Gate valve sliding plate brick for slag retaining of converter and preparation method thereof

A converter slag blocking and sliding brick technology, which is applied in the field of refractory materials, achieves the effects of simple preparation method, low energy consumption, and reduced transverse cracks and fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

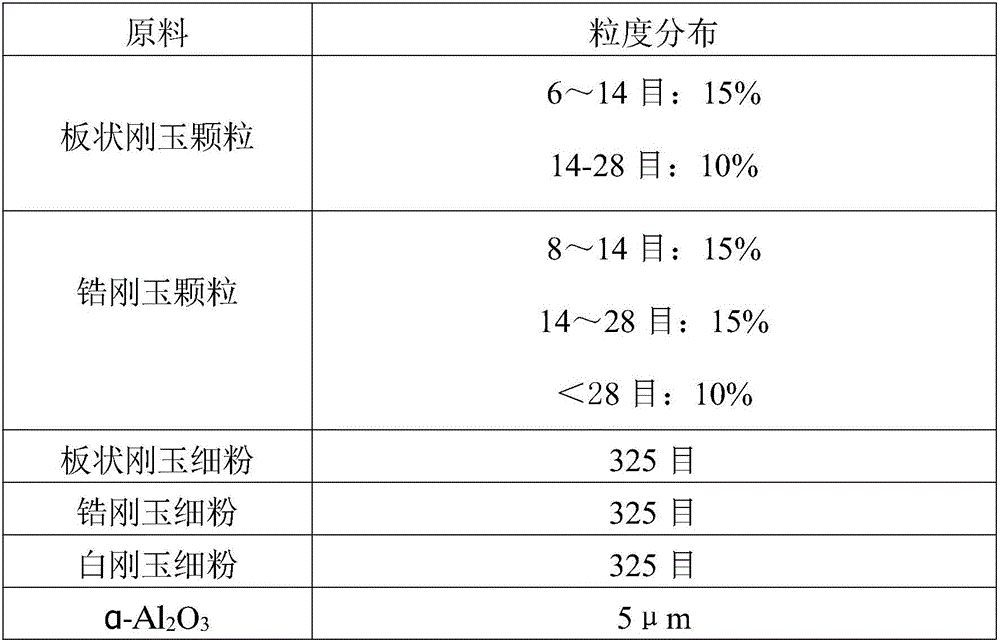

[0034] A gate valve sliding brick for converter slag, the composition of which is as follows by weight percentage: 25% of tabular corundum particles, 40% of zirconium corundum particles, 5% of tabular corundum fine powder, 5% of zirconium corundum fine powder, and 10% of white corundum fine powder %, α-Al 2 o 3 2.5% of fine powder, 1.8% of flake graphite, 0.7% of expanded graphite, 4% of metal aluminum powder, 4% of metal silicon powder, 2% of boron carbide, plus 5% of phenolic resin, of which:

[0035]

[0036] In this embodiment, the chemical composition of the tabular alumina is: Al 2 o 3 ≥98.5%, the pH value is neutral; the chemical composition of zirconium corundum is: Al 2 o 3 +ZrO 2 ≥98% and ZrO 2 ≥23%.

[0037] In this embodiment, the expansion factor of the expanded graphite is 150 times.

Embodiment 2

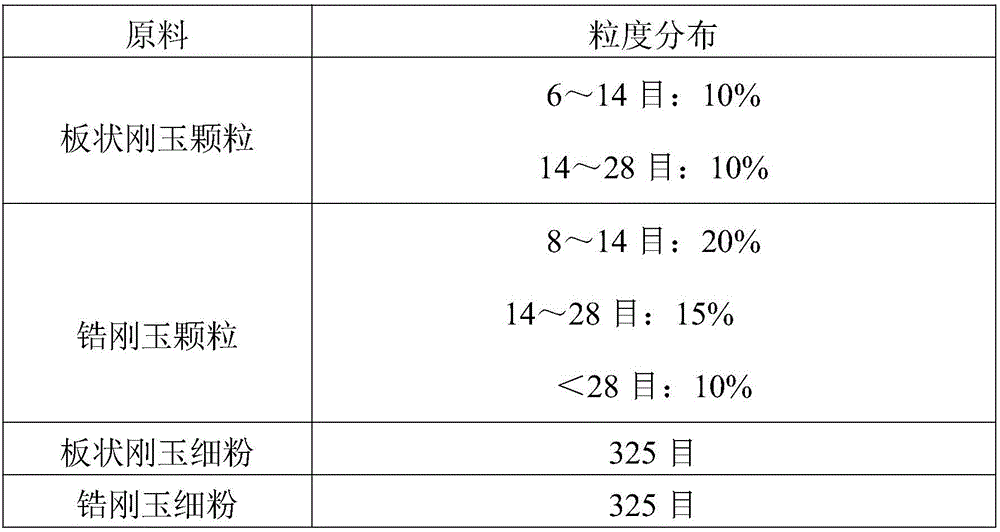

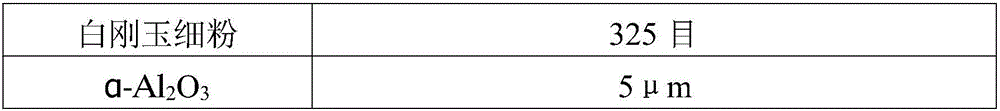

[0039] A gate valve sliding brick for converter slag, the composition of which is as follows by weight percentage: 20% of tabular corundum particles, 45% of zirconium corundum particles, 3% of tabular corundum fine powder, 3% of zirconium corundum fine powder, and 10% of white corundum fine powder %, α-Al 2 o 3 Micropowder 4%, flake graphite 1.5%, expanded graphite 1%, metal aluminum powder 5%, metal silicon powder 5%, boron carbide 2.5%, plus phenolic resin 5%, of which:

[0040]

[0041]

[0042] In this embodiment, the chemical composition of the tabular alumina is: Al 2 o 3 ≥98.5%, the pH value is neutral; the chemical composition of zirconium corundum is: Al 2 o 3 +ZrO 2 ≥98% and ZrO 2 ≥23%.

[0043] In this embodiment, the expansion factor of the expanded graphite is 200 times.

Embodiment 3

[0045] A gate valve sliding brick for converter slag, the composition of which is as follows by weight percentage: 30% of tabular corundum particles, 30% of zirconium corundum particles, 6% of tabular corundum fine powder, 6% of zirconium corundum fine powder, and 10% of white corundum fine powder %, α-Al 2 o 3 4% micropowder, 1% flake graphite, 1.5% expanded graphite, 4.5% metal aluminum powder, 4.5% metal silicon powder, 2.5% boron carbide, plus 5% phenolic resin, of which:

[0046]

[0047] In this embodiment, the chemical composition of the tabular alumina is: Al 2 o 3 ≥98.5%, the pH value is neutral; the chemical composition of zirconium corundum is: Al 2 o 3 +ZrO 2 ≥98% and ZrO 2 ≥23%.

[0048] In this embodiment, the expansion factor of the expanded graphite is 300 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com