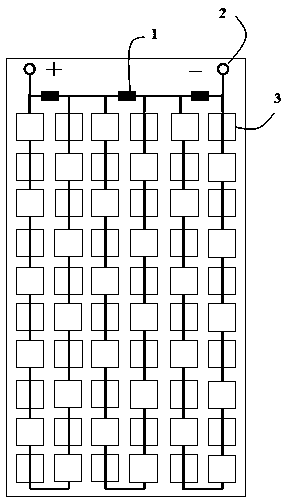

[0033] like figure 1 As shown, the present embodiment is composed of 10X6 vertically connected battery strings, each battery string is formed by 10 battery slices connected in series, and an optimizer is connected in parallel with two vertically connected battery strings.

Embodiment 2

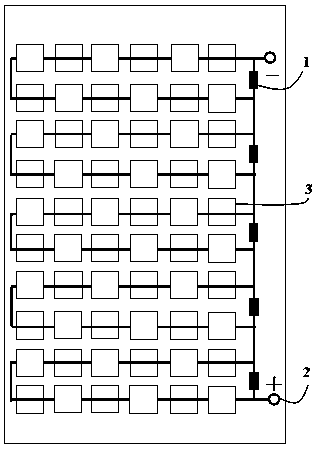

[0035] like figure 2 As shown, the present embodiment adopts 6x10 battery strings connected horizontally in series, and each battery string is formed by 6 battery slices connected in series, and an optimizer is connected in parallel with two horizontally connected battery strings.

[0036] For regular components:

[0037] One or more batteries are blocked or damaged. Since the current of the series circuit is determined by the minimum current, the current of all 60 batteries will be reduced, and the problematic battery will affect the power output of all batteries;

[0038] And for the optimizer component:

[0039] When the optimizer is connected in parallel with two strings of vertically connected battery strings, if one or more batteries in a certain battery string are blocked or damaged, only the output power of the two strings connected in parallel by the optimizer where the problematic battery string is located, i.e. 20 batteries, will be reduced. If it is affected, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com