Solar photovoltaic panel cleaning equipment with cleaning brushes capable of being adjusted in self-adaptation mode

A solar photovoltaic panel and self-adaptive adjustment technology, which is applied in the field of solar photovoltaic panel cleaning, can solve problems such as large differences in installation height of photovoltaic panels, inability to use such equipment for cleaning, and complicated road conditions in cleaning channels, so as to reduce requirements and ensure cleaning Effect, the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

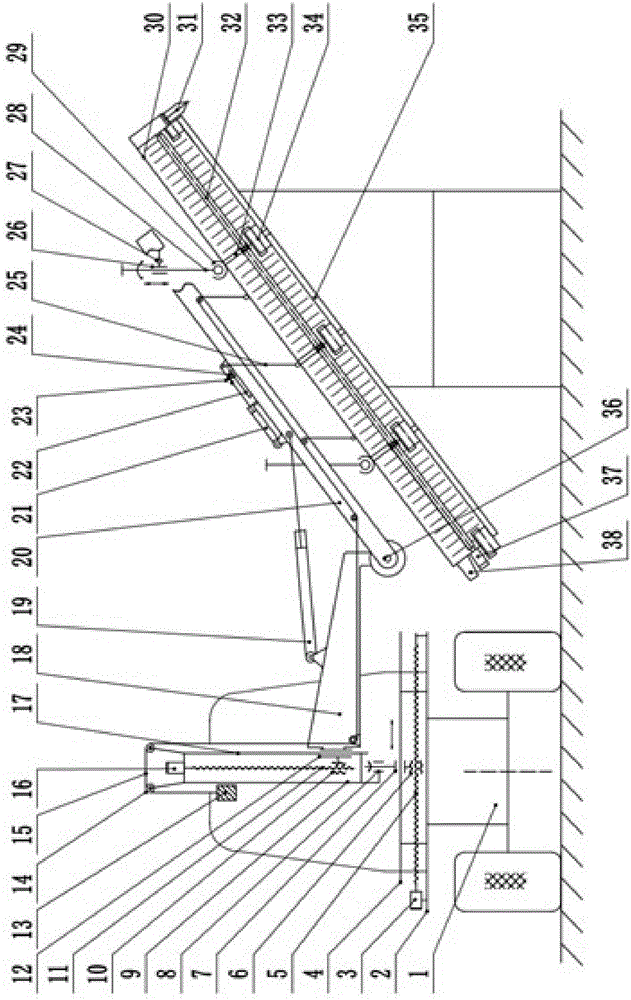

[0014] Such as figure 1 As shown, the present invention is a solar photovoltaic panel cleaning device with self-adaptive adjustment of the cleaning brush, which consists of four parts: a car body, an automatic adjustment device for the cleaning brush, an adaptive adjustment device for the cleaning brush, and a cleaning brush body. The car body is composed of a driving car 1 Composed of frame 2, the cleaning brush automatic adjustment device consists of a horizontal drive motor 3, a horizontal moving guide rail 4, a horizontal driving screw 5, a horizontal screw nut 6, a horizontal moving slider 7, a turntable 8, a column 9, and a vertical screw Nut 10, vertically moving lead screw 11, vertically moving slide block 12, vertically moving guide rail 17, main swing arm 18, main hydraulic cylinder 19, auxiliary swing arm 20 are composed; horizontal drive motor 3, horizontal drive lead screw 5, The horizontal moving guide rails 4 are respectively fixed on the frame 2, the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com