Steel fiber/polymer fiber dual-fiber reinforced concrete and preparation method thereof

A fiber-reinforced, polymer technology, applied in the field of concrete, can solve the problems of reduced concrete strength and no contribution to concrete strength, and achieves the effect of less initial cracks, no construction procedures and processes, and broad promotion prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

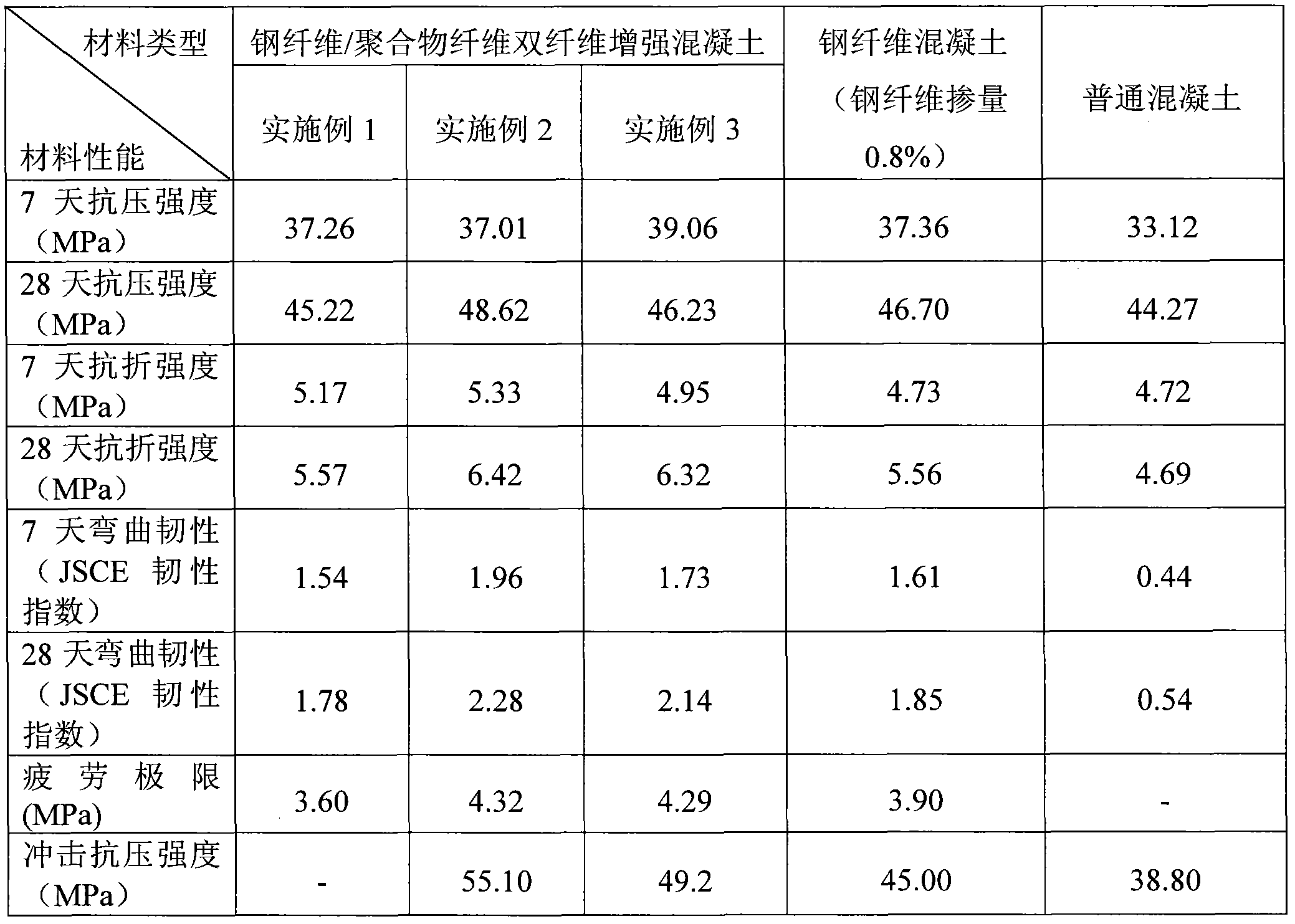

Examples

Embodiment 1

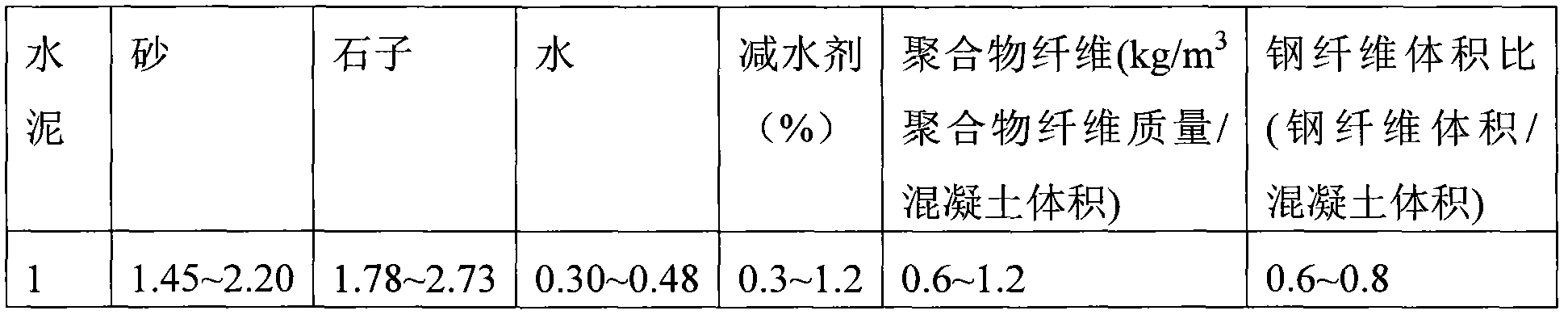

[0028] Raw materials for preparing steel fiber / polymer fiber double fiber reinforced concrete:

[0029] (1) Cement: Ordinary Portland cement with a strength grade of 32.5;

[0030] (2) Sand: river sand, apparent density 2.65g / cm 3 , bulk density 1400kg / m 3 , porosity 47.2%, mud content 1%, fineness modulus 2.8, medium sand;

[0031] (3) Crushed stone: artificially rolled granite crushed stone, particle size <20mm;

[0032] (4) Steel fiber: sheared steel fiber, length 30mm, equivalent diameter 0.69mm, aspect ratio 45, tensile strength > 755MPa;

[0033] (5) Polymer fiber: polypropylene fiber or polyacrylonitrile fiber, bundled monofilament, length 12 / 19mm, diameter 20 / 38μm, tensile strength > 500MPa;

[0034] (6) Water reducer: KJ-5 high-efficiency water reducer, high concentration, powder.

[0035]The preparation method of steel fiber / polymer fiber double fiber reinforced concrete is as follows:

[0036] (1) Clean the sand and gravel and keep them in a dry state;

[003...

Embodiment 2

[0043] Raw materials for preparing steel fiber / polymer fiber double fiber reinforced concrete:

[0044] (1) Cement: Ordinary Portland cement with a strength grade of 32.5;

[0045] (2) Sand: river sand, apparent density 2.65g / cm 3 , bulk density 1400kg / m 3 , porosity 47.2%, mud content 1%, fineness modulus 2.8, medium sand;

