Intelligent photovoltaic power adjustor and adjusting method

A power conditioner and photovoltaic technology, which is applied in the field of solar photovoltaic power generation, can solve problems that affect the performance and life of components, temperature rise or damage of components, and increase costs, so as to avoid hot spot effects and reduce mismatching of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

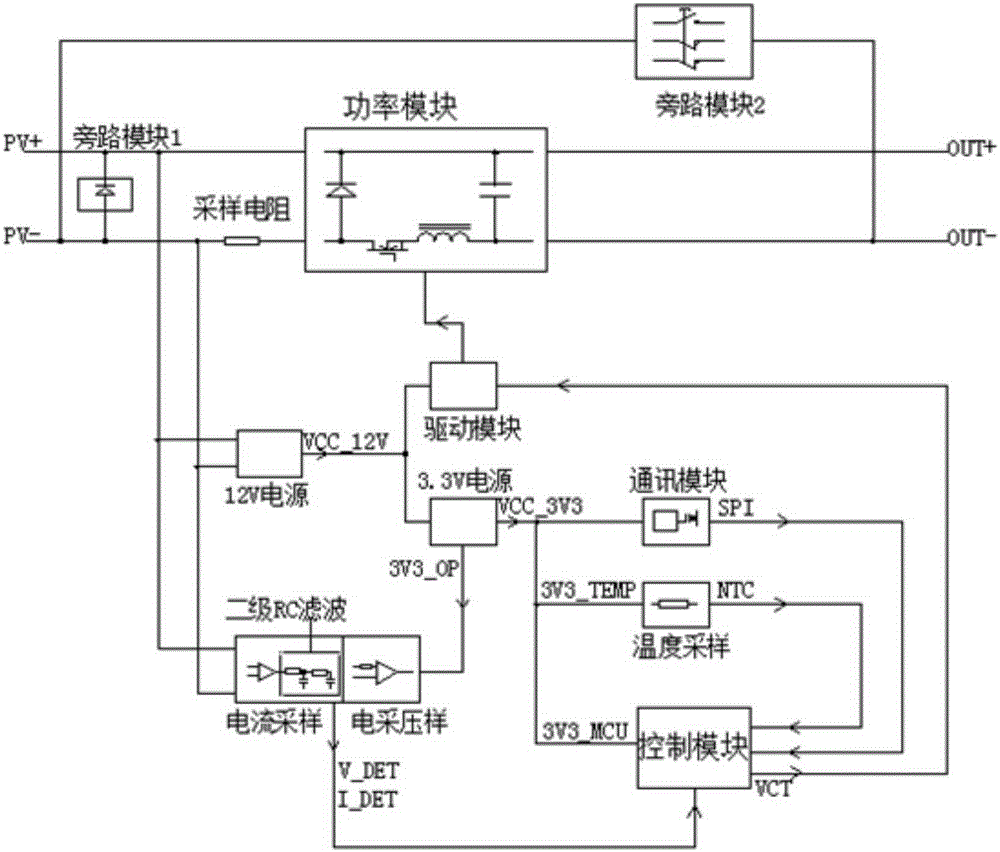

[0033] The intelligent photovoltaic power conditioner of the present invention includes a circuit board of an upper cover, a bottom case and an optional junction box module, wherein the circuit board is as figure 1 As shown, it contains 7 modules, which are power module, control module, drive module, communication module, sampling module, power module and bypass module. The power module provides working power for all other modules, and the input terminal of the power module is connected to the photovoltaic output of the component.

[0034] A sampling module is connected in parallel between the positive and negative poles of the input end of the power module, the sampling module is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com