Fireproof door core filling material and preparation method thereof

A fire door and core filling technology, applied in the field of fireproof materials, to achieve the effects of high hardness, strong adhesion and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

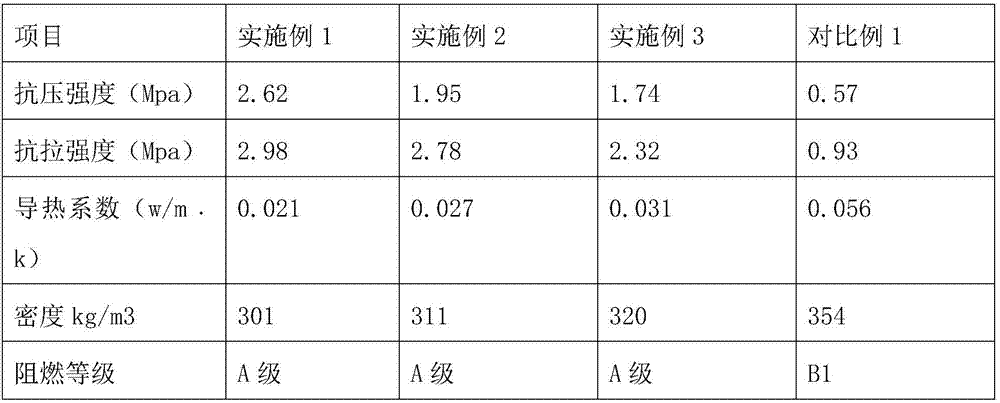

Examples

Embodiment 1

[0035] A fire door core filling material, comprising the following raw materials in parts by weight: 36 parts of perlite, 16 parts of bentonite, 11 parts of magnesium sulfate, 18 parts of magnesium oxide, 11 parts of calcium hydroxide, 6 parts of boron oxide, 6 parts of lignin, 8 parts of ceramic fiber, 19 parts of glass wool, 16 parts of zirconia, 11 parts of airgel, 12 parts of nano silicon carbide, 2 parts of inorganic binder and 9 parts of water.

[0036] Ceramic fiber is added to the raw material. Ceramic fiber has the characteristics of light weight, high temperature resistance, good thermal stability, good fire resistance, good thermal insulation and high tensile and flexural strength, which helps to improve the prepared fire door core The fire resistance and tensile properties of the material.

[0037] Glass wool is added to the raw material, and there are many tiny pores inside the glass wool, which perform well in thermal insulation, sound absorption, corrosion resis...

Embodiment 2

[0051] A fire door core filling material, comprising the following raw materials in parts by weight: 32 parts of perlite, 14 parts of bentonite, 10 parts of magnesium sulfate, 16 parts of magnesium oxide, 10 parts of calcium hydroxide, 4 parts of boron oxide, 5 parts of lignin, 5 parts of ceramic fiber, 17 parts of glass wool, 13 parts of zirconia, 8 parts of airgel, 6 parts of nano silicon carbide, 1 part of inorganic binder and 7 parts of water.

[0052] Ceramic fiber is added to the raw material. Ceramic fiber has the characteristics of light weight, high temperature resistance, good thermal stability, good fire resistance, good thermal insulation and high tensile and flexural strength, which helps to improve the prepared fire door core The fire resistance and tensile properties of the material.

[0053]Glass wool is added to the raw material, and there are many tiny pores inside the glass wool, which perform well in thermal insulation, sound absorption, corrosion resistanc...

Embodiment 3

[0067] A fire door core filling material, comprising the following raw materials in parts by weight: 40 parts of perlite, 18 parts of bentonite, 12 parts of magnesium sulfate, 20 parts of magnesium oxide, 12 parts of calcium hydroxide, 8 parts of boron oxide, 7 parts of lignin, 11 parts of ceramic fiber, 21 parts of glass wool, 19 parts of zirconia, 14 parts of airgel, 18 parts of nano silicon carbide, 3 parts of inorganic binder and 11 parts of water.

[0068] Ceramic fiber is added to the raw material. Ceramic fiber has the characteristics of light weight, high temperature resistance, good thermal stability, good fire resistance, good thermal insulation and high tensile and flexural strength, which helps to improve the prepared fire door core The fire resistance and tensile properties of the material.

[0069] Glass wool is added to the raw material, and there are many tiny pores inside the glass wool, which perform well in thermal insulation, sound absorption, corrosion res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com