Method for reducing transverse cracks of corners on surface of plate blank

A technology of transverse cracks and corners is applied in the field of reducing transverse cracks at the corners of the slab surface, which can solve problems such as difficult to achieve, and achieve the effects of reducing transverse cracks, saving costs and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

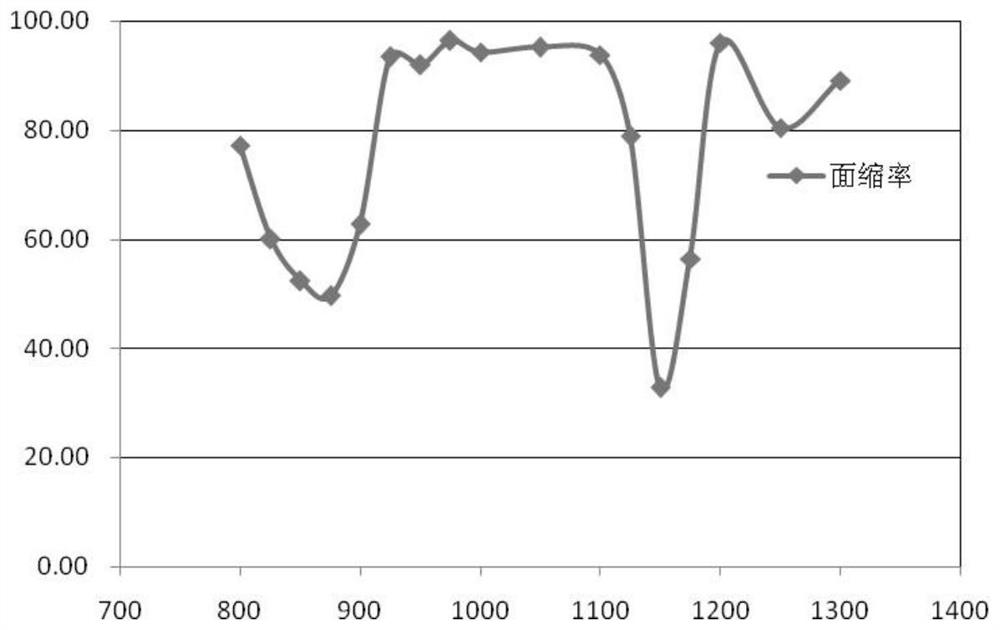

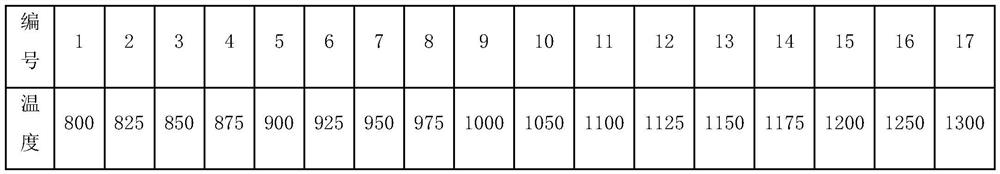

[0031] The steel type is SS400B, sampling is carried out according to the technical method and high-temperature tensile test is carried out, and the results of area reduction are as follows figure 1 shown. Depend on figure 1 It can be seen that the reduction of area of SS400B is relatively small (less than 60%) when the temperature is 825-900 °C, and the lowest reduction of area is 49.59% at 875 °C, so this temperature range is the third brittle temperature zone of the slab. During the production of this furnace, the billet section was 1250mm×230mm, which ensured a constant casting speed of 1.3m / min, a superheat of 27°C, normal crystallizer liquid level fluctuations, and a secondary cooling ratio of 0.68 / min, which met the requirements of the operating procedures. The chemical composition meets the standard requirements. Measure the temperature at the corner of the narrow face of the slab in the straightening section. The temperature at the center of the narrow face of t...

example 2

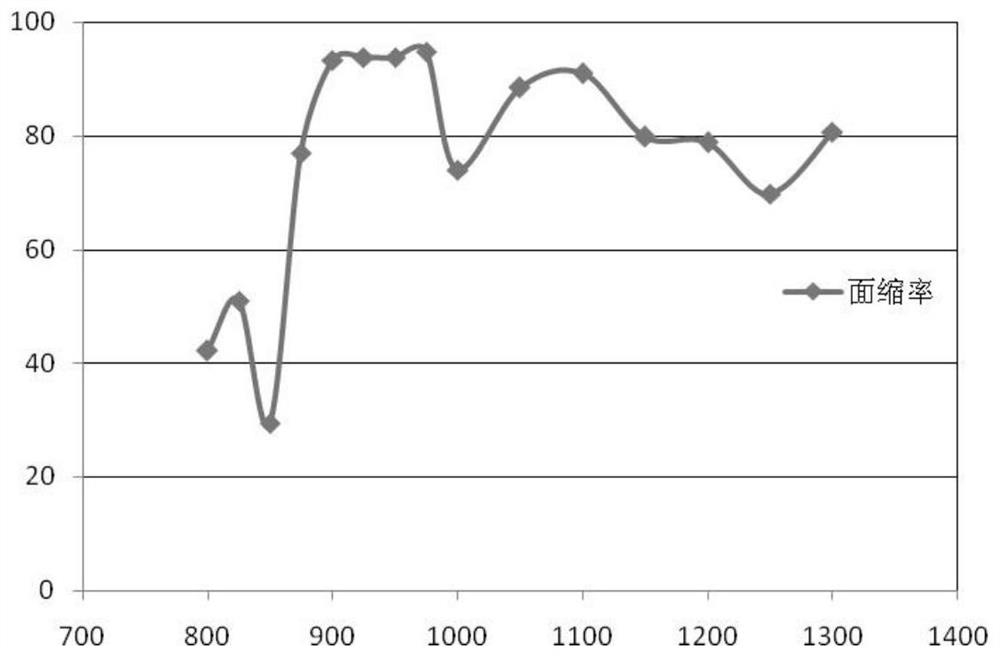

[0033] The steel type is L245M, and the sampling is carried out according to the technical method and the high temperature tensile test is carried out. The results of area reduction are as follows: figure 2 shown. Depend on figure 2 It can be seen that the reduction of area of L245M is relatively small (less than 60%) when the temperature is 800-875 ° C, and the lowest reduction of area is 29.44 % at 850 ° C, so this temperature range is the third brittle temperature zone of the slab. During the production of this furnace, the billet section is 1650mm×230mm, which ensures a constant casting speed of 1m / min, a superheat of 29°C, normal crystallizer liquid level fluctuations, and a secondary cooling specific water volume of 0.66L / min, which meets the requirements of the operating procedures. The chemical composition meets the standard requirements. Measure the temperature at the corner of the narrow face of the slab in the straightening section. The temperature at the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com