Isopropanol-based coating for lost foam casting steel and production method thereof

A technology of isopropyl alcohol and lost foam, applied in manufacturing tools, casting equipment, coatings, etc., can solve problems such as coatings that have not yet been found, and achieve the effects of overcoming the danger of excessive methanol toxicity, simplifying the process and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

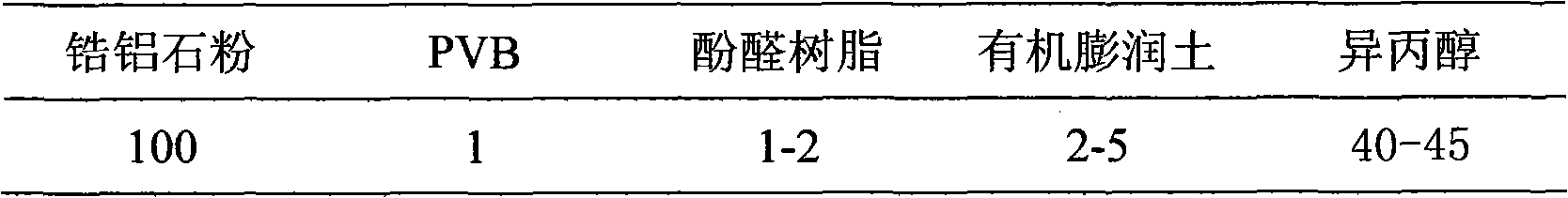

[0027] Disclosed is an isopropanol-based coating for lost foam cast steel. The coating uses zirconite powder as a refractory material, PVB and phenolic resin as a binder, organic bentonite as a suspending agent, and an appropriate amount of isopropanol as a material coating carrier liquid.

[0028] Further preferably, the mass ratio of the coating is: 100 parts of zirconite powder, 1 part of PVB, 1-2 parts of phenolic resin, 2-5 parts of organic bentonite, and 40-45 parts of isopropanol.

[0029] The isopropanol-based paint for lost foam cast steel of the present invention uses zirconite powder as a refractory material, PVB and phenolic resin are used as a binder to improve the coating strength, and organic bentonite is used as a suspending agent. Propanol is the material coating carrier fluid. The distribution ratio of each component of the specific coating is shown in Table 3.

[0030] Table 3 The ratio of each component of the coating (mass: %)

[0031]

[0032] A kind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com