[0046] (3) Crushed stone: artificially rolled granite crushed stone, particle size <20mm;

[0047] (4) Steel fiber: sheared steel fiber, length 30mm, equivalent diameter 0.69mm, aspect ratio 45, tensile strength > 755MPa;

[0048] (5) Polymer fiber: polypropylene fiber or polyacrylonitrile fiber, bundled monofilament, length 12 / 19mm, diameter 20 / 38μm, tensile strength > 500MPa;

[0049] (6) Water reducer: KJ-5 high-efficiency water reducer, high concentration, powder.

[0050] The preparation method of steel fiber / polymer fiber double fiber reinforced concrete is as follows:

[0051] (1) Clean the sand and gravel and keep them in a dry state;

[00...

Embodiment 3

[0058] Raw materials for preparing steel fiber / polymer fiber double fiber reinforced concrete:

[0059] (1) Cement: Ordinary Portland cement with a strength grade of 32.5;

[0060] (2) Sand: river sand, apparent density 2.65g / cm 3 , bulk density 1400kg / m 3 , porosity 47.2%, mud content 1%, fineness modulus 2.8, medium sand;

[0061] (3) Crushed stone: artificially rolled granite crushed stone, particle size <20mm;

[0062] (4) Steel fiber: sheared steel fiber, length 30mm, equivalent diameter 0.69mm, aspect ratio 45, tensile strength > 755MPa;

[0063] (5) Polymer fiber: polypropylene fiber or polyacrylonitrile fiber, bundled monofilament, length 12 / 19mm, diameter 20 / 38μm, tensile strength > 500MPa;

[0064] (6) Water reducer: KJ-5 high-efficiency water reducer, high concentration, powder.

[0065] The preparation method of steel fiber / polymer fiber double fiber reinforced concrete is as follows:

[0066] (1) Clean the sand and gravel and keep them in a dry state;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com