Large compound radiant heating rod and preparation method thereof

A compound radiation and heating rod technology, which is applied in the field of large compound radiation heating rod and its preparation, can solve the problems of short service life, scrapping and high brittleness of the heating rod, and achieve high tensile and flexural strength, increased heating volume, high temperature The effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

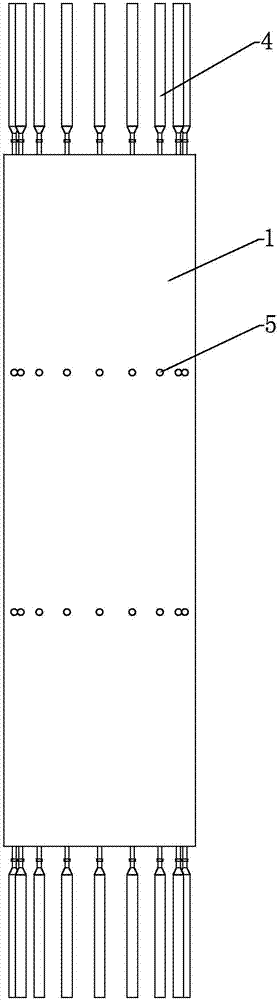

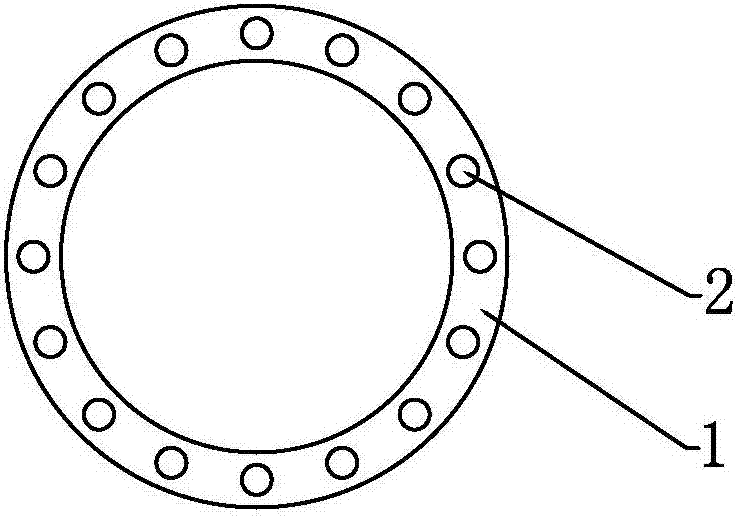

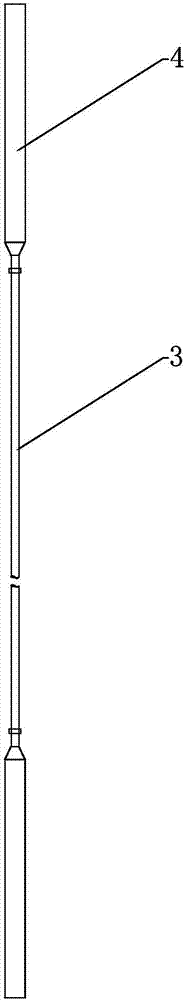

[0042] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0043] Such as Figure 1-Figure 3 As shown in , the large-scale composite radiant heating rod in this embodiment includes a fixed sleeve 1 made of insulating material, and several installation column holes are evenly penetrated on the wall of the fixed sleeve 1 along the axis direction of the fixed sleeve 1. 2. The mounting column holes 2 are arranged on the side wall of the fixed sleeve 1 in a circular shape, and a heating rod is inserted in each mounting column hole 2, and the heating rod includes a plurality of rod units The connected heating section 3 and the two conductive cold ends 4 welded to the two ends of the heating section 3, the outer wall of the fixed sleeve 1 adjacent to each mounting column hole 2 are provided with several holes connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com