Control method of direct-current photovoltaic power generating modules

A photovoltaic power generation module and control method technology, applied in photovoltaic power generation, AC network circuits, electrical components, etc., can solve the complex structure of photovoltaic power generation DC-DC converter system, reduce system energy conversion efficiency, and difficult to obtain component status information, etc. problems, achieve high component electrical parameter mismatch capability, fast fault diagnosis and fault location, and solve the effect of hot spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

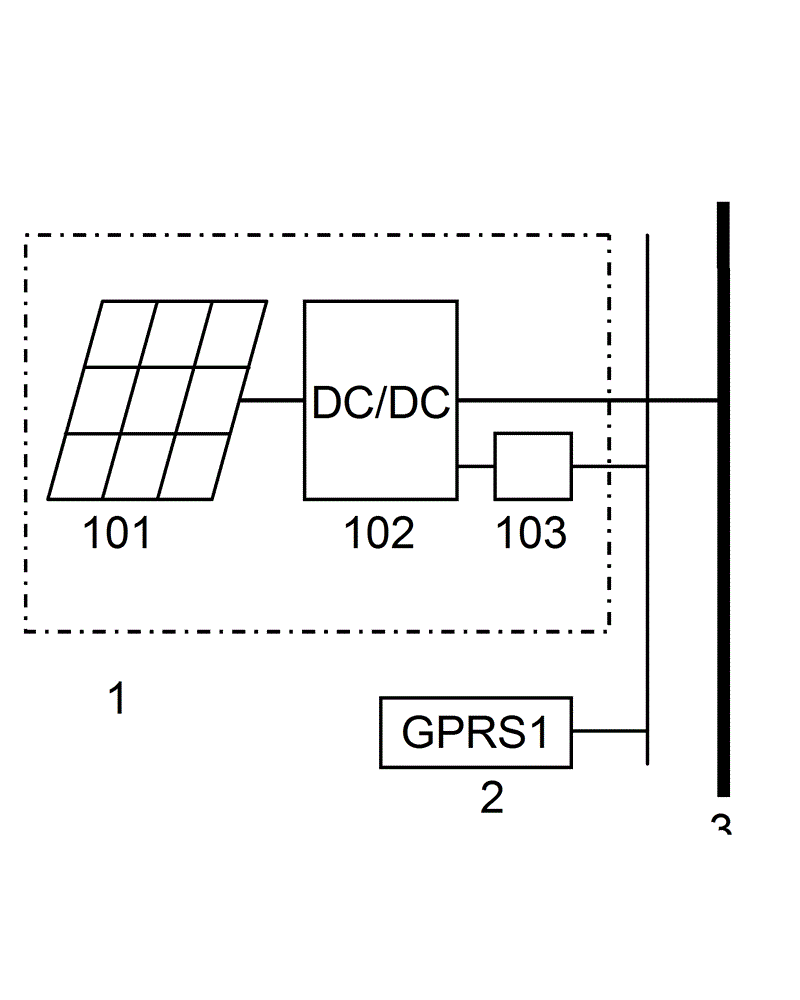

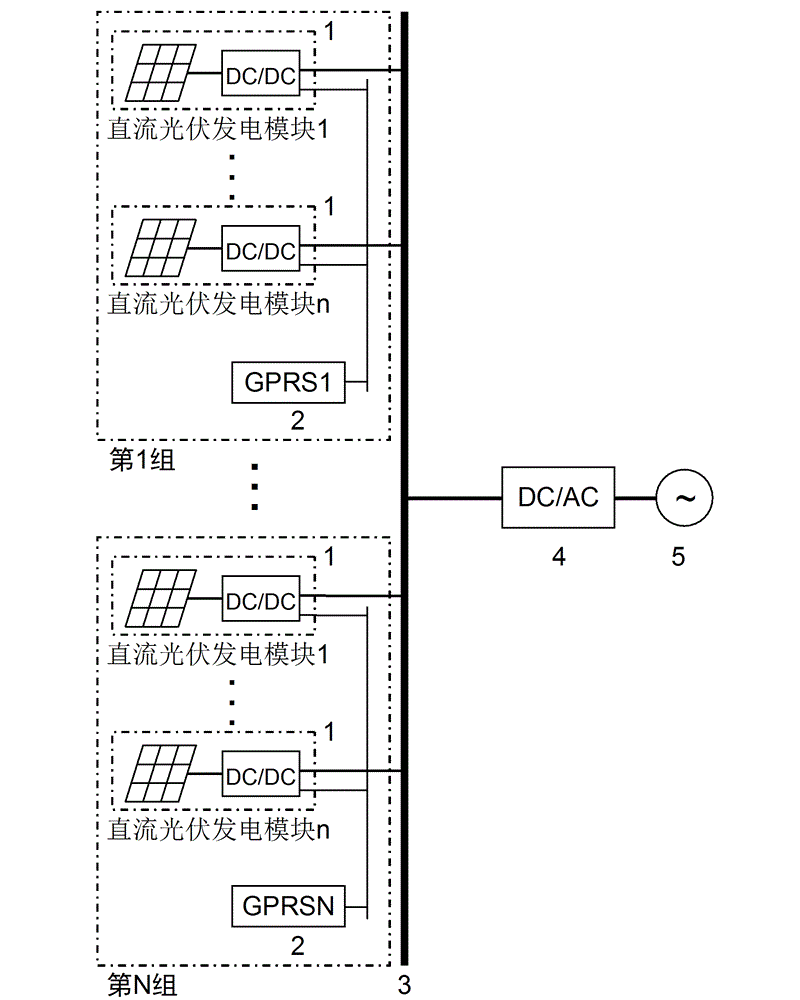

[0031] as attached figure 1 As shown, the present invention is a control method of a DC photovoltaic power generation module. The DC photovoltaic power generation module 1 is composed of a photovoltaic module 101, a DC micro-converter 102, and a communication module 103. One end of the DC micro-converter 102 is connected to the photovoltaic module 101. The other end is connected to the DC bus 3, and the DC micro-converter 101 is connected with its own control loop, and the control loop is connected to its communication module 103 to realize DC boost, maximum power point tracking (MPPT) and communication functions, and completely solve shadows, etc. The formed hot spot effect greatly improves the power generation efficiency of the system.

[0032] The DC micro-converter 102 adopts a DC-AC-DC structure. First, through DC-AC inversion, the DC power output by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com