Fiber mesh reinforced grouting full-length reinforced frozen pipe in double-layer sandwich cavity and construction method

A technology of freezing pipes and fiber nets, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems that the tensile, bending and corrosion resistance of frozen pipes cannot meet the requirements, cannot be completely eliminated, and safety hazards, etc., to achieve Avoid major safety hazards, increase tensile strength, and increase corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

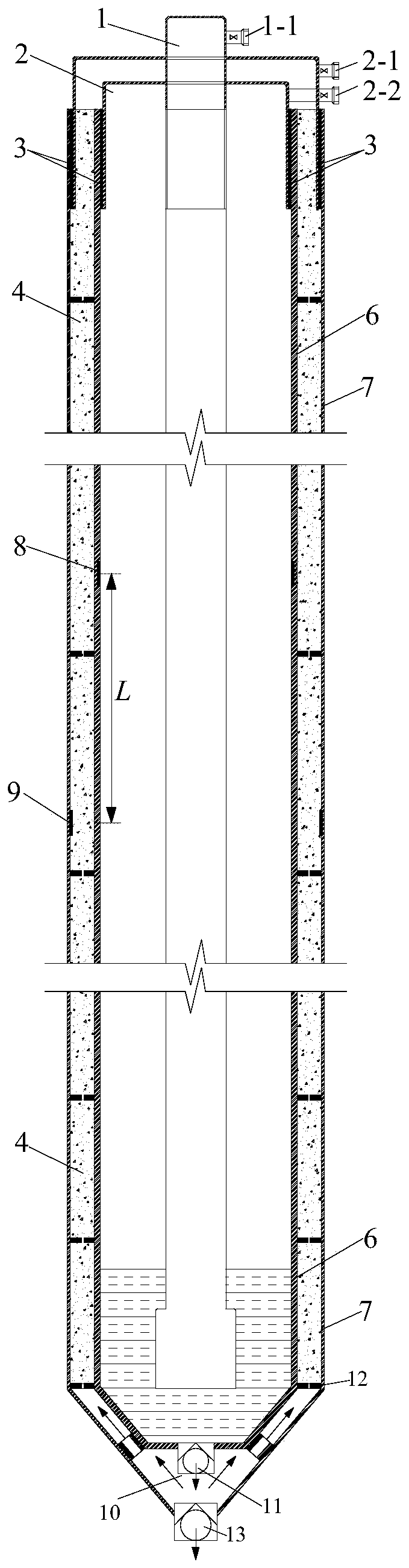

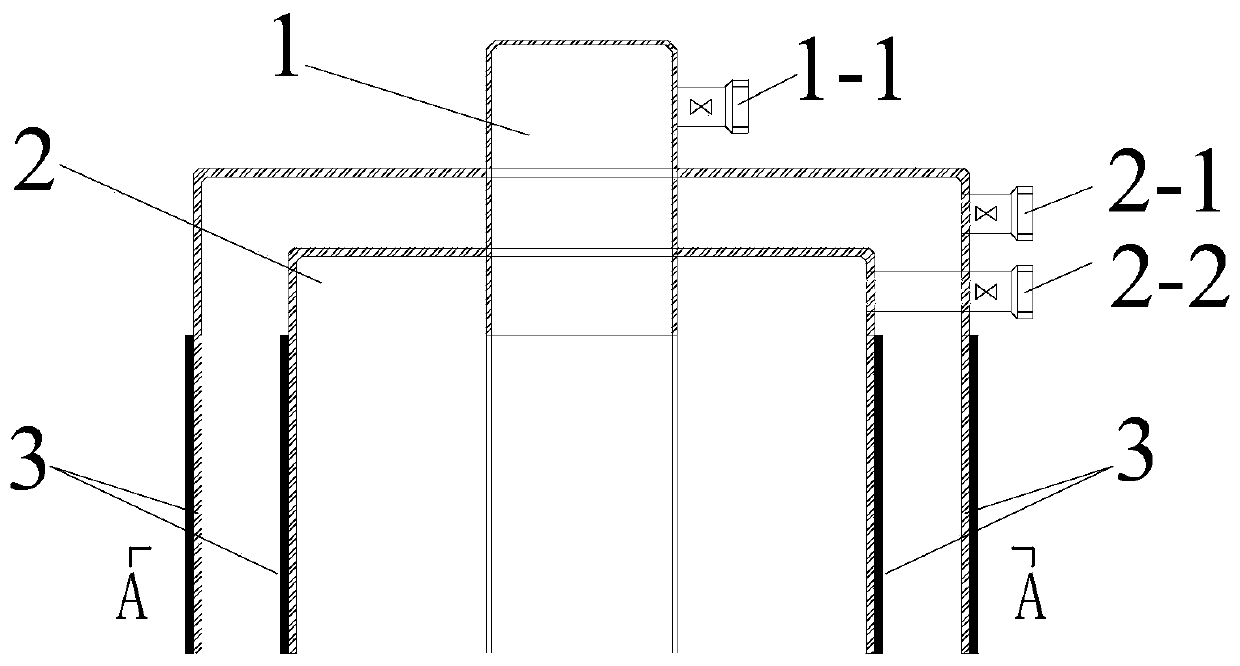

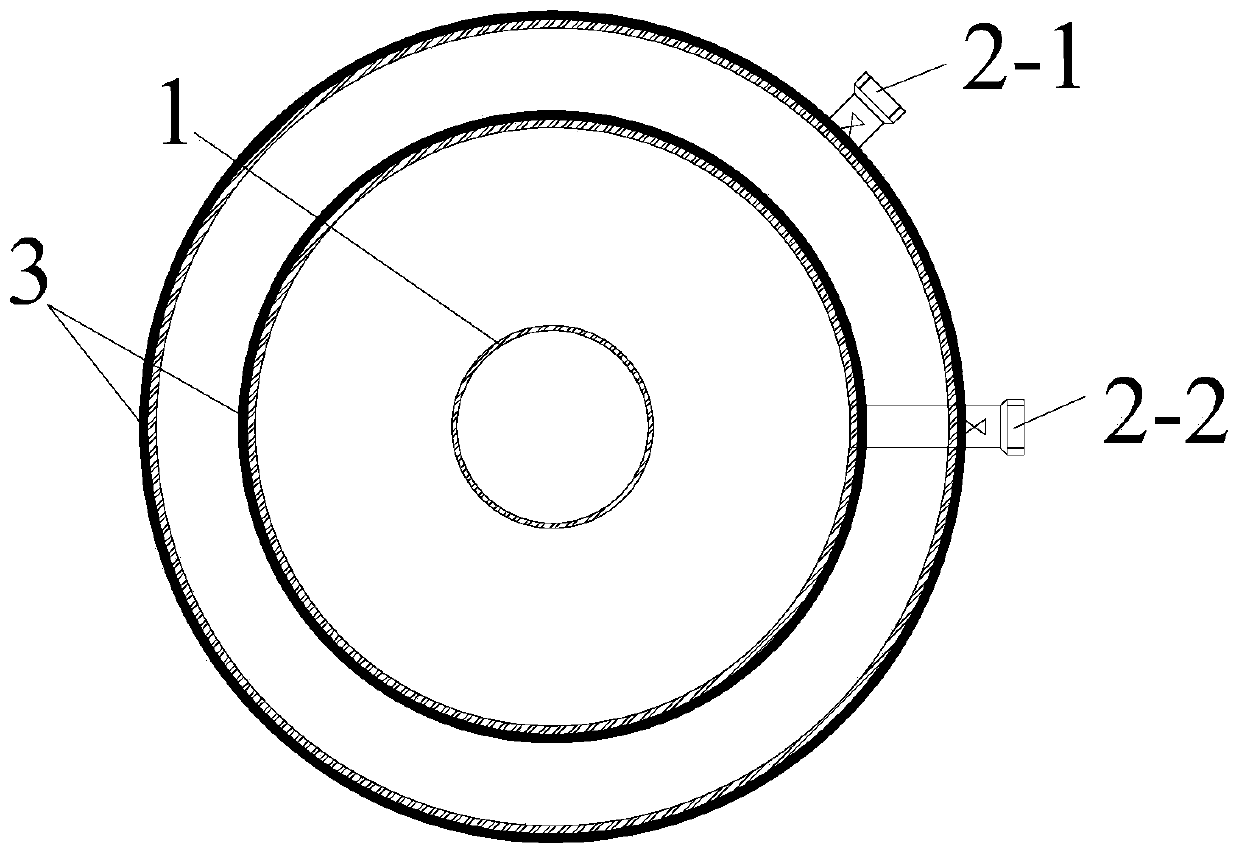

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

[0031] Such as figure 1 Shown, a kind of fiber reinforced grouting full-length reinforced freezing tube in the double-layer clamping cavity, comprises the double-layer freezing tube body with clamping cavity 4 that is made of inner wall layer 6 and outer wall layer 7, connects the bottom end of double-layer freezing tube body The bottom cone angle device 10 and the port sealing device 2 connected to the top of the double-layer freezing tube body. Bottom cone angle device 10 is double-layer clamp cavity structure equally, and is connected with the clamp cavity 4 of double-layer freezing pipe body, and the inner layer central position of bottom cone angle device 10 is provided with the first that communicates from double-layer freezing tube body to clamp cavity 4 A one-way check pressure valve 11, the outer layer central position of the bottom cone angle device 10 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com