High heat conductivity and insulation plastic as well as preparation method and application thereof

An insulating plastic, high thermal conductivity technology, applied in the field of materials, can solve problems such as low thermal conductivity and limited application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0129] The present invention also provides a preparation method of the high thermal conductivity insulating plastic, comprising the following steps:

[0130] a-1) Provide thermoplastic resin and composite thermally conductive filler;

[0131] a-2) mixing the thermoplastic resin and composite thermally conductive filler, and granulating to obtain the high thermally conductive insulating plastic.

[0132] In another preferred example, the thermoplastic resin and the composite thermally conductive filler are as described in the first aspect of the present invention.

[0133] In the present invention, the thermally conductive filler, thermoplastic resin, flame retardant, toughener and antioxidant are not particularly limited, and can be prepared by conventional methods or purchased from the market.

[0134] In another preferred example, the composite thermally conductive filler is prepared as follows:

[0135] b-1) providing the first mixture, the second mixed liquid and the coa...

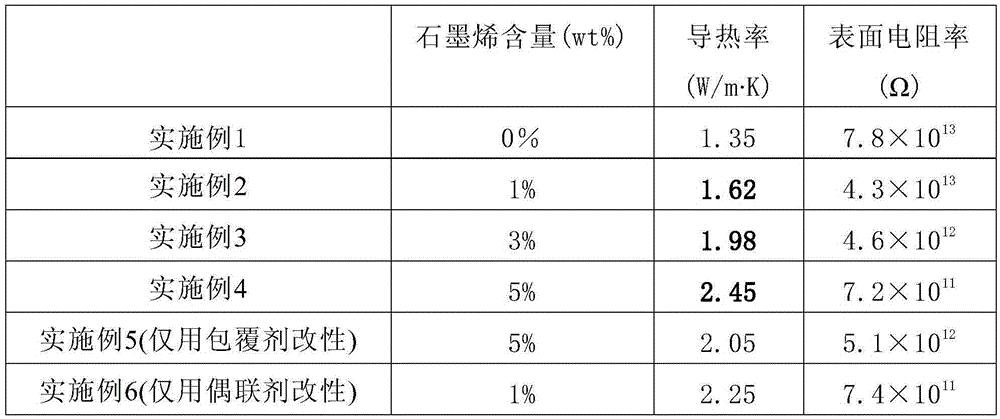

Embodiment 1

[0185] Embodiment 1 High thermal conductivity insulating plastic 1 (graphene content is 0wt%)

[0186] Dissolve 12.5g of coupling agent KH550 evenly in 80ml of a mixed solvent of absolute ethanol and water (the mixing ratio of absolute ethanol and water is 95:5), and then adjust the pH value of the solution system to 4 with acetic acid. Stir mechanically at a stirring speed of rpm for 20 min. At a stirring speed of 500 rpm, use a spray bottle to spray the resulting mixed solution into 2500 g of inorganic insulating heat-conducting filler MgO with a particle size of 50 μm to be stirred. After stirring continuously for 60 minutes, gradually increase the stirring speed to 2000 rpm , the friction between the materials makes the temperature of the materials rise. When the temperature rises to about 100°C, the coupling agent will react with the inorganic insulating heat-conducting filler MgO. After about 30 minutes of reaction, stop stirring, and wait for the temperature of the reac...

Embodiment 2

[0192] Embodiment 2 High thermal conductivity insulating plastic 2 (graphene content is 1wt%)

[0193] 2450g of inorganic insulating thermally conductive filler MgO with a particle size of 50 μm was uniformly mixed with 25000 ml of a slurry containing 50 g of graphene with a particle size of 20 μm, and dried to obtain a composite thermally conductive filler of graphene and MgO. Dissolve 12.5g of coupling agent KH550 evenly in 80ml of a mixed solvent of absolute ethanol and water (the mixing ratio of absolute ethanol and water is 95:5), and then adjust the pH value of the solution system to 4 with acetic acid. Stir mechanically at a stirring speed of rpm for 20 min. At a stirring speed of 500 rpm, use a spray bottle to spray the resulting mixed solution into the stirred composite heat-conducting filler. After continuous stirring for 60 minutes, gradually increase the stirring speed to 2000 rpm. The friction between the materials makes the temperature of the materials rise. Hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com